Hickok 539C User manual

STANDARD EIA GUARANTEE

The

Hickok

Electrical

Instrument

Company

warrants

instruments

manufactured

by

it

to

be

free

from

defective

material

or

factory

workmanship

and

agrees

to

repair

such

instruments

which,

under

normal

use

and

service,

disclose

the

de-

fect

to

be

the

fault

of

our

manufacturing.

Our

obligation

under

this

warranty

is

limited

to

repairing

any

instrument

or

test

equipment

which

proves

to

be

defec-

tive, when

returned

to

us

transportation

prepaid,

within 90

days

from

the

date

of

original

purchase,

and

provided

the

serial

number

has

been

made

known to

us

promptly

for

our

records.

This

warranty

does

not

apply

to

any

of

our

products

which

have

been

repaired

or

altered

by

unauthorized

persons

or

service

stations

in

any

way

so

as,

in

our

judgment,

to

injure

their

stability

or

reliability,

or

which

have

been

subject

to

misuse,

negligence,

or

accident,

or

which

have

had

the

serial

number

altered,

effaced

or

removed.

Neither

does

this

warranty

apply

to

any

of

our

products

which

have

been

connected,

installed,

or

adjusted

otherwise

than

in

accordance

with the

instructions

furnished

by

us.

Accessories,

including

all

vacuum

tubes

not

of

our

manufacture,

used

with

this

product

are

not

covered

by

this

warranty.

This

warranty

is

in

lieu

of

all

other

warranties

expressed

or

implied,

and

no

representative

or

person

is

authorized

to

assume

for

us

any

other

liability

in

connection

with

the

sale

of

our

products.

Parts

will

be

made

available

for

a

minimum

period

of

five

years

after

the

manu-

facture

of

this

equipment

has

been

discontinued.

Parts

include

all

materials,

charts,

instructions,

diagrams,

accessories,

etc.,

which

have

been

furnished

in

the

standard

model.

RETURNING EQUIPMENT FOR REPAIR

Before

returning

any

equipment

for

service,

under

warranty

or

otherwise,

the

Service

Department

in

Cleveland

must

first

be

contacted

giving

the

nature

of

the

trouble.

Instructions

will

then

be

given

for

either

correcting

the

trouble

or

re-

turning

the

equipment

to

one

of

our

service

stations.

All

correspondence

per-

taining

to

repairs

should

be

directed

to

the

Hickok

Electrical

Instrument

Company

10636

Leuer

Avenue,

Cleveland

8, Ohio -Attn.

Service

Department.

REGISTRATION CARD

The

above

guarantee

is

contingent

upon

the

attached

registration

card

being

returned

to

the

factory

im-

mediately

upon

receipt

of

the

equipment.

THE HICKOK

ELECTRICAL

INSTRUMENT COMPANY

Cleveland,

Ohio

AUTOMOBILE RADIO TUBES

It

often

happens

that

automobiles

operated

at

night

with

radio,

light,

fans,

etc.,

all

turned

on

at

the

same

time,

put

such

a

severe

109.d

on

the

auto

battery

that

the

battery

is

unable

to

deliver

full

voltage,

especially

in

slow

moving

traffic

or

when

waiting

for

traffic

light.

If

auto

radio

trouble

is

experienced,

much

time

can

be

saved

by

first

checking

the

tubes

at

6.3

volts,

then

switching

the

filament

voltage

to

5

volts.

If

tube

reading

drops

markedly

at

5

volts,

the

tube

should

be

replaced.

If

the

automobile

has

12

volt

radio

system,

first

check

the

tubes

at

12.6

volts,

then

drop

to 10

volts

for

recheck.

ACORN TUBES

Adapter,

Code

1050-9,

is

available

for

testing

Acorn

tubes

with

the

539C.

OPERATING INSTRUCTIONS

FOR

MODEL 539C

TRANSCONDUCTANCE TUBE

TESTER

FOREWORD

The

Model 539C Mutual Conductance

(Transconductance)

Thbe

Tester

is

designed

for

use

by

technicians,

engineers

and

others

who

demand

an

instrument

of

the

very

highest

qua-

lity

for

rapid

and

accurate

testing

of

vacuum

tubes.

Like

all

Hickok Tube

Testers,

it

is

based

upon

the

well known

formula

for

mutual

conductance,

f\ip

= Gm

6eg ,

where

ip

is

the

plate

current

change, eg

is

the

grid

voltage

change,

and

Gm

is

the

Mutual

Conductance

(Transconductance).

Mutual Conductance

and

Transconductance

are

used

interchangeably.

This

instrument

is

equipped with

three

meters,

all

made

in

our

own plant,

and

calibrated

with

great

accuracy.

(a) A

sensitive

Transconductance

meter

measuring

micromhos

in

six

ranges

up

to

60, 000

micromhos.

This

meter

also

has

a

scale

reading

to

200

volts

for

V. R.

tube

testing,

and

a

scale

reading

to 50

megohms

for

leakage

testing.

(b) An A. C.

voltmeter

which

insures

standardized

voltages

to

the

tube's

base,

and

(c) A two

range

(0-10, 0-50)

D.

C.

voltmeter

to

accurately

adjust

the

negative

bias

on

the

tube's

control

grid.

Also

a

scale

to 100 M. A. d.

c.

for

V.

R.

milliam-

peres.

Voltage

adjustments

are

made

while

the

tube

being

tested

is

delivering

its

rated

load.

NOTE: Always

check

a tube

for

shorts

before

pro~eeding

with Mutual Conductance

test.

OPERATING INSTRUCTIONS

Read

these

instructions

through

before

attempting

to

operate

the

tester.

1.

There

are

two

rectifier

tubes, an 83

and

a 5Y3GT

necessary

to

operate

this

tester.

They

are

included.

The

Short

Lamp

is

a

1/25

watt, 110 volt,

miniature

bayonet

base

neon

signal

lamp.

This

lamp

will

last

indefinitely

unless

broken.

The

Fuse

Lamp

is

a

standard

No. 81,

single

contact

auto

bulb.

This

can

be

pro-

cured

from

any

auto

dealer

or

gasoline

station

attendant.

This

fuse

lamp

is

in

the

primary

circuit

of

the

transformer.

- 1 -

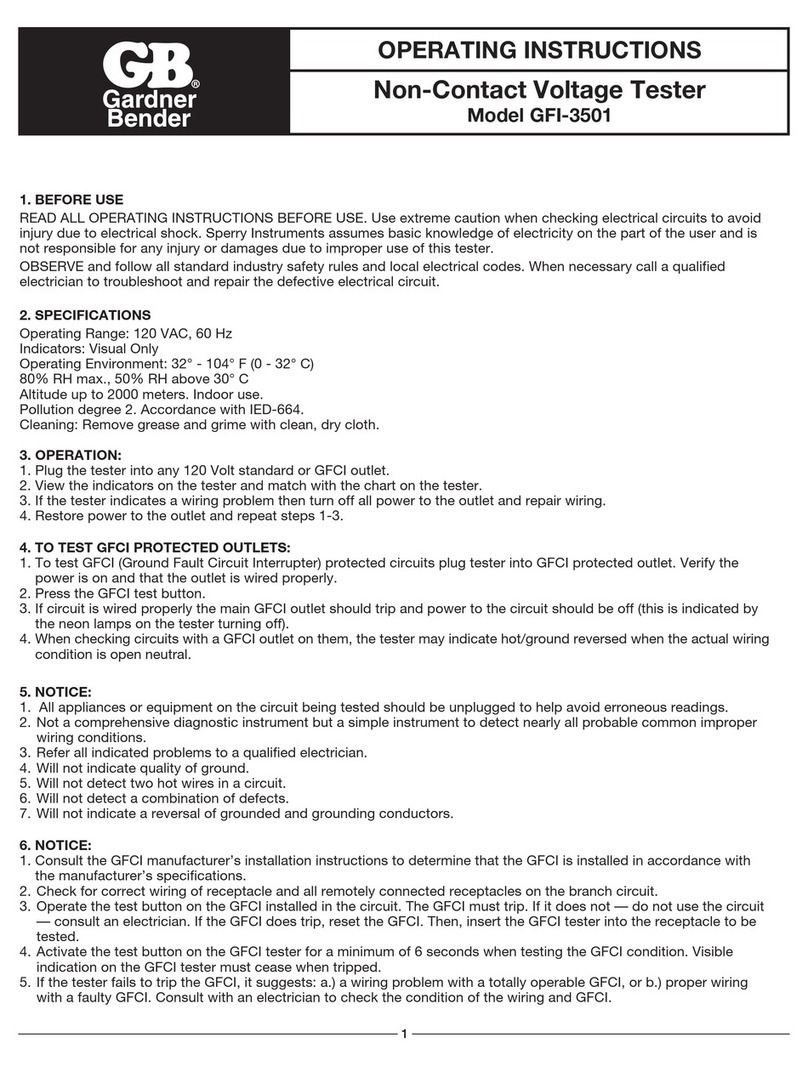

FUNCTIONS OF THE VARIOUS CONTROLS

3.

The

line

adjustment

control

rheostat

in

the

539C

Tester

is

connected

with a

small

A. C.

voltmeter

as

a

constant

calibration

indicator

which

is

normally

always

in

cir-

cuit.

The

small

A. C.

voltmeter

may

also

be

used

to

register

60

cycles

A. C.

line

voltage fed to the

set

by

operating

the

test

button

P7

deSignated

"LINE

TEST"

in

the

lower

right

part

of

the

control

panel.

