SEB ARNO KRUPS Nescafe Dolce Gusto KP10 Series User manual

SEB INTERNATIONAL SERVICE

KP10XXXX

PJ10XXXX

1

Service manual

CONTENTS

Main Components................................................................................................. 3

Overview of external parts............................................................................................ 3

Overview of internal parts............................................................................................. 4

Water circuit.................................................................................................................. 5

Technical data .............................................................................................................. 6

Operating.................................................................................................................. 8

Machine status..............................................................................................................8

Preparation, first use ..................................................................................................... 9

Preparing a beverage................................................................................................. 11

Economy mode (auto shut-off function) ..................................................................... 13

Empty fluid system for shipping.................................................................................. 14

Troubleshooting................................................................................................... 15

Repair....................................................................................................................... 19

Tools and repair accessories...................................................................................... 19

Repair work without disassembling the machine ....................................................... 19

Cleaning or replacing injector plate, deblocking of injector.................................... 19

General disassembly.................................................................................................. 22

Replacing water tank connector................................................................................. 27

Replacing pump ......................................................................................................... 28

Replacing NTC temperature sensor........................................................................... 32

Replacing thermoblock............................................................................................... 34

Replacing power cord with thermo fuses ................................................................... 34

Replacing power button assembly ............................................................................. 36

Replacing electronic mainboard................................................................................. 37

Replacing locking handle ........................................................................................... 40

Replacing extraction head.......................................................................................... 41

Wiring diagram..................................................................................................... 44

Function Tests........................................................................................................45

Function test equipment............................................................................................... 45

Heating up time............................................................................................................ 46

Water temperature....................................................................................................... 47

Maintenance............................................................................................................48

Descaling..................................................................................................................... 48

Daily care and final cleaning........................................................................................ 51

