SEB IDM8N User manual

DIVISIONE ELETTRONICA E SISTEMI

IDM8N

DIGITAL PERCENTAGE BIASED

DIFFERENTIAL PROTECTION RELAY

USER MANUAL

P501D812 June 2010

SEB Divisione Elettronica e Sistemi INDEX

INDEX

1GENERAL CHARACTERISTICS..................................................................................1

1.1 Operation of the differential thresholds..................................................................3

1.2 Transformer differential protection (ANSI 87T)......................................................6

1.3 Overcurrent thresholds (ANSI 51) .........................................................................6

1.4 Residual overcurrent (ANSI 51N) ..........................................................................7

2FRONT PANEL KEYS ..................................................................................................8

3FRONT PANEL LED SIGNALING ................................................................................9

4PROGRAMMING AND TEST .....................................................................................10

4.1 How to program the protection relay....................................................................10

4.2 How to modify a visualized parameter.................................................................11

4.3 Reset ...................................................................................................................11

4.4 Test of output relays ............................................................................................12

5DISPLAY AND PROGRAMMING ...............................................................................13

5.1 Standard display..................................................................................................13

5.2 Visualization structure .........................................................................................14

5.3 Address and time (fig. 1) .....................................................................................19

5.4 Display selection and drop-off delay (fig. 1).........................................................20

5.5 Rated values of the protected transformer (picture 2) .........................................21

5.6 Thresholds and time delays set-up (fig. 2)...........................................................24

5.6.1 Percentage biased differential thresholds (87T - fig. 2) ................................24

5.6.2 Overcurrent thresholds (51 - fig. 2)...............................................................27

5.6.3 Residual overcurrent thresholds (51N - fig. 2) ..............................................28

5.7 Output relays programming (fig. 3) ......................................................................29

5.8 Digital inputs function programming (fig. 3) .........................................................30

5.9 Parameter values visualization (fig. 4).................................................................31

5.10 Events (fig. 5) ......................................................................................................35

5.11 Trips counters (fig. 5)...........................................................................................38

6INSTALLATION ..........................................................................................................40

6.1 Supplied kit..........................................................................................................40

6.2 Cabling ................................................................................................................40

6.3 Relays R3 and R4 - Signaling / Command set-up ...............................................46

6.4 RS485 serial communication port........................................................................46

7TECHNICAL DATA.....................................................................................................47

8TABLE ........................................................................................................................48

Information printed in this manual subject to change without prior notice.

This manual must not be reproduced in whole or in part, in any form or by any means

without the express written permission of SEB Divisione Elettronica e Sistemi.

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

1

1 GENERAL CHARACTERISTICS

The protection relay IDM8N performs function as three-poles percentage biased

transformer differential protection relay (ANSI 87T) to protect transformers or generator-

transformer units; the user can select one or more of the functions listed in the table below:

FUNCTIONS ANSI

Three-poles percentage biased differential protection for

transformers 87T

Three-poles overcurrent protection 51

Residual overcurrent protection 51N

Each function is made by a set of threshold, which could be enabled or disabled in

independent mode.

THRESHOLDS - the following thresholds are available:

•1 differential percentage biased threshold (two branches)

•1 absolute value differential threshold

•6 overcurrent thresholds (three for each winding of the transformer)

•3 residual overcurrent thresholds (secondary side)

The available settings for each threshold are listed in Table B.

All the set-up and measured parameters can be visualized on the front panel display and

transmitted on the RS485 communication serial port.

TRIP DELAYS - All the thresholds are time definite. Relay trips are shown turning on LED

and with a specific message on the display.

The available settings for each timers are listed in Table B.

OUTPUT RELAYS - the IDM8N controls 4 output relays (named R1, R2, R3 and R4);

these relays can be programmed to be activated on START or TRIP conditions of one or

more thresholds.

START instantaneous activation of the output relay when at least

one of the measured current or parameter exceeds the

programmed threshold value

TRIP activation of the output relay when the programmed time

delay (TI) related to a threshold expires.

The quiescent state of each single relay R1, R2, R3 and R4 can be programmed as

normally energized (ON) or normally de-energized (OFF). An additional relay R5 (normally

energized) is controlled by the self-diagnosis routines to report detected fault conditions.

Related to each threshold, partial and total counters of TRIP conditions are available.