Readjust

after

pressing

the

P4

Test

Button.

4.

Selectors:

The

row

of

seven

selector

switches

across

the

center

of

the

control

panel

is

for

the

purpose

of

conducting

proper

voltages

to

the

tube's

base

pins.

On

the

roll

data

chart,

below the

word

"Selectors"

appear

the

switch

settings.

Example: JR-6237-5.

Starting

at

the

left

the

first

switch

is

set

at

"}",

the

~econd

switch

at

"R",

the

third

at

"6",

the

fourth

"2",

the

fifth

"3",

the

sixth

"7"

and

the

seventh"

5".

The

first

two

switches

control

the

filament

or

heater

connection~.

The

other

switches

control

the GRID, PLATE, SCREEN,

CA

WODE

and

SUPPRESSOR in

that

order.

In the

example

given above,

the

heater

terminals

are

connected

to

pins

8

and

1.

The

GRID

is

connected

to pin 6; PLATE, to pin

2;

SCREEN, to pin

3;

CATHODE,

to pin 7

and

SUPPRESSOR, to

pin

5.

These

switches

are

electrically

interlocked

in

such

a way

that

it

is

impossible

to

connect

two

different

voltage

elements

to

the

same

pin.

Thus

accidental

shorts

are

avoided.

5.

Short

Test:

In

the

Model 539C, Hickok

has

introduced

an

entirely

new

concept

in

short

and

leakage

testing.

In addition to

the

conventional neon

lamp

short

indication,

there

is

a d.

c.

leakage

test

which

registers

up to

SO

megohms

on

the

scale

of

the

large

Gm

meter.

Neon

Lamp

Short

Test.

Turning

the

SHORTS switch

successively

through

the

posi-

tions

1-2-3-4-5

connects

the

various

pairs

of

elements

inhurn

across

the

test

voltage.

Tubes

having

shorted

elements

will

complete

the

circuit

and

cause

the neon SHORT

lamp

to glow.

Tubes

may

be

tested

for

shorts,

either

hot

or

cold.

Normal

sensitivity

of

the neon

lamp

is

about

1/3

Megohni.

A

short

is

indicated

by a

steady

glow of

the

neon

lamp

in

certain

positions

of

the

SHORTS switch. A

shorted

tube should

be

discarded

without

further

test.

An

improved

neon

Short

Test

is

incorporated

in

the

design

of

this

tube

tester.

Wide

experience

has

demonstrated

t.":lat

most

satisfactory

results

are

obtained when

tubes

are

classified

for

short

test

purposes.

The

toggle switch

is

thrown to

miniature

and

subminiature

position

for

all

subminia-

ture,

button

seven

pin

and

button nine pin

tubes.

The

other

position

is

used

for

tubes

having

regular

base

pins,

including

loktal

base

tubes.

6. Locating Shorted

Elements

by Neon

Lamp.

In the following

table

(X)

under

any pOSi-

tion

indicates

that

the

neon

lamp

glows in

that

position.

- 2 -

KIND

OF

SHORT

I 2 3 4 5

HEATER -CATHODE X

HEATER

-

GRID

X X

HEATER

-

SCREEN

X X X

HEATER -PLATE X X X X

HEATER -

SUPPRESSOR

X X X X X

CATHODE

-

GRID

X

CATHODE

-

SCREEN

X X

CATHODE

-PLATE X X X

CATHODE

-

SUPPRESSO~

X 'X X X

GRID

-

SCREEN

X

GRID

-PLATE X X

GRID

-

SUPPRESSOR

X X X

SCREEN

-PLATE X

SCREEN

-

SUPPRESSOR

X X

PLATE -

SUPPRESSOR

X

6a~

Heater

Cathode

Leakage:

A

particularly

troublesome

defect

in

tubes,

especially

those

used

in

television,

is

a

leakage

between

heater

and

cathode.

This

leakage

may

be

quite

high,

somet.imes

running

to

several

megohms.

It

may

be

too high to

cause

the

neon

lamp

to glow

in

the

ordinary

way. However,

these

leaks

may

be

de-

tected

on

your

new 539C.

You will

note

that

a

heater-cathode

short

will

cause

the

neon

lamp

to glow on

posi-

tion 1 (one). While

the

short

switch

is

resting

on

position

1 (one),

during

short

test

operation

a

condenser

will

be

charging

through

the

leak.

If

the

switch

is

turned

from

position

1 (one)

to

position

2 (two), a

sharp

flash

of

the

neon

lamp

will

be

seen.

This

will

not

repeat

until the

switch

is

again

turned

to

position

1 (one) allowing

the

condenser

to

recharge

through

the

leakage.

Many baffling

cases

of

trouble

can

be

located

in

this

way.

It

has

been

established

that

heater

cathode

leakage

as

high

as

30

megohms

will

cause

"noise"

in

repeater

circuits

in

television

service

on

coaxial

lines.

6b.

Noise

Test:

The

short

test

circuit

is

also

used

in

making

noise

tests

on

vacuum

tubes.

Connections

are

made

from

the

nOise

test

jacks

to

the

antenna

and

ground

posts

of

any

radio

receiver.

The

tube

under

test

is

tapped

with

the

finger

as

the

SHORTS

switch

is

turned

through

positions

1-2-3-4-5.

Intermittent

disturbances

which

are

too

brief

to

register

on

the

neon

lamp

will

be

re-

produced

by

the

loud

speaker

as

static.

7.

Leakage

Test

on

Meter:

An

added

feature

in

the

Model 539C

is

its

ability

to

measure

element

leakage

up to 50

megohms

on

the

dial

of

the

large

Gm

meter.

The

research

- 3 -

engineer

and

technician

will find

this

feature

a

great

aid

in

routine

investigations.

Every

engineer

knows

that

in

certain

tube

applications,

leakage

is

more

significant

than in

others.

The

metered

leakage

feature

of

the

Model 539C

will

enable

him to

form

sound judgment

as

to

the

leakage

to

be

tolerated

in

different

applications.

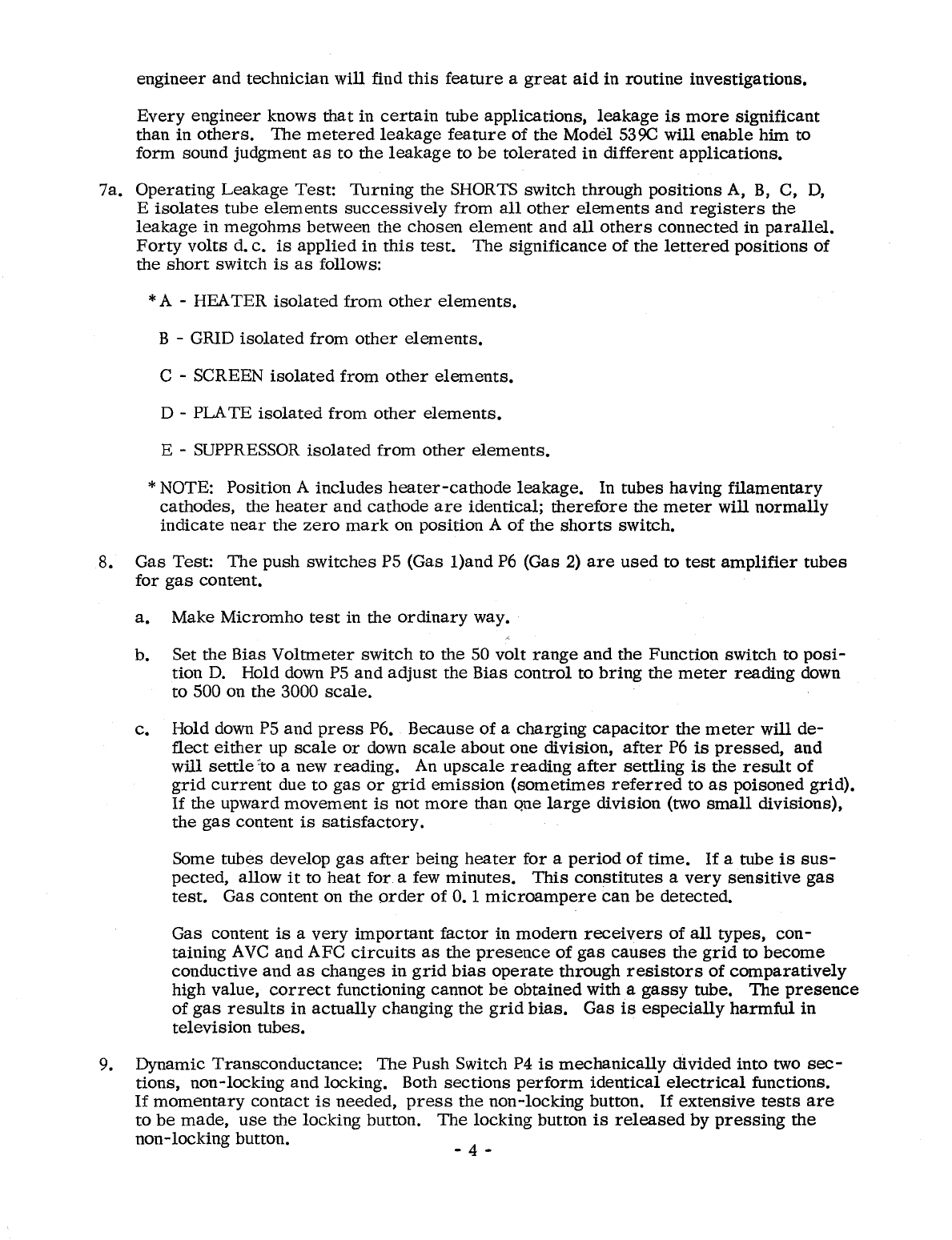

7a.