2

Service manual

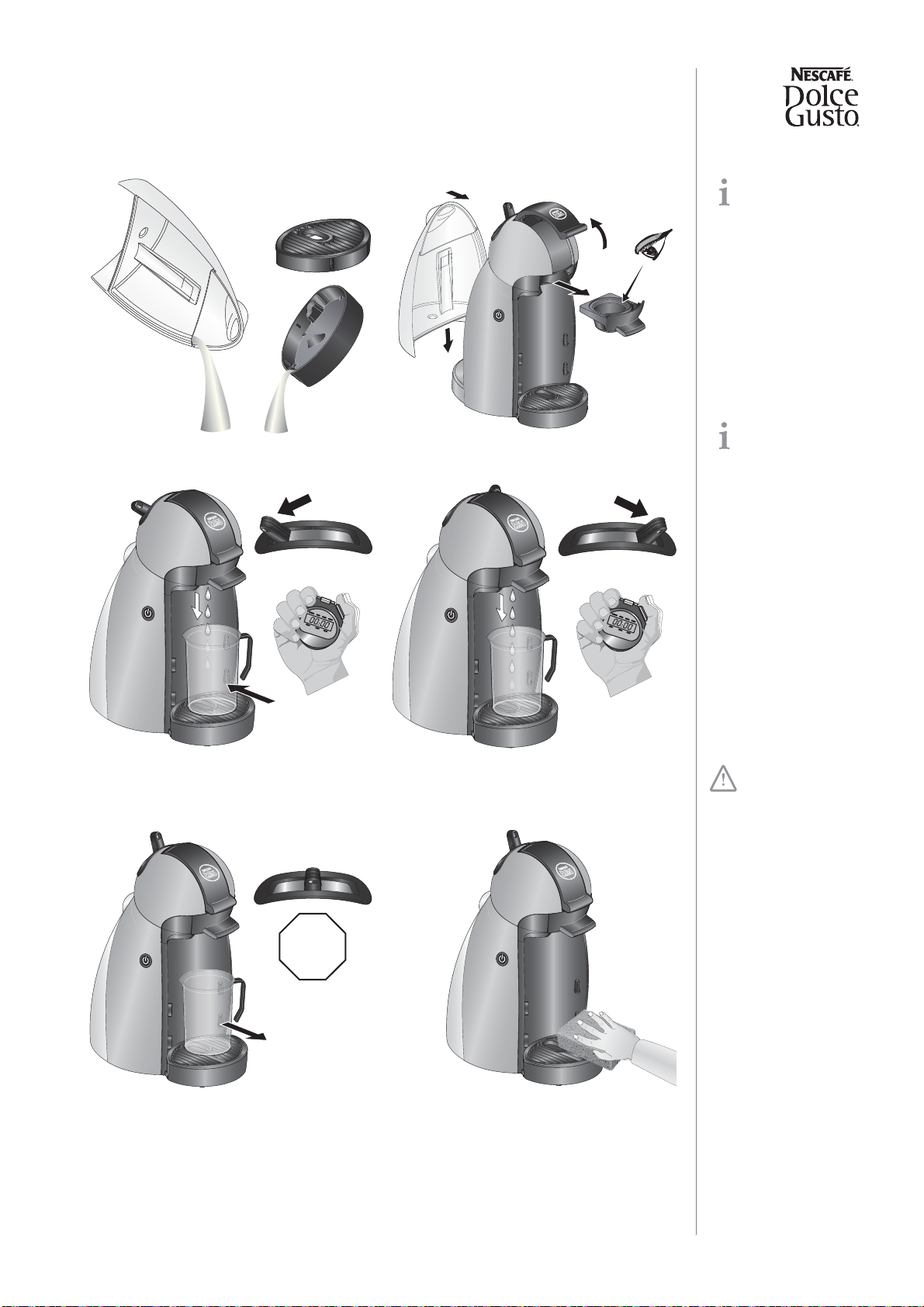

MAIN COMPONENTS

MAIN COMPONENTS

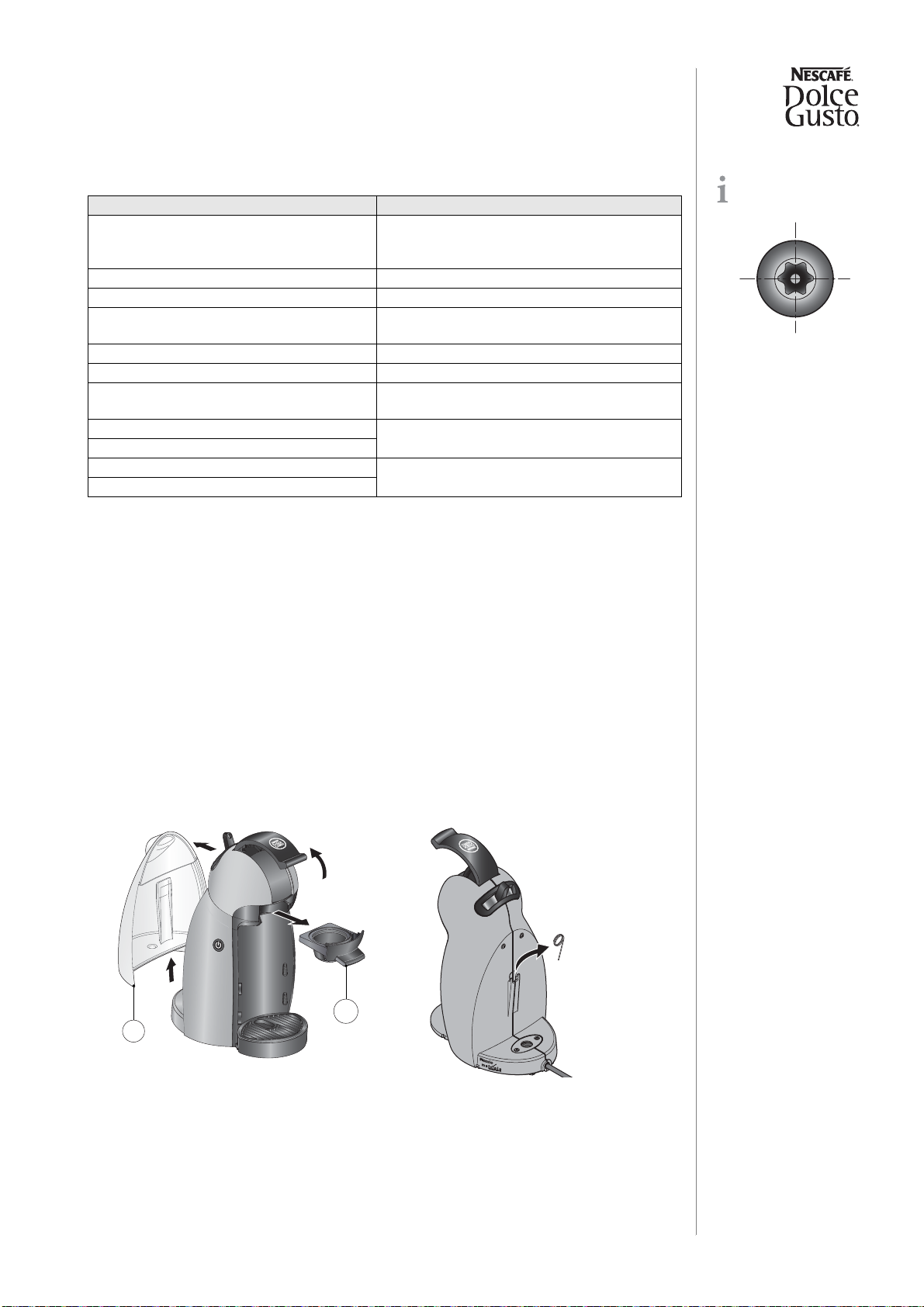

Overview of external parts

1. Water tank

2. Selection lever (cold / stop / hot)

3. Locking handle

4. Capsule holder

5. Drip grid

6. Drip tray

7. Power cord (e.g. with Swiss power plug)

8. Cleaning needle

9. Power button, illuminated

2

9

5

6

4

3

1

8

7

Cold Stop Hot

3

Service manual

MAIN COMPONENTS

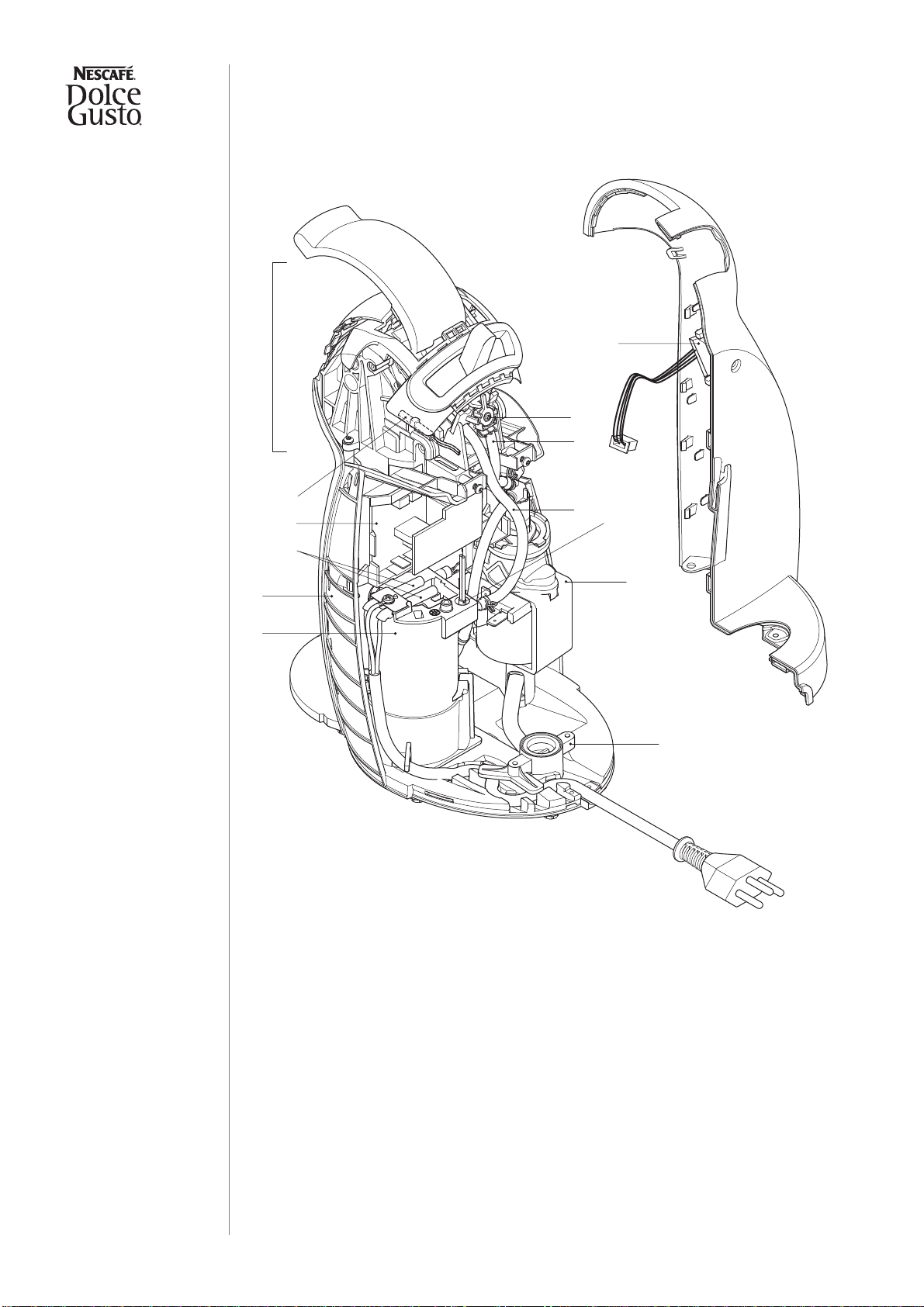

Overview of internal parts

1. Extraction head assembly

2. Reed sensor

3. Electronic main board with support

4. Thermo fuses (2x)

5. Main housing

6. Thermoblock

7. Power button assembly

8. Valve micro switch

9. Cold water pressure hose

10. Hot water pressure hose

11. NTC temperature sensor

12. Pump

13. Water tank connector

5

4

1

8

2

9

10

12

11

13

3

7

6

4

Service manual

MAIN COMPONENTS

Water circuit

1.Water tank with valve

2.Filter and connector

3.Pump

4.Thermoblock

5.Selection lever

6.Position cold

7.Position hot

8.Fconnector

9.Injector plate

10.Capsule holder

11.Injector

12. Capsuleholder

1

2

3

4

5

7

9

6

11

8

10

5

Service manual

MAIN COMPONENTS

Technical data

Mains voltage

Europe (UK, CH, DE, AT, FR, ES, PT, IT, NL, LU, BE, NO, SE, FI, DK,

GR, CZ, SK, PL, HU, RU, UA, LT, LV, EE, BG, RO, SI, BiH, SRB, HR)... 230 V / 50 Hz

USA / Canada...........................................................................................120 V / 60 Hz

Hong Kong.......................................................................................220 - 240 V / 50 Hz

Mexico..................................................................................................127 V / 50/60 Hz

Chile..........................................................................................................220 V / 50 Hz

Approvals.......................................................................VDE, SEV, CE, UL, CUL, JET

Power consumption

Europe ......................................................................................................max. 1’500 W

USA / Canada / Mexico.............................................................................max. 1’460 W

Hong Kong................................................................................................max. 1’500 W

Chile..........................................................................................................max. 1’340 W

Ratings (approx.)

Preheating ..........................................................................................................8.0 Wh

1 small cup (40 ml, Espresso) ............................................................................3.0 Wh

1 large cup (110 ml, Lungo) ................................................................................ 8.3 Wh

