Page 2

RULES FOR SAFE OPERATION

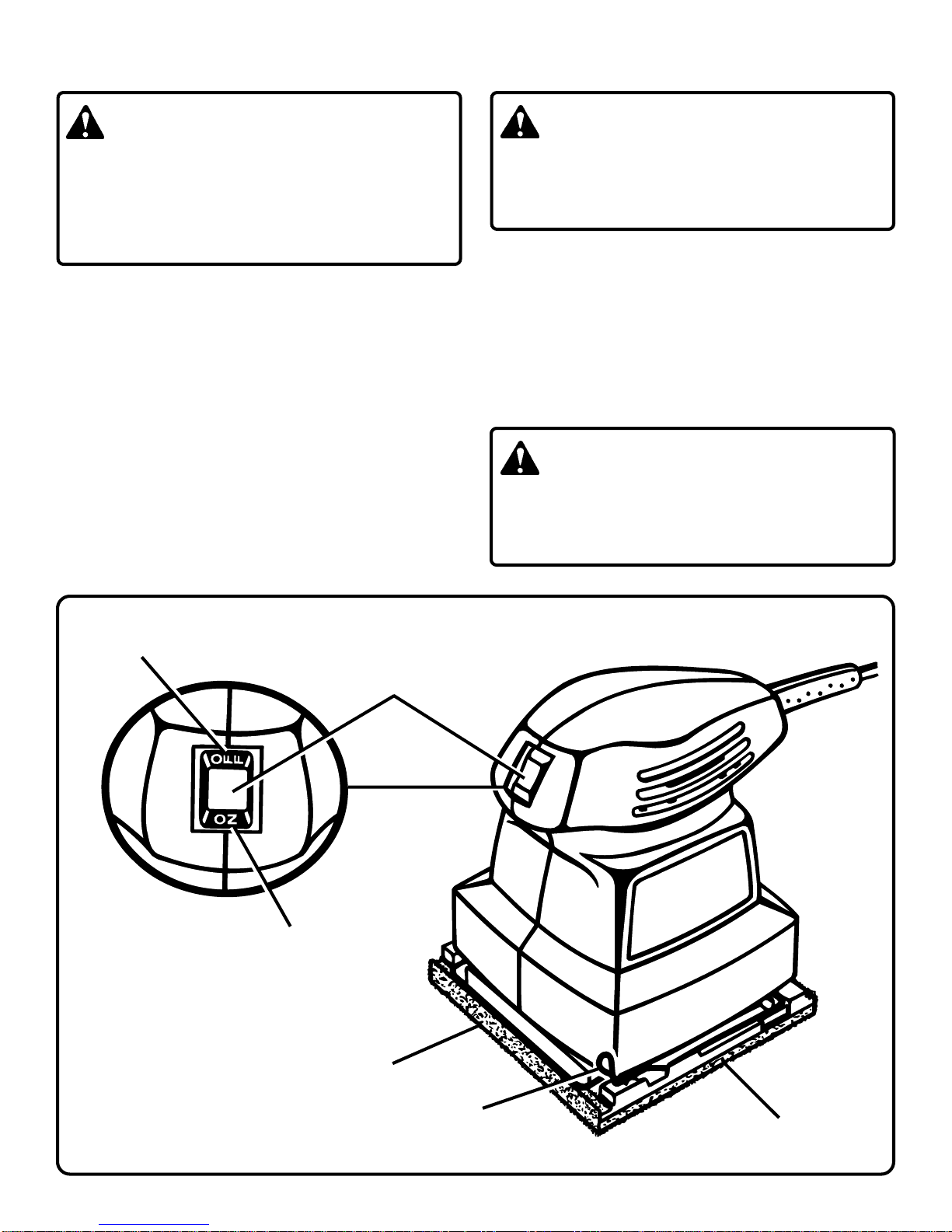

DOUBLE INSULATION is a concept in safety, in electric

power tools, which eliminates the need for the usual three

wire grounded power cord and grounded supply system.

Wherever there is electric current in the tool there are two

complete sets of insulation to protect the user. All exposed

metalpartsareisolatedfrominternalmetalmotorcomponents

with protecting insulation.

IMPORTANT - Servicing of a tool with double insulation

requires extreme care and knowledge of the system and

shouldbeperformedonlybyaqualifiedservicetechnician.

For service we suggest you return the tool to your nearest

Sears Store for repair. Always use original factory

replacement parts when servicing.

WARNING:

Do not attempt to operate this tool until you have read

thoroughly and understand completely all instructions,

safety rules, etc. contained in this manual. Failure to

comply can result in accidents involving fire, electric

shock, or serious personal injury. Save owner's manual

and review frequently for continuing safe operation, and

instructing others who may use this tool.

READ ALL INSTRUCTIONS

1. KNOW YOUR POWER TOOL. Read owner's

manual carefully. Learn its applications and

limitationsaswellasthespecificpotentialhazards

related to this tool.

2. GUARD AGAINST ELECTRICAL SHOCK by

preventing body contact with grounded surfaces.

Forexample:Pipes,radiators,ranges,refrigerator

enclosures.

3. KEEP GUARDS IN PLACE and in working order.

4. KEEPWORKAREACLEAN.Clutteredareasand

benches invite accidents.

5. AVOIDDANGEROUSENVIRONMENT.Don't use

power tool in damp or wet locations or expose to

rain. Keep work area well lit.

6. KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear safety glasses and be kept a

safe distance from work area. Do not let visitors

contact tool or extension cord.

7. STORE IDLE TOOLS. When not in use tools

should be stored in a dry and high or locked-up

place - out of the reach of children.

8. DON'T FORCE TOOL. It will do the job better and

safer at the rate for which it was designed.

9. USE RIGHT TOOL. Don't force small tool or

attachmenttodothejobofaheavydutytool.Don't

usetool for purposenot intended -for example -A

circular saw should never be used for cutting tree

limbs or logs.

10. WEAR PROPER APPAREL. Do not wear loose

clothing or jewelry that can get caught in tool's

moving parts and cause personal injury. Rubber

gloves and non-skid footwear are recommended

when working outdoors. Wear protective hair

coveringtocontainlonghairandkeepitfrombeing

drawn into nearby air vents.

11. ALWAYS WEAR SAFETY GLASSES. Everyday

eyeglasseshaveonlyimpact-resistantlenses;they

are NOT safety glasses.

12. PROTECT YOUR LUNGS. Wear a face mask or

dust mask if operation is dusty.

13. PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation.

14. DON'TABUSECORD.Nevercarrytoolbycordor

yank it to disconnect from receptacle. Keep cord

from heat, oil and sharp edges.

15. SECURE WORK. Use clamps or a vise to hold

work. Both hands are needed to operate the tool.

16. DON'T OVERREACH. Keep proper footing and

balance at all times. Do not use on a ladder or

unstable support.

17. MAINTAINTOOLSWITHCARE.Keeptoolssharp

at all times, and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

18. DISCONNECT TOOLS. When not in use, before

servicing, or when changing or adjusting

sandpaper,attachments,blades,bits,cutters,etc.,

alltoolsshouldbedisconnectedfrompowersupply.

19. REMOVEADJUSTINGKEYSANDWRENCHES.

Form habit of checking to see that keys and

adjusting wrenches are removed before turning

tool on.

20. AVOID ACCIDENTAL STARTING. Don't carry

plugged-in tools with finger on switch. Be sure

switch is off when plugging in.

WARNING:

The double insulated system is intended to protect the

user from shock resulting from a break in the tool's

internal wiring. Observe all normal safety precautions

related to avoiding electrical shock.