Secure Care 135DE User manual

A01350693 Rev: P ECO: 7476 Date: 04/14/08

Secure Care Products®, Inc.

Installation Manual

135DE System

39 Chenell Drive

Concord, NH USA 03301-8501

Phone: (800) 451-7917 / (603)223-0745

Fax: (603) 227-0200

http://www.securecare.com

© 2004 Secure Care Products®, Inc.

CONTENT IS SUBJECT TO CHANGE WITHOUT NOTICE

Please contact your

Distributor /

Installer for service …

Tel.: ___________________________

A01350693 Rev:P ECO: 7476 Date: 04/14/08 2

Table of Contents

SECTION 1 IMPORTANT NOTICES 6

PLEASE READ THIS MANUAL BEFORE BEGINNING THE INSTALLATION OF A SECURE CARE SYSTEM 6

SECTION 2 SYSTEM BLOCK DIAGRAM 9

SECTION 3 POWER AND GROUNDING REQUIREMENTS 10

SECTION 4 TYPICAL SYSTEM INSTALLATION 12

SECTION 5 SPECIFICATIONS 13

Device Electrical Specifications 13

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS 14

135DE Exit Panel 14

XIU 16

ID Nurse Station Console 17

203/204 LED Nurse Station Annunciator 18

Indoor/Outdoor Remote Keypad Layout 19

Indoor/Outdoor (N/O) Push Button Layout 19

SECTION 7 STANDARD FEATURES 20

Primary Reset (Escort) Code 20

Tertiary Reset (Escort) Code 20

Secondary Reset (Programming) Code 20

Selectable Delayed Egress Timing 20

Latching Delayed Egress 20

Software Verification 20

SECTION 8 THEORY OF OPERATION 21

SECTION 9 INSTALLATION AND CONNECTIONS 22

Basic Installation of Mounting Enclosures 22

Surface Mount Enclosure (XIU, 135DE) 22

Flush Mount Enclosure (XIU, 135DE) 23

A01350693 Rev:P ECO: 7476 Date: 04/14/08 3

Flush Mount Enclosure (ID Nurse Station Console, A02040901 LED Nurse Station Annunciator) 24

Surface Mount Enclosure (ID Nurse Station Console, A02040901 LED Nurse Station Annunciator) 25