1 travel mug (350 ml, Powder)..........................................................................25.0 Wh

Economy mode.....................................................................................................0.1 W

Flow rates (± 50 ml/min)

R&G / Espresso ...............................................................210 ml/min at approx. 8.0 bar

R&G / Lungo ....................................................................230 ml/min at approx. 7.5 bar

R&G / Cappuccino ...........................................................210 ml/min at approx. 8.5 bar

R&G / Latte Macchiato.....................................................210 ml/min at approx. 7.5 bar

Powder / Milk....................................................................320 ml/min at approx. 3.5 bar

Capacities

Water tank................................................................................................................0.6 l

Drip tray.....................................................................................................approx. 70 ml

Temperatures

Safety temperature (thermal cut-off)......................................................133 °C (271 °F)

Hot beverage outlet temperature .....................................85 °C ± 5 °C (185 °F ± 41 °F)

Permissible ambient temperature ......................................5 °C - 45 °C (41 °F - 113 °F)

6

Service manual

MAIN COMPONENTS

Various data

Pre-heating time.....................................................................................approx. 30 sec.

Pump pressure max.................................................................................13.5 ± 1.5 bar

Noise....................................................................................................... max. 65 dB(A)

Dimensions [mm]

Dimensions (D x W x H).................................................................220 x 159 x 287 mm

Power cord length ....................................................................................... approx. 1 m

Weight of machine (without water).......................................................... approx. 2.4 kg

Distance from drip grid to coffee outlet [mm]

Espresso.......77 mm

Mug.............120 mm

Tall glass .....150 mm

Higher cup...177 mm

220

287

159

77

120

150

177

7

Service manual

OPERATING

OPERATING

Machine status

After switching on, an automatic self-test is performed to check if the

- capsule holder is inserted (with reed sensor)

- NTC is connected,

- NTC is not short circuited,

- the thermoblock reaches the working temperature in about 30 seconds.

Operatingmodes anddetectedfailures areindicatedbyLED signalsofthe powerbutton

as listed in the following table:

Operating modes Power button LED signals

Economy mode / Off —

Heating up / self-test red, blinking, approx. 30 sec.

Ready green, steady

After beverage preparation

(cool-down time) red, blinking, approx. 5 sec.

