SEB RGDAT-A70 User manual

and

Ve

Use

Direct

and volt

(R

Version for Outdoor I

User manual

Project

irectional

and voltage

detect

(RGDAT-A

tdoor Installation

Project

ional fault

ge absence

detector

AT-A70)

ault

bsence

70)

P515D851

E

November 2019

Revision

M. Ferreri

G. Bonomo

Rev.

Date

Description

Draft

Checked

P515D851 Rev. E November 2019 Pag. 1 of 45

The informations in this document are propriety of Col – Divisione Seb.

No part of this document can be copied, reproduced or disclosed to third parties

without written authorization of Col – Divisione Seb.

©Col - Divisione Seb - 2017 - 2019

Updates and/or revisions

REV.

CHAP.

PAG.

Description

DATE

A

First issue

January 2017

B

Various

Various

Update related to the firmware 2.01 and

software 2.03

September 2017

C

Addendum B

43 and 44

Update related to the firmware 2.02 and

software 2.04

June 2018

D

Various

Various

Update reference documents

Add chapter for coupling between RGDAT

and sensors

Update related to software 2.05

December 2018

E

Various

Various

Update related to the firmware 2.10 and

software 2.10

November 2019

Index

PURPOSE OF THE DOCUMENT 4

REFERENCE DOCUMENTS 4

INFORMATION AND PRECAUTIONS 4

SUMMARY 5

Combined sensors 6

Combine RGDAT-A70 with sensors 6

FUNCTIONS 8

Phase overcurrent protection (51) 8

Earth fault overcurrent protection (51N) 8

Directional earth fault protection (67N) 8

Voltage presence function (59) 10

Residual overvoltage protection (59Vo) 10

Negative sequence overvoltage protection (59Vi) 11

Positive sequence undervoltage protection (27Vd) 11

Voltage sensors supervisor function (VSS) 11

Current converter 11

Features required by Endesa 12

TECHNICAL CHARACTERISTICS 13

Auxiliary power supply 13

Combined sensors 13

Digital input 13

P515D851 Rev. E November 2019 Pag. 2 of 45

Output relays 13

Current converter 13

RS232 serial communication 13

Environmental conditions 13

Mechanical characteristics 13

Terminal blocks 15

Terminal block MA 15

Terminal block MB 15

Connector to remote control system 16

Connection with combined sensors 17

PROGRAMMING SOFTWARE (RGDAT_A70) 19

Software installation 19

Software removal 19

Main window 19

“File” Menu 20

“Communication” Menu 21

“Read data” Submenu 21

“Send data” Submenu 24

“Setup data” Menu 25

“Procedures” Menu 30

“Preferences” Menu 35

“About” Menu 36

INSTALLATION 37

Mechanical assembly 37

Device RGDAT-A70 37

Combined sensors 37

Setting 37

COMMISSIONING 38

Voltage inputs calibration procedure 38

TROUBLESHOOTING 39

Self diagnostic function 39

ADDENDUM A 41

ADDENDUM B 44

Changes to firmware RGDAT-A70 44

Release 2.00 44

Release 2.01 44

Release 2.02 44

Release 2.10 44

Changes to software RGDAT-A70 44

Release 2.00 44

Release 2.01 44

Release 2.02 45

Release 2.03 45

Release 2.04 45

Release 2.05 45

Release 2.10 45

P515D851 Rev. E November 2019 Pag. 3 of 45

PURPOSE OF THE DOCUMENT

This document describes how to use and set up the device RGDAT-A70 (directional fault and voltage

absence detector) compliant with technical specification GSTP001 by ENEL.

This document is referred to the model installed on pole where are installed driven switch or recloser

(RGDAT-A70 /O, ENEL serial number 160004).

REFERENCE DOCUMENTS

• ENEL - GSTP001 - rev. 03 - December 11th 2017

• Col - Div. Seb - P515D404 Communication protocol - Rev. A - September 2016

• Col - 188 MN 0001_EN - Combi-Col-24-O Installation and instruction manual - Rev. 0 - December

2018

• Altea - CVS-P-24-O Technical specifications - Rev. 0 - October 23rd 2015

• Altea - CVS-P-24-O Installation Manual - Rev. 1 - October 23rd 2015

INFORMATION AND PRECAUTIONS

Before using the device RGDAT-A70, please read carefully the following instructions.

Avoid starting the installation, maintenance or setup of the equipment without consulting this manual.

