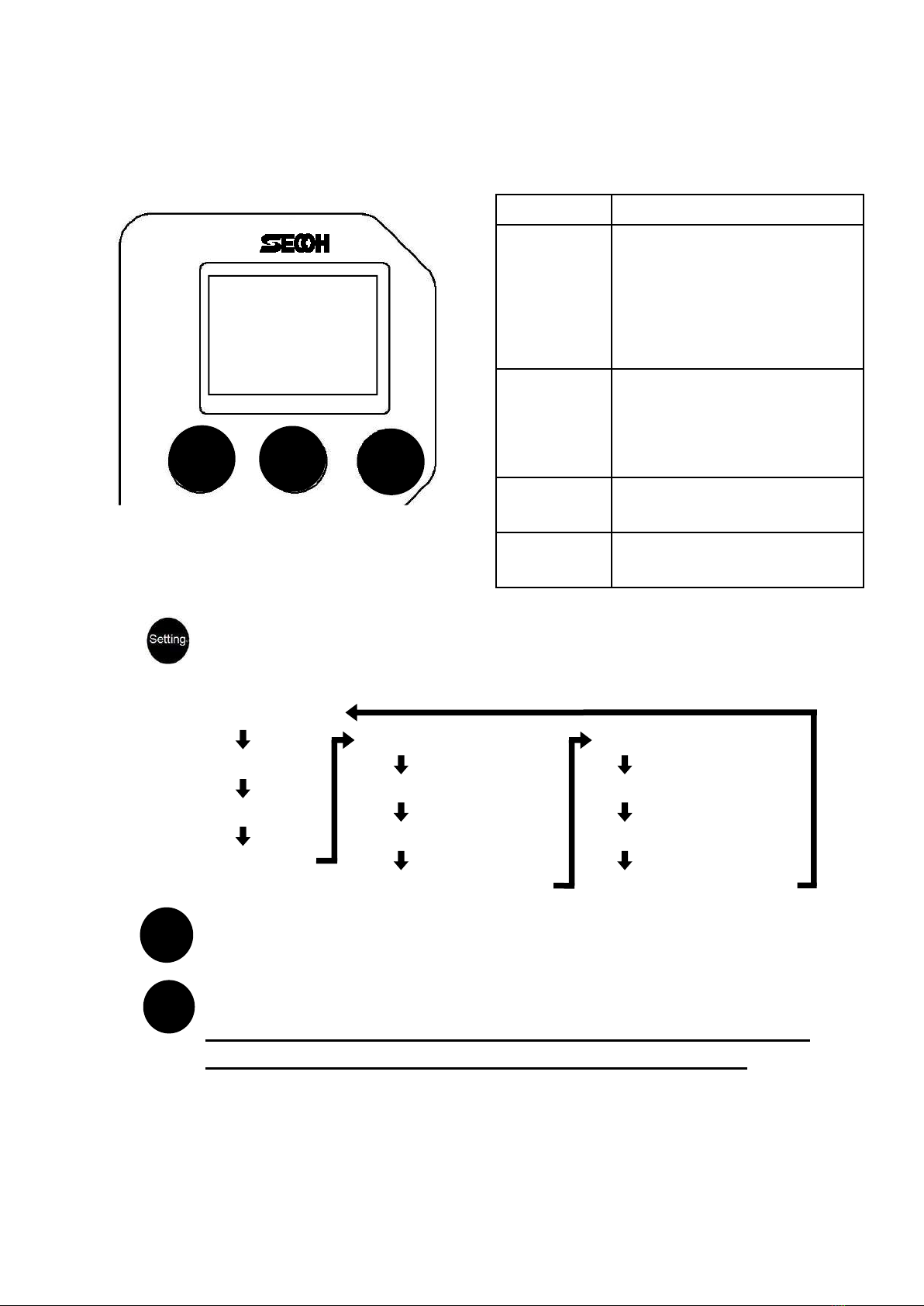

Secoh JDK-60T User manual

This manual suits for next models

2

Other Secoh Water Pump manuals

Popular Water Pump manuals by other brands

Grundfos

Grundfos Hydro Multi-B instructions

Zwilling

Zwilling Fresh & Save Vacuum Storage System operating instructions

GORMAN-RUPP

GORMAN-RUPP S Series MAINTENANCE AND REPAIR WITH TROUBLESHOOTING

Talon

Talon TP-72S manual

EINHELL

EINHELL ROYAL TDM 1000-S operating instructions

Becker

Becker VX 4.16 operating instructions

Espa

Espa CKE Series instruction manual

Grundfos

Grundfos AP80-100 Safety instructions and other important information

Ashland

Ashland EPF30 OPERATION, PERFORMANCE, SPECIFICATIONS and PARTS MANUAL

Wilo

Wilo Helix EXCEL 1004-2/25/V/KS,DN40,2.2kW Installation and operating instructions

Pentair

Pentair JUNG PUMPEN BAUFIX 100 instruction manual

Walrus

Walrus HQ800 Replacing

FUXTEC

FUXTEC FX-WP152 Original user manual

Lorentz

Lorentz PSk Series MANUAL FOR INSTALLATION, OPERATION, SERVICE

Wilo

Wilo PB BOOST FIRST Installation and operating instructions

MATO

MATO pneuMATO-fill operating instructions

Zoeller

Zoeller 1261-0001 manual

teel

teel 4RJ47 Operating instructions & parts manual