Descaling ready and during

descaling cycle green, slow blinking

Error mode red, rapid blinking

8

Service manual

OPERATING

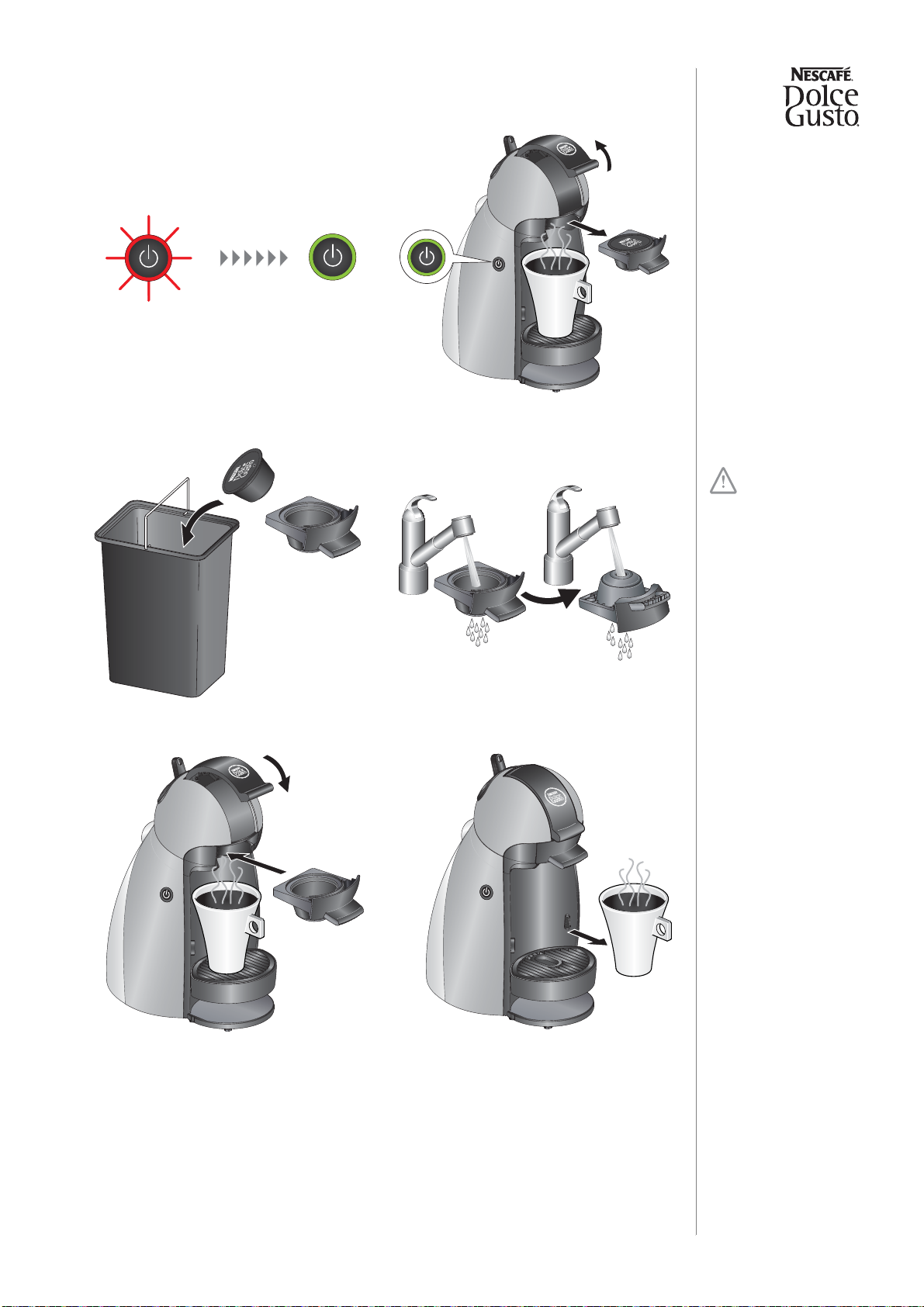

Preparation, first use

The new machine has to be rinsed properly before first use according to the following

sequence:

A timer or stop

watch is helpful to

observe the rinsing

times.

The machine will

not work without a

capsule holder inserted.

Do not insert a

capsule yet.

The pre-heating

time is approx.

30 sec.

1. Rinse water tank at first. Then fill

water tank up to max. level with

fresh, potable water.

2. Insert water tank.

3. Open locking handle.

4. Check that capsule holder is empty

(no capsule) for the following rinsing

procedure.

5. Insert capsule holder and close

locking handle.

6. Make sure that selection lever is in

central position.

7. Connect mains plug.

8. Place a jug with enough capacity

under outlet. 9. Switch machine ON.

10. Wait till power button lights up green.

MAX

MAX

9

Service manual

OPERATING

The drip tray is

height-adjustable in

3 levels.

11. Set selection lever to position "cold

water". Let water run through for

approx. 45 sec.

12. Set selection lever to position "hot

water". Let water run through for

approx. 45 sec.

13. Set selection lever to middle position

to stop rinsing.

14. Remove and empty jug.

15. Refill water tank.

16. Reinstall water tank. 17.

Adjust position of drip tray to cup size.

The machine is now ready for use.

~ 45 sec

~ 45 sec

STOP

MAX

MAX

10

Service manual

OPERATING

Preparing a beverage

Choose an

appropriate cup

size for beverage.

The locking handle

can only be

actuated if the selection

lever is in the middle

position.

Users allergic to

dairy products:

clean capsule holder

under running water

before use.

For filling amounts

see product package

of capsule or user manual.

The flow speed

depends on the

used capsule.

T

he machine does

not turn off auto-

matically.

Danger of hot

water and product

splashes - capsule can

burst.

Do not open locking

handle prematurely.

1. Check if water tank is filled.

2. Check if machine is ON and ready.

3. Re-adjust drip tray if necessary.

4. Place a cup under outlet.

5. Open locking handle and pull out

capsule holder.

6. Insert a capsule in capsule holder.

7. Insertcapsuleholderinmachineand

close locking handle.

8. Set selection lever to position "cold

water" or "hot water", depending on

beverage.

9. Push selection lever back to middle

position after specified filling amount

is in cup.

10. Do not open locking handle before

the power button stops blinking red

and turns to green.

STOP

11

Service manual

OPERATING

Risk of burning

from hot capsule.

