ENFORCER SLI 820R/-4 Tech Manual

SECO-LARM U.S.A., Inc.

Page 8

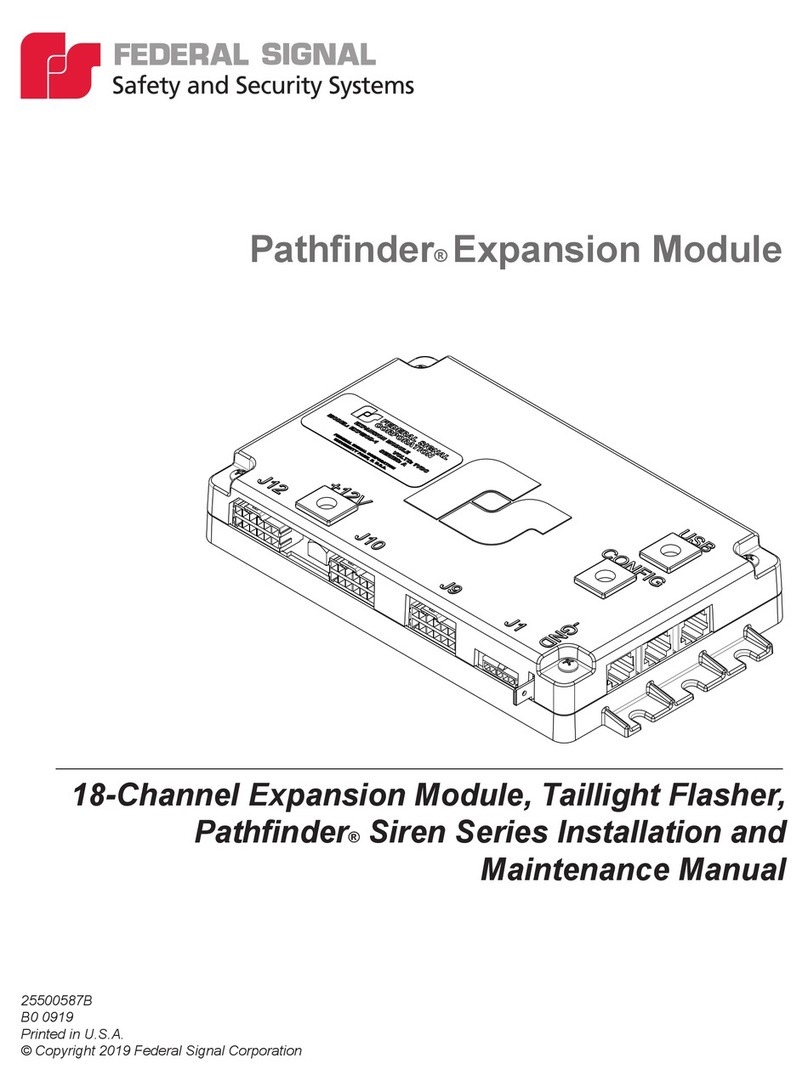

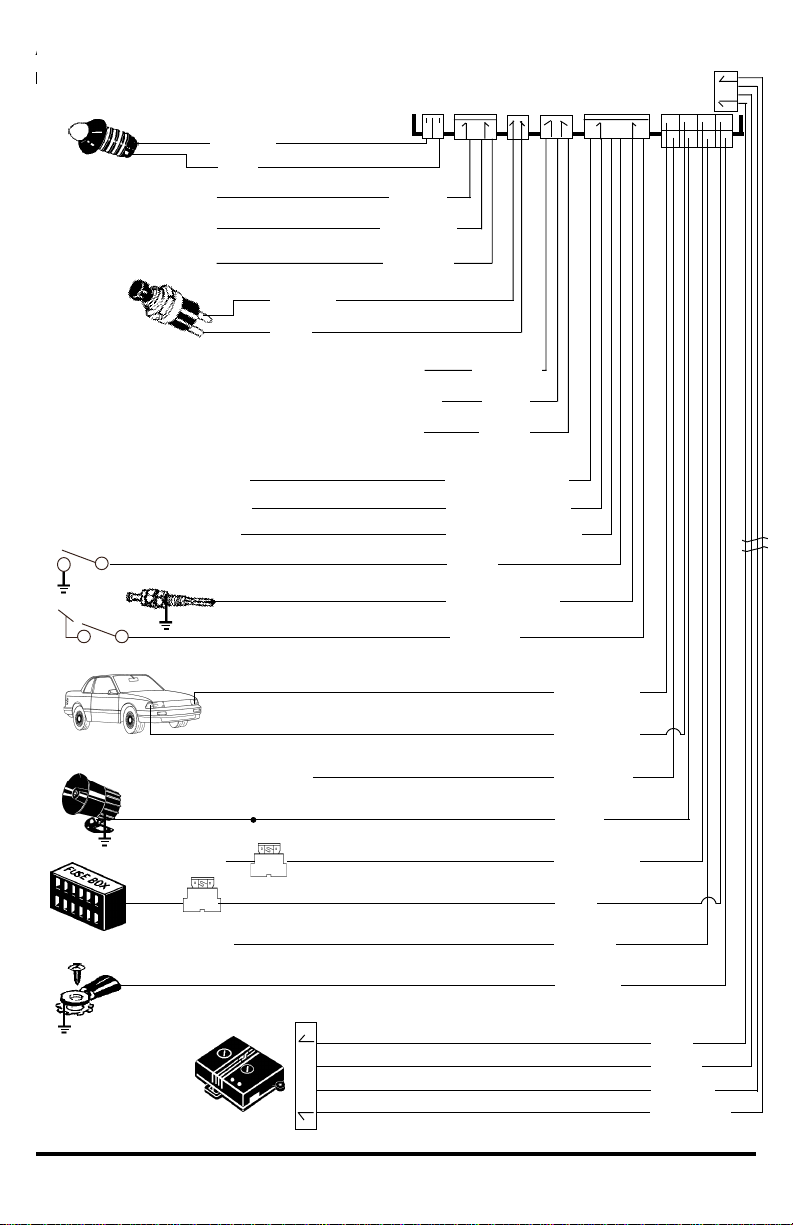

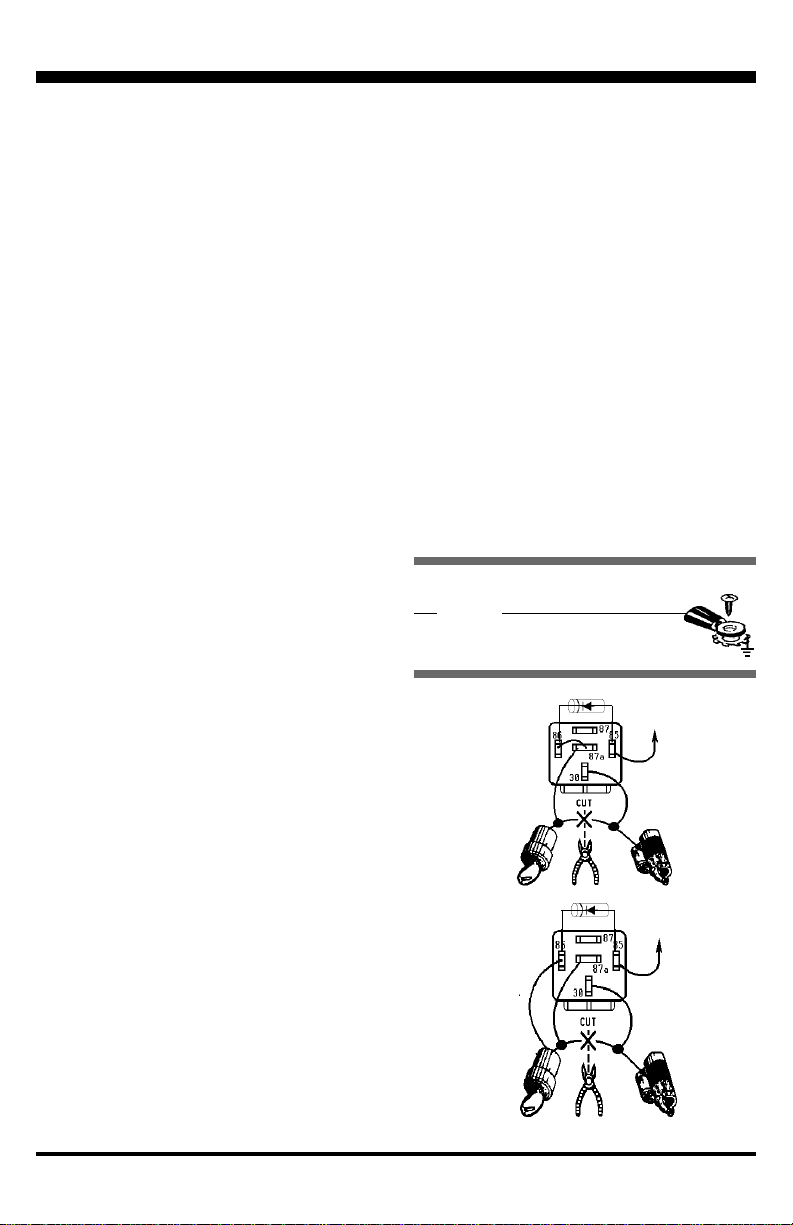

Siren BLACK wire (ground)

Siren RED wire

(siren +12V input)

Alarm PINK wire

(Siren +12V output,

2A max.)

Ø

Fig. 4 Connecting to the siren

B. Connect the sirens BLACK WI E directly to

the vehicles metal chassis. Scrape paint

from the metal surface, and use a factory

grounding bolt or a star washer.

C. Connect the alarms PINK WI E directly to

the sirens ED WI E.

Connector 2 (8-pin connector)

YELLOW WIRE (to ignition switch

oltage input)

Connect to a fuse or wire which outputs

+12VDC when the ignition key is in the ON and

STA T position, but not the ACC position. This

wire must be connected at all times to ensure

proper arming and disarming, as well as to

operate the VEPLe push-button switch.

Connector 3 (6-pin connector)

BLUE WIRE (neg. door trigger input),

fig. 5

A. Existing car door switches Use a VOM

meter to locate a wire (usually in the drivers

kick panel) which shows ground when any

door is open, and which is not ground when

all the doors are closed. Connect to the

BLUE WI E. (NOTE If this wire shows

+12VDC when a door is opened, see

PU PLE WI E below.)

B. If the vehicle (such as a delivery van) has no

existing car door switches Mount a pin

switch in every door you wish to protect.

Connect each switch to the BLUE WI E.

Connector 3 (6-pin connector)

PURPLE WIRE (pos. door trigger input),

fig. 6

Use a VOM meter to locate a wire (usually in the

drivers kick panel) which shows +12VDC when

any vehicle door is open, and which is not

+12VDC when all the doors are closed.

Connect to the PU PLE WI E.

Connector 3 (6-pin connector)