Remote Annunciation 26

A02030901 (A02040901) Nurse Station Annunciator 26

Secure Care Software to XIU Connection 27

Interfacing Magnetic Locks 28

Interfacing the Magnetic Solutions Lock 29

Interfacing Two Magnetic Solutions Locks 30

Interfacing the Push Button and Remote Keypad 31

Delayed Egress and Fire Alarm Connections 32

135DE Exit Panel to External Receiver Connections 33

Second External Receiver Connections 34

SECTION 10 PROGRAMMING 35

Reset (Escort) Codes 35

Primary Code 35

Secondary Code 35

Secondary Code Reset 35

Tertiary Code 35

Escort Time 35

Delayed Egress Release Time 36

Delayed Egress Activation Time 36

Latching Delayed Egress 37

One Second Irreversible Latching Delayed Egress 37

Fire Alarm Input Selection 38

Latching Fire Alarm 38

Life Safety Lock 38

Panel ID Code 38

PM Mode Feature 39

Software Version 39

Elevator Mode 39

Loiter Alarm 40

Advanced Security Mode 40

A01350693 Rev:P ECO: 7476 Date: 04/14/08 4

Antenna Selection 41

Antenna Range Adjustment 41

SECTION 11 TESTING 42

Recommended Weekly Testing 42

Testing Wandering Patient Monitoring with Lock 42

Delayed Egress Feature Test 42

Recommended Monthly Testing 42

Fire Alarm Release Feature Test 42

Recommended Annual Service 42

Battery Replacement 42

Using a Transmitter/System Tester 43

Testing a Transmitter Using the 135 Tester: 43

Testing a Door System Using the 135 Tester: 43

SECTION 12 TROUBLESHOOTING 44

SECTION 13 GENERAL PRODUCT WARRANTY STATEMENT 48

1. Notices 48

2. Limited Warranty 50

3. Limitations of Liability 51

4. Governing Law and Arbitration 51

5. Severability 52

6. Waiver 52

SECTION 14 COMPLIANCE INFORMATION 53

APPENDIX A UL LISTING REQUIREMENTS 55

APPENDIX B 230 VAC INPUT POWER SUPPLY CONNECTION 56

APPENDIX C FERRITE PLACEMENT 57

Recommended Ferrite Placement 57

Correct and Incorrect Ferrite Installation 58

APPENDIX D 983 EXTERNAL RECEIVER KIT 59

A01350693 Rev:P ECO: 7476 Date: 04/14/08 5

Table of Figures

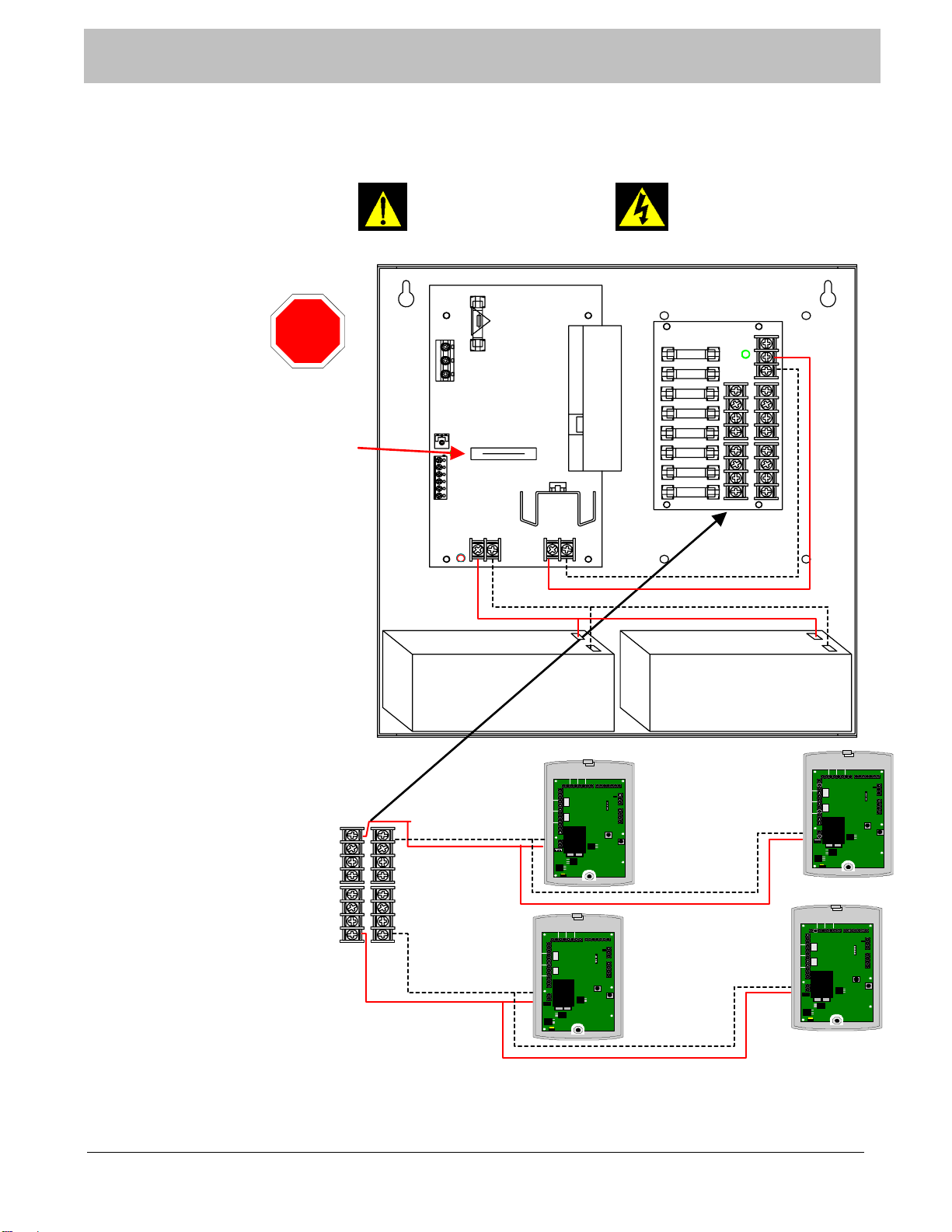

FIGURE 2-1 SYSTEM BLOCK DIAGRAM 9

FIGURE 3-1 POWER SUPPLY TO EXIT CONNECTION 11

FIGURE 6-1 FRONT VIEW OF 135DE EXIT PANEL 14

FIGURE 6-2 REAR VIEW OF 135DE EXIT PANEL 15

FIGURE 6-3 REAR VIEW OF XIU 16

FIGURE 6-4 REAR VIEW OF ID NURSE STATION CONSOLE 17

FIGURE 6-5 NEW A02030901 NURSE STATION ANNUNCIATOR 18

FIGURE 6-6 NEW A02040901 NURSE STATION ANNUNCIATOR 18

FIGURE 6-7 REAR VIEW OF REMOTE KEYPAD 19

FIGURE 6-8 REAR VIEW OF PUSH BUTTON 19

FIGURE 9-1 SURFACE MOUNT ENCLOSURE FOR EXIT PANELS 22

FIGURE 9-2 FLUSH MOUNT ENCLOSURE FOR EXIT PANELS 23

FIGURE 9-3 FLUSH MOUNT ENCLOSURE FOR NURSE STATIONS 24

FIGURE 9-4 SURFACE MOUNT ENCLOSURE FOR NURSE STATIONS 25

FIGURE 9-5 CONNECTION BETWEEN THE A02030901/A02040901 AND THE 135DE EXIT PANEL 26

FIGURE 9-6 XIU TO COMPUTER CONNECTION 27

FIGURE 9-7 135DE EXIT PANEL TO DORTRONICS LOCK CONNECTIONS 28

FIGURE 9-8 135DE EXIT PANEL TO MAGNETIC SOLUTIONS LOCK CONNECTIONS 29

FIGURE 9-9 135DE EXIT PANEL TO TWO MAGNETIC SOLUTIONS LOCKS CONNECTIONS 30

FIGURE 9-10 PUSH BUTTON AND REMOTE KEYPAD TO 135DE EXIT PANEL CONNECTION 31

FIGURE 9-11 DELAYED EGRESS AND FIRE ALARM CONNECTIONS 32

FIGURE 9-12 EXIT PANEL TO EXTERNAL RECEIVER CONNECTION 33

FIGURE 9-13 CONNECTING TWO EXTERNAL RECEIVERS 34

A01350693 Rev:P ECO: 7476 Date: 04/14/08 6

PLEASE READ THIS MANUAL BEFORE BEGINNING

THE INSTALLATION OF A SECURE CARE SYSTEM

This installation manual is provided for reference by purchasers and installers of Secure Care Products, Inc.’s

(“Secure Care’s”) systems. This manual is not intended as a catalog of warnings for the protection of anyone or as a

substitute for obtaining professional training or assistance in the design of a facility’s security procedures and systems, or in

the installation, set-up, testing, support, operation, maintenance, repair or use of Secure Care’s systems. Nothing in this

manual modifies the terms of Secure Care’s General Product Warranty Statement or of any written agreement signed by

Secure Care or creates further warranties or extends benefits of any sort to anyone beyond those already expressly established

in Secure Care’s General Product Warranty Statement and in any written contract signed by Secure Care.

