;

. l

table

of contents

"GUARANTEE

.#.

-RULES FOR SAFE OPERATION

ASSEMBLY INSTRUCTIONS

OPERATING

MAINTENANCE INSTRUCTIONS

REPAIR PARTS

3-7

7-10

10-13

15-23

tools required for assembly

of shredder-bagger

2 - 7

/16"

Wrenches

2 -

Yi"

Wrenches

2 -

9/16"

Wrenches

1 -

%"

Wrench

1 -

Pliers

1 -

Large

slotted

screwdriver

1 -

Large

phillips

screwdriver

assembly

A

letter

in

parenthesis

in

the

following

instructions

refers

to

an

arrow

in

an

adjoining

Figure

(Illustra-

tion),

unless

otherwise

stated.

When

R.H.

(Right

Hand) or

L.

H.

(Left Hand)

is

used,

it should be un·

derstood to mean

from

a

position

standing

at

the

han-

dles

and facing the Shredder-Bagger. Refer to

Fig.

1

Remove

all

parts

from

both inner

cartons.

All hard-

ware:

bolts,

nuts,

washers,

and

cotter

pins,

etc.

which

are

referred to

in

the

following

instruc~ions,

were

shipped

in a

plastic

bag.

Separate

all

bolts,

washers,

etc.,

according to

size.

Remove Shredder-

Bagger

from

carton.

Lay out

all

parts

for

assembly.

A

B

c

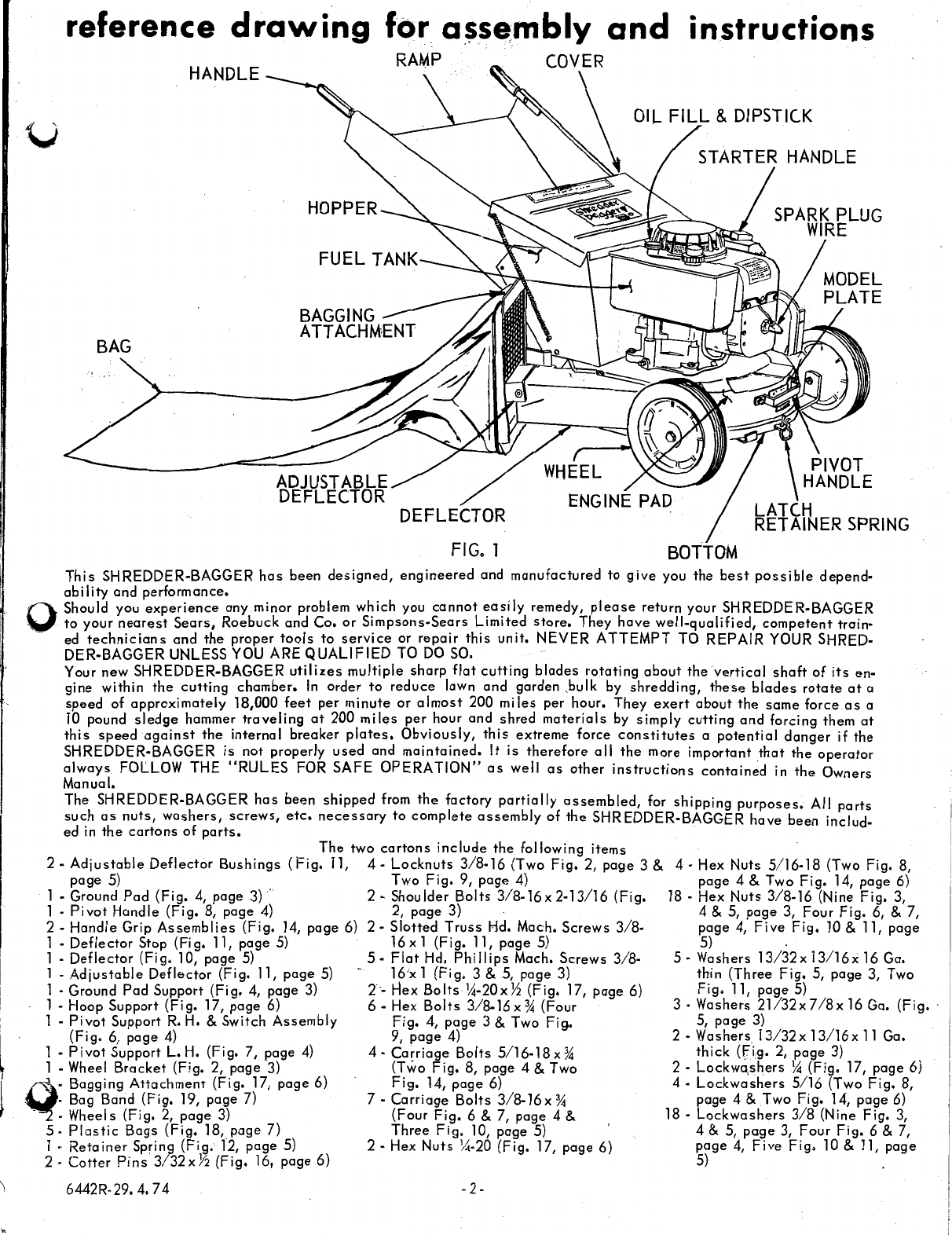

FIG. 3

2. Remove bottom from Shredder-Bagger. Refer

to

Fig.