Do not touch capsule

immediately after use.

11. Wait until power button lights up

green (approx. 5 sec). 12. Open locking handle and pull out

capsule holder.

13. Discard capsule in capsule bin. 14. Clean capsule holder.

15. Reinstall capsule holder or proceed

with second capsule of beverage. 16. Remove cup.

5 sec

12

Service manual

OPERATING

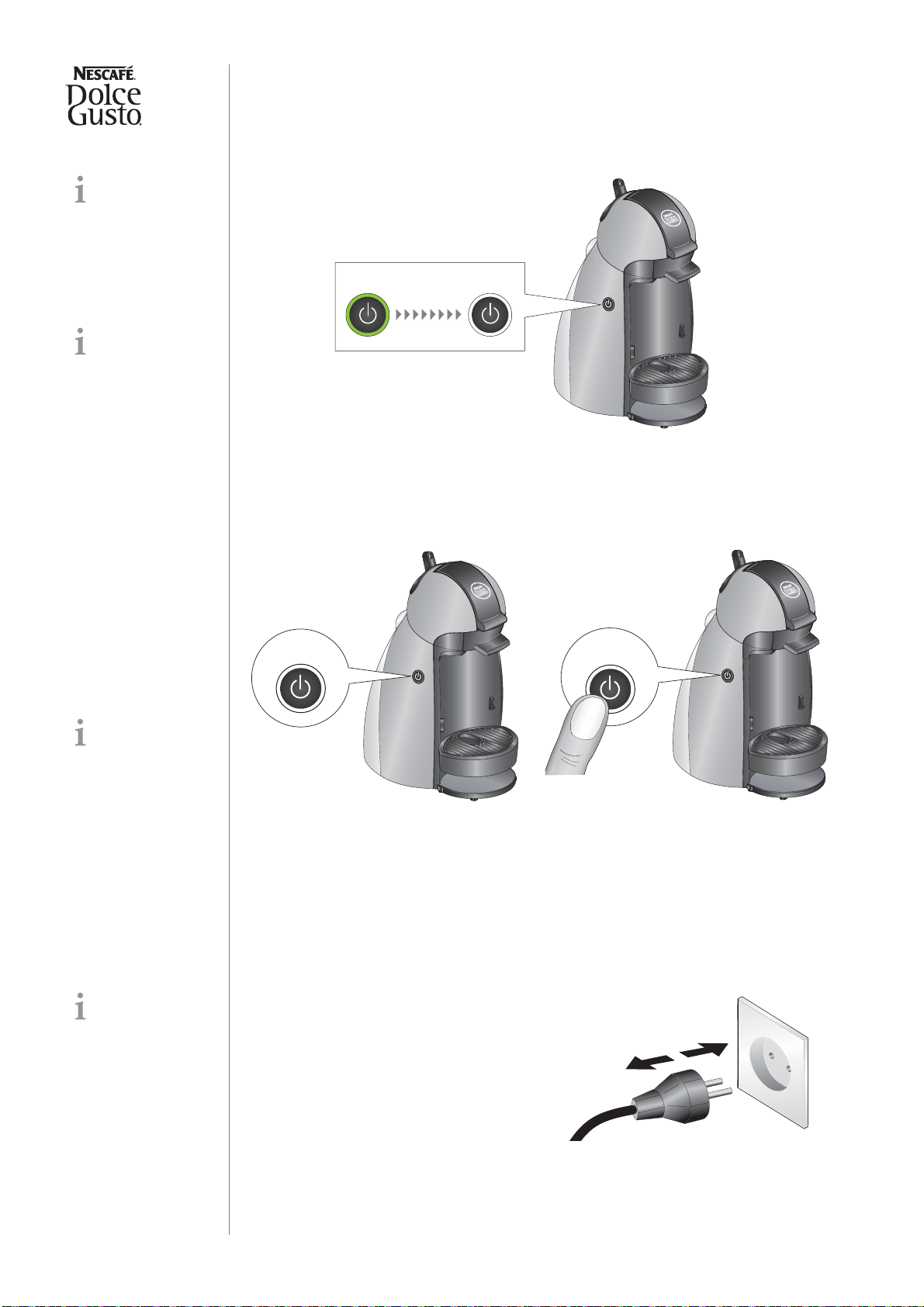

Economy mode (auto shut-off function)

After 5 minutes without operation, the machine switches itself OFF automatically.

To resume operation simply press power button.

Disable auto shut-off function

Aftertheautoshut-offfunction isdisabled themachinewillstayONwhenthepowerbutton

is pressed next time. To turn OFF the machine simply press the power button again.

Restore auto shut-off function

This feature helps

to save electricity by

reducing the amount of

power the machine

draws while it is not in

use and helps protect the

life of the machine.

For longer periods

of standstill

(vacation etc.):

• Plug out power cord.

• Empty water tank.

5 min

ON OFF

Ignore the light sig-

nals and wait until

the power button is no

longer illuminated.

1. Switch machine OFF. 2. Press and hold the power button for

about 30 seconds until the machine

turns OFF again.

OFF

~ 30 sec

A power failure can

restore the auto

shut-off function

accidently. 1. Unplug the machine to restore the

auto shut-off function.

13

Service manual

OPERATING

Empty fluid system for shipping

For shipping a

machine, it is

important to empty the

fluid system.

The machine will

not work without

inserted capsule holder.

Prolonged dry-

running can dam-

age the pump.

1. Empty water tank and drip tray. 2. Check that capsule holder is empty.

3. Reinstall capsule holder.

4. Set selection lever at position "cold

water". Let water run through for

approx. 5 sec.

5. Set selection lever at position "hot

water". Let water run through for

approx. 5 sec.

6. Setselectionlever at middleposition.

7. Remove and empty jug. 13. Clean machine and all accessories.

14. Send machine back with capsule

holder and all provided accessories.

~ 5 sec.

~ 5 sec.

