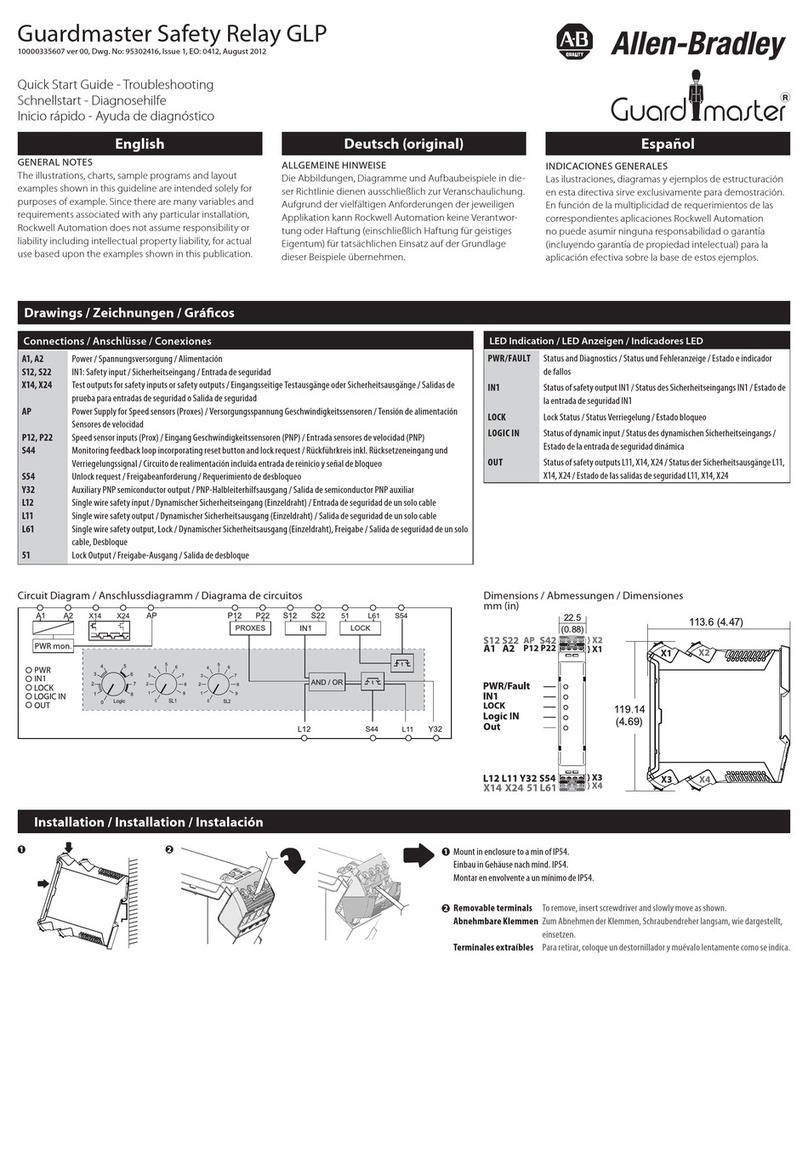

Rockwell Automation Publication 440R-IN081B-EN-P - February 2020 3

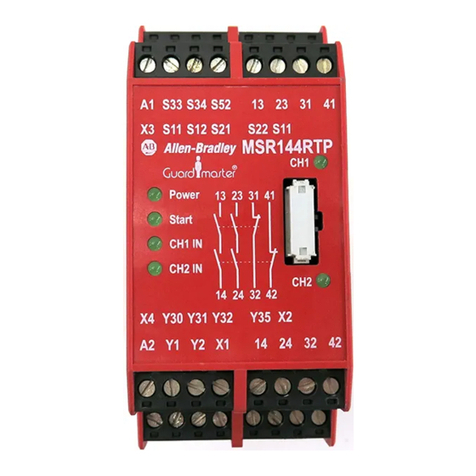

Back EMF Monitoring Relay Module

Connect Power Supply

Power for the MSR55P standstill module safety relay depends on the

model. The primary power supply is connected to terminals A1 and A2.

An auxiliary (12…30V DC only) supply voltage can be connected to

terminals A3/A4 to provide semiconductor diagnostics.

Depending on the model, the primary supply can be 24V DC, 115V

AC, or 230V AC. When an AC supply is used, both 50 Hz and 60 Hz

are acceptable.

When powering with 24V DC in the European Union, the DC supply

must have a Protective Extra-Low Voltage (PELV) rating. When

powering with 24V DC in the United States, the DC supply must have

both a PELV rating as well as an NEC Class 2 rating. Many of our

Bulletin 1606 power supplies are PELV and Class 2 compliant.