3.

Assemble

wheel

bracket

(B) with

wheels

to

bottom·

(D)

as

shown.

Use

two

3/8-16x

1

flat

hd.

phillips

mach.

screws,

lockw'ashers, and hex

nuts.

Screws,

lockwashers,

and hex

nuts

were

in

plastic

bag.

Tighten

nuts

securely.

--------

E

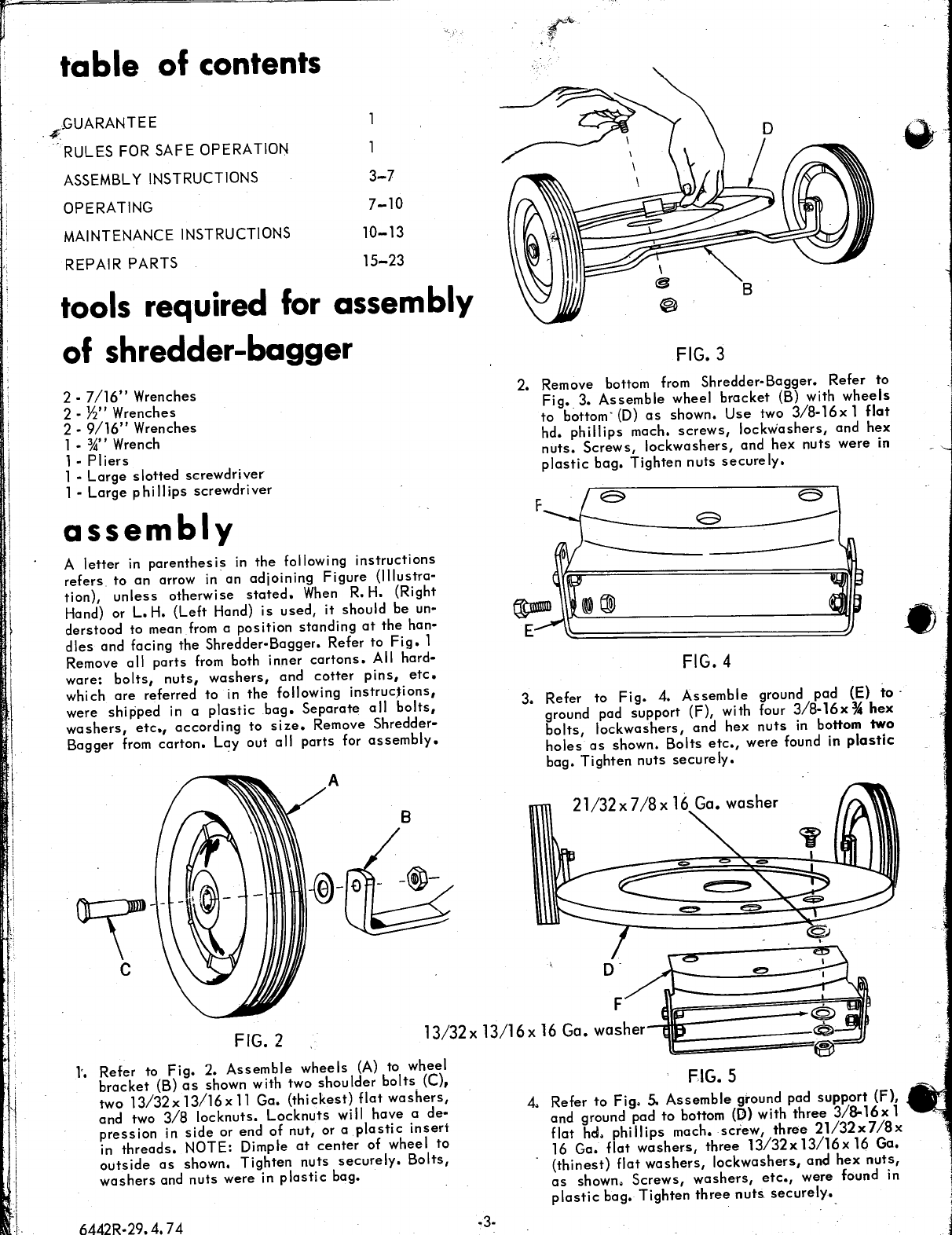

FIG. 4

3. Refer to

Fig.