1. Secure Care is Not Responsible for the Locks

ALL LOCKS USED WITH SECURE CARE’S SYSTEM ARE DESIGNED, MANUFACTURED, LABELED AND

DELIVERED SOLELY BY AN INDEPENDENT VENDOR OVER WHOM SECURE CARE HAS NO CONTROL

AND FOR WHOSE ACTIONS OR FAILURES TO ACT SECURE CARE DISCLAIMS ALL RESPONSIBILITY.

REGARDLESS OF WHETHER THE LOCKS CARRY SECURE CARE’S LOGO OR NAME OR ANY OTHER

TRADEMARK, SERVICE MARK OR TRADE NAME USED OR CLAIMED BY SECURE CARE, SECURE

CARE DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, WITH RESPECT TO THE LOCKS AND/OR

THEIR USE WITH OR OPERATION IN THE SECURE CARE SYSTEM, INCLUDING, WITHOUT

LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, TITLE AND/OR NON-INFRINGEMENT. SECURE CARE ALSO DISCLAIMS ALL OBLIGATIONS

WITH RESPECT TO THE LOCKS AND/OR THEIR USE WITH OR OPERATION IN THE SECURE CARE

SYSTEM THAT MIGHT OTHERWISE ARISE OR BE IMPLIED FROM THE FACT THAT SUCH LOCKS

CARRY SECURE CARE’S LOGO OR NAME OR ANY OTHER TRADEMARK, SERVICE MARK OR TRADE

NAME USED OR CLAIMED BY SECURE CARE OR FROM THE DELIVERY OR INSTALLATION OF THE

LOCKS WITH SECURE CARE SOFTWARE, PARTS AND/OR PRODUCTS OR FROM A COURSE OF

DEALING OR USAGE IN TRADE. ALL RESPONSIBILITY FOR DESIGNING, MANUFACTURING,

LABELING AND WARNING OF HIDDEN DEFECTS OR DANGERS IN THE LOCKS AND/OR THEIR USE

WITH AND OPERATION IN THE SECURE CARE SYSTEM RESTS EXCLUSIVELY WITH THE

INDEPENDENT VENDOR, AND ANY CLAIMS, COSTS, DAMAGES OR LIABILITIES ARISING FROM THE

LOCKS AND/OR THEIR USE WITH OR OPERATION IN THE SECURE CARE SYSTEM SHALL BE MADE

SOLELY AGAINST THE INDEPENDENT VENDOR.

2. Secure Care Is Not Responsible for The Computer Hardware.

IF YOU PURCHASE COMPUTER HARDWARE THROUGH SECURE CARE AND REQUEST THAT SECURE

CARE SOFTWARE BE INSTALLED AND TESTED ON THAT HARDWARE AT THE FACTORY, SECURE

CARE WARRANTS ONLY THAT THE HARDWARE AND THE SOFTWARE PACKAGES WERE INSTALLED,

SET-UP AND TESTED PRIOR TO SHIPMENT IN ACCORDANCE WITH ALL SECURE CARE PRODUCT

MANUALS AND THAT, AT THE TIME THE HARDWARE AND THE SOFTWARE PACKAGES WERE

FINALLY INSPECTED AT THE FACTORY, THEY WERE PERFORMING (SUBJECT TO SECURE CARE’S

SPECIFIED TOLERANCES) IN ACCORDANCE WITH SECURE CARE’S SPECIFICATIONS. SECURE CARE

WILL NOT BE RESPONSIBLE FOR ANY DEFECTS IN OR PROBLEMS CAUSED BY THE HARDWARE, ALL

CLAIMS FOR WHICH MUST BE MADE TO THE HARDWARE MANUFACTURER AND/OR VENDOR.

SECURE CARE DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, WITH RESPECT TO THE

HARDWARE AND/OR ITS USE WITH OR OPERATION IN THE SECURE CARE SYSTEM, INCLUDING,

WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, TITLE AND/OR NON-INFRINGEMENT. SECURE CARE ALSO DISCLAIMS ALL

OBLIGATIONS WITH RESPECT TO THE HARDWARE AND/OR ITS USE WITH OR OPERATION IN THE

SECURE CARE SYSTEM THAT MIGHT OTHERWISE ARISE OR BE IMPLIED FROM THE FACT THAT

SUCH HARDWARE CARRIES SECURE CARE’S LOGO OR NAME OR ANY OTHER TRADEMARK,

SERVICE MARK OR TRADE NAME USED OR CLAIMED BY SECURE CARE OR FROM THE DELIVERY

OR INSTALLATION OF THE HARDWARE WITH SECURE CARE SOFTWARE, PARTS AND/OR

PRODUCTS OR FROM A COURSE OF DEALING OR USAGE IN TRADE. ALL RESPONSIBILITY FOR

DESIGNING, MANUFACTURING, LABELING AND WARNING OF HIDDEN DEFECTS OR DANGERS IN

SECTION 1 IMPORTANT NOTICES

A01350693 Rev:P ECO: 7476 Date: 04/14/08 7

THE HARDWARE AND/OR ITS USE WITH AND OPERATION IN THE SECURE CARE SYSTEM RESTS

EXCLUSIVELY WITH THE HARDWARE MANUFACTURER AND/OR VENDOR, AND ANY CLAIMS,

COSTS, DAMAGES OR LIABILITIES ARISING FROM THE HARDWARE AND/OR ITS USE WITH OR

OPERATION IN THE SECURE CARE SYSTEM SHALL BE MADE SOLELY AGAINST THE HARDWARE

MANUFACTURER AND/OR VENDOR.