Operating

Leakage

Test:

Thrning

the SHORTS

switch

through

positions

A,

B,

C,

D,

E

isolates

tube

elements

successively

from

all

other

elements

and

registers

the

leakage

in

megohms

between

the

chosen

element

and

all

others

connected

in

parallel.

Forty

volts

d.

c.

is

applied

in

this

test.

The

significance

of

the

lettered

positions

of

the

short

switch

is

as

follows:

*A - HEATER

isolated

from

other

elements.

B - GRID

isolated

from

other

elements.

C - SCREEN

isolated

from

other

elements.

D - PLATE

isolated

from

other

elements.

E - SUPPRESSOR

isolated

from

other

elements.

*NOTE: Position A

includes

heater-cathode

leakage.

In

tubes

having

filamentary

cathodes,

the

heater

and

cathode

are

identical;

therefore

the

meter

will

normally

indicate

near

the

zero

mark

on

position

A

of

the

shorts

switch.

8.

Gas

Test:

The

push

switches

P5 (Gas

l)and

P6

(Gas

2)

are

used

to

test

amplifier

tubes

for

gas

content.

9.

a.

Make

Micromho

test

in the

ordinary

way.

b. Set

the

Bias

Voltmeter

switch

to the 50

volt

range

and

the

Function

switch

to

posi-

tion

D.

Hold down

P5

and

adjust

the

Bias

control

to

bring

the

meter

reading

down

to 500 on

the

3000

scale.

c.

Hold down P5

and

press

P6.

Because

of

a

charging

capacitor

the

meter

will

de-

flect

either

up

scale

or

down

scale

about one division,

after

P6

is

pressed,

and

will

settle

'to a new

reading.

An

upscale

reading

after

settling

is

the

result

of

grid

current

due

to

gas

or

grid

emission

(sometimes

referred

to

as

pOisoned

grid).

If

the

upward

movement

is

not

more

than

Qne

large

division (two

small

divisions),

the

gas

content

is

satisfactory.

Some

tubes

develop

gas

after

being

heater

for

a

period

of

time.

If

a tube

is

sus-

pected,

allow

it

to

heat

for. a few

minutes.

This

constitutes

a

very

sensitive

gas

test.

Gas

content

on the

order

of

O.

1

microampere

can

be

detected.

Gas

content

is

a

very

important

factor

in

modern

receivers

of

all

types,

con-

taining A

VC

and

AFC

circuits

as

the

presence

of

gas

causes

the

grid

to

become

conductive

and

as

changes

in

grid

bias

operate

through

resistors

of

comparatively

high value,

correct

functioning cannot

be

obtained

with a

gassy

tube.

The

presence

of

gas

results

in

actually

changing

the

grid

bias.

Gas

is

especially

harmful

in

television

tubes.

Dynamic

Transconductance:

The

Push Switch

P4

is

mechanically

divided

into

two

sec-

tions, non-locking

and

locking. Both

sections

perform

identical

electrical

functions.

If

momentary

contact

is

needed,

press

the

non-locking button.

If

extensive

tests

are

to

be

made,

use

the locking button.

The

locking button

is

released

by preSSing

the

non-locking button. - 4 -

The

indicating

meter

will

register

the

tube's

value

in

eight

ranges:

A. 60, 000

f-lmho

at

.25

Volt

signal.

B.

30, 000

f-lmho

at

.25

Volt

signal.

C. 15, 000

f-lmho

at

.25

Volt

signal.

D.

6, 000

IJ.mho

at

.5

Volt

signal.

E.

3,000

j1.ffiho

at

2.5

Volt

signal.

F.

600

IJ.mho

at

1.

Volt

signal.

G.

Rectifiers

and Diodes, no

signal.

H. Voltage

Regulator

tubes.

The

600

micromho

range

was

designed

especially

to

test

subminiature

tubes.

Low

plate

and

screen

volts

are

automatically

applied

when FUNCTION switch

is

set

on

posi-

tion

F.

The

FUNCTION switch

automatically

changes

the

signal

volts

when the

appropriate

setting

is

made.

The

chart

setting

for

the

tube to

be

tested

will

indicate

where

the

FUNCTION switch

should

be

set,

such

as

A,

B,

C,

D,

E,

F,

G

or

H,

in

the

column

preceding

Micromhos.

The

Micromho

values

printed

on the

data

roll

are

minimum

values.

Good

tubes

will

read

above

these

values.

In

the

column

headed

BIAS

VOLTS

is

listed

the

exact

voltage

to which the

BIAS

VOLTS

meter

is

to

be

set

when

testing

a tube. Make final

bias

adjustment

after

the

P4

button

is

pressed.

Certain

pemode tubes, such

as

the

3A4,

are

tested

with

reduced

screen

voltage.

This

is

accomplished

by holding down

PI

and

pressing

P4. Specific

instructions

are

printed

in

the

NOTATIONS column

for

each

tube

requiring

reduced

screen

voltage.

10.

Rectifier

Test.

The

push

switches

PI,

P2

and

P3

are

used

to

test

various

types

of

rectifier

elements.

a.

The

push

switch

PI

is

used

when

testing

detector

diodes~

It

applies

a low

voltage which will not

injure

the

delicate

cathode. Good diodes

will

cause

the

meter

pointer

to

read

above

mark,

RECTIFIERS

and

DIODES O.

K.

b. Push switch

P2

is

used

when

testing

cold

cathode

rectifiers

such

as

the OZ4.

This

applies

a voltage sufficiently high

to

ionize

the tube

and

start

conduc-

tion.

,.,.

Good tubes will

read

above the

mark,

RECTIFIERS

and

DIODES

O.

K.

c.

Push switch

P3

is

used

when

testing

ordinary

rectifier

tubes

such

as

the

SY3.

This

switch

applies

a

medium

voltage which

is

best

adapted

to

reveal

defects

in

this

type

of

tube. Goad

tubes

will

read

above

the

mark,

RECTI-

FIERs

and

DIODES

O.

K.

In the

chart

column

headed

SHUNT

are

listed

the

numbers

to which the SHUNT

dial

is

to

be

set

when

testing

Rectifiers

and Diodes.

- 5 -

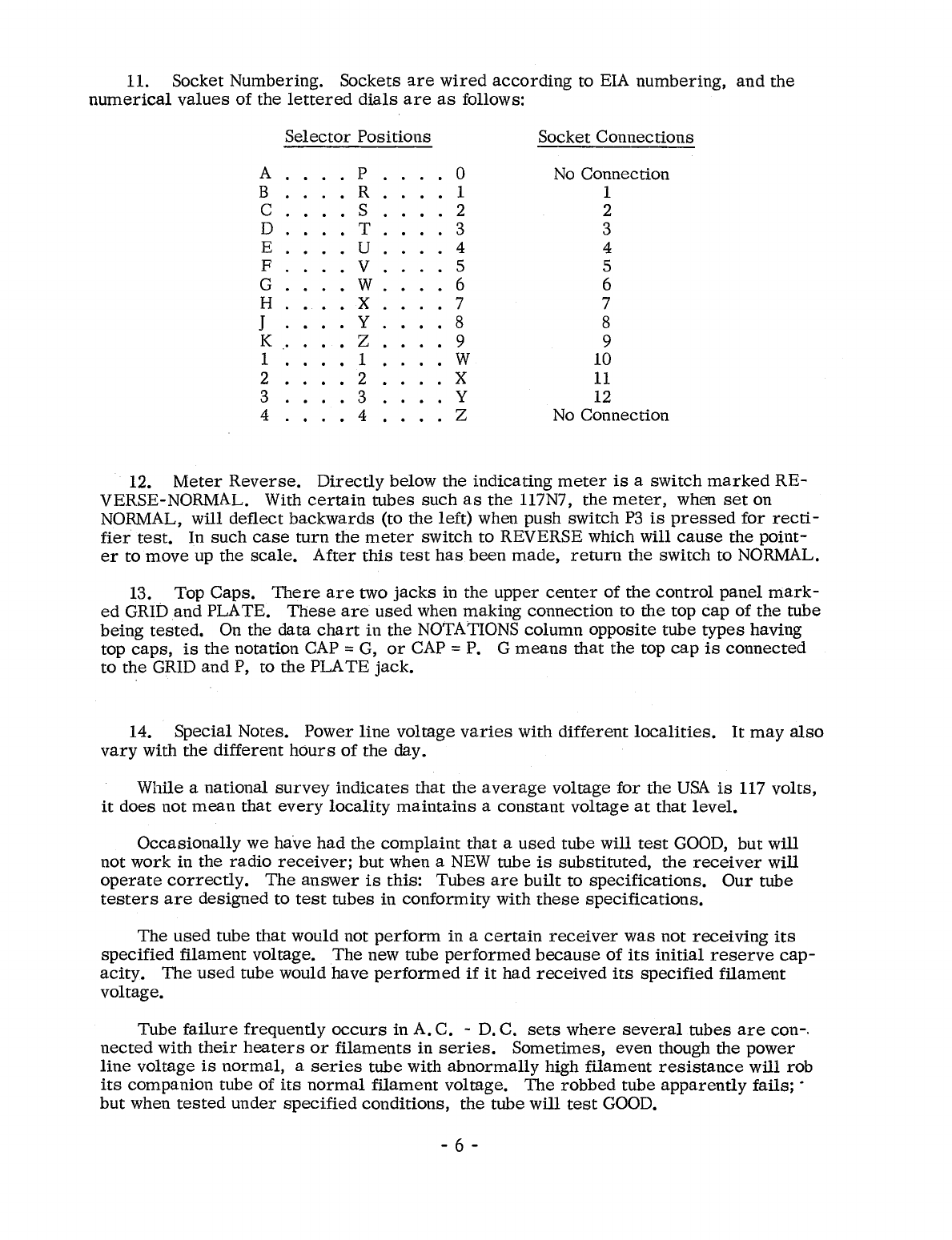

11. Socket

Numbering.