4.

Assemble

ground pad (E)

to·

ground pad support (F), with four

3/8-16x

%

hex

bolts,

lockwashers

and

hex

nuts

in

bottom two

holes

as

shown.

B~lts

etc.,

were found in

plastic

bag. Tighten

nuts

securely.

FIG. 2

F

l3/32x

13/16x

16

Ga. washer

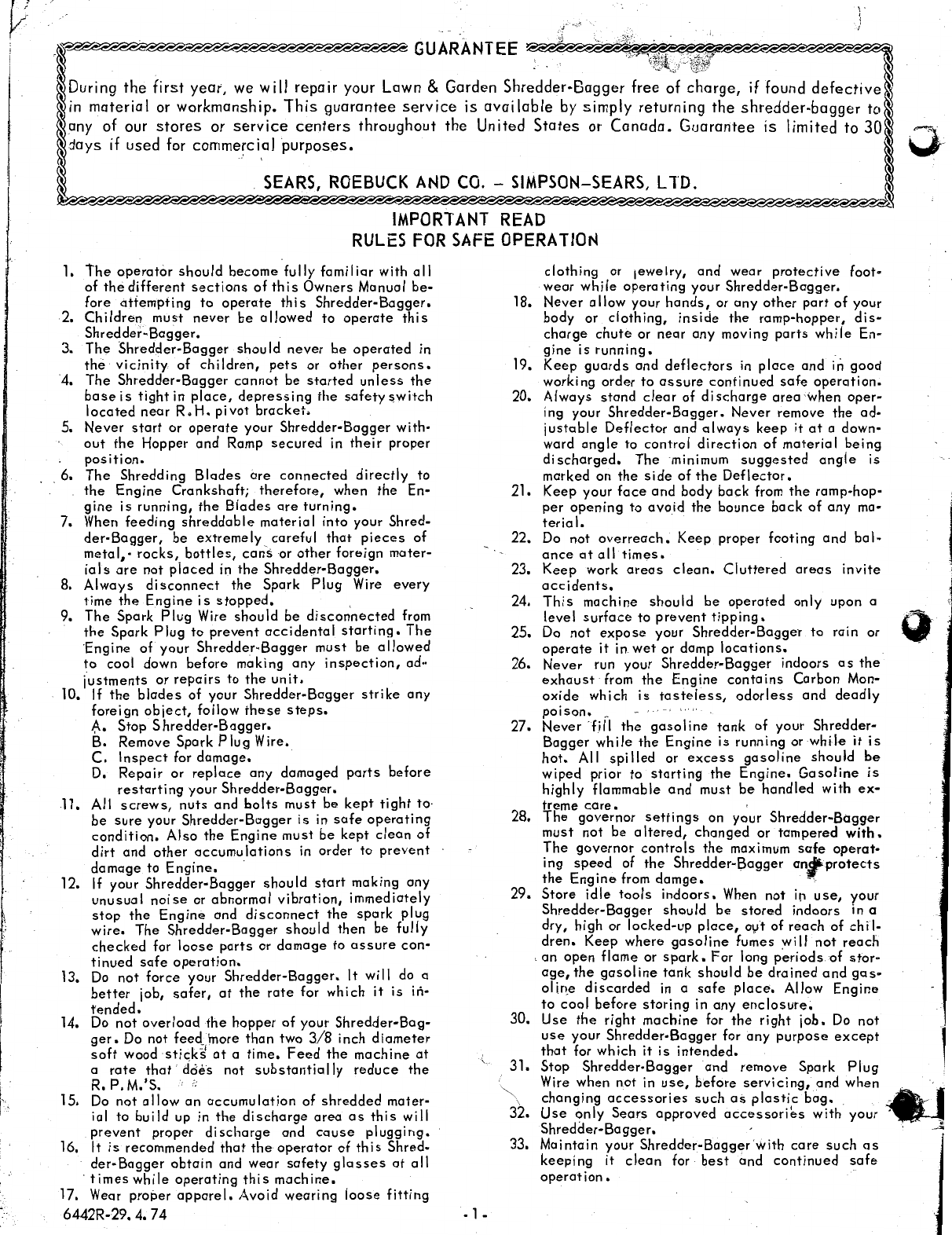

l'. Refer to

Fig.

2.

Assemble

wheels

(A)

to wheel

bracket

(B)

as

shown with two

shoulder

bolts_ (C),

two

13/32x

13/16x

11

Ga.

