Sedgwick 571 Troubleshooting guide

571

HOLLOW CHISEL MORTICER

OPERATION AND MAINTENANCE

INSTRUCTIONS

M. SEDGWICK & COMPANY LIMITED

Stanningley Field Close, Leeds, U.K. LS13 4QG

Tel. +(44) 113 257 0637 Fax. +(44) 113 239 3412

MACHINE SERIAL NO. 571AA

571 Operation/Maintenance Instructions Page 2 of 19

Manufacturers EC Declaration of Conformity

The following machine has undergone ‘conformity assessment’ and has been

self-assessed in accordance with:

Schedule IV of the Supply of Machinery (Safety) Regulations 1992 and

Amendment No. 2063

MANUFACTURER’S NAME AND ADDRESS:

M. Sedgwick & Company Limited

Swinnow Lane

Leeds

LS13 4QG

England

RESPONSIBLE PERSON:

Mr G. Sedgwick (Managing Director)

MACHINE DESCRIPTION:

Hollow Chisel Morticer type 571

DIRECTIVES COMPLIED WITH:

Supply of Machinery (Safety) Regulations 1992

Amendment No. 2063 1994

Draught Proposal CEN/TC 142

SIGNATURE OF AUTHORISED REPRESENTATIVE

_________________________________

571 Operation/Maintenance Instructions Page 3 of 19

List of Contents

Page No.

Design And Purpose

Illustration

Machine Specification

5

5

Installation .

Handling Instructions

Foundation Drawings

Installation Instructions

Electrical Installation

7

8

9

9

Operating Instructions

Switch Gear

The Lever

Chisel Head

Table Clamp

10

11

11

11

Table Movement

Mortise Depth

Mortise Length

11

11

11

Setting Up

Mortising Hard And Soft Woods

Diagnosing Faults In Mortising

12

13

14

Limitations Of Use And Safe

Working Practices

Operator Training

14

Health And Safety Advice

Dust

Noise

Recorded Noise Levels

15

15

16

Maintenance

Lubrication

Parts Diagram

Parts List

17

18

19

571 Operation/Maintenance Instructions Page 4 of 19

Introductory

This Instruction Manual is designed for you in accordance with The Supply Of Machinery (Safety)

Regulations 1992, and the Supply of Machinery (Safety) (Amended) Regulations 1994, which

implement the European Machinery Directive 89/392/EEC. We strongly recommend that in order

to ensure good safe working practise you read it prior to commencing either installation or

operation of the machine. Your supplier will be pleased to provide any further advice or

assistance that you might require.