Sockets

are

wired

according

to EIA

numbering,

and

the

numerical

values

of

the

lettered

dials

are

as

follows:

A

B

C

D

E

F

G

H

J

K

1

2

3

4

Selector

Positions

P

R

S

.T

U

V

.W

.X

Y

••

Z

1

••

2

3

. 4

o

1

2

3

4

5

6

7

8

9

W

X

y

Z

Socket

Connections

No

Connection

1

2

3

4

5

6

7

8

9

10

11

12

No

Connection

12.

Meter

Reverse.

Directly

below

the

indicating

meter

is

a

switch

marked

RE-

VERSE-NORMAL. With

certain

tubes

such

as

the

117N7,

the

meter,

when

set

on

NORMAL,

will

deflect

backwards

(to

the

left)

when

push

switch

P3

is

pressed

for

recti-

fier

test.

In

such

case

turn

the

meter

switch

to

REVERSE which

will

cause

the

point-

er

to

move

up

the

scale.

After

this

test

has

been

made,

return

the

switch

to NORMAL.

13. Top

Caps.

There

are

two

jacks

in

the

upper

center

of

the

control

panel

mark-

ed

GRID

and

PLATE.

These

are

used

when

making

connection

to

the

top

cap

of

the

tube

being

tested.

On the

data

chart

in

the

NOTATIONS

column

opposite

tube

types

having

top

caps,

is

the

notation CAP =

G,

or

CAP =P. G

means

that

the

top

cap

is

connected

to

the

GRID

and

P,

to

the

PLA

TE

jack.

14.

Special

Notes.

Power

line

voltage

varies

with

different

localities.

It

may

also

vary

with

the

different

hours

of

the

day.

While a

national

survey

indicates

that

the

average

voltage

for

the

USA

is

117

volts,

it

does

not

mean

that

every

locality

maintains

a

constant

voltage

at

that

level.

Occasionally

we

have

had

the

complaint

that

a

used

tube

will

test

GOOD,

but

will

not

work

in the

radio

receiver;

but

when a

NEW

tube

is

substituted,

the

receiver

will

operate

correctly.

The

answer

is

this:

Tubes

are

built

to

specifications.

Our

tube

testers

are

designed

to

test

tubes

in

conformity

with

these

specifications.

The

used

tube

that

would not

perform

in a

certain

receiver

was

not

receiving

its

specified

filament

voltage.

The

new

tube

performed

because

of

its

initial

reserve

cap-

acity.

The

used

tube would have

performed

if

it

had

received

its

specified

filament

voltage.

Tube

failure

frequently

occurs

in A.

C.

-

D.

C.

sets

where

several

tubes

are

con-.

nected

with

their

heaters

or

filaments

in

series.

Sometimes,

even

though the

power

line

voltage

is

normal,

a

series

tube with

abnormally

high

filament

resistance

will

rob

its

companion tube

of

its

normal

filament

voltage.

The

robbed

tube

apparently

fails;

.

but

when

tested

under

specified

conditions,

the

tube

will

test

GOOD.

- 6 -

The

Model 539C

is

valuable

in

matching

tubes

for

push-pull

stages

and

other

appli-

cations

where

matched

tubes

are

essential.

15.

Life

Test.

The

Model 539C DYNAMIC MUTUAL CONDUCTANCE TUBE

TES-

TER

is

equipped with a

special

feature

to

enable

Life

Test

to

be

made

on

the

tube. In

the

center

of

the

control

panel

is

a

switch

designated

CATH.

ACT.,

NORM.

and

TEST.

While

holding

everything

else

at

normal

this

switch

reduces

the

filament

voltage

by

10%.

a.

Measure

the

mutual

conductance

in

the

ordinary

way with

switch

set

on

NOR-

MAL.

b.

Throw

the

CATH.

ACT.

switch

to

TEST

position.

The

mutual

conductance

should

not

drop

more

than 20%.

c.

After

making

life

test

return

the

switch

to NORMAL

for

all

other

tests.

In

testing

the

35Z5

and

45Z5

rectifier

tubes

it

is

advisable

to

turn

the

power

off

for

about

15

seconds

after

throwing

the

CATH.

ACT.

switch

to

TEST

to allow

the

cathode

to

cool.

Then

turn

the

power

on

and

note

new

reading

of

the

meter.

16.

Self

Bias.

Provision

is

made

to

test

tubes

under

self

bias

condition. In

the

up-

per

edge

of the

control

panel

are

two binding

posts

designated

SELF

BIAS.

These

posts

are

normally

shorted

by

an

attached

bar.

To

use

SELF

BIAS,

connect

a

suitable

bias

re-

sistor

together

with

an

electrolytic

capacitor

of

2000

I.Ltd

in

parallel

across

these

binding

posts.

The

positive

terminal

of

the

capacitor

should

be

connected

to

the

positive

binding

post.

The

toggle

switch

in

the

upper

left

of the

control

panel

is

thrown

from

NORMAL

po-

sition

to the

SELF

BIAS

position.

The

bias

volts

under

self

bias

condition

depends

upon

the

value

of

the

resistor

inserted

between

the

self

bias

posts

mentioned

above,

and

also

upon

the

plate

current

flowing.

Tube

handbooks

can

be

used

as

a

guide

to

the

value

of

the

self

bias

resistance

to

use.

When

completing

the

self

bias

test,

reconnect

the

two binding

posts

by

the

normal

short-

ing

bar

and

throw

the toggle

switch

back

to

the

NORMAL

position.

17.

Plate

Current.

In the

upper

center

of

the

control

panel

are

two

posts

designated

PLA

TE

CURRENT.

These

posts

are

normally

shorted

by

an

attached

bar.

A

suitable

low

resistance

D.

C.

milliammeter

connected

across

these

posts

will

measure

the

plate

current

flowing

through

the

tube being

tested.

Connect

the

positive

terminal

of

the

meter

to

the

positive

binding

post.

NOTE

A

D.

C.

milliammeter

connected

into

the

SELF

BIAS

circuit

will

measure

the

total

cathode

current.

In

measuring

rectifier

tube

current

the

meter

reading

must

be

multiplied

by two,

because

rectifier

tubes

conduct

only

during

a

positive

half-cycle,

whereas

the

meter

integrates

over

a

complete

cycle.

In

checking

thyratrons

such

as

the

884

and

885,

the

bias

voltmeter

should

be

set

initially

at

its

highest

negative

value

(about 40

volts).

The

designated

button

is

held

down

while

the

bias

voltage

is

gradually

reduced

until

the

tube"

strikes",

that

is,

begins

to

con-

duct, which

is

indicated

by a

sudden

deflection

of

the

meter.

The

chart

indicates

the

ap-

proximate

voltage

at

which the

tube

strikes.

There

may

be

a

small

variation

above

or

be-

- 7 -

low

the

given

striking

voltage.

The

meter

indication for a good tube

is

above the point

designated

"RECTIFIERS OK".

18.

Filament

and

Heater

Continuity.

1.

Turn

the

tester

on.

2.

Set the

selectors

as

per

chart

for

the tube to

be

tested.

3. Set

the

FILAMENT switch on BLST

instead

of

voltage

indicated

on

the

chart.

4. Set

the

SHORT

TEST

switch

on

position

5.

5.

Place

the

tube in the

proper

socket.

If

the neon

lamp

glows,

the

filament

is

good

and

a

complete

test

should then

be

made

on the tube, by

setting

FILAMENT

switch

on the

proper

tap,

and

while the tube

heats,

rotate

the SHORT TEST SWITCH

several

times

thru

1 to 5

positions.

If

no

shorts

are

in-

dicated,

set

the

switch in TUBE

TEST

position

and

proceed

to

test

the

tube

as

per

chart.

If

the neon

lamp

does not glow, the

filament

is

open

and

further

test

is

unnecessary.

Certain

tubes

such

as

the

35Z5-50Z7,

etc.,

with tapped

filaments

have

special

continuity

test

settings;

see

roll

chart.

NOTE

It

sometimes

happens

that

a

filament

will show

con-

tinuity when cold, but will open when

it

warms

up.

19. Voltage

Regulator

Tubes.

a.

Set

the

selectors

for

V.

R. tube to

be

tested.

The

test

data

for

V. R.

tubes

will

be

found

at

the top

end

of

the

roll

chart.

For

example,

the

OA3.

b.

Set

FIL

VOLTAGE switch to

OFF.

c.

Set

selector

switches

to AP-0502-0.

d. Set function

switch

on

range

H,

V. R. TEST.

e.