3. Several Factors Outside the Secure Care System Can Affect its Performance

Secure Care’s software, parts and products are designed for operation in a wireless system. However, the range,

performance, and predictability of any wireless system, including Secure Care’s, is dependent on several factors,

including, but not limited to, the following: building structure; environmental extremes (e.g., temperature, earth

tremors, air pollution, etc.); the proximity of other wireless devices; the presence of variable speed products; sources

of Radio Frequency Interference (RFI); physical orientation and positioning of the equipment; and sources of

Electro Static Discharge (ESD). Secure Care is not responsible for the effect of these types of factors on operation

of its software, parts and products and disclaims all responsibility for any claim relative thereto.

4. The Secure Care System Must be Properly Installed

Secure Care's system must be installed, set-up, tested, supported, operated, maintained, repaired and used only in

accordance with all manuals and instructions (including the user, installation, technical and other manuals) issued

by Secure Care (the "Product Manuals"). It is your responsibility to assure that any person who might be installing,

setting-up, testing, supporting, maintaining or repairing the Secure Care system knows the contents of and has

access to the Product Manuals and has successfully completed Secure Care technical training. It is also your

responsibility to assure that any person who might be operating or using this Product knows the contents of and

has access to the Product Manuals and has successfully completed Secure Care in-service training. Secure Care can

not be responsible for performance problems caused by a failure to follow prescribed and appropriate procedures

for installation, set-up, testing, support, operation, maintenance, repair and use.

All adjustable features on new and repaired Secure Care software, parts and products are shipped with “factory

default” settings. These “factory default” settings may not comply with building and life safety codes or other

applicable laws and regulations in the location where they are installed or operated. Secure Care strongly

recommends, therefore, that the settings on all Secure Care software, parts and products be checked and, if

necessary, reset to comply with local building and life safety codes and other applicable laws and regulations at the

time of any installation, set-up, testing, support, maintenance or repair.

5. Performance of the Secure Care System Software Depends on Proper Maintenance

Secure Care’s system is driven by software. However, the performance and reliability of any software-driven system

depends on adequately maintaining the recommended minimum configuration of computing platform, operating

systems and applications programs and on regularly performing industry-standard and application-specific backup

processes. If recommended minimum configurations of computing platform, operating systems, and applications

programs are not adequately maintained, or if appropriate backups are not regularly performed, the software may

not drive the system as intended. Secure Care is not responsible for operational problems caused by a failure to

perform these maintenance and backup procedures and disclaims all responsibility for any claim relative

thereto.

6. Only a Qualified Service Technician Should Work on a Secure Care System

Secure Care does not authorize, and strongly recommends against, any installation or field replacement of software,

parts or products by untrained contractors or facility staff. Such work can be hazardous, can render the system

ineffective and will void any Secure Care warranty or liability that might otherwise relate to the system.

Before any software, parts or products which have been designed and manufactured by Secure Care can be safely

installed, set-up, tested, supported, maintained or repaired, technical training in accordance with standards

established by Secure Care is required. Regardless of how Secure Care’s software, parts or products are obtained,

they should not be installed, set-up, tested, supported, maintained or repaired by any person who has not

satisfactorily completed that technical training (a “qualified service technician”.) When Secure Care’s software,

parts or products are sold separately from installation services, it is assumed that only a qualified service technician

A01350693 Rev:P ECO: 7476 Date: 04/14/08 8

will conduct any installation, set-up, testing, support, maintenance or repair involving that software, part or

products.

7. Any Work Must Comply with Electrical and Life Safety Codes

It is important that any installation, set-up, testing, support, operation, maintenance, repair or use involving the

system comply with all local and national electrical and life safety codes. If you have any questions about

compliance with those codes, please contact your local authorities.

8. Immediately Have Replacements or Repairs Checked On-Site by a Qualified Service Technician

Secure Care receives and responds to telephone and dial-in inquires (the “Help Line”) about its software, parts and

products for the purpose of discussing users’ experiences with Secure Care’s system, helping users better understand

how their systems work, and providing ideas about what may be causing difficulties. However, Secure Care cannot

accurately diagnose the cause of any problems or give complete instructions on how to fix problems over the

telephone or Internet. The only way to assure that software, parts or products are installed, set-up, tested,

supported, maintained or repaired correctly or that a Secure Care system is functioning properly is to have it

examined on site by a qualified service technician. In addition, Secure Care software, parts and products cannot be

operated or used correctly by anyone who has not successfully completed Secure Care in-service training. Secure

Care’s Help Line is not a substitute for on-site diagnosis and servicing by a qualified service technician or for

successful completion of Secure Care in-service training. Secure Care strongly recommends that any installation,

set-up, testing, support, maintenance or repair of a system that is performed by a person who has not satisfactorily

completed technical training in accordance with standards established by Secure Care be immediately checked on-

site by a qualified service technician.

WARNING: EVEN SLIGHT MODIFICATIONS TO THE SYSTEM OR CHANGES IN THE OPERATING

ENVIRONMENT MAY CAUSE SECURE CARE’S SYSTEM TO MALFUNCTION. THE ONLY WAY TO

ASSURE THAT SECURE CARE’S SYSTEM HAS BEEN INSTALLED, SET-UP, TESTED, SUPPORTED,

MAINTAINED AND REPAIRED CORRECTLY IS TO HAVE A QUALIFIED SERVICE TECHNICIAN DO THE

WORK.

9. The Secure Care System is not a Substitute for Careful Identification and Monitoring by

Professional Staff

Secure Care’s software, parts and products have been designed to augment a facility’s reasonable procedures for

protecting residents, patients, and infants. However, no system or combination of procedures and equipment can

eliminate all risk or assure complete security. Secure Care’s system is not intended as a substitute for the careful

identification and monitoring of residents, patients, and infants by a facility’s professional staff.