The device RGDAT-A70 has to be used by staff specially trained for the purpose.

For proper operation of the device, you must follow these guidelines:

• The RGDAT-A70 device is intended for use by qualified personnel with knowledge of the physical

phenomena and the risks related to electricity. Training and education of the personnel expert in

the use of the device is competence of the buying company of the product itself.

• The device should be used only when it appears in good condition, ie there are no signs of

damage. Its use must be made in accordance with the security rules of the specific workplace and

application.

• The security conditions and criteria are guaranteed under the conditions of use described in this

manual. Improper use of the device or the included accessories may cause damage to people, to

the device or to the equipment connected to it. The manufacturer and distributors are not liable for

any damage caused by improper use of the device. The user assumes all responsibility and risk.

• This user manual must always be available at the place where the device RGDAT-A70 is installed.

• Before using the device RGDAT-A70, the staff assigned to RGDAT-A70 must read this user

manual. This also applies to all persons who also occasionally works with the device RGDAT-A70.

• Any breaking or modification to the case, or any part of the equipment, could impair the proper

functioning of the device.

• Do not use the device RGDAT-A70 in extremely humid environments and/or if there is risk of

condensation inside the device. To avoid the risk of electric shock, do not plunge the equipment or

the supplied accessories in the water or other liquids.

• Do not use the device RGDAT-A70 in the presence of open flames.

• Do not use the device RGDAT-A70 in environments where there are flammable gases or vapors.

• Avoid moving the equipment when it is in use, in order to avoid accidental detach of the cables that

may create a dangerous situation for the user.

• For your safety, avoid using non-compliant cables, damaged or worn.

P515D851 Rev. E November 2019 Pag. 4 of 45

• Before powering up the device, make sure that the protective earth is properly connected. The

ground connection must be made using the appropriate bolt on the right side of the metal

container. The failure to connect the protective earth may cause a safety hazard.

SUMMARY

The fault detector RGDAT-A70 for outdoor installation is made according to technical specification

GSTP001 by ENEL; it is installed on pole where are installed driven switch or recloser in order to

provide local and remote signaling of short circuit faults and ground faults that may occur in medium

voltage distribution network, as well as to signal the absence of line voltage. This information can help

to locate the section of the network affected by fault.

The voltage and current measurements are obtained by 3 combined sensors (one for each phase).

The voltage measurements are used for directional earth fault function and to detect the presence/

absence of line voltage; values of phase voltage V4, V8 and V12 are processed in order to eliminate

measurement errors caused by combined sensors using the voltage inputs calibration function.

The device RGDAT-A70 uses current measurement to detect phase faults producing a current greater

than a threshold value and ground faults both in isolated neutral networks and in compensated neutral

networks.

The device RGDAT-A70 implements the following protection / functions:

51

phase overcurrent

51N

earth fault overcurrent

67N

directional earth fault

59

voltage presence function

27Vd

positive sequence undervoltage

59Vi

negative sequence overvoltage

59Vo

residual overvoltage

VSS

voltage sensors supervision function

There are 3 relay outputs, which generally have the following functions:

relay TS51A

signals the intervention of short-circuit function for phase faults

(polyphase or double single-phase to ground)

relay TS67AV

signals the intervention of directional earth fault function for line side

faults (with reverse direction disabled)

relay TSPresV

managed by voltage presence function

It is also available a different operating mode, called Voltage Monitoring Mode, alternative to the

above indicated functions, in which all protective functions are disabled and only the voltage presence

function is active, but it is managed in a different way (please make reference to document GSTP001

by ENEL).

P515D851 Rev. E November 2019 Pag. 5 of 45

The device RGDAT-A70 has a current converter with output 4÷20 mA for sending the measurement of

phase current to a remote control unit. The current converter is galvanically insulated from the other

electronic circuits and from the auxiliary power of RGDAT-A70.

On the front of the device there are the following light signals:

three green LEDs

signaling the presence of phase voltages V4, V8 and V12

one white LED

signaling inversion of surveillance direction of the directional earth

fault protection

one orange LED

signaling trip of phase overcurrent protection (51) or earth fault

overcurrent protection (51N), memorized

one red LED

signaling trip of directional earth fault protection (67N), memorized

one red LED

(blinking)

signaling intervention of self-diagnostic function

Using a specific digital input it is possible to enable the inversion of surveillance direction of directional

earth fault protection.