Power to A1/A2 is required to operate the MSR55P standstill module

safety relay. Power to A3/A4 is only necessary if the solid-state auxiliary

status signals (ON and ERR) are used.

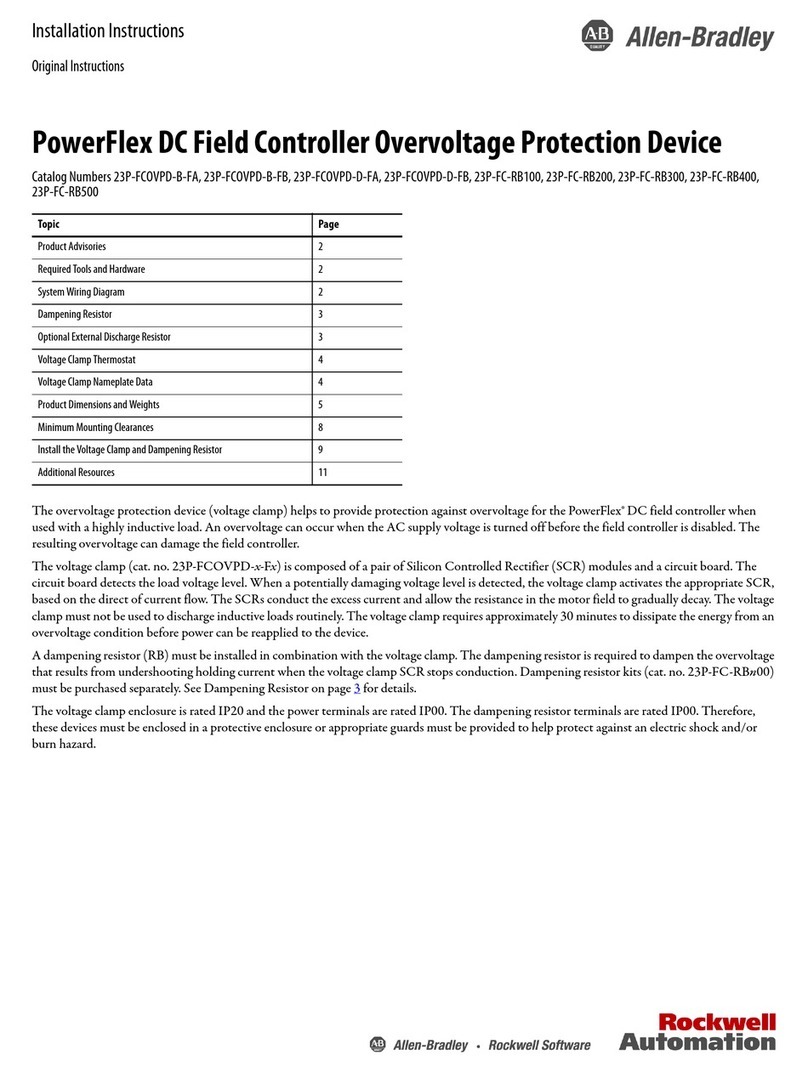

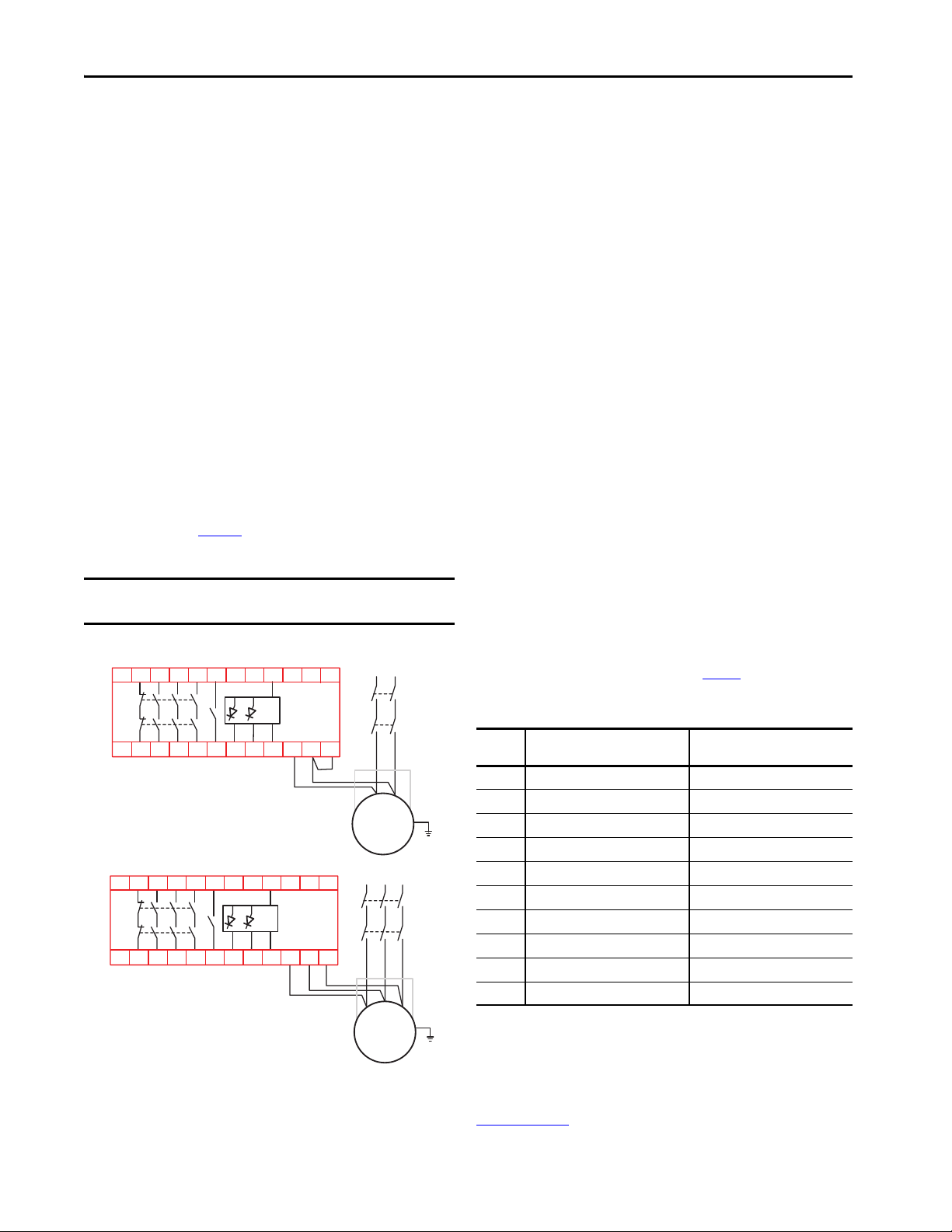

Motor Winding Inputs

The motor windings are connected to terminals L1, L2, and L3. The

connections must be made directly at the motor with no electrical

devices (like transformers and contactors) between the motor and the

MSR55P safety relay. Figure 3 shows wiring for a single-phase, DC, and

a three-phase motor.

Figure 2 - Motor Connections

Surge Suppressors

Because of the potentially high current surges that occur when switching

inductive load devices, such as motor starters and solenoids, the use of

surge suppression is required. Adding a suppression device prolongs the

life of the relay outputs and reduces the effects of voltage transients and

electrical noise from radiating into adjacent systems.

Since this is a safety-related system, the surge suppression device must

connected across the load device. The surge suppression device must not

be connected across the MSR55P safety relay contacts.

For outputs that use 24V DC, we recommend 1N4001 (50V reverse

voltage) to 1N4007 (1000V reverse voltage) diodes for surge

suppression. The diode must be connected as close as possible to the

load coil.

For outputs that use 120V AC or 240V AC, we recommend metal oxide

varistors.

Configuration

The configuration of MSR55P safety relays is accomplished by