(thickest)

flat

washers,

and two

3/8

lockouts,

Lockouts

will

have

a

de·

pression

in

side

or end of nut, or a

plastic

insert

in

threads.

NOTE: Dimple

at

center

of wheel

to

outside

as

shown. Tighten

nuts

securely.

Bolts,

washers

and

nuts

were in

plastic

bag. .

6442R-29.4. 74

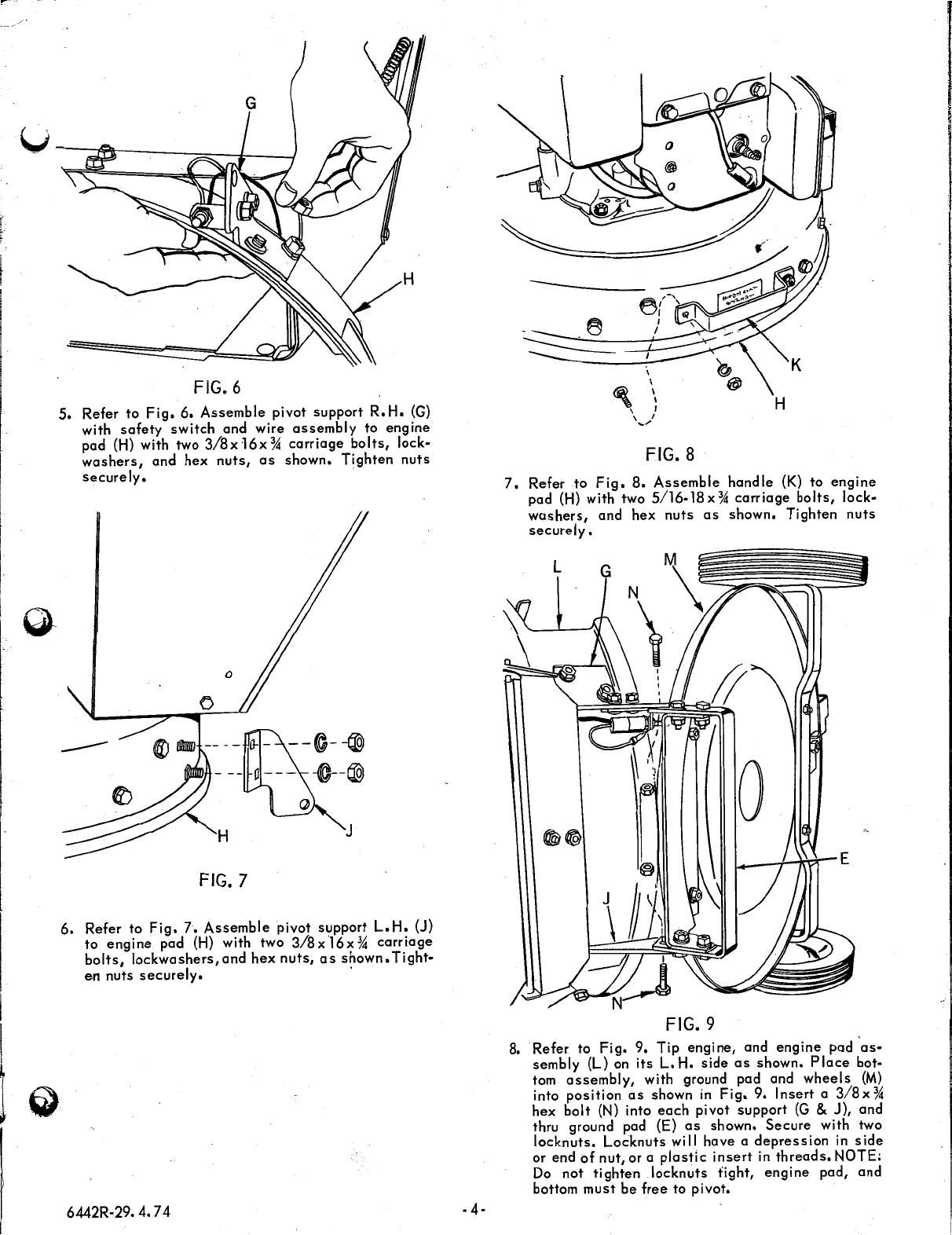

FIG. 5

4. Refer to

Fig.

S.

Assemble

ground pad

support

(F),

and ground pad to bottom

(D)

with

three

3/8-16x

1

flat hd.

phillips

mach.

screw,

three

21/32x7/8x

16 Ga.

flat

washers,

three

13/32x

13/16x

16 Ga.

(thinest)

flat

washers,

lockwashers,

and

hex

nuts,

as

shown.

Screws,

washers,

etc.,

were found in

p

las

tic

bag. Tighten

three

nuts

securely._

~-·

•