The connection between RGDAT-A70 and remote control unit is made with components and

dimensions indicated in ENEL specification GSTP001. There is a multicore cable from the cable gland

placed on top of the metal container; its wires are connected to terminal block MB, according to

connection diagram shown in this manual.

On the electronic board of RGDAT-A70 there is a 9-pin D-Sub RS232 serial connector, which is used

for device configuration and for commissioning procedures.

A specific software, running under Microsoft Windows®(Windows XP and later), allows you to do

configuration, monitoring, checking and update the firmware of the device RGDAT-A70.

These operations are described in detail in the following chapters of this document.

Combined sensors

The combined sensors integrate the following functions into a single device:

• post insulator

• voltage transducer

• current transducer

It is used one combined sensor for each phase.

For more detailed information on such devices, please refer to the document “CVS-P-24-O Technical

specifications” by Altea.

Combine RGDAT-A70 with sensors

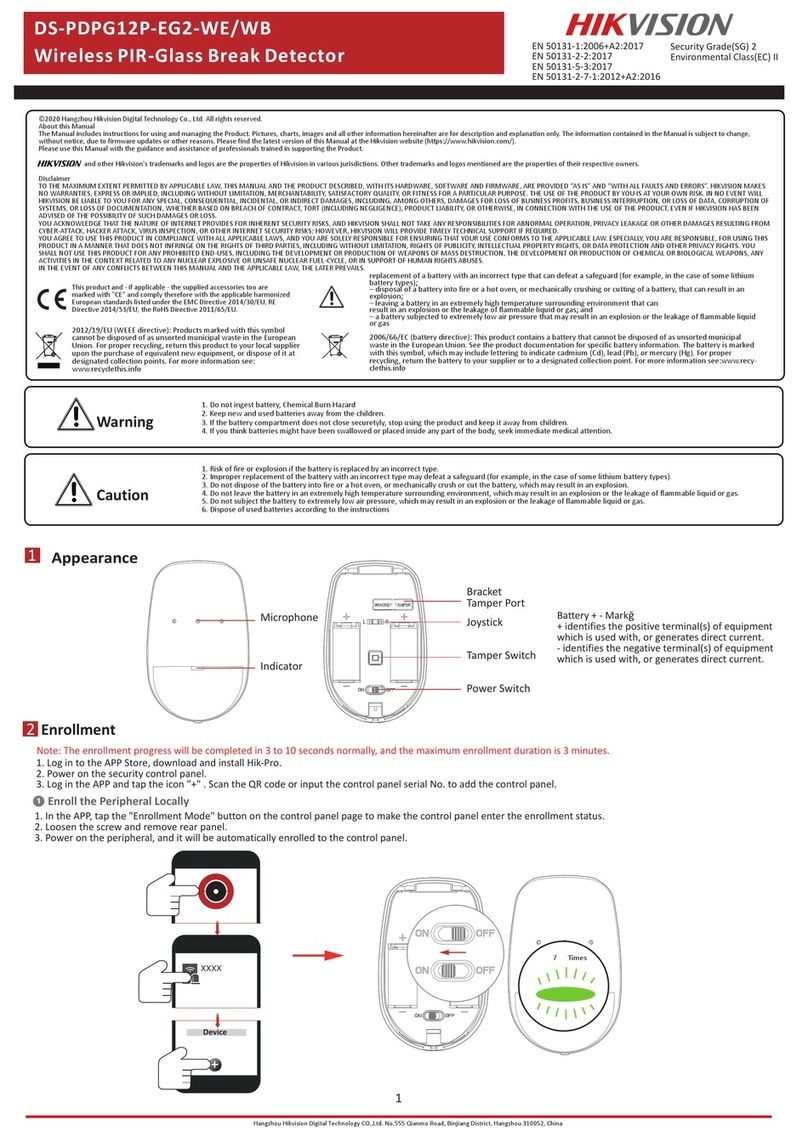

To ensure the correct operation between RGDAT-A70 and combined sensors, you must use the type

of combined sensors with which the device was originally supplied.

On the front of the RGDAT-A70 and on the electronic board adhesive labels are applied, indicating

which type of combined sensors can be used with the specific RGDAT-A70, as shown in the following

table.