Revised 11/16/07

A01350693 Rev:P ECO: 7476 Date: 04/14/08 9

SECTION 2 SYSTEM BLOCK DIAGRAM

PERSONAL

COMPUTER

WITH

SECURE CARE

SOFTWARE

XIU

135 135 500DE

MAGNETIC LOCK

ELEVATOR

CONTROL

(135 and 135DE

only)

FIRE ALARM

CONTROL

Connection

required for any

device with

magnetic door lock.

EXTERNAL

ANTENNA

(135 and 135DE only)

EXTERNAL

KEYPAD

NURSE

STATION

PUSH

BUTTON

135DE

POWER

SUPPLY

POWER

SUPPLY

POWER

SUPPLY

POWER

SUPPLY

or

RS232 one way to Nurse Station or

Secure Care Software

Earth ground

connection at J1

position "F"

POWER

SUPPLY

Bi-directional CAN (Controller Area Network) communications bus. Maximum 94 devices connected to XIU.

MAGNETIC LOCK

FIRE ALARM

CONTROL

Connection

required for any

device with

magnetic door lock.

SUPPLY

POWER

A01350691, Rev. A

Fig. 2

Figure 2-1 System Block Diagram

NOTE: This diagram is UL required. Do not remove or change Part Number or Figure #.

A01350693 Rev:P ECO: 7476 Date: 04/14/08 10

Each Exit Panel will require a 110/220/230VAC duplex outlet specific to regional or country options (minimum 2 Amp) within ten

cable feet of the intended installation location. The use of emergency power circuits is highly recommended due to possible facility

power failures.

NOTES:

•Power Wire: 14/2 stranded, unshielded (SCP Part # C60008473). Power wire is a UL requirement. Failure to

use this wire removes the UL listing.

•Power Supply: SCP Part # C40006008. For overseas 230VA Power Supply refer to Appendix B.

•Do not connect to a receptacle controlled by a switch.

•Do not extend the power supply cord provided. The maximum distance the duplex outlet should be from

the Exit Panel is ten cable feet.

SECTION 3 POWER AND GROUNDING REQUIREMENTS

A01350693 Rev:P ECO: 7476 Date: 04/14/08 11

FIR

EPUS

HDOO

REGRES

S

LOCK AUX

SECURECARE

PRODUCTS

AUXLOCK

-

+

NO C

NC NO C

NC NO C

NC NO C

NC - +

KEYPAD

ON

1 2 3 4

1 2 3 4 5 6

7

1 2 3

4CANL CANH GND

FIR

EPUS

HDOO

REGRES

S

LOCK AUX

SECURECARE

PRODUCTS

AUXLOCK

-

+

NO C

NC NO C

NC NO C

NC NO C

NC - +

KEYPAD

ON

1 2 3 4

1 2 3 4 5 6

7

1 2 3

4CANL CANH GND

FIR

EPUS

HDOO

REGRES

S

LOCK AUX

SECURECARE

PRODUCTS

AUXLOCK

-

+

NO C

NC NO C

NC NO C

NC NO C

NC - +

KEYPAD

ON

1 2 3 4

1 2 3 4 5 6

7

1 2 3

4CANL CANH GND

FIR

EPUS

HDOO

REGRES

S

LOCK AUX

SECURECARE

PRODUCTS

AUXLOCK

-

+

NO C

NC NO C

NC NO C

NC NO C

NC - +

KEYPAD

ON

1 2 3 4

1 2 3 4 5 6

7

1 2 3

4CANL CANH GND

COMMON POWER OUTPUTS

FUSED POWER OUTPUTS

N

P

+

-

+

+

+

-

-

-

Max 8 Per

output

Max 8 Per

output

Maximum 32

exits per

power supply

(6 Amp)

NOTE:

Refer to

manufacturer’s

documentation when

installing the power

supply

12VDC

12VDC

COMMON POWER OUTPUTS

FUSED POWER OUTPUTS

N

PPD8

N P S

MAIN FUSE

L G N

3.5A 250V

AL600ULXB

AC

+BAT-

DC

+ DC -

BAT FAIL NC C NO NC C NO

AC FAIL

FNAME

24VDC OPEN

12VDC CLOSED

Verify Switch Is Set

For 12VDC Before

Applying Power To

Power Supply

STOP

115VAC

Power

Mains

Non-Power

Limited

+--

+

Battery 1 Battery 2

•

Risk of shock

•

Dry location use only

•

For indoor use only

NOTE

: Refer to

Appendix D for

OverSeas 230VA

Power Supply

Figure 3-1 Power Supply to Exit Connection

SECTION 3 POWER AND GROUNDING REQUIREMENTS

A01350693 Rev:P ECO: 7476 Date: 04/14/08 12

As with any Wandering Monitoring System, each application can be different. Use the guidelines below as a basic understanding of

what a standard application would be like.

•Identify all the equipment that is to be installed. Inspect for any damage that may have resulted during shipment. If

damage is found, notify the shipping carrier immediately and arrange for an inspection. Be sure to retain all shipping

and packing materials.

•Install all communication wires from each exit system to the remote system annunciator location.

•Determine the location of the Exit Control Panel, making sure to accommodate for any local, state, or federal codes

or guidelines including ADA requirements, and mount as required. Standard applications would place this

equipment on the wall at the center of the door height on the latch side.

•Mount the Electromagnetic Lock in strict accordance with the manufacturer installation instructions. Be sure to

comply with all Life Safety and Electrical Codes as required.

•Mount the Magnetic Door Contacts provided with the Exit Kit on the latch side of the door. These contacts provide

a method of monitoring the open or closed status of the door.

•Route all necessary peripheral connection wires into the Exit Control Panel mounting box. These would include wires

such as communication, magnetic contacts, exit power, magnetic lock power, etc.