Turn

the

bias

volts

toggle switch to V. R.

volts

and

mils.

f.

Turn

V.

R.

volts

knob fully

counter

clockwise.

g.

Turn

power

adjust

knob fully

clockwise.

Press

P4-LOCK.

h.

Place

V.

R. tube in

proper

socket

and

turn

power

ON.

i.

Turn

V.

R.

voltage

control

knob slowly

clockwise.

The

large

Gm

meter

should

start

to

read

d.

c.

volts

on

the

0-200

volt

scale.

j.

Example: In the

notations

column

for

the

OA3

tube

appears,

"Starts

at

about

100 Volts -Regulation = 5

volts

from

5 to 40 mao

".

In

the

column

marked

MIN. MUT.

CONDo

is

the nominal

operating

voltage for

this

tube -75V.

k. When

the

V. R. tube

strikes

as

explained in (j) above, the

voltmeter

reading

will drop

back

to

operating

voltage.

The

V. R.

current

is

read

on

the

0-100

- 8 -

m.

a.

range

of

the

bias

meter.

1.

For

the

OA3

example

adjust

the

m.

a.

current

from

5

to

40

milliamperes

by

turning

the V. R.

volts

and

mils

knob.

The

OA3

tube

should-not

exhibit

a

voltage

change

of

more

than 5

volts.

m.

When

completing

a

V.

R. tube

test

unlock P4

push

button.

20.

Ohmmeter

Feature.

The

Model 539C

tube

tester

can

be

used

as

a

utility

ohm-

meter

as

follows:

a.

Set

the

SHORTS

switch

on

position

B.

b.

Connect

two

prod

leads

into

the

grid

and

plate

jacks

in

the

center

of

the

con-

trol

panel.

The

red

plate

jack

will

be

the

positive

lead.

c.

Touch

together

the

two

prods

and

adjust

the

ohmmeter

pointer

to

zero.

Re-

sistance

up to 50

megohms

can

be

read

directly

on

the

megohm

range.

d.

Electrolytic

capacitors

can

be

checked

for

leakage.

Observe

that

the

red

(plate)

jack

is

connected

to

the

positive

pole

of

the

capacitor.

21. NORMAL-LOW

Plate

Volts.

In

the

NOTATIONS

column

of

the

data

chart

for

some

tubes

will

be

found PLATE VOLTS =LOW.

This

notation

indicates

that

the

PLATE

VOLTS

switch

located

just

above

the

FUNCTION

switch

is

to

be

set

on

the

LOW

position.

Return

the

switch

to NORMAL

for

all

other

tubes.

22.

Heater

-

Current.

In

the

lower

right

hand

corner

of

the

panel

will

be

found two

binding

posts

which

are

normally

connected

together

by

a

jumper.

By

removing

this

jumper

and

connecting

a

suitable

Milliammeter

or

Ammeter

between

these

two binding

posts,

the

indicating

instrument

will

read

the

current

being

drawn

by

the

heaters

of

the

tube

under

test.

The

actual

voltage

at

the

tube

under

test

will

be

the

voltage

as

indicated

by

the

fila-

ment

selector

switch

minus

the

voltage

drop

across

the

indicating

Milliammeter

or

Am-

meter.

This

voltage

will

generally

be

of

a

very

low

magnitude,

but

can

be

calculated

by

mUltiplying the

current

normally

drawn

by

the

tube

under

test

by

the

impedance

of

the

meter

connected

in

series

with

this

tube,

or

it

can

be

actually

measured

with

a

sensitive

AC

Voltmeter.

If

the

impedance

of

the

meter

is

much

more

thanO.

2

ohms,

the

voltage

drop

might

be

appreciable

percentage-wise

to

the

voltage

delivered

to

the

tube.

For

example,

if

the

current

at

the

tube

is

normally

0.6

amperes,

and

the

impedance

of

the

current

measuring

instrument

were

O.

5

ohms,

the

resultant

loss

would

be

the

product

of

these

two,

or

O.

3

of

one volt.

23. Pilot

Lamp

Testing.

The

center

of

the

large

7-pin

socket

is

used

to

check

pilot

lamps.

Set

the

filament

selector

switches

on HR.

Set

the

filament

voltage

switch

to

the

proper

voltage

for

the

lamp

being

tested.

- 9 -

TO

TEST

BALLAST TUBES

1.

Turn

Tester

on.

2. Set

filament

switch

to BLST.

3. Set SHORT

TEST

switch

on

5.

4. Set

first

selector

switch to

letter

shown

in

column

marked

(first

selector

switch). Set

all

numbered

selectors

on

zero.

5. ROTA

TE

second

selector

switch. NEON LAMP SHOULD LIGHT IN POSITIONS NOTED.