P515D851 Rev. E November 2019 Pag. 6 of 45

RGDAT front panel

RGDAT electronic board

Sensors

CVS-P-24-O

Sensors

COMBICOL-24-O

P515D851 Rev. E November 2019 Pag. 7 of 45

FUNCTIONS

Phase overcurrent protection (51)

To ensure protection against polyphase failures, the device RGDAT-A70 has a phase overcurrent

protection, in tripolar configuration, with a single threshold. The device acquires the measurement of

phase currents by combined sensors and provides a fault signal when the current of one or more

phases exceeds the threshold value.

The threshold value of phase overcurrent protection is programmable from 20 A to 900 A, in steps of

10 A. The threshold has a trip delay, whose value can be set from 0.05 to 5 s, in steps of 0.01 s.

Signaling protection intervention is provided by relay TS51A, whose contacts are connected to

terminal block MB and acquired by remote control system. An orange LED on the front of device turns

on when a trip occurs.

Earth fault overcurrent protection (51N)

To ensure protection against double phase to ground failures, the device RGDAT-A70 has an earth

fault overcurrent protection, with a single threshold. The device calculates the earth current using the

measurements of the phase currents and provides a fault signal when the earth current exceeds the

threshold value.

The threshold value of earth fault overcurrent protection is programmable from 10 A to 200 A, in steps

of 2 A. The threshold has a trip delay, whose value can be set from 0.05 to 5 s, in steps of 0.01 s.

Signaling protection intervention is provided by relay TS51A, whose contacts are connected to

terminal block MB and acquired by remote control system. An orange LED on the front of the device

turns on when a trip occurs.

Directional earth fault protection (67N)

To ensure protection against earth faults, both in isolated neutral networks and in compensated

neutral networks, the device has a directional earth fault protection, with two thresholds (67NS1 and

67NS2); each threshold can be enabled independently from the other. The two thresholds have a

different set of angular sector of intervention (60÷255° for 67NS1, 60÷120° for 67NS2).

Through the use of an external signal coming from the remote control system, it is possible to control

the surveillance direction of the protection when power is supplied from the opposite side of the

network (surveillance direction at busbar side of Secondary Substation). In this operation mode, the

angular sector of intervention of the thresholds are: 240÷75° for 67NS1, 240÷300° for 67NS2.

The following figure illustrates, for example, the angular sector of intervention of threshold 67NS1 in

the two different operating modes.

P515D851 Rev. E November 2019 Pag. 8 of 45

With a proper setting in the setup program you can modify the angular sector of intervention for the

threshold 67NS1 to 60÷245° (default direction) and 240÷65° (inverted direction).

The device calculates the earth current using the measurements of the phase currents, calculates the

homopolar voltage using the measurement of the phase voltages and computes the phase angle

between the homopolar voltage and the earth current.

The directional earth fault protection requires the setting of the following parameters:

• residual voltage threshold (Threshold 67 Vo) adjustable range 1÷40% En, in step of 1%

• earth fault current threshold (Threshold 67 Io) adjustable range 1÷40 A, in step of 0.5 A

The directional protection detects an earth fault if all the following conditions occur simultaneously:

• residual voltage greater than the threshold 67Vo

• earth fault current greater than the threshold 67Io

• the phase angle between the residual voltage and the earth fault current is inside of angular sector

of intervention of the threshold (phase angle Io compared with Vo in lag clockwise and with reverse

signal absent)

This threshold has a trip delay, whose value can be set from 0.11 to 5 s, in steps of 0.01 s.

Signaling intervention of threshold 67NS1 is provided by relay TS67AV; in case of intervention of

threshold 67NS2, the relays TS67AV and TS51A activate simultaneously. The contacts of relays are

connected to terminal block MB and acquired by remote control system. A red LED on the front of the

device turns on when a trip occurs.

With an appropriate configuration, you can use as reference the negative sequence voltage instead of

the zero sequence voltage. In this operation mode, the thresholds 67NS1 and 67NS2 described

above are disabled and a directional threshold is activated with the following configuration

parameters:

• negative voltage threshold, adjustable range 1÷40% En, in step of 1%

• earth fault current threshold, adjustable range 1÷200 A, in step of 0.5 A

The angular relationship between the negative sequence voltage (Vi) and the residual current that

determines the intervention of the threshold is shown in the following figure:

P515D851 Rev. E November 2019 Pag. 9 of 45

In fault recording event function, a trip of directional earth fault threshold with negative sequence

voltage as reference, is labelled as 67N.S1, and in detailed data you will see the angle between that

voltage and residual current.