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

2

DIGITAL INPUTS - there are available 6 digital inputs to activate the following functions

(when enabled by the programmed set-up):

•on/off ANSI function

•on/off thresholds (single threshold or all thresholds)

•STATO function (recording of measures on external event)

For each digital input can be programmed the condition that activates the related

functions:

HI voltage = > 20V dc / ac

LO voltage = 0 ÷ 10 V dc / ac

The digital input acquisition is valid when the voltage value stays in the range HI or LO for

at least 40 ms.

DISPLAY OF MEASURES - the user can select the continuous display of a measured

differential current or of a stabilizing current (primary values or relative values); all the

measured currents can be transmitted to an external controller through the RS485 port.

EVENTS - information related to the last 8 events (TRIP or STATO) are recorded in the

EEPROM memory.

Information includes the threshold set-up and activated relays (TRIP event only), the

measured currents, the digital input status, date and time of the event.

SELF-DIAGNOSIS - the software includes a non stop monitoring module that controls the

functionality of all hardware and software resources of the protection relay.

Detected fault conditions are reported by:

•diagnostic message on the display

•glow of a red LED on front panel

•R5 output relay drop-off

The fault condition signaling stays until faults are pointed out by the monitoring module;

during this condition the protection functions are suspended to avoid unsuitable tripping.

STATUS FUNCTION - when the STATO function is activated by one of the digital input

(when programmed) the protection relay memorizes information related to measured

currents and digital input status (see par. 5.10 - EVENTS). The recorded information

allows an analysis of trip causes in co-operative protection relays systems.

REMOTE COMMUNICATION - the opto-insulated serial port RS485 can communicate

with a personal computer or a remote control and monitoring system equipped with an

RS485 interface or with a standard RS485/RS232 converter.

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

3

It is possible to select the communication standard between STANDARD (ASCII 7 bit -

Seb protocol) and MODBUS (ASCII mode, SLAVE).

All the set-up and measured parameters can be transmitted on the RS485 communication

serial port; when communication is active (LED REMOTE glows), the operator on front

panel can visualize the relay set-up but changes of parameters are disabled (ENTER and

buttons disabled).

1.1 Operation of the differential thresholds

The IDM8N relay performs functions as percentage biased differential protection relay for

two windings transformers; the tripping characteristic is presented in figure A.

A differential protection relay operates on the principle of current comparison and with a

healthy protected object the current leaving is the same as that which entered it. Any

measured current difference is a clear indication of a fault condition within the protected

zone.

Id - differential current - vectorial difference between the input current and the output

current of the protected object

''1'11 IIId −=

Three differential current values are computed, one for each phase; the differential

thresholds are verified for each differential current.

Ip - stabilizing current - half-sum of the vectors of the input and output currents of the

protected object used to stabilize the protection relay operations in presence of faults

external to the protected zone.

2

''1'1

1

II

Ip +

=

When short-circuit currents due to faults external to the protected zone are flowing through

the protected object it is possible to have measured differential currents due to current

transformer errors or saturation. The stabilizing current is used to stabilize the protection

relay operation in these conditions.

Differential thresholds

Two differential thresholds are available:

Id> percentage biased differential threshold

Id>> second differential threshold (absolute value)

The relay operates when:

threshold Id>> the following disequation is verified

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

4

>>≥ IdId

threshold Id> ALL the following disequations are verified:

>≥ IBId

()

IpPId ∗≥ 1

()

DIIpPId −∗≥ 2

where:

|Id| module of the differential current

|Ip| module of the stabilizing current

IB> insensibility threshold

P1, P2: slopes of the tripping characteristic

DI intersection of the P2 straight line with Id/In axis

The listed disequations define the operating characteristic as presented in figure A and

they are verified with all the differential currents (and their stabilizing currents) related to

phase currents.

The differential threshold Id>> and the second branch of the operating characteristic

related to Id> threshold (slope P2) can be programmed ON/OFF.

All the differential thresholds are definite time (0.03 ÷ 999.99 s).

The minimum activation time of the output relay is programmable in order to avoid short

commands to switchgears when CT’s saturate.

The differential thresholds Id> and Id>> are referred to the rated current of the protected

transformer normalized with the ratio of the installed CT’s in order that the value of

measured currents on the primary and secondary windings can be directly compared.

For this purpose, two coefficients named KTA1 and KTA2 are used. They are referred to

the primary winding and to the secondary winding of the transformer and they are the ratio

between the rated value of the CT and the rated value of the related circuit.