STOP

14

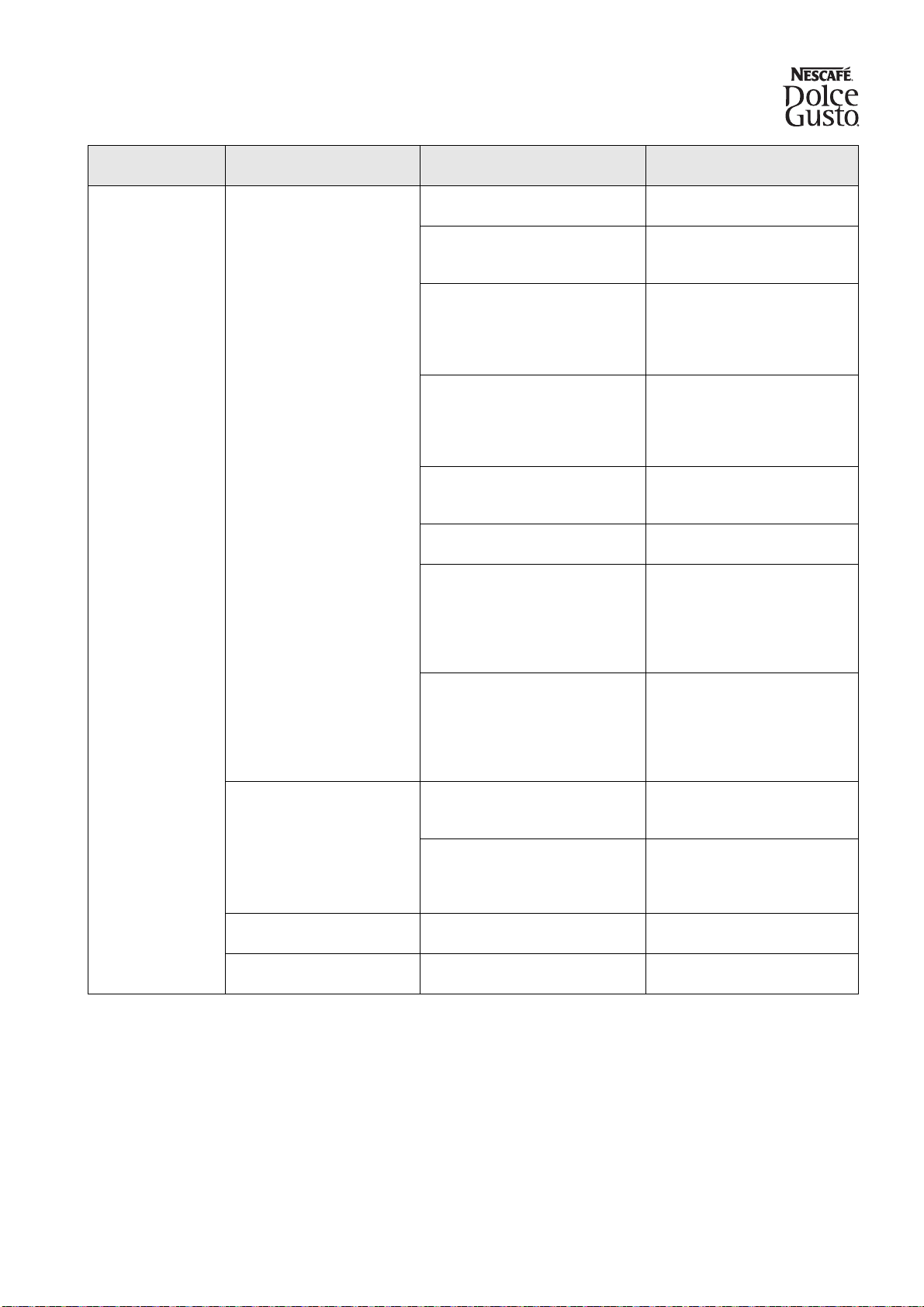

Service manual

TROUBLESHOOTING

TROUBLESHOOTING

Checklist

The checklist enables you to rapidly locate faults on the machine and to initiate appropriate repair action.

Follow the check procedure. Repair any faults found and check if the machine is operating perfectly.

Check

procedure Symptoms Action / repair work Further action /

repair work

1 Check general

condition of machine

with

accessoriesand

look for visible

damage

1.1 Parts of housing are

broken or damaged (e.g.snap

connections or latches)

YES - Replace parts if necessary

NO - Go to point 1.2 —

1.2 Accessories are broken or

damaged

YES - Replace all broken or

damaged accessories

NO - Go to point 1.3 —

1.3 Shaky extraction head YES - Fasten 2 screws on extrac-

tion head

NO - Go to point 1.4 —

1.4 Power cord is damaged YES - Replace power cord

NO - Go to point 2 —

2 Check mechanical

elements

2.1 Capsule holder inserts

correctly into the extraction

head?

YES - Go to point 2.2

NO - Replace capsule holder NO - Check injector plate

2.2 Capsule holder magnetic

at all (right corner at back-

side)?

YES - Go to point 2.3

NO - Replace capsule holder. —

2.3 Magnet on backside of

capsule holder: Epoxy resin

cover cracked or brittle?

YES - Replace capsule holder

NO - Go to point 2.4 —

2.4 Drip tray inserts correctly

in all 3 levels?

YES - Go to point 2.5

NO - Check if drip tray is deformed

or damaged, replace if necessary. —

2.5 Damaged / broken locking

handle or selection lever?

YES - replace extraction head if

necessary

NO - Go to point 2.6

—

2.6 Selection of hot or cold is

possiblewhenextractionhead

is opened?

YES - Replace the extraction head

NO - Go to point 2.7 —

2.7 Locking handle can be

pulled up while making a

beverage?

YES - Replace the extraction head

NO - Go to point 3 —

3 Fill water tank

3.1 Water tank is leaking on

transport YES - Replace water tank

NO - Go to point 3.2 —

3.2Watertankisleakingwhen

it is inserted in the machine

YES - b) Try new water tank and

check if it is still leaking

NO - Go to point 4

YES - Replace water tank

connector

NO - Replace old water tank

15

Service manual

TROUBLESHOOTING

4 Plug into mains

and switch ON

machine

4.1 Machine (with capsule

holder inserted) is not working

- no function

YES - a) Check if power cord is

functional YES - Go to point b)

NO - Replace it

YES - b) Check if all electrical

connectors are connected

YES - Go to point c)

NO - Connect them

YES - c) Check if thermoblock’s

thermal cutoff fuses (133 °C) are

defective

YES - Replace power cord and

electronic mainboard. If neces-

sary replace also the ther-

moblock.