Voltage presence function (59)

This function uses three phases voltages measurement, and provides the voltage presence signaling

when the value of at least one of the phase voltages is higher than 80% of the rated value of phase

voltage.

The voltage presence function has two thresholds values:

• voltage presence threshold, set at 80% of rated voltage (with accuracy of 4%)

• voltage absence threshold, set at 20% of rated voltage (with accuracy of 4%)

These thresholds are used to detect transitions between voltage presence/absence condition as

follows:

• starting from the condition of line voltage absence, the logical state Voltage Presence is

acknowledged if, for at least 250 ms, it is detected the condition:

(V4 > 80%Vn) OR (V8 > 80%Vn) OR (V12 > 80%Vn)

• starting from the condition of line voltage presence, that logical state is no more acknowledged if it

is detected the condition:

(V4 < 20%Vn) AND (V8 < 20%Vn) AND (V12 < 20%Vn) without delay.

Voltage Presence signaling is provided by relay TSPresV, whose contacts are connected to terminal

block MB and acquired by remote control system. Three green LEDs on the front of the device, one

for each phase voltage, turns on when the voltage presence condition is detected for that phase.

Residual overvoltage protection (59Vo)

This protection function can be enabled or disabled by the user (default is disabled).

The threshold value of residual overvoltage protection can be set from 1% to 40% of rated voltage, in

steps of 1%. This threshold has a time delay, whose value can be set from 0.05 to 60 s, in steps of

0.05 s.

By means of the programming software, signaling protection intervention of residual overvoltage

threshold is user configurable on TS67AV and/or TS51A relay, whose contacts are connected to the

terminal block MB and acquired by remote control system (default TS67AV).

P515D851 Rev. E November 2019 Pag. 10 of 45

Negative sequence overvoltage protection (59Vi)

This protection function can be enabled or disabled by the user (default is disabled).

The threshold value of negative sequence overvoltage protection can be set from 1% to 40% of rated

voltage, in steps of 1%. This threshold has a time delay, whose value can be set from 0.05 to 60 s, in

steps of 0.05 s.

By means of the programming software, signaling protection intervention of negative sequence

overvoltage threshold is user configurable on TS67AV and/or TS51A relay, whose contacts are

connected to the terminal block MB and acquired by remote control system (default TS51A).

Positive sequence undervoltage protection (27Vd)

This protection function can be enabled or disabled by the user (default is disabled).

The threshold value of positive sequence undervoltage protection can be set from 20% to 110% of

rated voltage, in steps of 1%. This threshold has a time delay, whose value can be set from 0.05 to 60

s, in steps of 0.05 s.

By means of the programming software, signaling protection intervention of positive sequence

undervoltage threshold is user configurable on TS67AV and/or TS51A relay, whose contacts are

connected to the terminal block MB and acquired by remote control system (default TS67AV).

Voltage sensors supervisor function (VSS)

This function can be enabled or disabled by the user (default is disabled).

This function uses the residual voltage measurement and has a threshold value that can be set from

1% to 40% of rated voltage, in steps of 1%. This threshold has a time delay, whose value can be set

from 0.05 to 600 s, in steps of 0.05 s.

Permanence of residual voltage above the programmed threshold for a time longer than the value set

for the delay time is used to detect a fault condition of the voltage transducers of combined sensors,

therefore the function 67N is disabled and relay TSPresV is placed in quiescent status (the three

green LEDs used by voltage presence function will emit a flashing warning). Protection functions 51

and 51N are not affected by this kind of anomaly.

Current converter

The device RGDAT-A70 provides to remote control system a 4÷20 mA current output, proportional to

the value of the current measured by current sensor connected to pin 2 of terminal block MA.

Using the configuration software, the user can program the full scale value of current output, from 100

A to 900 A, in steps of 10 A.

You can also set up the measurement output as unidirectional or bidirectional. The direction of the

measurement is determined by evaluating the angle between the positive sequence voltage and the

positive sequence current (direction "positive" for angle between ±90°).

In the case of unidirectional measurement, the entire current range (4÷20 mA) is used to set the full

scale.

In the case of bidirectional measurement, there is this division of the scale:

• 4÷12 mA for “negative” measurement

• 12÷20 mA for “positive” measurement

P515D851 Rev. E November 2019 Pag. 11 of 45

• the full scale parameter is divided equally between "positive" and "negative" (ie if imposed 500 A as

full scale parameter, the scale in bidirectional mode will be ± 250 A).