•Prepare all wires and make connections to the exit system. Special care should be taken to prevent loose connections

and shorts.

•Proceed to the remote system annunciator location to mount as required. This device should be easily visible by staff

for monitoring of the system. Common locations are centralized nurse stations or staffed reception areas.

•Make all necessary wiring connections as shown on the following pages.

•Plug in all power supplies and batteries. The system is now ready for testing.

SECTION 4 TYPICAL SYSTEM INSTALLATION

A01350693 Rev:P ECO: 7476 Date: 04/14/08 13

Device Electrical Specifications

XIU, 500DE, 135, 135DE & ID Exit Panels

•Input Power: 12VDC/1A

•Relay Specifications: Max. 30VDC (only) 1 Amp

•Battery Back Up: Rechargeable 9VDC Ni-MH battery

•Battery Back Up Time: Approximately 30 minutes

Nurse Station SCP P/N A02280903

•Input Power: 12VDC/500mA

•Battery Back Up: Rechargeable 9VDC Ni-MH battery

•Battery Back Up Time: Approximately 30 minutes

Magnetic Lock

•Input Power: 12VDC/1A

•Battery Back Up: None

UL Product Listings

•UL 294

•UL 1069

SECTION 5 SPECIFICATIONS

A01350693 Rev:P ECO: 7476 Date: 04/14/08 14

135DE

®

1 2 3

4 5 6

7 8 9

0

#

*

Secure Care Products, Inc.

Panel Information

135DE Exit Panel

Door is Alarming

( Flashing Red )

Door is armed ( Red )

LED will turn off when

Escort Code is entered.

Flashing Red Fire is

activated.

Transmitter

is within

range of

panel (Red)

When two transmitters

are present, center LED

is solid. When three or

more transmitters are

present, center LED

will blink. Keypad Punch

Indicator center LED

lights when any key is

pressed.

Panel is On

( Green )

Transmitter is

being

detected

(Flashing

Yellow)

135DE Exit Panel

NOTE: Not all exit panels will have every feature set or all components populated. Refer to specific part

number or exit panel model name for available feature sets.

Figure 6-1 Front View of 135DE Exit Panel

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS

A01350693 Rev:P ECO: 7476 Date: 04/14/08 15

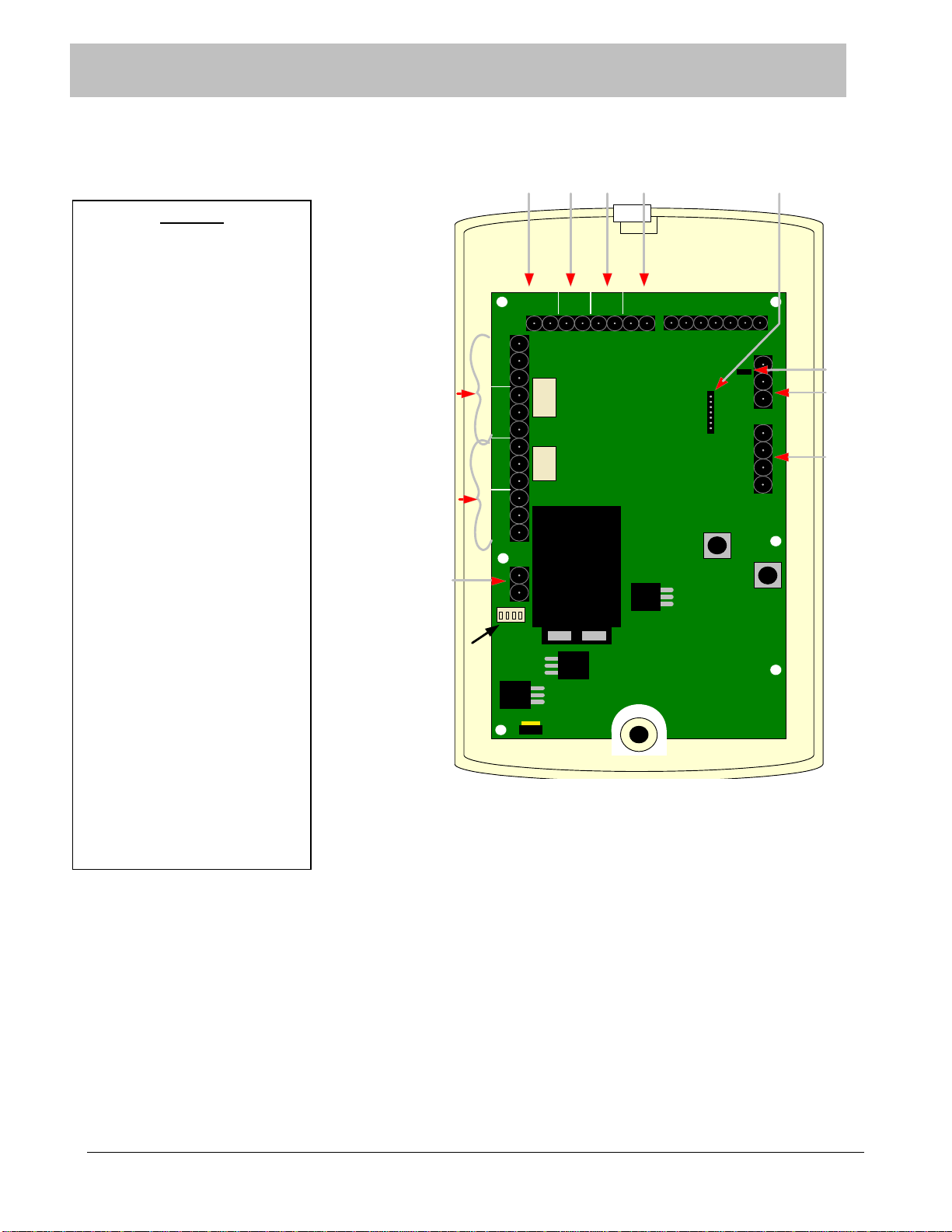

Figure 6-2 Rear View of 135DE Exit Panel

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS

LEGEND

1. Electromagnetic lock Delayed

Egress connection

2. Normally Closed door contact

connection

3. Momentary Push Button or

Non-latching Key Switch

4. Fire alarm Normally Open dry

alarm relay connection (field

selectable)