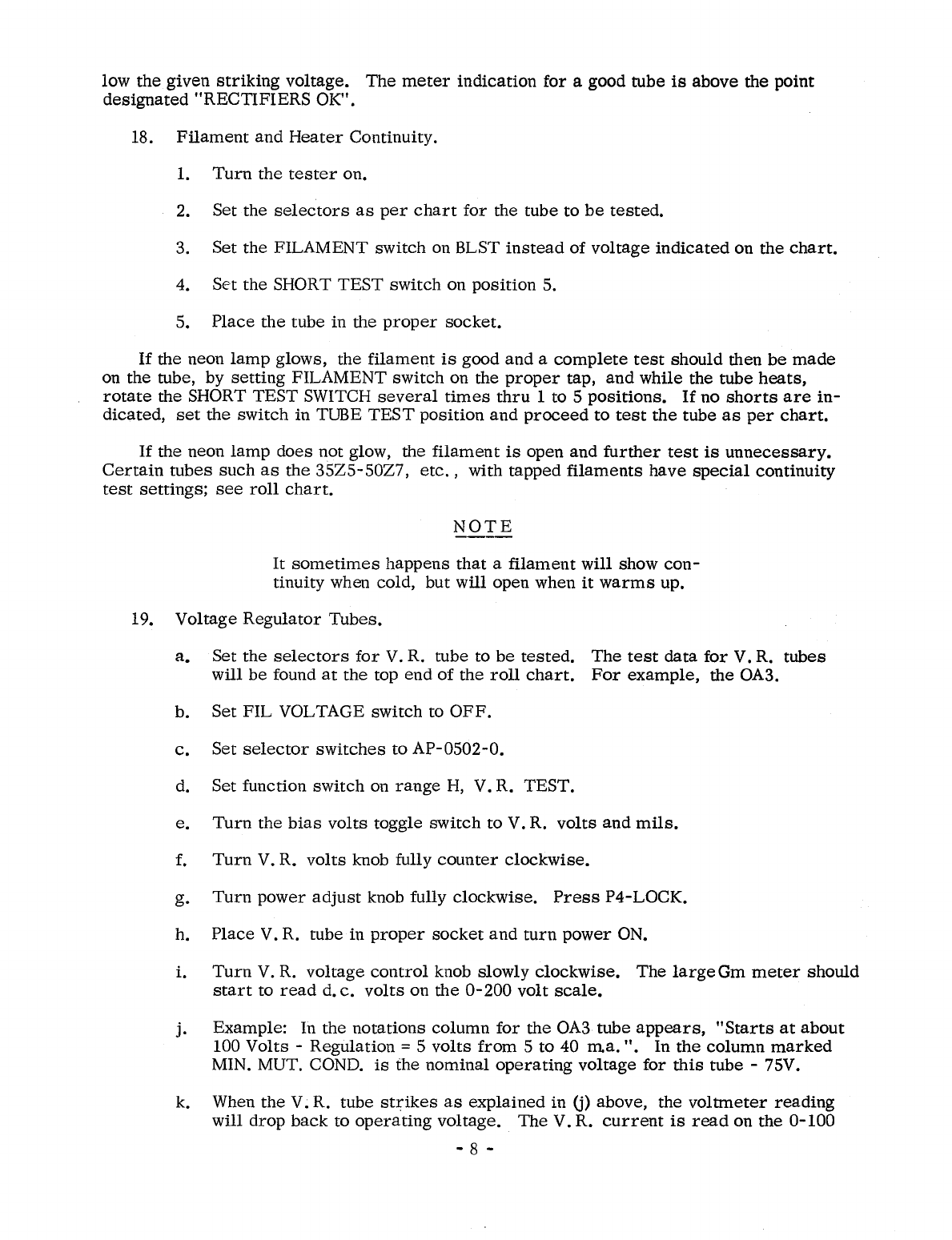

First

Neon

Lamp

Should

Light

TUBE TYPE

Selector

in

these

positions

1A1-IB1-1C1-1E1-1F1-1G1-1]I-lK1-1V1

E R

1Y1-1Z1

IL1-1N1-1P1-1QI-1R1G-1SIG-1

T1G-1U1G H S

2 E R

2UR224 H T Y

2LR212 J R S U

3 E R

03G

H T

4-5

E R

6-133 H T

6-6AA-7-8-9

E R

10A-lOAG H T

lOAB

E R

Kl7B-M17C-BM17C H T Y

M17HG-M17H H R Y

D S

K23B-K23C H T Y

KX23B

E R T

KX30C E R T

M30H H R Y

D S

30A-K30A H T

K30D H S T Y

33A-33AG H T

K34B

H T Y

36A H T

K36B-BK36B-L36B-L36C H T Y

KX36Z E R

KX36C E R T

36D-L36D H S T Y

L360T H R S T U Y

K36H-M36H-M36HG H R Y

D S

40A1 H S

L40SI-L40S2 H S T V

42A

H T

-10 -

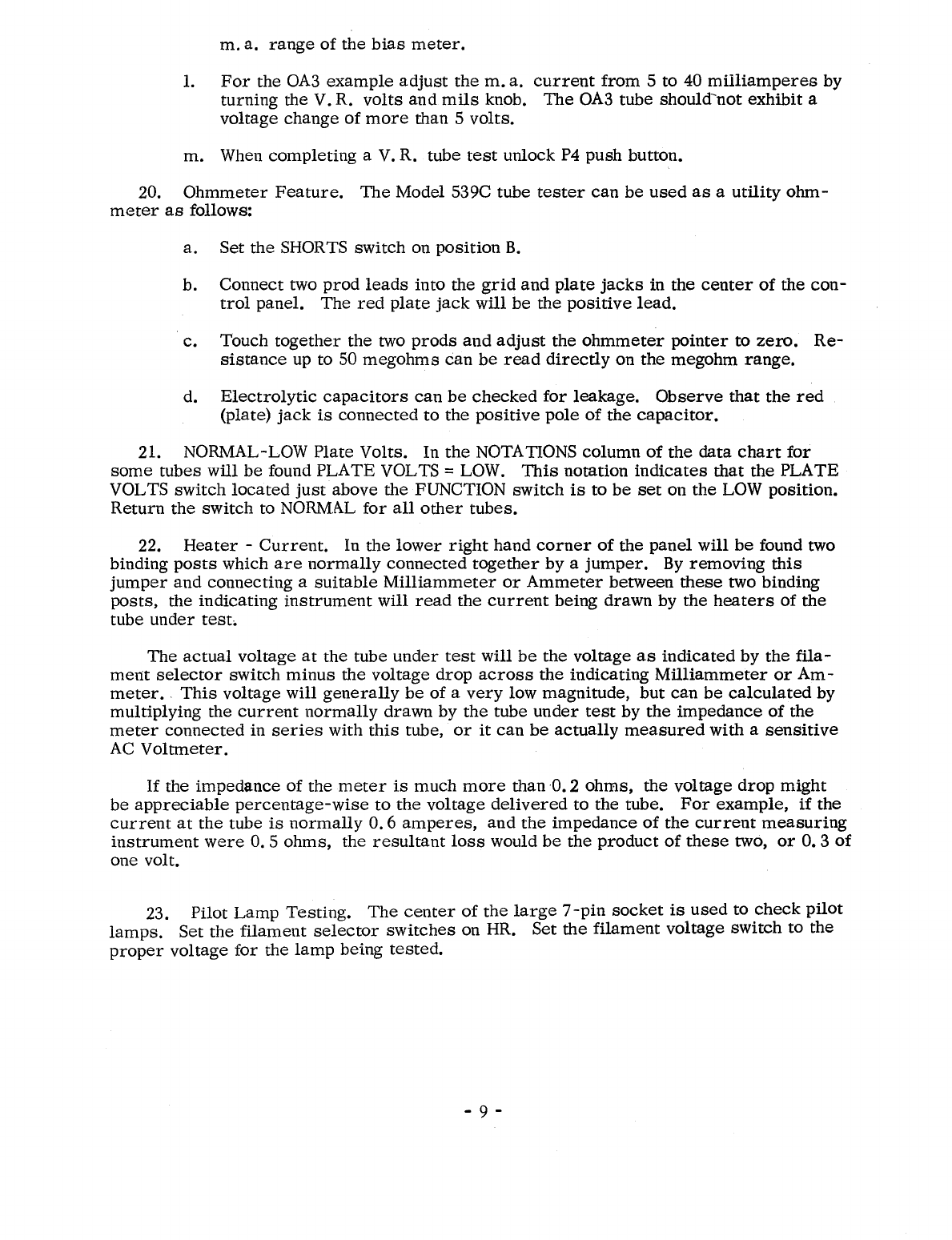

First

Neon

Lamp

Should

Light

TUBE TYPE

Selector

in

these

;x>sitions

42AI

J U

42A2-42B2 J R U

K42B

-L42B-M42B H T Y

KX42B-LX42B-L42BX E R T

K42C-L42C-M42C

H T Y

BK42D-K42D-

L42D

H S T Y

LX42D-L42DX E R S T

K42E-L42E

H T Y

L42F

H Y

0 S

42HA-42HJ H R

E S T

M42H-M42HG H R

,y

0 S

KX42C E R T !

L42S1 H S T V i

49A-49AJ-K49AJ H T

KX49A E R T

49AI

J U

49A2-49B2 J R U

K49B-L49B-M49B-BM49B-K49C H T y

M49C-BM49C-BK49C-

K49E-

L49E

,

K49D-BK49D-

L49D

H S T Y

L49F

H Y

0 S

M49H-M49HG H R Y

0 S

KZ49B-KZ49C H S ; V

K49BJ

-L49BJ H T U Y

L49S2 H S T

:V

49AJ-K49AJ H T

KX49B-LX49B-LX49C E R T ,

L49DJ H S T U Y

L49S3 H S T V

50A2 E R T

50A2MG-50B2 H S V

50X3 E R

K52H-M52H H R Y

0 S

K54B

H T Y

55A-K55A H T

55Al

I

U'

KX55A E R

55B-K55B-M55B-BM55B-L55BG H T Y

LX55B E R T ;

55A2-55B2 J R U ;

K55C-L55C H T

Ii

I y

I

-

11

-

First

Neon

Lamp

Should

Light

TUBE TYPE

Selector

in

these

?Ositions

KXSSC E R T

KSSCP H T V Y

KSSD-LSSD H S T Y

LSSE-MSSE H T Y

LSSF-MSSF-BLSSF H Y

D S

KSSH-MSSH-MS5HG H R Y

D S

LSSSl-LS5S2 H S T V

60R30G E R T

64.23

H T

-

67A H T

K67B-L67B H T Y

L73B-K74B-L74B H T Y

KX74C E R T

80A H T

K79B-K800-K8OC-L80B H T Y

KX80B

E R T

K80F H Y

D S

KX87B-LX87B E R T

L90B H T Y

K90F-M90F-K92F-M92F

H Y

D S

92A H T

L92B-95K2 H T Y

L99D

H S T Y

lOOR8

E R T

120R E R

120R8 E R T

13SK1 H T Y

13SK1A H T U Y

140L4-140L8-140R4-140R8

E R T

140R E R

140L44 E R T

140R44 E R S T

16SL4-16SR4-16SR8 E R T

16SR E R

16SL44-16SR44 E R S T

18SL4-185L8-18SR4-18SR8 E R T

185R E R

18SL44-185R44 E R S T

200R-2S0R E R

2S0R8 E R T

290L4 E R T

300R4-320R4 E R T

340 E R

R08-1

H T U Y

-12 -

First

Neon Lamp Should Light

TUBE

TYPE

Selector

in

these

positions

E14980-W43357-W45788-3613

H T Y

3334-3334A

H S T Y

-

3613 H T Y

8593-8598-8601-8664

H T Y

3CR241

H S T Y

3ER248

H S T U y

--

B9M15822 C T

E V

G X Y

B9M16067 H S T V W y

1B9M16275 C T U V W X Y

1B9M16534 H S T V W y

B9M17571 J S T

H U V Y

B9M18941 C R T

E V

G X Y

17A470303 H R S V

J W

E T

17A485459 H R S W

E T

TBR102D-TBR104D C R T U V

G X Y

TBR103D C R U V

G X Y

397021 C R T

-'

397022

E V W

397023 H Y

397036

. B V

R S V

r-.