Features required by Endesa

With firmware and software version starting from 1.10, some features required by customer Endesa

were introduced to fit the operation of RGDAT-A70 with its needs.

In detail:

•the command of relay TS51A is issued only when, after tripping of thresholds 51, 51N, or 67N.S2,

the condition of "Voltage Absent" is detected within a certain time (TAtt, programmable, default 0.4

s, the timer starts when thresholds drop out).

•the command of relay TS67AV is issued only when, after tripping of thresholds 67N.S1 or 67N.S2,

the condition of "Voltage Absence" is detected within a certain time (TAtt, programmable, default 0.4

s, the timer starts when thresholds drop out).

•the return to quiescent status of relays TS51A and TS67AV occurs when "Voltage Presence"

condition is detected and that condition holds for a certain time (TDis, programmable, default 10 s).

•if there is no return of power within a certain time (TDurata, programmable, default 4 hours), relays

TS51A and TS67AV return to quiescent status anyway.

•LEDs 51 and 67 follow the state of respective relay.

•event logging also records the issuance of commands to relays TS51A and TS67AV, in addiction to

tripping of various thresholds.

This function is disabled in default configuration.

P515D851 Rev. E November 2019 Pag. 12 of 45

TECHNICAL CHARACTERISTICS

Auxiliary power supply

Rated value 24 VDC

Range of application 19 ÷ 29 VDC

Typical power consumption (at 24 VDC) 110 mA

Combined sensors

Rated transformation ratio (voltage) 25000 V / 1 V

Rated transformation ratio (current) 260 mV/kA (at 50 Hz)

Rated frequency 50 - 60 Hz

Connection to RGDAT shield cable with connector RJ45, length 8 m

Digital input

Type of circuit Optoinsulated

Rated voltage As auxiliary power supply

Supply power consumption typical 3 mA

Output relays

Type of contacts Normally open

Rated voltage 250 V

Rated current 5 A

Breaking capability (24 VDC, L/R = 40 ms) 0.2 A

Current converter

Measurement range 0 ÷ 900 A (programmable)

Operating mode Unidirectional / bidirectional (programmable)

Output current 4÷20 mA

Precision 10 %

Maximum output load 700 Ω

Response time < 300 ms

RS232 serial communication

Type of connector D-sub, 9 pin, female

Settings 9600 baud, 8 data bit, no parity, 1 stop bit

Protocol Custom (see document P515D403)

Environmental conditions

Operating temperature -10 ÷ +70 °C

Relative humidity ≤93% (without condensing)

Storage temperature -25 ÷ +70 °C

Mechanical characteristics

The RGDAT-A70 is housed in a metallic case, whose dimensions are shown in the following figure.

P515D851 Rev. E November 2019 Pag. 13 of 45

The device is supplied with 4 screws and 4 M5 stainless steel washers for fixing.

On the right side of the box there is a M10 ground terminal.

On the front cover of device, starting from the top, there are:

• three GREEN LEDs, to signal the voltage presence of three phases of MV network

• a WHITE LED, to signal the inversion of surveillance direction of directional earth fault protection

• an ORANGE LED, to locally signal the intervention for polyphase fault or double single-phase

ground fault

• a RED LED, to locally signal the intervention for line side single-phase fault

• a RED LED, blinking, to signal a device failure

On the top side of case there is a cable gland for the connection cable with remote control unit.

P515D851 Rev. E November 2019 Pag. 14 of 45

On the lower side of case there are the outputs (with cable gland) for connections with combined

sensors.

Terminal blocks

Terminal block MA

It is the terminal block on which you connect the voltage signals and current signals by combined

sensors.

Pin number

Signal name

Notes

1

COM_I

Current sensors common connection (connected

to ground)

2

I_4

Current signal I4

3

I_8

Current signal I8

4

I_12

Current signal I12

5

V_4

Voltage signal V4

6

V_8

Voltage signal V8

7

V_12

Voltage signal V12

8

COM_V

Voltage sensors common connection (connected

to ground)

Terminal block MB

It is the terminal block used by the connection cable to the remote control system. There are the

power supply inputs, the outputs relay signals, the 4-20 mA current outputs and the inputs to reverse

surveillance direction of directional earth fault protection.