Design and Purpose

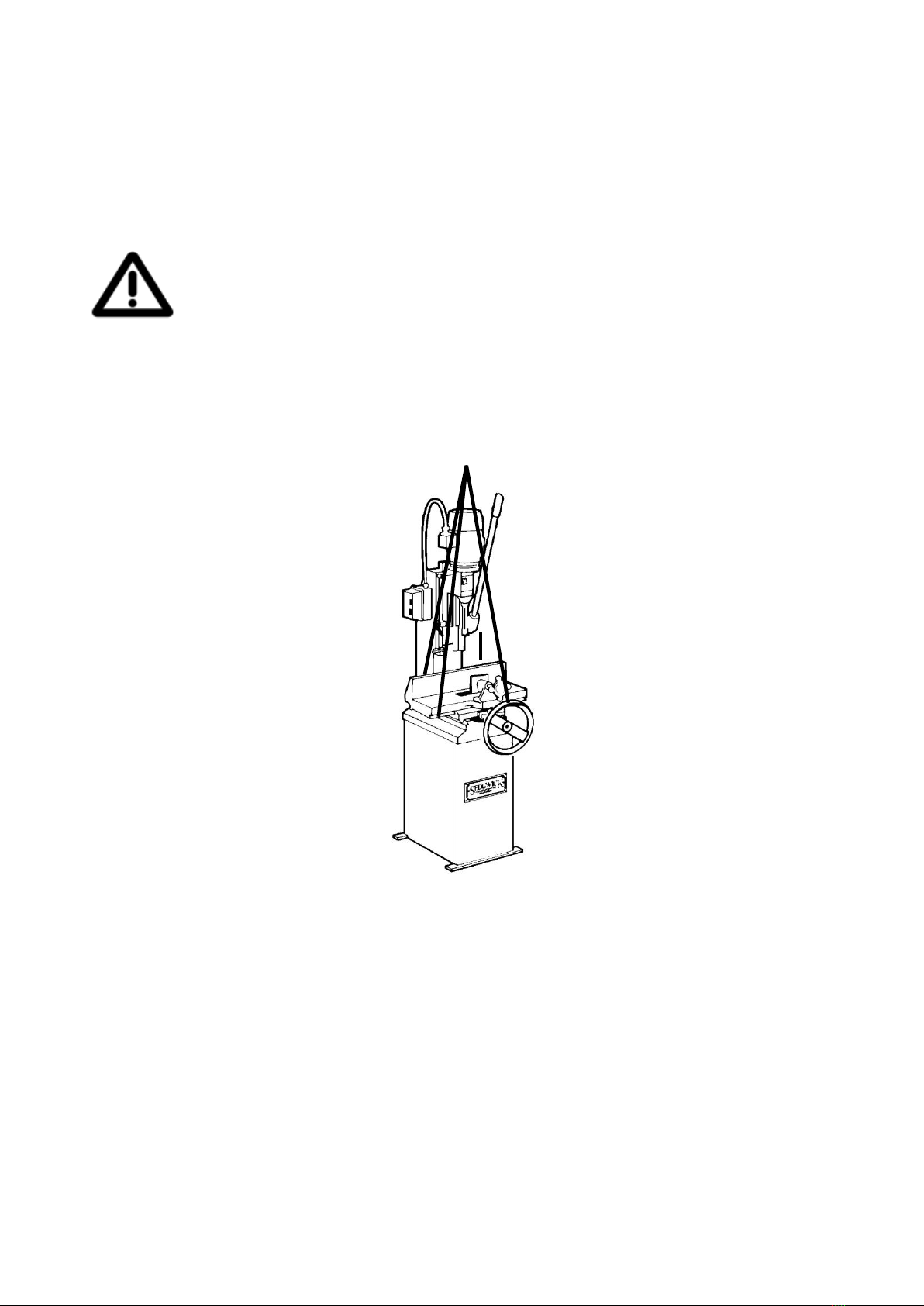

The Sedgwick Hollow Chisel Morticer Type 571 is a hand fed machine used for producing square

cornered mortice holes of various lengths and widths.

The machine is not designed for any other purposes except as set out above. The

operator of the machine shall be solely liable for any damage that results from

improper use of the machine.

The machine should not be modified in any way without the written consent of the

manufacturer. Please also refer to Section 11.0 regarding use of unauthorised spare parts.