In other words:

1

1

1

In

In

KTA TA

=

Where InTA1 is the rated value of CT (for example: 300, in case of a 300 / 5 CT) and In1is

the rated value of the current in the primary side of the transformer, for example 250 A. In

this case the value of KTA1 is: 300 / 250 = 1.2

The same argument is valid for secondary winding parameters.

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

5

The secondary rated value of phase CT is selectable 1 A or 5 A for each side of the

transformer to be protected.

For its internal processing, the relay converts the measured currents as referred to 5 A

value. This operation is irrelevant for the user.

Threshold values are referred in terms of the rated current In of the corresponding

installed CT’s.

Operating characteristic - figure A

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

6

1.2 Transformer differential protection (ANSI 87T)

The protection relay IDM8N has been designed to provide three-poles percentage biased

differential protection function to transformer and generator-transformer units.

The relay IDM8N protects two windings transformers; in table A (see ref. D2) there are the

vectorial groups of the transformers which can be protected by the relay.

The insertion of the protection relay is presented in figure 6. The CT’s are installed on both

sides of the protected transformer; in the case of generator-transformer unit, the CT’s are

installed on the HV side of the transformer and on the star-point side of the generator.

The differential relay IDM8N does not require the use of intermediate current transformers

as the phase angle and the current amplitude compensation are carried out by the

protection relay itself; the compensation is function of the programmed characteristics

related to:

•coefficients KTA1 and KTA2

•power transformer vector group

•type of connection if the primary winding is Y (insulated or grounded)

The connection of the power transformer to the network may cause an inrush current

which can be several times the rated current and, with a time constant up to several

seconds. This transient condition appears as a differential current to the protection relay

and it would make the relay trip.

A relatively high content of second harmonic components is typical for the inrush current

while they are nearly absent in case of a short-circuit.

Likewise overexcitation conditions are cause of odd harmonic components (3rd and 5th).

To avoid unsuitable trips, on protection relay IDM8N it is possible to activate (ON/OFF)

and to program (in terms of % Id) two harmonic thresholds (on 2nd and 5th harmonic

components as the 3rd harmonic components are often eliminated through the use of delta

windings).

The harmonic stabilization is activated if at least for one of the phases the measured 2nd

and 5th harmonic content of the differential current exceeds the programmed thresholds;

when the harmonic stabilization is active, the trip related to Id> threshold will be blocked

The harmonic restrain does not effect the Id>> threshold operation.

1.3 Overcurrent thresholds (ANSI 51)

Six overcurrent thresholds are available and actionable, 3 for each side of the transformer,

to guarantee a back-up protection against faults external to the protected transformer or

generator-transformer unit. The function of the overcurrent thresholds is to give an

additional protection to the transformer if the fault condition has not been eliminated by

protection relays closer to the fault.

IH> 1

st primary winding overcurrent threshold

IH>> 2

nd primary winding overcurrent threshold

SEB Divisione Elettronica e Sistemi GENERAL CHARACTERISTICS

7

IH>>> 3rd primary winding overcurrent threshold

IL> 1

st secondary winding overcurrent threshold

IL>> 2

nd secondary winding overcurrent threshold

IL>>> 3rd secondary winding overcurrent threshold

All overcurrent thresholds are definite time; the available settings for each threshold and

time delays are listed in Table B.

Overcurrent threshold values of function ANSI 51 are referred in terms of the rated current

In of the corresponding installed CT’s.

1.4 Residual overcurrent (ANSI 51N)

Three residual overcurrent thresholds are available and actionable, to guarantee

protection against earth faults internal to the protected zone in the secondary side of the

transformer.

IE> 1

st residual overcurrent threshold

IE>> 2

nd residual overcurrent threshold

IE>>> 3rd residual overcurrent threshold

All residual overcurrent thresholds are definite time; the available settings for each

threshold and time delays are listed in Table B.

Residual threshold values of function ANSI 51N are referred in terms of the rated current

Ion of the earth CT.

Note: the relay has two inputs to measure the residual current, one with rated value 1 A

(D1-D2 on CB1) and one with rated value 5 A (D1-D2 on CB2). The earth CT has to

be connected to the inputs referred to its own rated value and the relay has to be

programmed according to the CT rated value (see rif. D11).