NO - Go to point d)

YES - d) Check if power button and

indicator (LED) is functional

YES - Go to point e)

NO - Replace power button

assembly. If

necessary replace electronic

mainboard also

YES - e) Check if reed contact is

functional

YES - Go to point f)

NO - Replace extraction head

YES-f)Checkif pumpis working at

position "cold water" YES - Go to point g)

NO - Go to point h)

YES - g) Check if pump is working

at position "hot water"

YES - Go to point 4.3

NO-Replacetheextractionhead

(valve switch might be broken).

If still not working,

replace also electronic main-

board.

YES - h) Check if pump's thermal

cut off fuse (98 °C) is defective

YES - Replace pump

NO - Replace pump

or electronic mainboard

or extraction head

4.2Indicator(LED)flashesred

3 times a second (error mode)

YES - a) Check if NTC temperature

sensor is functional

NO - Replace NTC temperature

sensor

YES - Go to point b)

YES - b) Check if electrical wires

are functional

NO - Go to point 4.3

YES - Replace electronic main-

board

NO - Replace defective wire(s)

4.3 Machine is working

without capsule holder YES - Replace the extraction head

NO - Go to point 4.4 —

4.4 Machine is hissing if selec-

tion lever is in middle position YES - Replace the extraction head

NO - Go to point 5 —

Check

procedure Symptoms Action / repair work Further action /

repair work

16

Service manual

TROUBLESHOOTING

5 Checks while

preparing a

beverage

5.1 No extraction possible (no

water at coffee outlet)

YES - a) Water tank is empty? YES - Fill water tank

NO - Go to point b)

YES - b) Water tank is correctly

inserted? YES - Go to point c)

NO - Insert water tank correctly

YES - c) Filter in water tank

connector is blocked or not in right

position?

YES - Clean filter or replace

water tank connector if neces-

sary

NO - Go to point d)

YES - d) Fluid system is empty?

YES - Prime fluid system without

a capsule: Set selection lever at

position cold and hot water for

about 10 sec successively.

NO - Go to point e)

YES - e) Fluid system is blocked by

scale?

YES - Descale the fluid system

NO - Go to point f)

YES- f) Injector is stillcloggedafter

descaling?

YES - Deblock injector with

cleaning needle or replace

injector plate

NO - Replace extraction head

5.2 Hot water temperature is

too low (less than 70 °C /

158 °F)

YES - a) Check if NTC temperature

sensor is functional

NO - Change NTC temperature

sensor

YES - Go to point b)

YES - b) Fluid system is scaled?

YES - Descale fluid system

NO - Replace electronic main-

board

YES - c) Valve malfunction? YES - Replace extraction head

NO - Go to point d)

YES - d) Flow rate of pump out of

range?

YES - Replace pump

NO - Go to point 5.3

5.3 Hot water temperature is

too high (more than 95 °C /

203 °F)

YES - a) Check if NTC temperature

sensor is functional

NO - Change NTC temperature

sensor

YES - Go to point b)

YES - b) Fluid system is scaled? YES - Descale fluid system

NO - Go to point 5.5

YES - d) Flow rate of pump is out of

range?

YES - Replace pump

NO - Go to point 5.4

5.4 Cold water temperature

too high (5 °C / 41 °F more

than water tank temperature)

YES - Valve malfunction?

NO - Go to point 5.5

YES - Replace extraction head

NO - Go to point 5.6

5.5 Selection lever does not

remainatposition"cold water"

or "hot water"

YES - Replace extraction head

NO - Go to point 5.6 —

5.6 The capsule does not fall

out of the capsule holder

YES - Check capsule and capsule

holder for deformations

NO - Go to point 6

YES - Replace capsule holder if

necessary

Check

procedure Symptoms Action / repair work Further action /

repair work

17

Service manual

TROUBLESHOOTING

6 Check for leaks

and/or flow rate

while preparing a

beverage

6.1 Leakage at extraction

head

YES - a) Capsule has multiple

perforations?

NO - Go to point 6.2

YES - Perforate capsule only

once, see user manual

NO - Replace extraction head

6.2 Water underneath the

machine YES - Defective pressure hoses?

NO - Go to point 6.3

YES - Replace defective pres-

sure hoses with clips

NO - Go to point 6.4

6.3 Flow rate out of range

YES - a) Fluid system is scaled? YES - Descale the fluid system

NO - Go to point b)

YES - b) Injector plate is blocked?

YES - Deblock injector with

cleaning needle

and descale again

NO - Go to point c)

YES - c) Filter of water tank

connector is blocked?

YES - Clean filter or replace

water tank connector if neces-

sary

NO - Replace pump

7 Check for loud

noises or vibrations

7.1 Check vibrations while

putting a plastic beaker on the

drip grid

YES - Coffee machine or plastic

beaker is moving around

YES - a) Check if drip tray and

drip grid are inserted correctly,

set it right if necessary

NO - Go to point b)

YES - b) Check if rubber feet are

missing, replace if necessary

NO - Go to point c)

YES - d) Pump is not firm in its

support, replace it

NO - Go to point c)

7.2 Check vibrations on the

water tank (water is waving) YES - Water tank is vibrating on the

machine?

YES - Pump is not firm in its

support, replace it

NO - Go to point 8

8 Perform final tests

9 Perform final

cleaning

Check

procedure Symptoms Action / repair work Further action /

repair work

18

Service manual

REPAIR

Tools and repair accessories

With the following tools, all described disassembly and repair work can be done:

Repair work without disassembling the machine

Without disassembling the machine, you can clean, replace or repair the following parts:

• Water tank (pos. 6)

• Capsule holder (pos. 17)

• Injector plate (pos. 19)

• Drip tray (pos. 13) and drip grid (pos. 14)

Cleaning or replacing injector plate, deblocking of injector

Solid residues in the water circuit can block the injector completely. An example is the

development of calcium particles if the machine is not descaled periodically. Therefore

this error appears during descaling frequently.