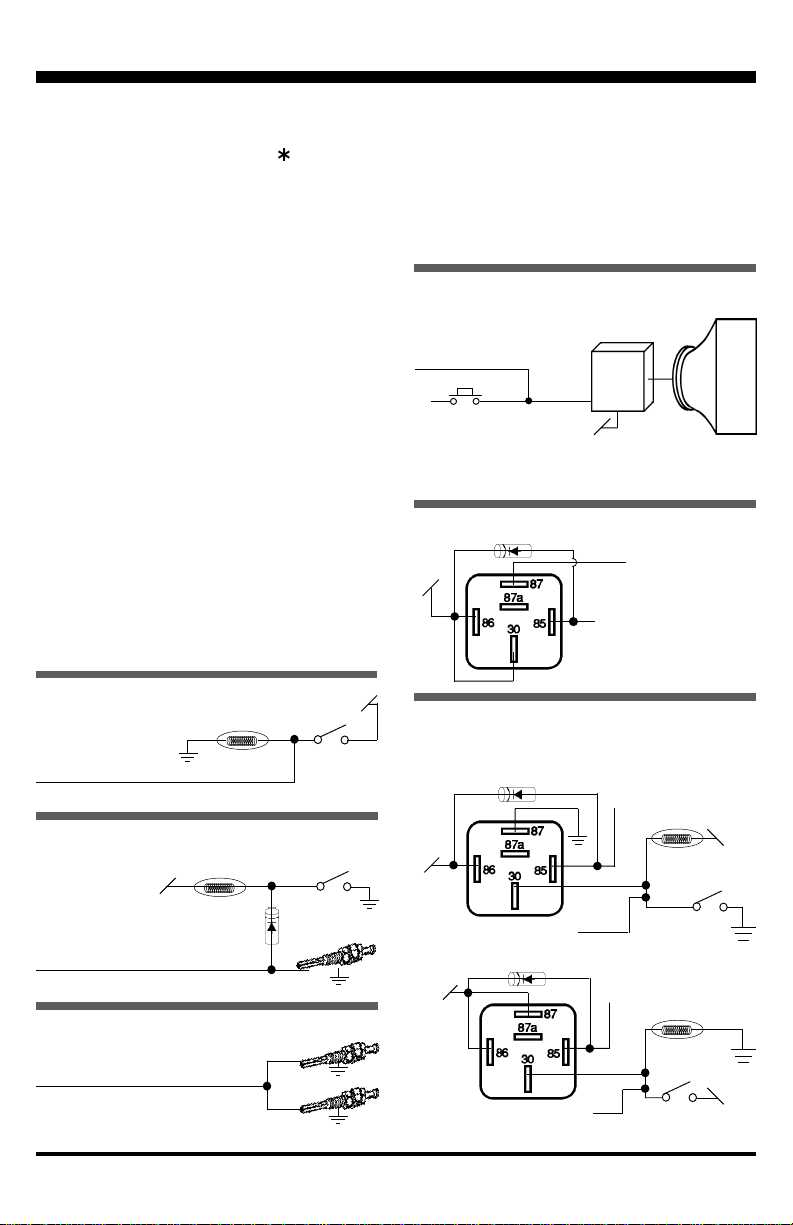

BLUE/WHITE WIRE (negati e hood/

trunk trigger input), figs. 7 & 8

A. If the vehicle has a trunk switch, but no hood

switch Use a VOM meter to locate the wire

which shows ground when the trunk is open,

and which is not ground when the trunk is

closed. Mount a pin switch in the hood.

Connect both to the BLUE/WHITE WI E as

shown in fig. 7.

B. If the vehicle has no existing hood or trunk

switches Mount a pin switch in both the

hood and the trunk. Connect both switches

to the BLUE/WHITE WI E as shown in fig. 8.

Connector 3 (6-pin connector)

BROWN/WHITE WIRE ( (-) factory

honking horn output), fig. 9

Programmable - Supplies a pulsing 200mA

output to drive a (-) factory car horn relay.

A. Operation - When the alarm is triggered, this

wire pulses 200mA to activate the (-) factory

horn honk relay found in most vehicles. This

allows the alarm to honk the horns and blast

the siren at the same time.

B. Connection - Connect the B OWN/WHITE

WI E directly to the negative input of the

vehicles factory horn relay (it should show

() when the vehicles horn button is

pressed). Make sure this input draws less

than 200mA of current. Otherwise, add a

30A relay to honk the horns.

Connector 3 (6-pin connector)

BLACK/WHITE WIRE (2nd ch. output),

fig. 10

Note -- 2nd channel output works only if the

optional ENFO CE remotes are used.