407100,

H

408100 H R S V

D U

gYl407300 H S T V W Y

571606 C R T

E V W

H Y

-13 -

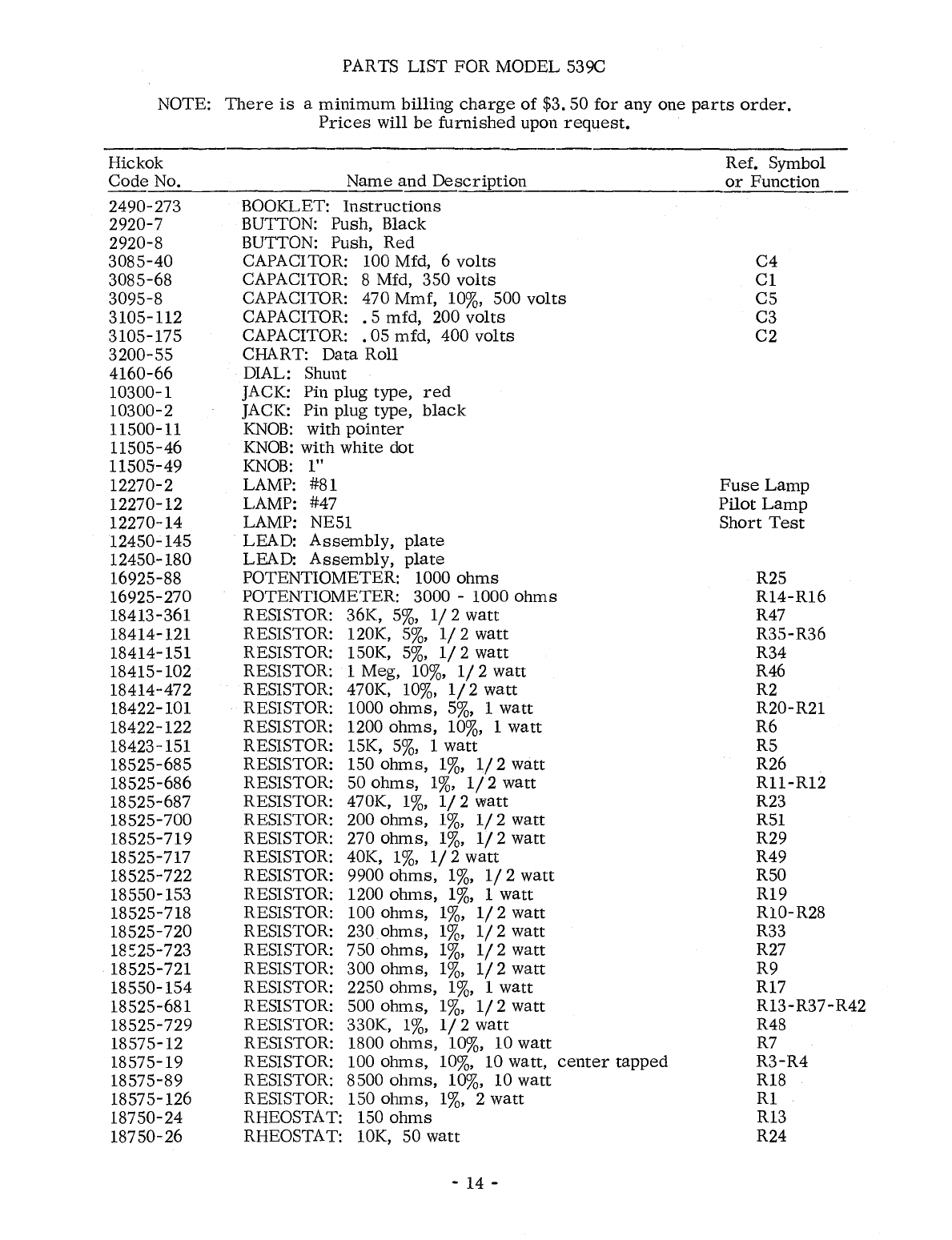

PARTS LIST FOR MODEL 539C

NOTE:

There

is

a

minimum

billing

charge

of

$3. 50

for

anyone

parts

order.

Prices

will

be

furnished

upon

request.

Hickok Ref. Symbol

Code

No.

Name

and

Description

or

Function

~~--------------~~-~~~~~~~------.-------------~~~~~

2490-273 BOOKLET:

Instructions

2920-7 BUTTON: Push, Black

2920-8 BUTTON: Push,

Red

3085-40

CAPACITOR: 100 Mfd, 6

volts

3085-68 CAPACITOR: 8 Mfd, 350

volts

3095-8 CAPACITOR: 470 Mmf,

10%,

500

volts

3105-112 CAPACITOR:

.5

mfd, 200

volts

3105-175 CAPACITOR:

.05

mfd,

400

volts

3200-55

CHART: Data Roll

4160-66 DIAL: Shunt

10300-1 JACK: Pin plug type,

red

10300-2 JACK: Pin plug type,

black

11500-11

KNOB:

with

pointer

11505-46

KNOB:

with

white

dot

11505-49

KNOB:

1"

12270-2 LAMP: #81

12270-12 LAMP: #47

12270-14 LAMP: NE51

12450-145 LEAD:

Assembly,

plate

12450-180 LEAD:

Assembly,

plate

16925-88 POTENTIOMETER: 1000

ohms

16925-270 POTENTIOMETER: 3000 -1000

ohms

18413-361 RESISTOR: 36K,

5%,

1/2

watt

18414-121 RESISTOR: 120K,

5%,

1/2

watt

18414-151 RESISTOR: 150K,

5%,

1/2

watt

18415-102 RESISTOR: 1 Meg,

10%,

1/

2

watt

18414-472 RESISTOR: 470K,

10%,

1/2

watt

18422-101 RESISTOR: 1000

ohms,

5%,

1

watt

18422-122 RESISTOR: 1200

ohms,

10%,

1

watt

18423-151 RESISTOR: 15K,

5%,

1

watt

18525-685 RESISTOR: 150

ohms,

1%,

1/2

watt

18525-686 RESISTOR: 50

ohms,

1%,

1/2

watt

18525-687 RESISTOR: 470K,

1%,

1/2

watt

18525-700 RESISTOR: 200

ohms,

1%,

1/2

watt

18525-7l9

RESISTOR: 270

ohms,

1%,

1/2

watt

18525-717 RESISTOR: 40K,

1%,

1/2

watt

18525-722 RESISTOR: 9900

ohms,

1%,

1/2

watt

18550-153 RESISTOR: 1200

ohms,

1%,

1

watt

18525-7l8

RESISTOR: 100

ohms,

1%,

1/2

watt

18525-720 RESISTOR: 230

ohms,

1%,

1/2

watt

18::25-723 RESISTOR: 750

ohms,

1%,

1/2

watt

18525-721 RESISTOR: 300

ohms,

1%,

1/2

watt

18550-154 RESISTOR: 2250

ohms,

1%,

1

watt

18525-681 RESISTOR: 500

ohms,

1%,

1/2

watt

18525-729 RESISTOR: 330K,

1%,

1/2

watt

18575-12 RESISTOR: 1800

ohms,

10%, 10

watt

18575-19 RESISTOR: 100

ohms,

10%,

10 watt,

center

tapped

18575-89 RESISTOR: 8500

ohms,

10%, 10

watt

18575-126 RESISTOR: 150

ohms,

1%,

2

watt

18750-24 RHEOSTAT: 150

ohms

18750-26 RHEOSTAT: 10K, 50

watt

-14 -

C4

Cl

C5

C3

C2

Fuse

Lamp

Pilot

Lamp

Short

Test

R25

R14-R16

R47

R35-R36

R34

R46

R2

R20-R21

R6

R5

R26

R11-RI2

R23

R51

R29

R49

R50

R19

R10-R28

R33

R27

R9

R17

RI3-R37-R42

R48

R7

R3-R4

R18

Rl

R13

R24

PARTS LIST FOR MODEL 539C

NOTE:

There

is

a

minimum

billing

charge

of

$3. 50

for

anyone

parts

order.

Hickok

Code No.

19350-1

19350-113

19350-364

19350-367

19350-365

19350-381

19350-383

19350-76

19350-93

19350-94

19350-95

19350-

96

19350-97

19350-98

19350-220

19910-61

19911-7

19911-55

19912-480

19912-479

19912-202

19912-304

19912-308

19912-312

20800-103

20800-169

20875-6

20875-28

Emission

Grid

Control

and

Gas

Test

Prices

will

be

furnished

upon

request.

Name

and

Description

SOCKET: Bayonet

for

81

Lamp

SOCKET: Bayonet Neon

and

Pilot

Lamp

SOCKET: 10 pin

SOCKET: Novar

SOCKET:

Compactron

SOCKET:

Nuvistor,

5 pin

SOCKET:

Nuvistor,

7 pin

SOCKET: 7 pin

miniature

SOCKET: 4 pin

SOCKET: 5 pin

SOCKET: 6 pin

SOCKET: 7 pin

SOCKET: Lokta1

SOCKET: Octal

SOCKET: Subminiature, combination 7

and

8 pin

SWITCH: Gang, 8

buttons

SWITCH:

Meter

reverse

SWITCH: Toggle DP-DT

SWITCH:

Suppressor

and Cathode

SWITCH:

Selectors

SWITCH:

Filament

Volts

SWITCH: 3 P-

DT

SWITCH: Function

SWITCH:

Short

Test

TRANSFORMER:

Filament

TRANSFORMER:

Plate

TUBE:

5Y3GT/G

TUBE:

83

TESTING TELEVISION PICTURE TUBES

WIlli

lliE

CRT-1

ADAPTER

Selectors

Fil

Bias Shunt

HS-3508-4

6.3

o G

Ref. Symbol

or

Function

Press

PI

Good

tubes

should

read

above

line

marked

RECTIFIERS

AND

DIODES

OK.

HS-5308-4

6.3

* D P5

* Hold down P5

and

rotate

Bias knob.

Meter

should

move

up

and

down

scale

if

grid

is

operation.

GAS

TEST: Hold down

P5

and

adjust

bias

until

meter

reads

one

small

division. While holding

P5

down,

press

P6.

If

meter

pointer

moves

up

scale

more

than one division, tube

is

gassy.

NOTE: In

ordering

parts

or

materials

for

this

instrument,

the

serial

number

must

be

given in

order

to

identify

properly

the

material

required.

-

15

-

01

I.

BINDING POSTS

FOR

INSERTING METER

TO

READ

~ER

CURRENT

el17

~

.75

.50

.35

~

.25

,r1

NORMA

L C

.20

TEST

!

~

o-:¥-

~

+

0R-

_ACT.

~

~

~

r-

~

~

03

<>

*

50

~

*

I-

*

~

*

~

04

50

~

~

.

BLS

OFF

g PILOT

LAMP

0 J 0

20

K

06

r--r"

L 1.2K

Pl70

M

N

170 0

F>

~5

P

~

I~~A

$

FUSE

~

lAMP

~

0

:

l~'·o

c.< S

ON

l-

F

OFF

1~160

G

POWER

1~

__

160

ri'f3f

3

0 H

~

C

r"=/

1~5

015

I~

50

E

ni

?