SEB Divisione Elettronica e Sistemi FRONT PANEL KEYS

8

2 FRONT PANEL KEYS

The 5 push-buttons on the front panel allow to visualize all the protection parameters and

to modify the protection set-up.

right arrow

down arrow

programming session activation or parameter confirmation

change or increment of the selected parameter

reset of the protection relay (rif. par. 4.3)

VISUALIZATION OF PARAMETERS

•all visualizations are circular and they can be displayed using the two arrow push-

buttons.

•the structure of the visualizations and their contents are showed in Figures 1, 2, 3, 4

and 5.

•when the sealable transparent front panel is installed only the arrow push-buttons

and the RESET push-button are accessible to prevent unauthorized modification of

the protection set-up.

MODIFICATION OF PARAMETERS

•remove the transparent sealable front panel to access ENTER and push-

buttons.

SEB Divisione Elettronica e Sistemi FRONT PANEL LED SIGNALING

9

3 FRONT PANEL LED SIGNALING

POWER

(green)

⊕auxiliary supply available

FAIL

(red)

⊕fault condition detected by SELF-DIAGNOSIS software

REMOTE

(red)

⊕communication session active on RS485 port

87

(red)

⊕trip condition on Id> or Id>> threshold (ANSI 87T)

51

(red)

⊕trip condition on overcurrent threshold IH>, IH>>, IH>>>, IL>,

IL>> and IL>>> (ANSI 51)

51N

(red)

⊕trip condition on residual overcurrent threshold IE>, IE>> and

IE>>> (ANSI 51N)

The last trip condition (threshold indication) is also shown on front panel display; if a trip of

function 87 or 51 has occurred, also the fault phases are shown on the display.

More information on trip condition is presented in the recorded EVENT (see par. 5.10).

SEB Divisione Elettronica e Sistemi PROGRAMMING AND TEST

10

4 PROGRAMMING AND TEST

The protection relay is easily programmable following the instructions in the next

paragraphs:

•HOW TO PROGRAM THE PROTECTION RELAY

•HOW TO MODIFY A VISUALIZED PARAMETER

All parameters can be freely modified; the proper protection set- up as required by the

plant management is submitted to the operator's judgment.

4.1 How to program the protection relay

The programmable parameters are showed in Figures 1, 2, 3, 4 and 5 at the following

references:

B2 ÷ B7 relay address (RS485) and date/time

C1 ÷ C4 display and drop-off time

D1 ÷ D11 rated values of the protected transformer

E1D ÷ E10D threshold set-up and time delays 87T

E1F ÷ E5F threshold set-up and time delays 51

E1R ÷ E5R threshold set-up and time delays 51N

G1 ÷ G14 output relays functions

H1 ÷ H6 digital input functions

S1 ÷ S22 partial trip counters reset

The programming sequence is the following:

1) SELECT the visualization (on display) of the parameter to be modified using the

arrow push-buttons

2) ACTIVATE the PARAMETER MODIFICATION session depressing the [ENTER]

push-button and modify the parameter value

3) END the parameter modification session depressing again the [ENTER] push-

button

4) REPEAT the procedure from 1) to 3) for all the parameters required to obtain the

new protection relay set-up

5) CONFIRM the new protection relay set-up at the visualization CONFIRM PROG?

(Figure 1, ref. J1) within 5 minutes depressing the push-buttons [ENTER], up to

visualize YES and [ENTER] again to confirm.

NOTE The protection relay continues to operate using the previous set-up until the new

set-up is confirmed as at point 5) above; the visualization of the modified

parameters before the new set-up confirmation is only temporary to allow an easy

definition of the new protection set-up.

SEB Divisione Elettronica e Sistemi PROGRAMMING AND TEST

11

If the new set-up is not confirmed within 5 minutes from the last pressed push-button, the

protection relay visualizes again the previous set-up (the parameters set-up that the

protection relay is still using).

4.2 How to modify a visualized parameter

When the parameter to be modified is visualized on front panel display do the following

sequence:

1) PRESS [ENTER] to activate the parameter modification session

If one or more parameters are modifiable, on the first of them will appear a blinking cursor.

If no parameters are modifiable, no blinking cursor will appear.

2) MODIFY THE PARAMETER pressing the arrow push-buttons and

when two parameters are modifiable, the push-button allows to

point-out the parameter to be modified (the selected parameter will

blink

when numerical parameters are pointed-out the push-button allows

to select the digit to be modified

increasing of the parameter

a) the digits are increased by 1 unit

b) the other parameters are presented following the selection

list

3) PRESS [ENTER] to end parameter modification session

The modification session is ended and the parameter stops to blink

NOTE if a numerical parameter is selected out of the accepted range (as shown in Table

D) when the push-button [ENTER] is pressed for few seconds an error message

will be displayed as:

Errore

nei dati

and the parameter will be displayed again with the former value.