571 Operation/Maintenance Instructions Page 5 of 19

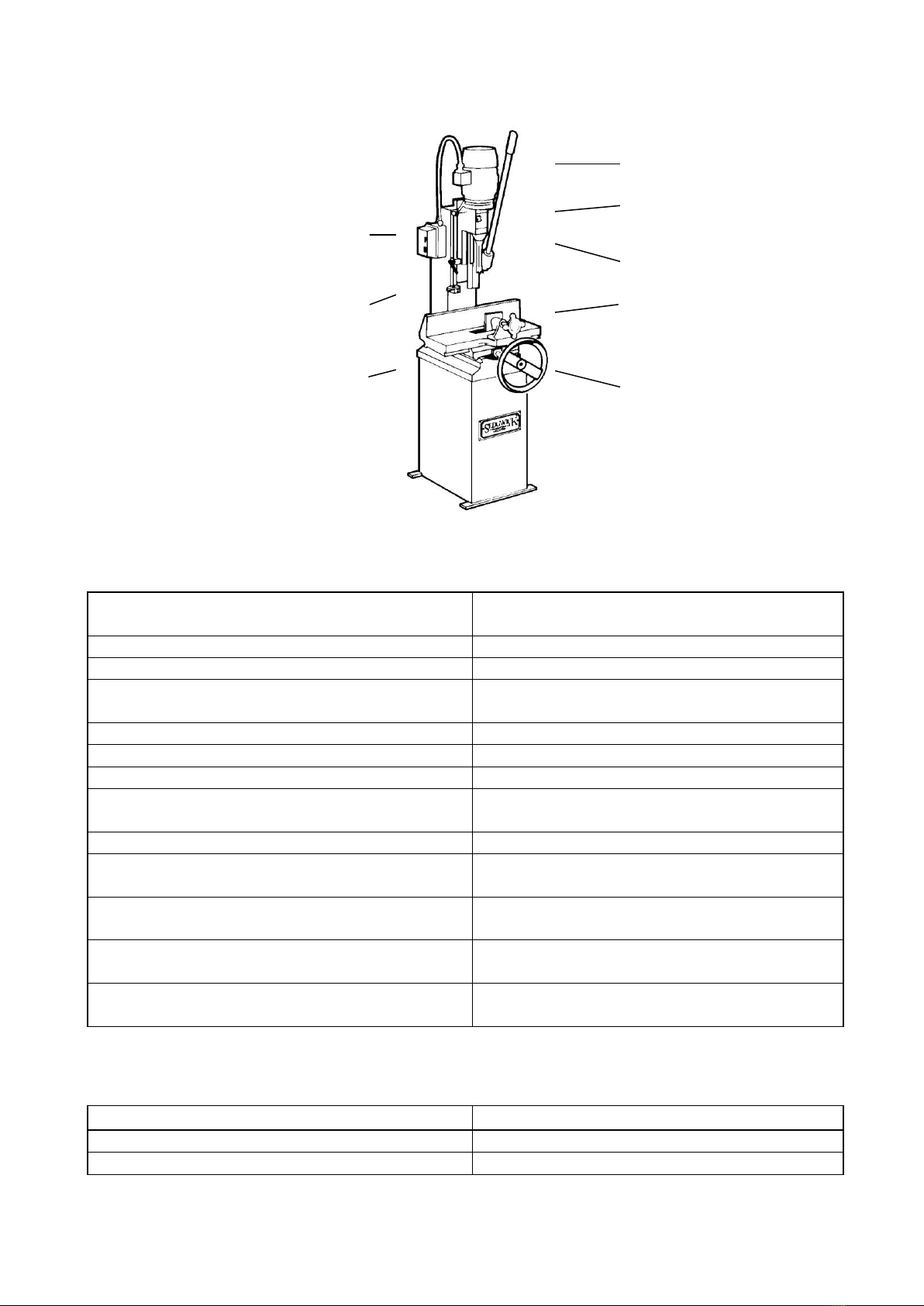

Illustration

1.2 Machine Specification

MAXIMUM CHISEL SIZE - IN HARDWOOD

IN SOFTWOOD

19mm

25mm

TIMBER CAPACITY

255x200mm

STROKE OF CHISEL HEAD

120mm

TABLE MOVEMENT -LONGITUDINAL

-LATERAL

430mm

80mm

DEPTH STOP

STD

HAUNCH STOP

STD

LENGTH STOPS

STD

VOLTAGE / FREQUENCY

3 PHASE + EARTH; 400/230 V –50/60 Hz

1 PHASE + N + EARTH ; 230V / 50/60 Hz

MOTOR RATING

1.1Kw

MOTOR FULL LOAD CURRENT IN AMPS

3 PH 2.5A

1 PH 6.6A

STARTING CURRENT IN AMPS

3 PH 15.0A

1 PH 39.6A

REQUIRED FUSE SIZE IN AMPS

3 PH 10A/ph

1 PH 20A

REQUIRED CABLE SIZE

3 PH 2.5mm2

1 PH 2.5mm2

1.3 Shipping Details

DIMENSIONS - Length x Width x Height

735x630x1520mm

NETT WEIGHT

160 Kg

Total Weight, including Packing Crate

221 Kg

OPERATING LEVER

CHUCK GUARD

CHISEL BRACKET

ADJUSTMENT

TIMBER CLAMP

LONGITUDINAL AND LATERAL

ADJUSTMENT OF TABLE VIA

SINGLE HANDWHEEL

STOP/START BUTTONS

DEPTH AND HAUNCH STOPS

LENGTHS STOPS

571 Operation/Maintenance Instructions Page 6 of 19

1.4 Personal Protective Equipment (PPE)

Operators of the machine should observe Health & Safety guidance as to use of PPE when

operating the machine, in particular:

Use of protective clothing e.g. tear-resistant sturdy overalls.

Use of protective footwear e.g. wear safety shoes with protective toes and

sturdy grips which are penetration resistant

Gloves –avoid wearing gloves when operating the machine to avoid the gloves

getting caught;

Hair - persons with long hair should tie their hair up and wear a hairnet (to avoid

the risk of hair being tangled on the machine);

Ears - wear hearing protection such as earplugs or earmuffs to avoid exposure to

noise

1.5 Residual Risks

The machine is considered operationally safe when used in accordance with this manual

however the following residual risks should be considered and adequate steps taken to

ensure such risks are minimised:

The machine is powered by electricity. Before carrying out any maintenance, cleaning

or repair work to the machine, ensure the machine is switched off and cannot be

inadvertently switched on again. If work is required on any electrical component of the

machine, ensure that the voltage supply is completely isolated. Do not remove any

safety devices or alter them to prevent them from functioning correctly.

Electrical energy can cause serious risk to health. Damaged

or broken electrical insulation materials (e.g. cabling) or

individual components (e.g. the motor/starter) can cause

electrical shocks which can cause death.

• Risk of injury from contact with the chisel

• Risk of injury through accidental contact with rotating parts –do not attempt to

remove any guarding from the machine during machining

• Risk of injury due to ejected workpieces

• Hearing damage as a result of exposure to high noise levels – take precautions

• Damage to lungs due to the inhalation of dust, which can vary when working with

different types of wood/wood with varying moisture content.