adjusting the two switches on the front face. Each switch control knob

rotates two potentiometers. The recommended practice is to set the

switches to the minimum setting initially, and then adjust them as

necessary to reduce nuisance tripping while maintaining a safe

application.

V

m

- Monitoring Voltage

The trip voltage of the back EMF is adjusted by the 10-position Vm

potentiometer. When the back EMF drops below the voltage level, the

MSR55P standstill module safety relay begins the delay timer. After the

timer expires, the outputs are de-energized. Table 2 shows the settings of

each of the catalog numbers.

Table 2 - Vm- Monitoring Voltage Settings

t

s

- Time Delay

When the back EMF of the motor drops below the Vm voltage setting,

the standstill delay timer starts. The delay time is set by the 10-position

ts potentiometer. During the timing cycle, the OUT indicator flashes.

Table 3 on pa g e 4 shows the delay time for each setting. After the delay

expires, the outputs are energized.

IMPORTANT The three connections create two safety monitor channels. L1

is common to the two channels, which are L2 and L3.

L1 L2 L3

M

K1

K2

A2

X1 X2

1L2L3L

X3

34 44

A1 A3113233

2142ON

ERR A454

43 53

L1 N

M

K1

K2

A2

X1 X2

1L2L3L

X3

34 44

A1 A3113233

2142ON

ERR A454

43 53

Single-phase and DC Motor

Three-phase

Position 440R-S35014, 440R-S35015,

440R-S35016 [Volts]

440R-S35011, 440R-S35012,

440R-S35013 [x10mV]

10.2 2

20.3 3

30.4 4

40.5 5

50.7 7

61.0 10

71.5 15

82 20

93 30

10 4 40