4.3 Reset

When the push-button [RESET] is pressed, the protection relays returns to the standard

condition:

•reset of glowing LEDs

SEB Divisione Elettronica e Sistemi PROGRAMMING AND TEST

12

•drop-off of tripped relays

•reset of any parameter changed but not confirmed (parameters are shown as

confirmed at the end of the last programming session)

•display on STANDARD MODE (Figure. 1, ref. A1 - par. 5.1)

4.4 Test of output relays

When the output relays test is selected (Figure. 3, ref. G9) it is possible to command an

output relay (one at the time) to trip from the current status allowing functional tests on

electrical plants.

The output relays are activated with the following sequence:

1) SELECT THE VISUALIZATION of the desired output relay to be tested

TEST R1

OFF

2) PRESS [ENTER] to activate the test session; the message OFF will start to blink.

3) PRESS and the message on the display will change as:

TEST R1

ON

4) PRESS [ENTER] to command the instantaneous trip of the output relay (change of

the current status).

The relay will stay on the new condition until:

•the or [RESET] push-button is pressed

•the ENTER push-button is pressed and the sequence at points 3) and 4) is

repeated (presenting OFF condition)

The same procedure will be used for R2, R3 and R4 relays.

SEB Divisione Elettronica e Sistemi DISPLAY AND PROGRAMMING

13

5 DISPLAY AND PROGRAMMING

The contents and the structure of the displayed messages are shown in figures 1, 2, 3, 4

and 5; the references A1, B1, B2 etc. identify specific displayed messages in the figures.

5.1 Standard display

A1 - STANDARD DISPLAY

It is the standard displayed message without operator's intervention (no push-buttons

pressed for at least 5 minutes) or when the RESET push-button has been pressed.

The displayed information is function of the protection relay status.

NORMAL FUCTIONING

During this state the following information can be visualized (as defined by set-up):

Protection function (ANSI code) - the display shows the ANSI codes of the main functions

(87T – 51 – 51N).

Measured current and parameters - the display shows one of the measured currents or

one of the differential currents (IdR, IdS, IdT) or the stabilizing currents (IpR, IpS, IpT); the

information to be visualized is selected by operator (ref. C1).

The currents are visualized as primary value and/or relative value (In).

ON TRIP CONDITION

When a trip condition occurs the protection relay visualizes the TRIP message that

includes the threshold related to the trip; the displayed messages are as the following:

TRIP

Id> r

TRIP

Id>> rs

TRIP

IH> t

TRIP

IE>

The information of the trip, as well the glowing of the related LEDs, is displayed until the

[RESET] push-button is pressed.

For trip condition related to functions 87T or 51, it is shown also the information related to

the fault phase(s).

Note: information related to fault phase (R, S, T) is referred to the insertion diagram in

picture 6. In case of trip of threshold Id> or Id>>, the fault phase is according to

compensation factors related to the transformer’s vector (rif. D2).

If a new trip condition occurs, the displayed information will be updated; information related

to previous trips is recorded in EVENTS memory.

FAULT CONDITION

When a permanent or temporary fault condition is detected by the self-diagnosis module,

the following message is displayed:

FAIL

eeeeeeee

SEB Divisione Elettronica e Sistemi DISPLAY AND PROGRAMMING

14

The string eeeeeeee can be:

HARDWARE Detected fault condition on hardware or software resources of the

protection relay; all functions are suspended.

Corrective action - replace the protection relay and contact SEB post

sales service.

5.2 Visualization structure

ANSI 87T

51 51N

FAIL

eeeeeeee

TRIP

Id>

IdR

xx.xx In

IDM8N PROTOCOL

yyyyyyyy

BAUDRATE

nnnn

NR RELE

xxx

NR SERIE

zzzzzzzz

VERS SW

zz.zz

gg/mm/aa

hh:mm:ss

SET-UP VALORI

NOMINALI

SET-UP

TRAFO

TARATURA

SOGLIE

FUNZIONI

RELE

INGRESSI

DIGITALI

CONFERMA

PROG?..