The following section offers a guide to transporting, assembling, and installing the machine.

These are all skills that should not be attempted by those who have not received relevant

training.

571 Operation/Maintenance Instructions Page 7 of 19

2.0 Machine Handling

The following section offers a guide to transporting, assembling and installing the machine,

which should be done following an adequate risk assessment. Movement, adjustment or

installation of the machine should not be attempted without proper training in the handling of

heavy machinery.

There is a risk of physical injury when moving the machine. The machine could

be damaged or written-off if not handled properly during transportation.

Always use a sling or hoisting device equipped with safety hooks within the safe working load of

the machine weight. Check the sling is in good condition before starting the handling operation.

Machine weights are provided in 1.3 above. Sling underneath either side of the machine table,

ensuring that you do not catch the starter etc. Do not walk or stand under the machine during

lifting.

Upon arrival, check that the machine has not suffered any damage during transit. Reuse or

recycle any packaging materials, e.g. wooden pallet, and where not possible to do so, dispose

of them in accordance with local refuse requirements.

2.1 Positioning

Around every aspect of all woodworking machines there should be clear and unobstructed space

to enable the work being done at the machine to be done without risk of injury to operators.

Consider the position of the machine, with regard to other fixed equipment and walls.

571 Operation/Maintenance Instructions Page 8 of 19

You must ensure that there is an ample power supply available to operate the machine,

together with good lighting and ventilation. Do not operate or store the machine outdoors.

Ensure the environment for operating woodworking machinery is kept clean and tidy and damp-

free. Only operate the machine in ambient temperatures.

The chosen floor space on which to site the machine should be in good and level condition to

enable the machine to be anchored at four points. Holes for M10 foundation bolts (not supplied)

are provided in the machine base. Level the tabletop by packing under the feet of the base as

