SAFETY INSTRUCTIONS CONT/NUED

[] ADDITIONAL SA!FETY INSTRUCTIONS FOR BELT/DISC SANDER

DO NOT OPERATE YOUR SANDER UNTIL IT IS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE INSTRUCTIONS.

I .THIS SANDER IS DESIGNED TO SAND

WOOD OR WOOD-LIKE PRODUCTS

ONLY. Sanding or grinding other materials

could result in fire, injury or- damage to

workpiece_

2 MOUNT AND USE this sander on

hoxizontal surfaces only. Operating sander

when mounted on non-horizontal surfaces

might result in motor damage_

3IF THERE IS ANY TENDENCY for the

machine to tip over or move during any

use, the sander must be securely fastened

to the bench top or supporting surface,

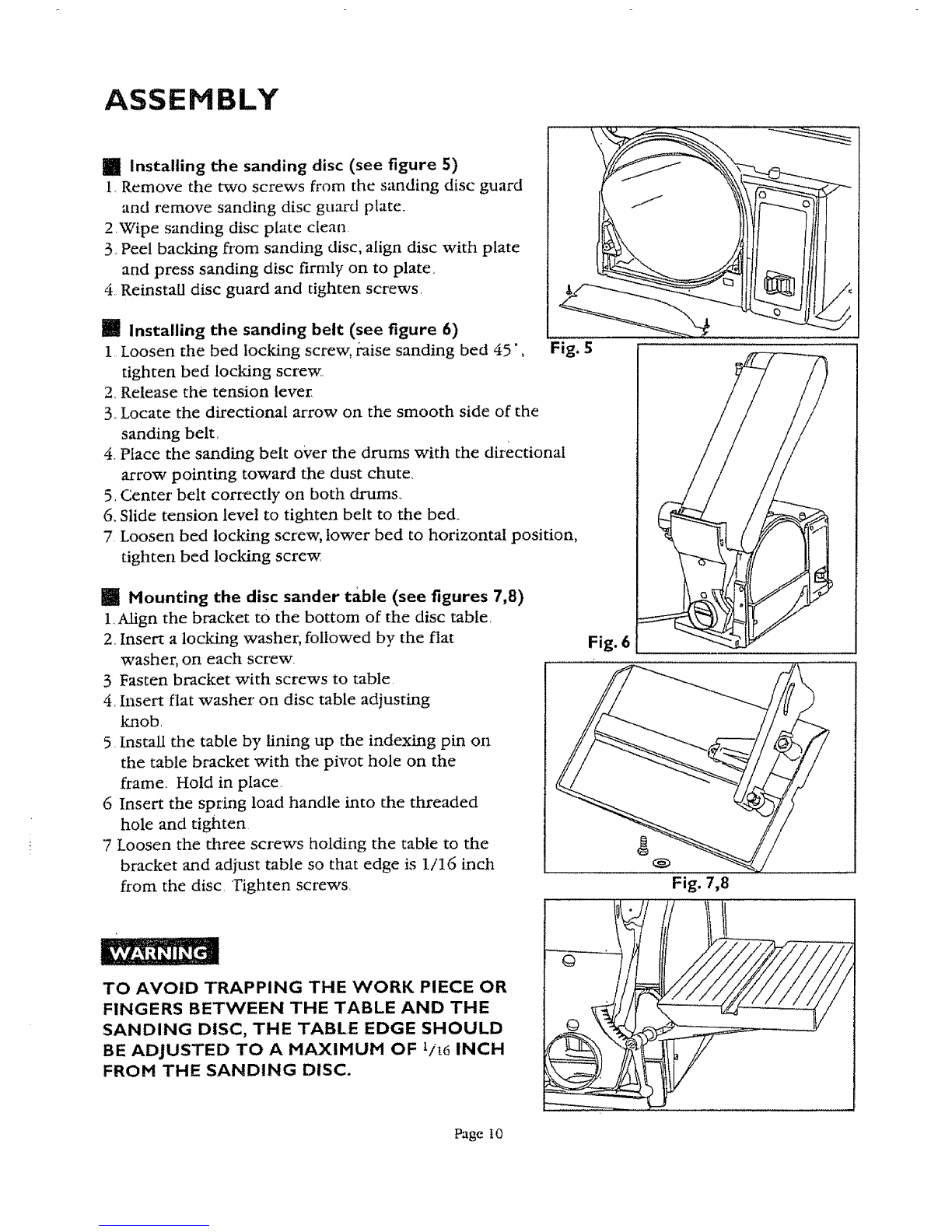

4. MAKE SURE the sanding belt is instaUed

in the correct direction See directional

arrow on back of belt,

5. ALWAYS have the tracking adjusted

properly so the belt does not run off the

pulleys

6 DO NOT USE sanding belts or discs that

are damaged, torn, loose, Use only correct

size sanding belt mid disc

7 ALWAYS HOLD the workpiece firmly

when sandingAvoid awkward hand

positions when a slip could cause a hand

to move into the sanding belt or disc.

Sand only one workpiece at a time.

8, ALVVAYS HOLD the workpiece firmly on

the table when disc sanding and when

using either table when belt sanding,

9, ALWAYS SAND ON THE

DOWNWARD SIDE of the sanding disc

when using the disc sander Sanding on the

upward side of the disc could cause the

workpiece to fly up which could be

hazardous,

10 ALWAYS maintain a minimum clearance

of 1/16 inch or less between tile table or

backstop and the sanding belt or disc

1 1, DO NOT sand pieces of material that are

too small to be safely supported

12. WHEN sanding a large workpiece, provide

additional support at table height.

13. DO NOT sand with the workpiece

unsupported. Support the workpiece with

the backstop or tableiFhe only exception

is curved work performed on the outer

sanding drum.

14. ALWAYS remove scrap pieces and other

objects from the table, backstop or belt

before turning the sander "ON?'

15 N EVE R perform layout, assembly or set-up

work on the table while the sander is

operating,

16 NEVER use solvents to clean plastic parts,

Solvents could possibly dissolve or other

wise damage the material, Only a soft damp

cloth should be used to clean plastic parts,

17. SHOULD any part of your sander be

missing, damaged, or fail in any way, or

any electrical components fail to perform

properly, shut off switch and iemove plug

f_'om power supply outlet. Replace

missing, damaged Or failed parts before

resuming operation

18 NEVER YANK THE POWER CORD

out of the receptacle. Keep cords away

from heat, oil and sharp edges.

19 HAVE AN ELECTRICIAN REPLACE

OR REPAIR damaged or worn cords

immediately,

iSAVE THESE INSTRUCTIONS ]

Page 4