Domelig t

+12VDC

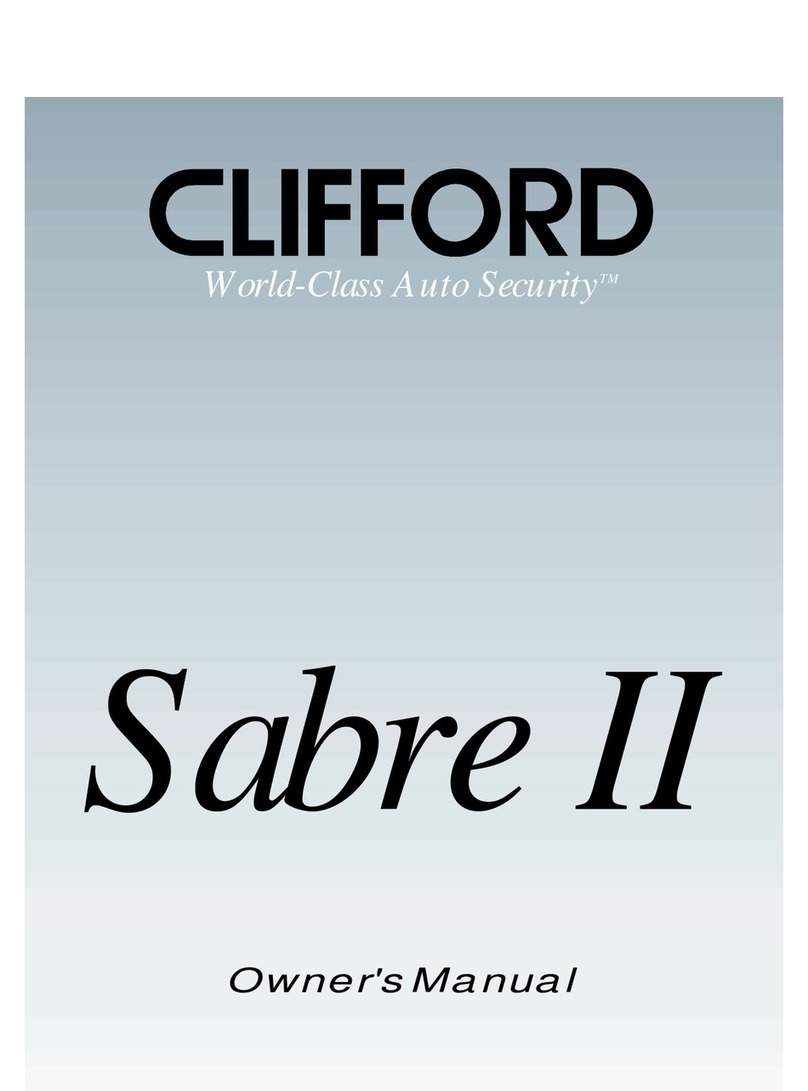

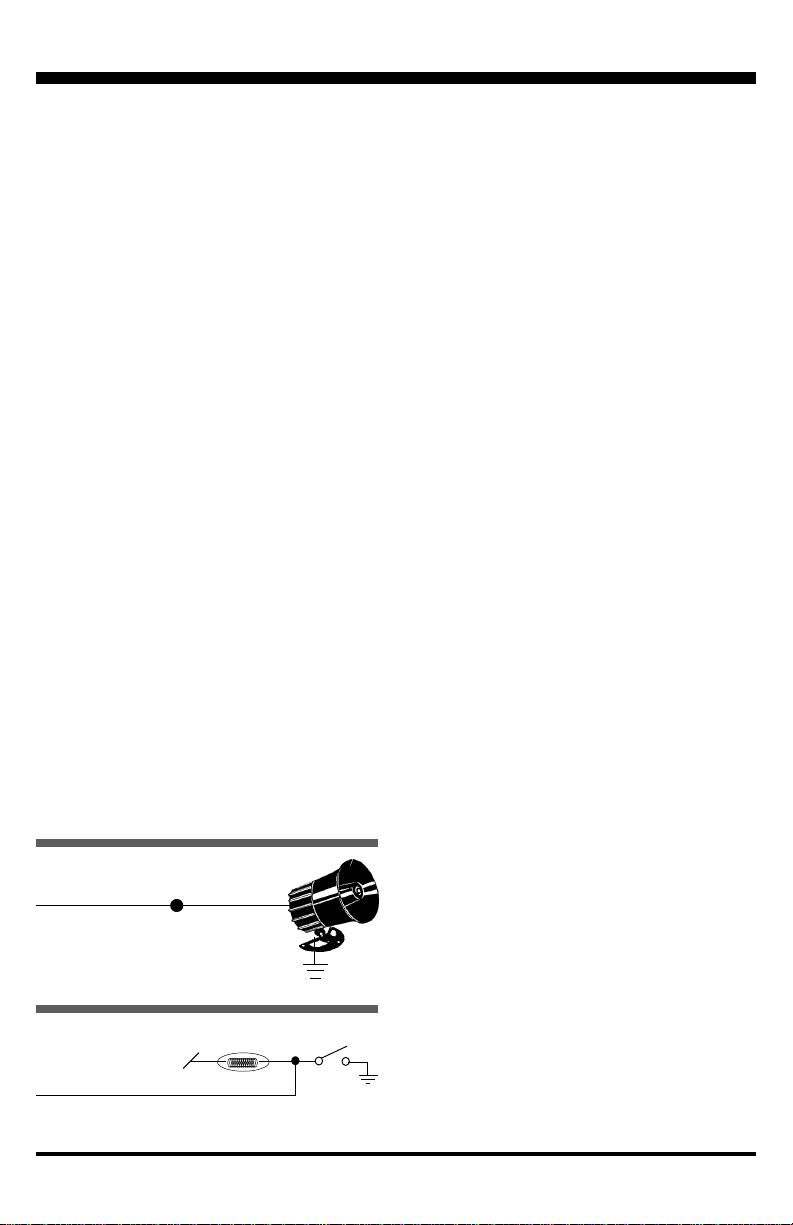

×Alarm BLUE wire (neg. door trigger input)

Door

switc

Fig. 5 Connecting to negative door

triggers