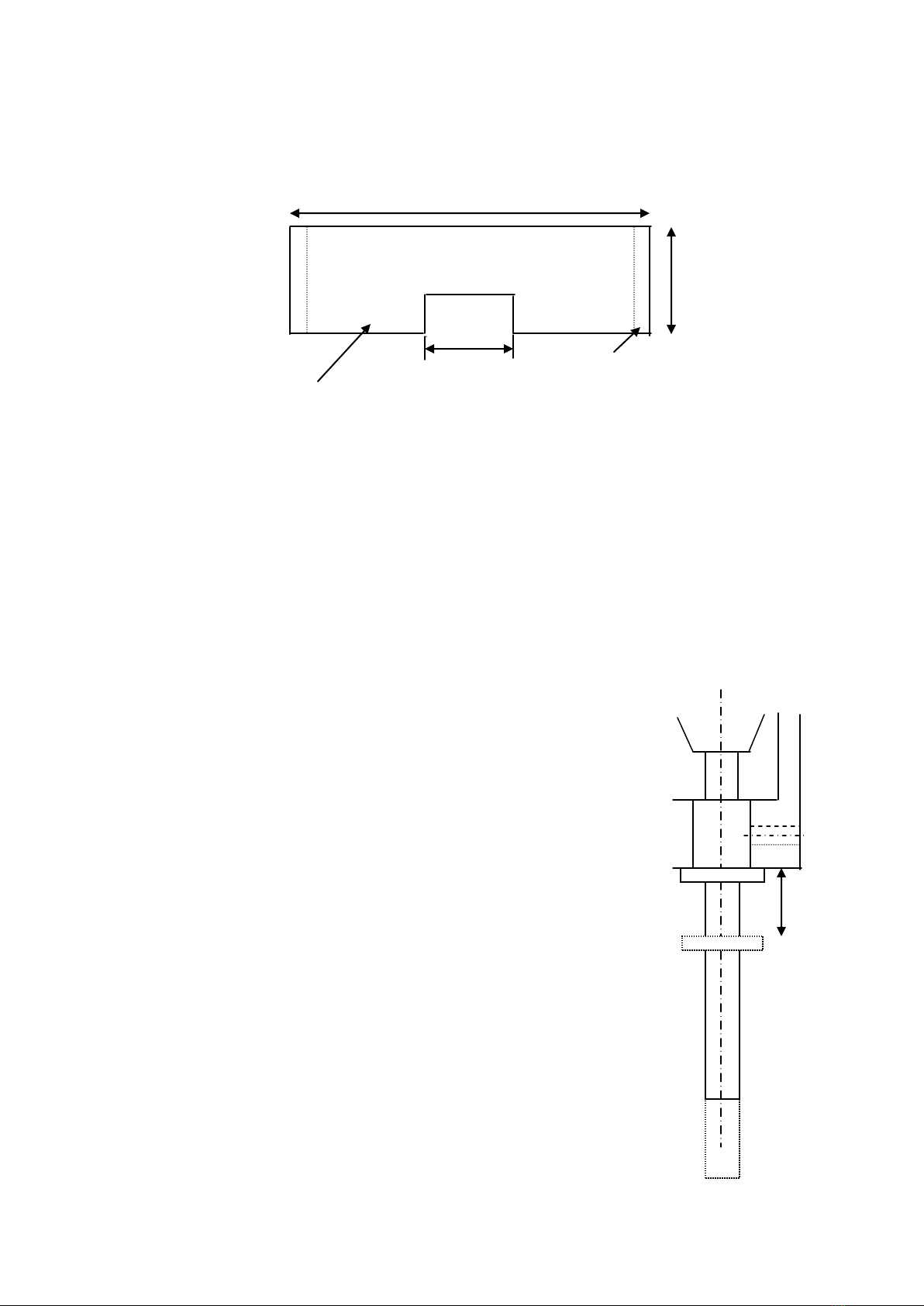

required. The following drawing shows a lay-out of the anchor openings:

340mm

440mm

160mm

310mm

215mm

215mm

Table Movement

571 Operation/Maintenance Instructions Page 9 of 19

3.0 Installation

1. Remove the protective rust preventative using turpentine or paraffin. Do not use any solvent,

petrol or gas oil, which might dull or oxidise the paintwork. Lightly oil cleaned surfaces to

prevent rusting.

2. The counterbalance weight is fastened to the inside of the machine stand for transport

purposes and should be released prior to operation. Remove the bolt at the rear of the stand

whilst at the same time exerting downward pressure on the operating lever, this will enable

the weight to drop safely into its operating position.

3. Take the oil nipples from the toolkit and insert them into the two M8 tapped holes at the

centre of the rear of the column.

4.0 Electrical Installation

Electrical wiring should be carried out by a competent electrician following the directions given

below. Reference should be made to the appropriate wiring installation rules, e.g. in the UK the

16th edition of the IEE Wiring Regulations for Electrical Installation (BS7671).

The motor and starter have been wired in at the factory and tested before despatch.

All that is required is to connect the power supply to the starter from your isolator.

Check that the supply details on the motor plate correspond with the site supply.

It is important that the correct cable size is used to avoid a voltage drop at the motor

terminals. If the motor is operated on a voltage outside, plus or minus 6% of the spot

voltage, then premature failure will occur.

It is important to check rotation of the motor which should be clockwise when viewed

from above the machine.

Should you encounter problems on start up check for the following likely causes:

PROBLEM

LIKELY CAUSE

CORRECTIVE ACTION

Fails to start

Main supply switched off

Overload tripped

Fuse blown

Loose wire

Coil failure

Check main switch

Reset overload

Check and replace fuses (check all

three on three phase)

Check all connections

Check circuit of hold in coil

Overload trips during

starting

Low voltage

Low voltage

Low voltage

Check supply-voltage both on no load

and on moment of switch on. Allowed

variation plus/minus 6%

Check that correct cable size has been

used to install the machine. Change if

necessary.

Long runs of cable can cause voltage

drop. Check that voltage is not outside

the minus 6% tolerance.

Re-site the machine nearer supply or

increase the cable size to compensate.

571 Operation/Maintenance Instructions Page 10 of 19

Three phase machines only:

1 fuse blown

Machine jammed

It is possible for 3 phase machines to

operate with only 2 phases of the

supply. This will create an overload

situation and will eventually cause

premature failure, this is known as

single phasing. Check all fuses.

Check spindle is free to rotate, clean

as necessary.

Slow acceleration

Low voltage

For a motor (particularly a single-phase

permanent capacitor motor) to reach

its required starting torque a healthy

line voltage is essential.

5.0 Switch Gear

5.1 Start / Stop Buttons

The motor is started by pushing the green (power on) button on the starter panel, and stopped

using the red (power off) button.

5.2 Circuit Protection

In case of a mains failure the starter is fitted with no volt release protection and will not restart

without being switched on again. The starter is also fitted with an overload protection device.

An electrical overload occurs where an electric motor is subjected to a greater load than it was

designed for. This can be caused by short circuit, by incorrect installation, or by misuse

(including poor machine maintenance). The inbuilt breaker will therefore help prevent damage

to the motor should such a situation occur. The motor cannot be restarted until the breaker has

reset itself.