Pin number

Signal name

Notes

1

+VALIM

Power supply input (+24V)

2

TS51A

TS51A relay output

3

TSPRESV

TSPresV relay output

4

OUT_4-20+

4÷20 mA current output (+)

5

TS67AV

TS67AV relay output

6

not used (not connected)

7

OUT_4-20-

4÷20 mA current output (-)

8

INV_IN

Reverse signal digital input

P515D851 Rev. E November 2019 Pag. 15 of 45

Pin number

Signal name

Notes

9

+VALIM

Reverse signal digital input (common)

10

-VALIM

Power supply input (GND 24V)

The following figure shows the layout of the electronic board, with indication of where terminal blocks

MA and MB are placed, and relative pin numbering.

Connector to remote control system

The following figure shows the design of the connector to the remote control system.

P515D851 Rev. E November 2019 Pag. 16 of 45

Signals are placed on the connector to the remote control system according to the following table:

Pin number

Signal name

Notes

1

+VALIM

Power supply input (+24V) and remote signals

reference

2

TS51A

TS51A relay output

3

TSPRESV

TSPresV relay output

4

OUT_4-20+

4÷20 mA current output (+)

5

TS67AV

TS67AV relay output

6

OUT_4-20-

4÷20 mA current output (-)

7

+VALIM

Reverse signal digital input (common)

8

INV_IN

Reverse signal digital input

9

-VALIM

Power supply input (GND 24V)

Connection with combined sensors

To facilitate the connection between the cables of the combined sensors and the RGDAT-A70, this

one is supplied with a proper adapter; one side of the adapter is connected to the terminal block MA

and the other side has 3 connectors RJ45 to plug the cables of the combined sensors.

The adapter is factory connected to terminal block MA.

Each RJ45 connector has a label to indicate the related phase.

The following image refers to the above indicated arguments.

P515D851 Rev. E November 2019 Pag. 17 of 45

P515D851 Rev. E November 2019 Pag. 18 of 45

PROGRAMMING SOFTWARE (RGDAT_A70)

To perform a series of activities with RGDAT-A70 such as parameterization, diagnostics, monitoring,

etc. it is available a dedicated software, whose name is RGDAT_A70; to ensure proper operation with

RGDAT-A70 conform to ENEL specification GSTP001, it is required that this software is in version

2.00 (or later). You can use the software also with RGDAT-A70 of the previous generation1.

This software runs fine on PC with Microsoft Windows®operating system (Windows Xp or newer,

updated with the latest Service Pack available).

The software is multi-language (at the time of preparation of this document supported languages are:

Italian, English, Spanish) and it has a graphical user interface, for easy use.

Communication between PC and RGDAT-A70 is made with an RS232

port, so it is necessary that the PC is equipped with this kind of port (if a

physical serial port is not present on the PC, you can use an USB-RS232

converter).

To connect PC and RGDAT-A70 you must use a "straight" serial cable,

such as the one shown in the figure.

If you use an USB-RS232 converter with male connector, you can connect

it directly to RGDAT-A70 without interposing any further extension cable.

To gain access to the serial connector placed on the electronic board of RGDAT-A70, it is necessary

to open the cover of the equipment, acting on the prominence in the right side of the cover.

This document refers to the English version of the various parts of user interface.

Software installation

There is a setup wizard, which is activated by running "Setup.exe".

There is an alternate way to start the wizard, running the file “Setup_RgDatA70.msi”.

During the setup wizard the user must specify the installation folder of the software.

At the end of installation an icon is created on the “desktop” of the computer; that icon can be used to

run the software.

Note: If an old version of the software is installed on the PC, you must remove it before installing

the new one.

Software removal

You can remove the software using the standard procedures of the operating system.

Please refer to operating system documentation.

Main window

This window allows you to select the various activities you can perform.

There are various menus, each one of them gives access to a specific functionality, the toolbar, to

facilitate some operations, and the status bar, to display specific operating conditions.

P515D851 Rev. E November 2019 Pag. 19 of 45

1In this document are shown the dialog boxes related to setting parameters for RGDAT-A70 conform to ENEL

specification GSTP001. In case of use of the software with RGDAT-A70 of the previous generation (conform to

ENEL DY1059-A70) some dialog boxes are different.

“File” Menu

It has five entries; four of them are used for storing data on file and the last one to quit the program.

The entries have the following behavior:

• the item “New” loads default data in the program database

•the item “Open” opens a standard dialog box to select the file for reading configuration data

previously saved

• the item “Save” stores configuration data in a file

•the item “Save as” enables saving configuration data to a different file from the one in use (it

shows a standard dialog box to select the name of the new file to store data2).