MISURE E

EVENTI

STATO

SEGNALI

EVENTI

TOTALIZZ

SCATTI

A1

B1

VISUALIZZAZIONI

ALTERNATIVE

B2

J1

B3

Visualizzazione dati nominali della protezione

(Fig. 2)

Set-up parametro trasformatore protetto

(Fig. 2)

Visualizzazione taratura SOGLIE

(Fig. 2)

Visualizzazione set-up RELE'

(Fig. 3)

Visualizzazione set-up INGRESSI DIGITALI

(Fig. 3)

Visualizzazione STATO SEGNALI

(Fig. 4)

Visualizzazione EVENTI

(Fig. 5)

Visualizzazione TOTALIZZATORI

(Fig. 5)

B4 B5 B6 B7

Figure 1

SEB Divisione Elettronica e Sistemi DISPLAY AND PROGRAMMING

15

SET-UP VALORI

NOMINALI

DISPLAY

eeeeeeee

CONTRAST

LIV n

T-DROP

xx.xx s

SET-UP

TRAFO

N-AVVOLG

2

TR-TYPE

eeeeeeee

CS-AT

eeeeeeee

TA1P

zzzzz A

TA1S

n A

KTA1

x.xx

TA2P

zzzzz A

TARATURA

SOGLIE

87T

ccc

Id>

n.nn In

P1

xx %

P2 ccc

xxx %

Q

nn.nn In

Id>> ccc

zz.zz In

T Id>>

rrr.rr s

51

ccc

IH>

ccc

IH>

nn.nn In

IH>

vvvvvv A

T IH>

zzz.zz s

51N

ccc

IE>

ccc

IE>

n.nnn In

IE>

vvvvvv A

T IE>

zzz.zz s

Da FIGURA 1

C1

D1

E1D

E1F

E1R

C2

D2

E2D

E2F

E2R

C3

D3

E3D

E3F

E3R

D4

E4D

E4F

E4R

D5

E5D

E5F

E5R

D6

E6D

D7

D10

E7D

TA2S

n A

KTA2

x.xx

IoP

zzzzx A

IoS

n A

TH2 ccc

xx %

D8

D11

E8D

D9

A

lla FIGURA 3

MODO

DEBUG xx

C4

T Id>

zzz.zz s

TH5 ccc

xxx %

D10D

E9D

IL>>>

ccc

IL>>>

nn.nn In

IL>>>

vvvvvv A

T IL>>>

zzz.zz s

IE>>>

ccc

IE>>>

n.nnn In

IE>>>

vvvvvv A

T IE>>>

zzz.zz s

Figure 2

SEB Divisione Elettronica e Sistemi DISPLAY AND PROGRAMMING

16

FUNZIONI

RELE

R1

NORM ccc

R1 Id>

xxxxxxxx

R1 Id>>

xxxxxxxx

R1 TH2

xxxxxxxx

R1 TH5

xxxxxxxx

R1 IH>

xxxxxxxx

R1 IH>>

xxxxxxxx

R1 IH>>>

xxxxxxxx

R2

NORM ccc

R3

NORM ccc

R4

NORM ccc

INGRESSI

DIGITALI

DIG1 cc

xxxxxxxx

DIG2 cc

xxxxxxxx

DIG3 cc

xxxxxxxx

DIG4 cc

xxxxxxxx

DIG5 cc

xxxxxxxx

DIG6 cc

xxxxxxxx

CONFERMA

PROG?..