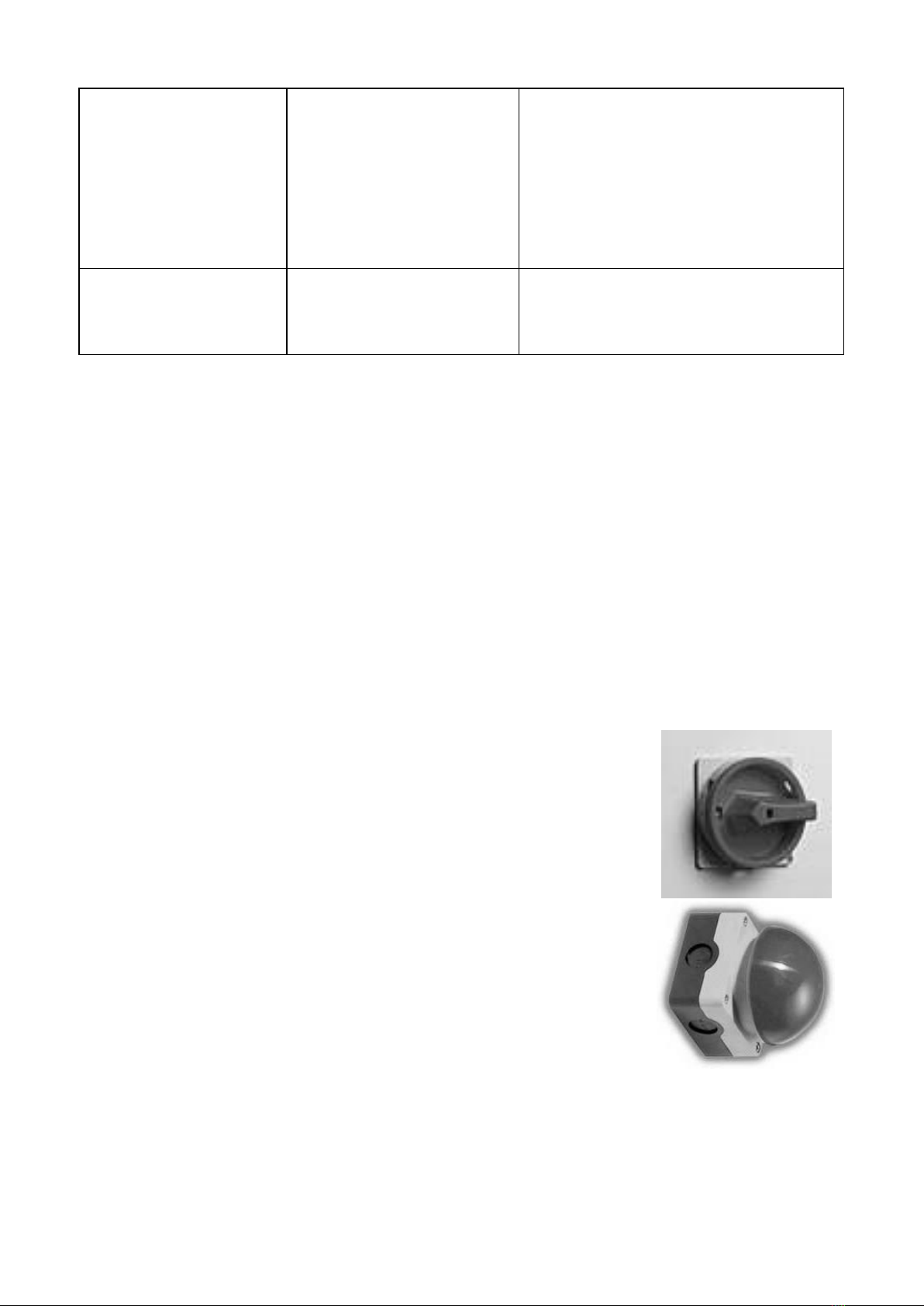

5.3 Optional Padlockable Isolator

With this switch in the OFF position the machine is effectively isolated

from the supply to allow personnel safe access for maintenance or repair

work and to prevent dangerous restarts. In order to prevent unauthorised

use of the machine the switch can also be secured in the OFF position

using a padlock.

To operate the machine, first turn the isolator to the ON position.

5.4 Optional Emergency Foot Operated Stop Switch

This switch is provided for use in emergency situations only. We do not

recommend that it is used in lieu of the stop switch on the front of the

starter panel. The foot switch, once pressed will remain locked in the off

position. To restart the machine it is necessary to release the switch by

pulling it towards you.

571 Operation/Maintenance Instructions Page 11 of 19

Controls

THE LEVER The operating lever used to control the movement of the chisel

bracket can be adjusted to suit the height of the operator as follows:

Loosen the M8 allen screw in the lever boss, slide the bar into the

correct position and re-tighten.