A pin-torx screw

head looks like this:

Tools Applications

Torx screwdriver for security screws,

Pin-TX 10

Fastening screws for

- extraction head

- side panels / water tank connector

Phillips screwdriver no. 1 Fastening screw of fuse holder on thermoblock.

Screwdriver with blade width 4 mm To open latches and snap connections

Flat nose pliers Flat receptacles, hose clips, filter element of

water tank connector

Fork wrench no. 12 Adjustable pump connector

Cutter (stanley knife) Cut new pressure hoses to length.

Cutting pliers To cut cable ties on pressure hoses and H-

connector

Small hammer Clamp spring (NTC temperature sensor)

Piercer

Pointed pliers NTC temperature sensor

Heat conducting paste

1. Remove water tank (pos. 3).

2. Remove capsule holder (pos. 17). 3. Switch off and unplug machine.

4. Take cleaning needle out of support.

3

17

19

Service manual

REPAIR

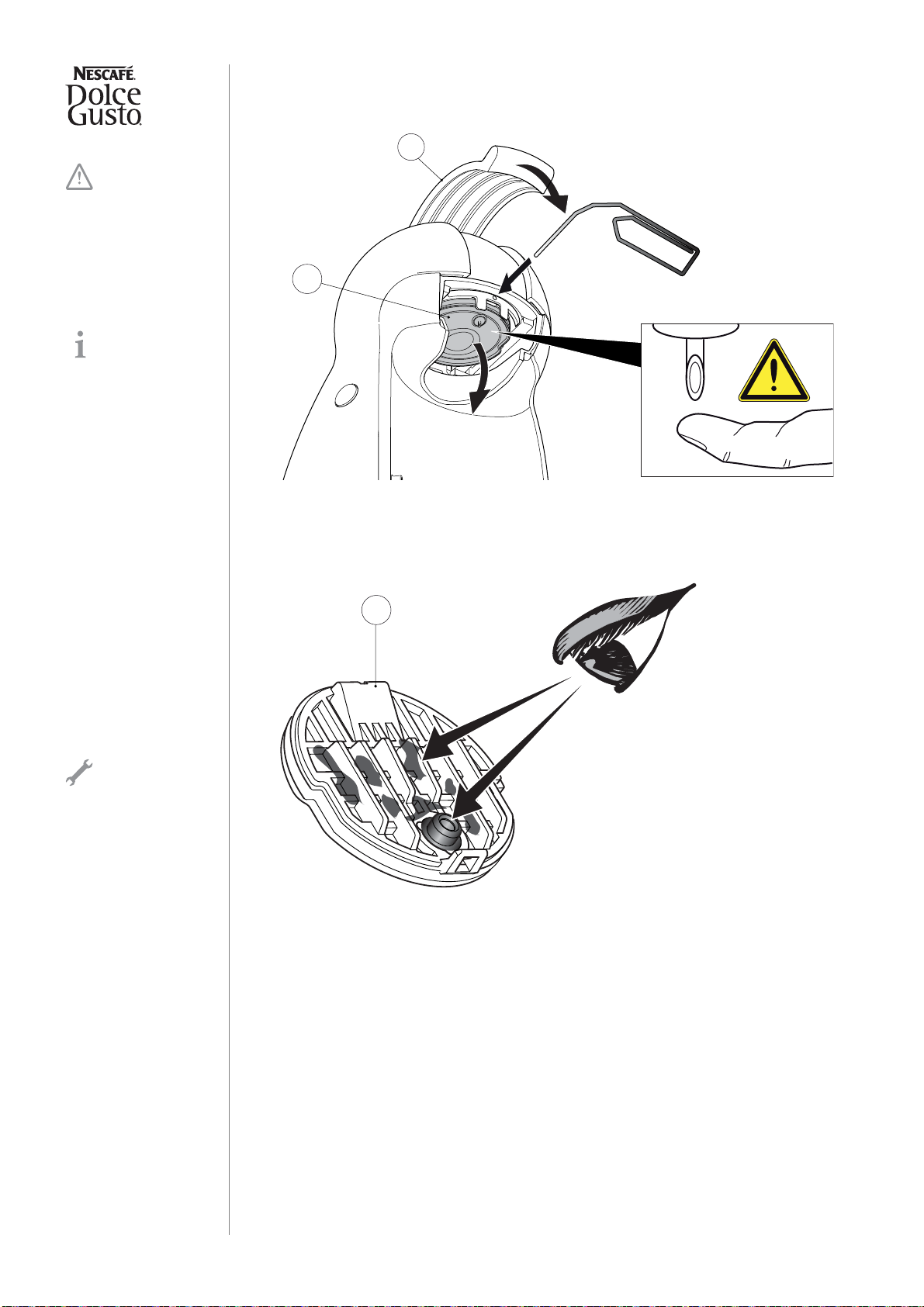

5. Close locking handle (pos. 2).

6. Release latch by pressing a suitable pin (dia. 1.8 mm max. e.g. a paper clip)

through hole and remove injector plate (pos. 19) by pulling it down.

7. Examine upper side of injector plate (pos. 19).

8. Clean interior space of sealing ring with a toothpick etc.

Danger of injury -

sharp pointed

injector!

The extraction

head is adjusted to a

specific injector plate

(pos. 19). Therefore do

not mix up different

injector plates acciden-

tally.

19

2

If upper side of

injector plate is wet

and badly soiled, the

sealing ring is defect. In

that case replace injector

plate.

19

20

This manual suits for next models

1

Table of contents

Other SEB Coffee Maker manuals

Popular Coffee Maker manuals by other brands

Slayer

Slayer Professional Series user manual

Ninja

Ninja CE200C Series owner's guide

Franke

Franke A1000 Original operating instructions

Jura

Jura Impressa J6 Quick reference guide

Grindmaster

Grindmaster Grind'n Brew-10H Operation and Operation and instruction manual

TREVIDEA

TREVIDEA G3 FERRARI TIFFANY user manual