Da FIGURA 2

J1

G1

H1

G2

H2

G3

H3

G4

H4

G5

H5

G6

H6

G7 G8

R1 IL>

xxxxxxxx

G9

Alla FIGURA 4

R1 IL>>

xxxxxxxx

G10

R1 IL>>>

xxxxxxxx

G11

R1 IE>

xxxxxxxx

G12

R1 IE>>

xxxxxxxx

G13

R1 IE>>>

xxxxxxxx

G14

TEST R1

yyyyyyyy

G15

Figure 3

SEB Divisione Elettronica e Sistemi DISPLAY AND PROGRAMMING

17

MISURE E

EVENTI

STATO

SEGNALI

STATO

SOGLIE

Id>

stato

Id>>

stato

TH2

stato

TH5

stato

IH>

stato

IL>>>

stato

PARAMETR

TRAFO

Ka=

x.xx

Kb=

x.xx

Kc=

x.xx

Ear = xx

Far = xx

Gar = xx

Ebr = xx

Fbr = xx

Gbr = xx

Fbs = xx

Gbs = xx

Eat = xx

Fat = xx

Gat = xx

Ebt = xx

STATO

RELE

R1 ccc

R2 ccc

R3 ccc

R4 ccc

STATO

DIGITALI

DIG1 ww

DIG2 ww

DIG3 ww

DIG4 ww

DIG5 ww

DIG6 ww

STATO

MISURE

IR1=xx.x

yyyyy A

IS1=xx.x

yyyyy A

IT1=xx.x

yyyyy A

IR2=xx.x

yyyyy A

IS2=xx.x

yyyyy A

IT2=xx.x

yyyyy A

IdT =

xx.xx In

Id$ # =

xx.xx In

TH2R

nn%

TH2S

nn%

STATO

PASSANTI

IpR =

xx.xx In

IpS =

xx.xx In

IpT =

xx.xx In

Xr =

xx.xx In

Yr =

xx.xx In

Xs =

xx.xx In

Da FIGURA 3

L1

X1

M1

N1

P1

Y1

L2

X2

M2

N2

P2

Y2

L3

X3

X10

N3

P3

Q3

Y3

L4

X4

X11

P4

Q4

Y4

L5

X5

X12

P5

Q10

Y5

L10

X6

P6

Q11

Y6

IE>>>

stato

Eas = xx

Fas = xx

Gas = xx

Ebs = xx

Fbt = xx

Gbt = xx

IR=x.xxx

yyyyy A

IR1 2a

xx.xx In

IT2 5a

xx.xx In

TH2T

nn%

TH5R

nn%

TH5S

nn%

TH5T

nn%

Ys =

xx.xx In

Xt =

xx.xx In

Yt =

xx.xx In

L13

X7

P7

Q12

X8

P8

Q13

X9

Q14

P19

Q15

Y7 Y8 Y9

Alla FIGURA 5

IE>

stato

L11

IE>>

stato

L12

STATO

DIFFER.