P515D851 Rev. E November 2019 Pag. 20 of 45

2The example shows a Windows 7 dialog box; with other operating systems the dialog box could be different.

Table of contents

Popular Security Sensor manuals by other brands

Abus

Abus FUBW50110 Installation instructions and user manual

C.P. Electronics

C.P. Electronics MWS3A-PRM-2CH installation guide

HIK VISION

HIK VISION DS-TDSB00-EKT/POE/4M user manual

Paradox

Paradox Digigard DG85 installation guide

seeed studio

seeed studio RG-9 quick start guide

Abus

Abus PLBW10000 quick guide

C.P. Electronics

C.P. Electronics EBDHS-DNET1 installation guide

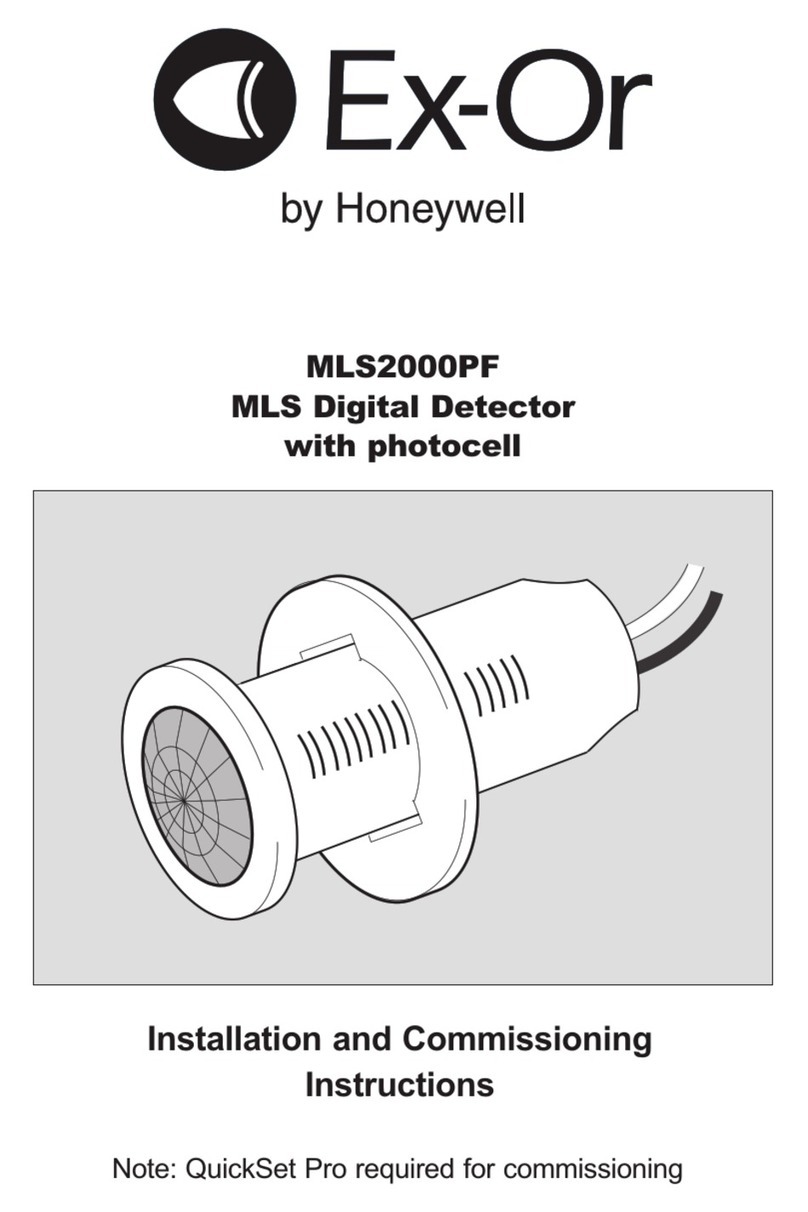

Exor

Exor MLS2000PF Installation and commissioning instructions

Tinker & Rasor

Tinker & Rasor APS manual

Rf-t

Rf-t Safe Place Mother Transmitter user guide

TECHNO-AC

TECHNO-AC SUCCESS CBI-436N Technical description and operating instructions

Alarmcom

Alarmcom ADC-S40-DC installation guide