CHISEL HEAD The chisel bracket can be adjusted to suit the size of the work piece

as follows:

Isolate the machine. Open the chuck guard, manually support the

chisel bracket, and slacken the 24mm AF hexagon nut inside the

head with the spanner provided. Position the chisel bracket to the

required height, re-tighten the hex nut and close the chisel guard.

TABLE CLAMP The workpiece clamp can be secured in any position along the tee slot

using the locking lever provided. Its face is pre-drilled to accept a wooden

pad to help prevent possible marking of the workpiece.

TABLE MOVEMENT The table has both longitudinal and lateral movement, controlled by

the single handwheel. Push in and turn for lateral adjustment, pull out

and turn for longitudinal movement.

MORTICE DEPTH The depth of mortice is controlled by pulling the haunch stop lever

towards the operator and adjusting the collar on the stop rod to the

required depth.

Note: When cutting a deep mortice it is advisable to take the chisel down in stages of about

25mm, moving the table along for each successive cut. This enables the chisel to clear itself of

chips, and avoids subsequent overheating, particularly when cutting hard or green wood. DO

NOT OVERLOAD. The motor switch is fitted with a thermal overload cut-out, and if the motor is

overloaded will automatically switch it off. If this occurs, check the rotating parts are running

freely, and lubricate if required. If all is free then it may be necessary to reduce drilling

pressure slightly, i.e. operate at a lower rate of feed.

SETTING OUT FENCE In order to set the position of the mortice in relation to the end of the

timber the turnover stop can be adjusted either side of the table.

Note: Long or heavy timbers should be supported off the table.

MORTICE LENGTH The length of mortice may be controlled using the two length stops on

the bar at the front of the table.

571 Operation/Maintenance Instructions Page 12 of 19

Preparation for Use

Before commencing any work on this machine it is recommended that a wooden sub table is

made as illustrated below:

560mm

105mm 25x25 Battens

12-16mm thick

Setting Up For Hollow Chisel Mortising

SEQUENCE:

1. Ensure that the machine is electrically isolated.

2. Select the correct size of chisel and auger, together with chisel bush, spanners and allen key.

3. Check that the chisel and auger have been correctly sharpened and are in good condition,

i.e. that the chisel is free from cracks and damaged points, and that the auger and cutting

edges are in good condition.

Following the guidelines below fit the chisel and auger in the chisel bracket.