5. Controlled area network (CAN)

connection

6. Remote Internal/External

Keypad connection (seven pin)

7. Electromagnetic lock relays ,

one and two connections

8. Auxiliary relays (one and two

connections)

9. DC power input connections.

10. CAN Bus termination jumper

11. External Model 135Receiver

connection. See Appendix D at

the end of this manual.

12. Dipswitches Power/Volume

FIRE PUSH DOOR EGRESS

LOCK AUX

CAN

L

CANHGND

SECURE CARE PRODUCTS

AUXLOCK

- +

NO C NC NO C NC NO C NC NO C NC - +

KEYPAD

O N

1 2 3 4

1 2 3 4 5 6 7

1 2 3 4

23416

7

8

9

5

12

10

1- Power

2- Mute

3-Loud/Soft

4- Not Used

11

A01350693 Rev:P ECO: 7476 Date: 04/14/08 16

XIU

FIRE PUSH DOOR EGRESS

AUX

CA

NL

CANHGND

SECURE CARE

PRODUCTS

LOCK

- +

NO C NC

- +

KEYPAD

O

N

1 2 3 4

1 2 3 4 5 6 7

1) POWER

2) NOT USED

3) NOT USED

4) NOT USED

LOCK

NO C NC AUX

NO C NC NO C NC

2

4

5

6

3

1

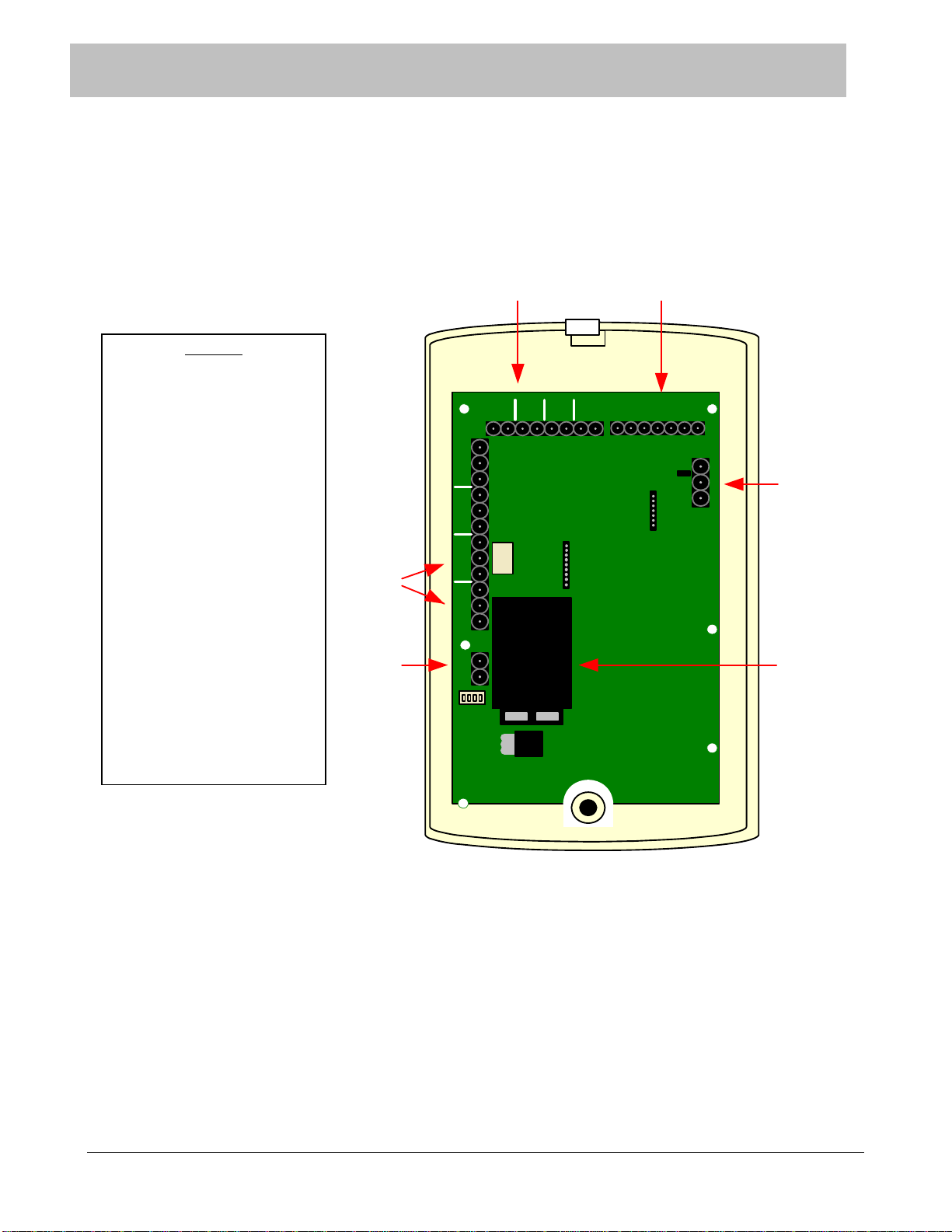

Figure 6-3 Rear View of XIU

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS

LEGEND

1. XIU to XIU (Only used

with Cutband System. Refer to

ID with Stat Manual)