014 r- RI6

IK

?3K

I

I

~

L_

--

-

l@

E1

8.5K

RIO

1·2K

f4--

IIII

I-

l-

022

600

020

IK

02

i~L7

470K

?rl

P6

053

~

01

150 L

r;=:F-

ru~es

P5

~;~

P4

LOCK

Ir:

~~~

P4

NON

LOCK

HI-

LOW

PLATE

VOLTS

r.b:~TL.

~~r~

~

Ir

0

~I

II

I

~[~

~27UF

07

[.BK

1\

-

052

~go

fbOo

Oil

012

500

50

50

I

I

oa;.9

I

~~

~

BIAS

SECTION

RANGE

~

~'«'!Q.H

;.2..

_I

~

~~

~o

REAR

f-o:

f{

0

SEC110NS' o °

o 0

023 024

R49

~

470K

10K

40K

~

~

OEV

:

NORI

I-

~ R50

021 BUF 9.9K

"

~

=ftJ

051

(-------I-,;;:LF

BIAS

200

<

QMI

~j

02

40

0'

'"

0'

0 d 0

0'

60

SELECTOR

NO.

I

(FILAMENT

POS.)

0°00°0

"@"

o 0

~

0

~

O 0

o

:t

0

Oo

0

o 0

v)J

~\\1;

~'V~

~fr~~

I J 00

FUNCTION

SW~TCH

,

,

---

--

--

-'

, I

, I

o~;

1:

~

:0«i

o, 0 o ,

~~

f

~

o , 0

o 0 0

0:=

o 0

000

~

0°

°

00

0

0°

°0

9.~

~'i&

~

~©~

~o

00

~

&1>0

00°

00

OS

II

R37

R3B

R39

040

15K

500

60

40

40

'V

~'~

~L

~~

R43

R44

198 2

~

I

PANEL

LAMP

TEST

SOCKET

~

OCTAL

/0,,0

ffi,;;

O)Q~O

f1:.5;

S(LECTOR

NO.2

(FILAMENT

NEQ

0°00°0

"@"

f 0 }

00

:)

00

o 0

00 0

~~1

~~ :~

~~~~

f(f

00

-:=J

025

I.

026

150

-f-

R27

750

r--

- - -

,

C6

,

GR)~

~~

R2B

o, 0 100

WaoO

r-

020

270

I-

~

033

230

~O

C3

.05.L1f

041

R42

60

500

'V

LOCTAL

o,q

f'~

~;

.......---

r--

,---

r-

II

•

.!

-

~

~

o 0

o 0

o

b.2-

W

lEo~

-

t

LOCTAL

O'C?

~")

~;

II

=

==

=1-

-

.~

-I"'

~

o 0

°0

~~

u,

IW

NOVAL 8 PIN

IiOlf

~

SUB

MiN.

SPIN

NUVISTOR

--"7ci

~

P"\

0.'

GO

0,

70

ff-i0

O.

10

o 0

00

0

·0

~)

0

~,

'~I?~~

SHORTING

BAR

ACROSS POSTS

FOR INSERTING

SELF

BIAS

O'~

~.6'I

IN

LINE

~

I~

6

{,

&6

&<11

0'

'0

010

'20

~

JIll

~

SHORT TEST

SWITCH

/

/

SELECTOR

NO.4

(PLATE)

0

000

0

0

0

~u~

rK~~~~

~

(1

00

R4S

IMEG

"!~

IOOllF

6W.Y,

J.lMHO

METER

1.5K

11511A

-----

______

,_.L

____

-1------,.-------

~o~

/

/

~~

O~

I~~o

r!L

o 0

~-~

0

~

00~

°O:~

°O:~

o :0-

0"

0

0

00

°

P--

t-<"

0 0

00

I~<

R47

~

LiI~

t 36K

O~O

O~O

......;.;)l:;

io.i

0

.0'

R480:~

-oJ

0

To

00

°OOb

O~

330KO

00

0

.....

..........,

~

0

.3.

:..

R.,

HI

150~

~

NOISE

TES{f

C5

2501<

1

R36

I

470

120K

500V

I

~I

'~35

T

II

120K

NE-51

~NOVAR

COMPACTRON

q

'?60~

~~~9P90:-

0,

70

0'

'0

0'

"0

rr-:

0

rff!~O

SELECTOR

NO· 5

(SCREEN)

0

0\

0°

000

~~~

~

~~

~

rr~~

-.l

I

PLATE

@..

I-

~~~~:~N:,:O~~G'

~~

POST FOR

INSERTING

METER

TO REAO

PLATE

CURRENT.

~

GRID

CAP

R32

.7

I--

7PIN

NUVISTQFI

INJ

Ito

~

=

~

'0

ill

• FRONT OF SECTIONS

FRONT

ANa

REAR

SECTIONS

ELECTRICALLY

CONNECTED.

*LEFT

END OF

ALL

SWITCHES

IS

THE

KNOB

END.

SELECTOR

SELECTOR

NO.6

NO

7

(CATHODE)

(SUPPR[:;:'uHl

~cQa

~OO

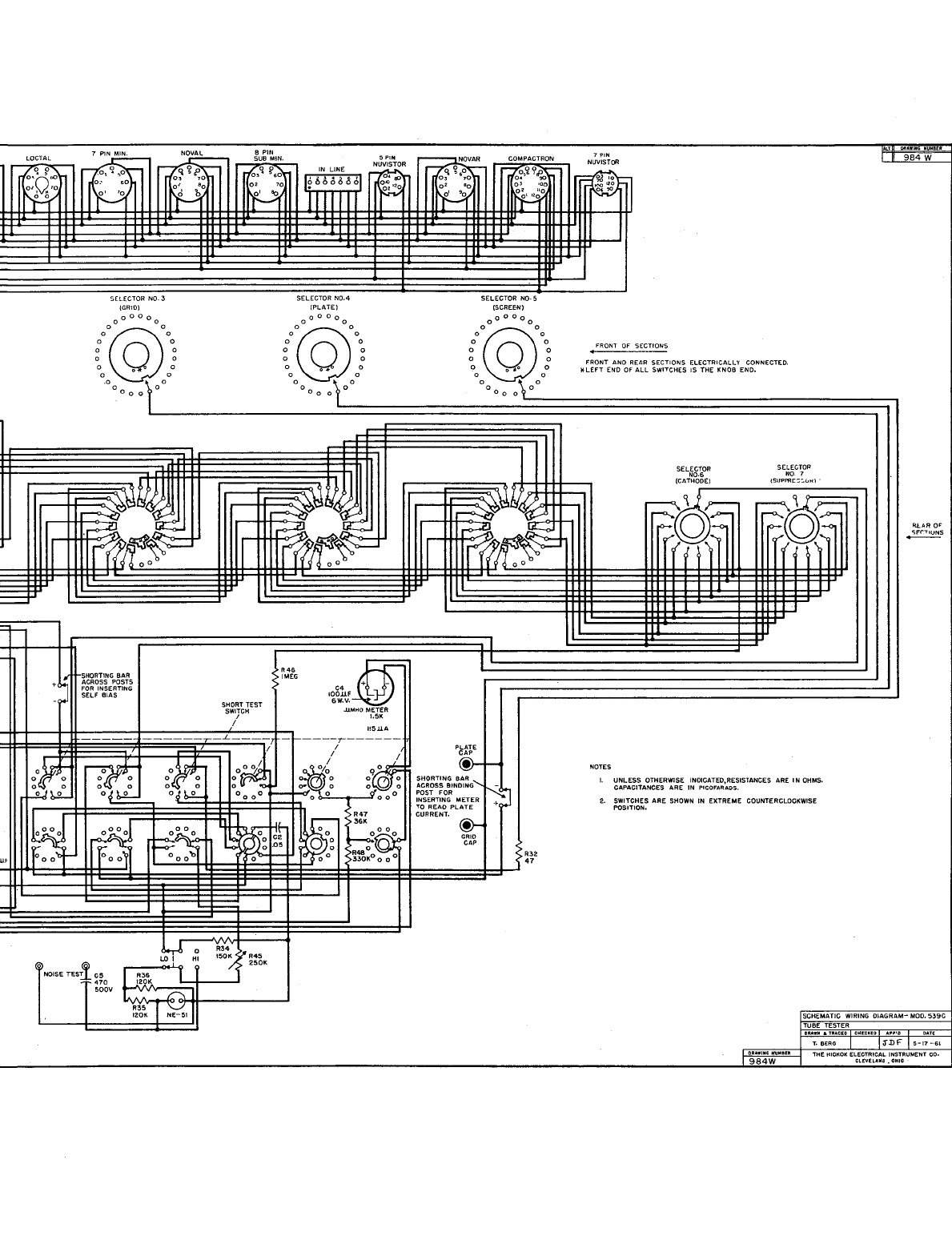

NOTES

I.

UNLESS

OTHERWISE INDICATfD,RESISTANCES ARE

IN

OHMS.

CAPACITANCES

ARE

IN

PICOFARADS.

2.

SWITCHES

ARE

SHOWN

IN

EXTREME

COUNTERCLOCKWISE

POSITION.

SCHEMATIC

WIRING

DlAGRA

TUBE TESTER

DIlAIIlI.TRACEO

CH[CKEO

""1"0

984W

984

W

RlAR

O~

~S

Table of contents

Other Hickok Test Equipment manuals