IdR =

xx.xx In

IdS =

xx.xx In

Q1 Q2 Q9

X$ #a =

xx.xx In

Y21Y10

Figure 4

Table of contents

Other SEB Relay manuals

Popular Relay manuals by other brands

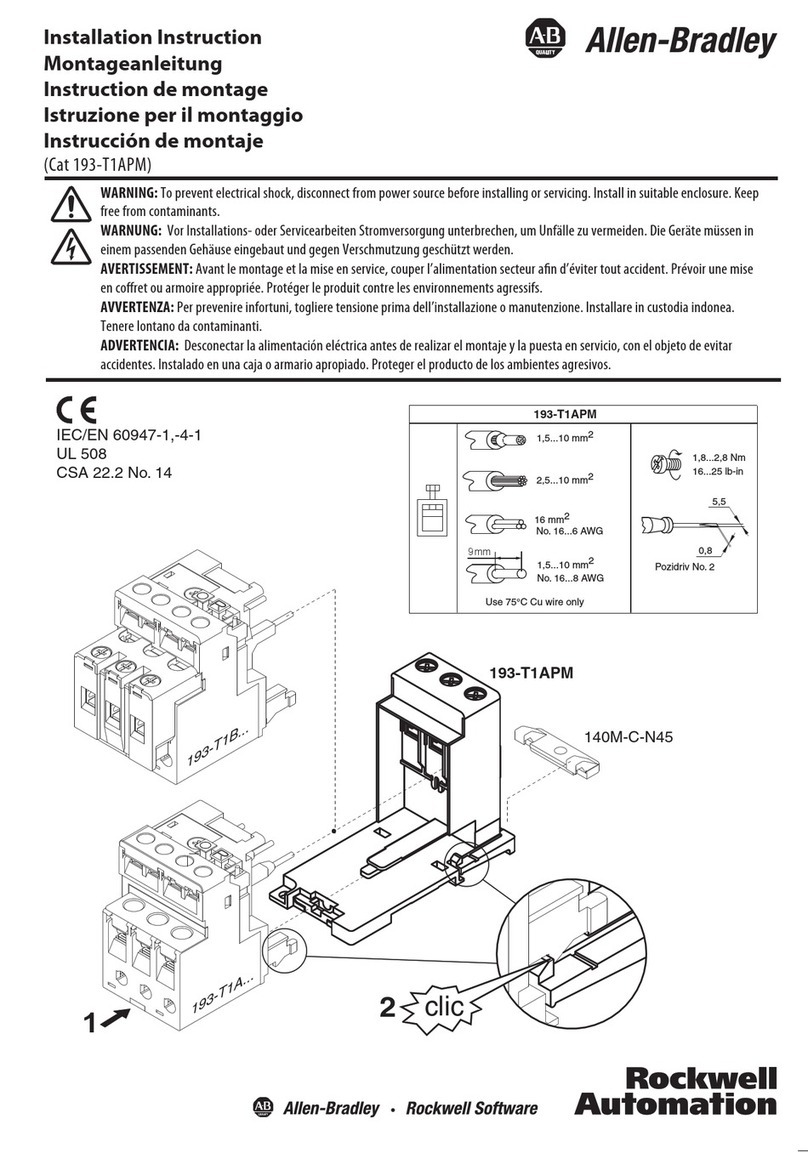

Rockwell Automation

Rockwell Automation Guardmaster MSR57P user manual

Omron

Omron G9SE-201 user manual

Rockwell Automation

Rockwell Automation Allen-Bradley 193-T1APM Installation instruction

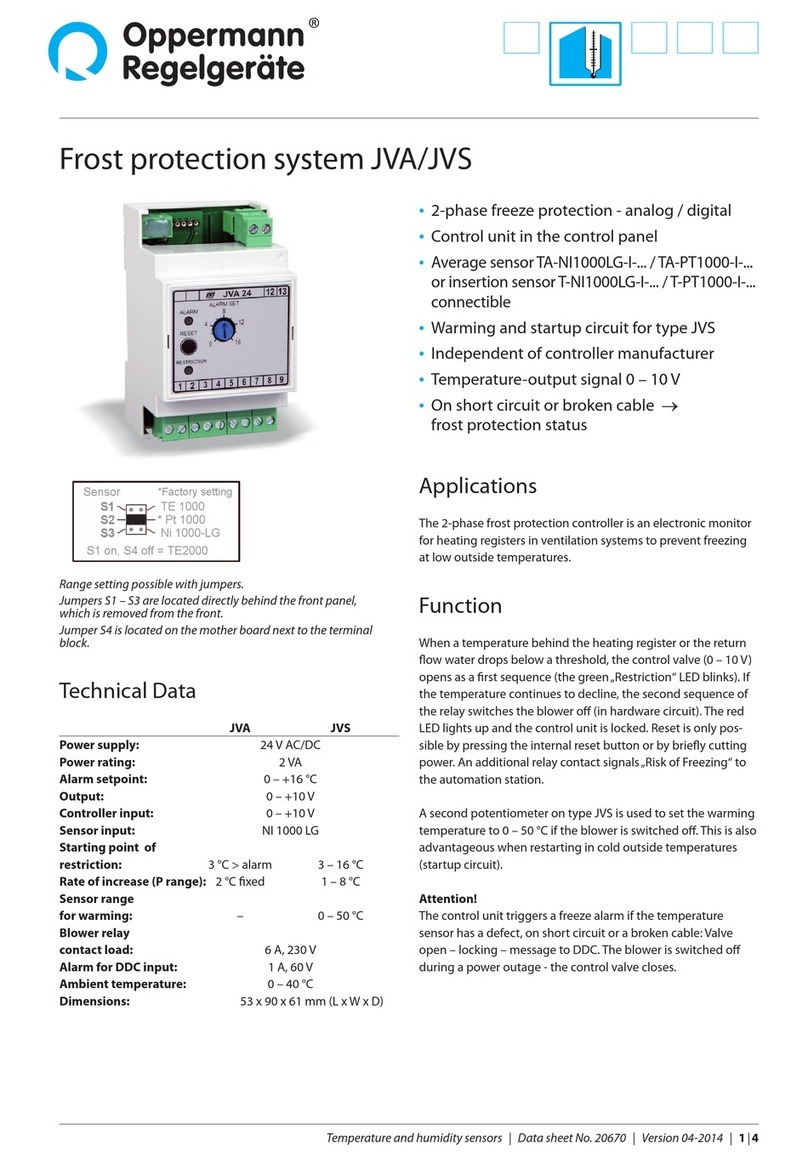

Oppermann Regelgeräte

Oppermann Regelgeräte JVA manual

Circutor

Circutor WRU-10 quick start guide

Rockwell Automation

Rockwell Automation Allen-Bradley 440R-GL2S2T user manual