2. RS-232 connection to

Nurse Station or SCP Software

3. Controlled area network

(CAN)

4. Back up battery holder

5. DC power input connection

6. Auxiliary relay connection

(Form C Relays that activate

during a cutband alarm)

A01350693 Rev:P ECO: 7476 Date: 04/14/08 17

ID Nurse Station Console

y

y

y

123

4

5

6

7

8

9

10

11 12

1. POWER

2.MUTE

3.LOUD/SOFT

4.N/A

Figure 6-4 Rear View of ID Nurse Station Console

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS

LEGEND

1. Non-volatile RAM storage

2. RS-232output chip

3. RS-232 output connector

4. Software EPROM

5. RS-232 device input

connections ( Term. 9-16)

6. RS-232 input chip (Term.

13-16)

7. RS-232 input chip (Term. 9-

12)

8. Dry contact device input

(Term. 1-8)

9. DC input power connector

10. DC power regulator and

heat sink

11. Power / Volume control

switches

12. Back up battery holder

A01350693 Rev:P ECO: 7476 Date: 04/14/08 18

203/204 LED Nurse Station Annunciator

NOTE: Actual Nurse Station connections may differ from figures below.

Figure 6-5 New A02030901 Nurse Station Annunciator

Figure 6-6 New A02040901 Nurse Station Annunciator

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS

LEGEND

1. Form C output relay

2. DC power inputs

3. Dry contact position inputs

(1-4)

4. Volume adjustment

5. Dry contact position inputs

(5-8)

6. DC power inputs

7. Shield drain ground

connection

8. Volume adjustment

LEGEND

1. Form C output relay

2. DC power input

3. Dry contact position inputs

(1-4)

4. Volume adjustment

+4321

-

All Terminal strips are

removable for ease of

installation

4

2 3

M L H

1

NO C NC

+4321

-

All Terminal strips are

removable for ease of

installation

M L H

NO C NC

+4321

-

All Terminal strips are

removable for ease of

installation

M L H

NO C NC

1 2 3

4

5

67

8

A01350693 Rev:P ECO: 7476 Date: 04/14/08 19

Indoor/Outdoor Remote Keypad Layout

Figure 6-7 Rear View of Remote Keypad

Indoor/Outdoor (N/O) Push Button Layout

Figure 6-8 Rear View of Push Button

SECTION 6 SYSTEM COMPONENT DESCRIPTIONS

1

2

3

LEGEND

1. Mounting screw holes

2. Seven pin connector for seven

conductor ribbon cable

3. Steel faceplate

LEGEND

1. Mounting screw holes

2. Spade lug terminal

connectors (Normally Open –

Activated Closed)

3. Steel Faceplate

1

2

3

A01350693 Rev:P ECO: 7476 Date: 04/14/08 20

SECTION 7 STANDARD FEATURES

The selective monitoring system is designed to augment your policy regarding security of infants, small children, or residents. If used

and tested properly, the system will provide many years of trouble free operation. The standard system consists of an Exit Panel, the

electromagnetic lock, the Receiver/Antenna, magnetic door contacts, and an active Transmitter.

The standard mode of operation for the Exit System allows free access of the door by nurse staff members and visitors but quietly

locks the door when a transmitter approaches the door. When the transmitter leaves the monitored area, the door unlocks and access

is again available for the nurse staff and visitors. If a nurse staff member is required to escort a transmitter out of the protected area,

an escort code can be entered into the Exit Panel keypad to allow both the nurse staff member and the transmitter to pass through

the perimeter without creating an alarm.

Other key features are described below and can be activated at the time of installation or at any time afterward by a trained

technician.

Primary Reset (Escort) Code – This code is used to reset an alarm condition or escort a monitored transmitter through a door

without creating an alarm condition. In the Advanced Security Mode, the primary reset (escort) code will not allow access through a

monitored door location. This code should not be given to family members or visitors. Only nurse staff members should be

allowed to reset an alarm condition or escort a transmitter out of the building without creating an alarm.

Tertiary Reset (Escort) Code - This code is used to reset an alarm condition or escort a monitored transmitter through a door

without creating an alarm condition. In the Advanced Security Mode, the tertiary reset (escort) code will not allow access through a

monitored door location. This code should not be given to family members or visitors. Only nurse staff members should be

allowed to reset an alarm condition or escort a transmitter out of the building without creating an alarm.

Secondary Reset (Programming) Code –In the Advanced Security Mode, the secondary code is used to escort a transmitter through

a monitored door. This code is also used to enter the programming mode of the system. This code should only be given to

authorized nursing staff members.

Selectable Delayed Egress Timing – This feature allows the Exit Panel to be programmed for either a 15 or 30 second release on

activation of the delayed egress function. Per NFPA Life Safety Code 101, local life safety officials must be contacted for guidance

on requirements for local jurisdictions prior to being programmed.

Latching Delayed Egress – Enabling the latching delayed egress function of the Exit Panel allows the electromagnetic lock to

remain unlocked whenever the delayed egress cycle has released the door and a monitored transmitter has exited the perimeter. A

valid reset (escort) code entered by an authorized staff member is required before the door is available to lock again.

Software Verification – The software verification feature allows the user to determine which software version is installed in the Exit

Panel. The Exit Panel will blink the LED’s and chirp the sounder located on the front of the panel in specific sequences that are to

be counted for identification.

PM Mode – This feature allows the Exit Panel to be programmed to lock and unlock automatically at certain times of the day

whether a transmitter is near a monitored area or not.

Loiter Alarm – When activated, this feature will create an alarm condition whenever a monitored transmitter remains within the

detection range of an exit for a predetermined period of time.

Table of contents

Other Secure Care Test Equipment manuals