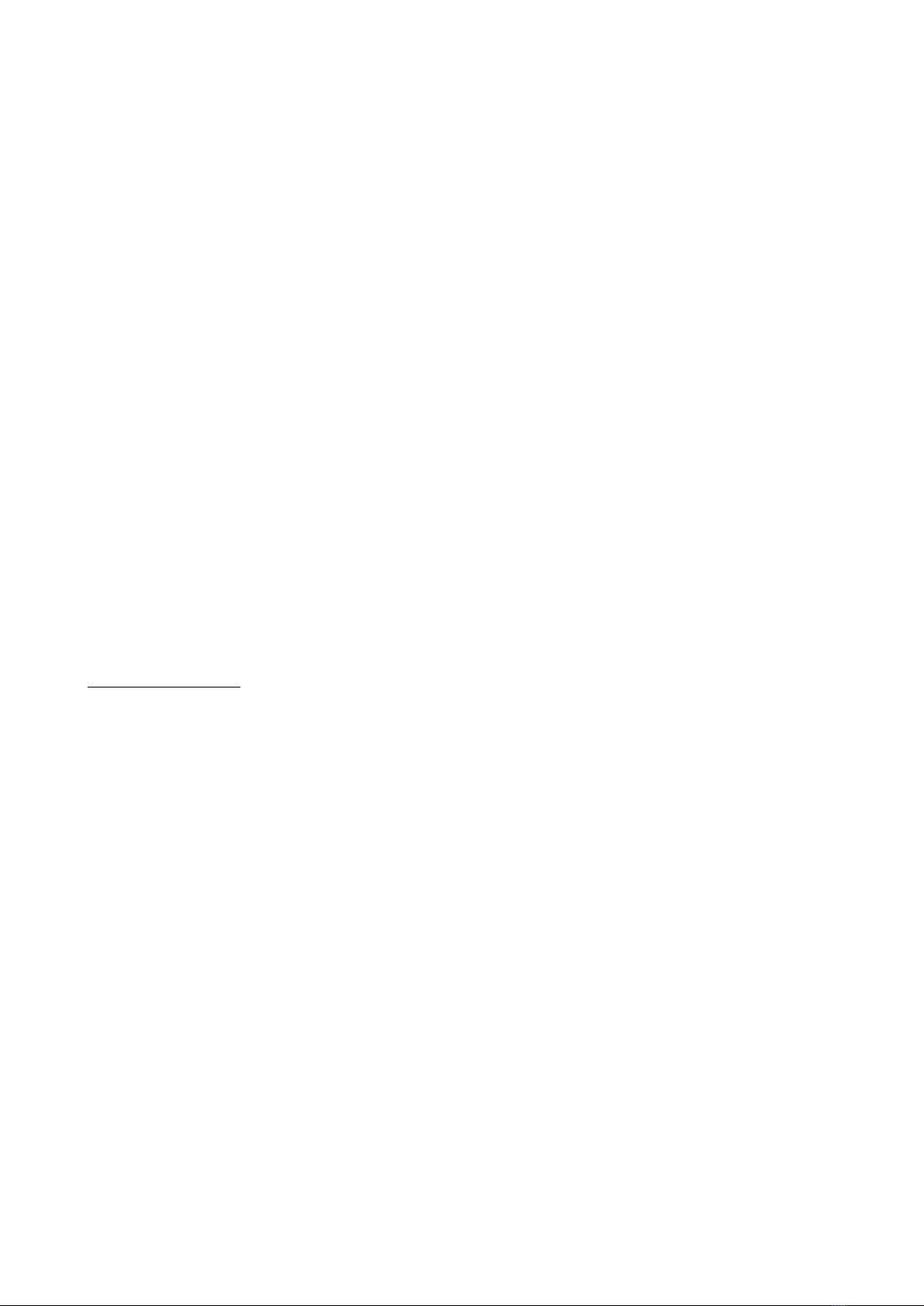

Insert auger (with chisel slotted onto it) into the

adjustable chuck to its uppermost limit and tighten in

place, the chisel will then rest upon the wings of the

auger in position as shown in dotted image.

Measure dimension ‘A’ carefully, then remove the auger

and shorten its shank end by a distance 1mm less than

dimension ‘A’ measured.

Insert chisel into the chisel socket until the chisel

shoulder butts firmly up to the underface of the chisel

socket and lock screw ‘B’.

Insert auger once more to its uppermost limit. Its

scribing wings should be found to clear the chisel

internal cutting bevel by the distance allowed. Finally,

tighten the auger and the machine is then ready for

cutting.

Note: the lower point on the bit must clear the bottom

point of the chisel and not rub against the chamfer. It is

advisable to file a flat on the chisel to enable the

locking screw to grip firmly and not burr the shanks,

making removal difficult. Always ensure the chip relief

in the chisel is left to right and not front to back and

always cut away from the relief to ensure good chip

ejection.

The chisel should be mounted with its chip ejector slots

facing along the workpiece. Rotate the auger by hand to

check that it runs freely without rubbing

A

B

160mmm

m

571 Operation/Maintenance Instructions Page 13 of 19

5. Clear all tools from the machine and position the clamp as previously described.

Move the headstock down to the workpiece, to check the alignment of the chisel with the

mortice position. Set the depth stop.

6. Return the lever to the rest position. Switch on the isolator.

7. Switch on the machine and cut a trial mortice.

8. Check the mortice for position, depth and finish.

Note. A squirt of oil along the length of the auger will reduce the noise it emits when running.

Morticing Hard and Soft Woods

1. Keep the face side towards the fence.

Edge

2. Position the mortice to be cut opposite the clamp. This prevents the chisel lifting the wood

away from the table, which would occur if the mortise were too far away from the clamp.

3. Turn the workpiece ‘end to end’. This ensures that the face side is kept towards the fence

when cutting through mortise.

4. Work from both sides when cutting through mortises, as breakout on the back-edge could

occur if the chisel was taken right through. Set the chisel depth stop to enable just about a half

of the depth of mortise to be cut from each side.

5. Position the chisel about 25mm above the workpiece when the lever is in the rest position by

positioning the chisel bracket. This avoids unnecessary long movements of the headstock lever,

and reduces the effort required to produce a mortise.

6. The chuck guard must be in position.

7. Make a gradual cut when using the chisel. Remember that on the first cut all four sides of the

chisel are enclosed by the timber, making withdrawal of the chisel from the workpiece difficult.

Order of Morticing

1 2 3 4 5 6 7

Chip ejection slot facing

Face side towards

fence, mortice position

opposite cramp.

571 Operation/Maintenance Instructions Page 14 of 19

8. Do not traverse the table when the chisel is in contact with the bottom of the mortise, as this

could damage the auger and strain the mortise chisel.

9. In the interests of ease, for an extended life of mortise chisels, and for speedy working, it is

preferable to use sharp but shallow strokes on the handle, i.e. about 25mm deep for softwoods,

and 12mm deep for hardwoods. This applies particularly to wet or abrasive timber.

Faults Diagnosis

FAULT

CAUSE

REMEDY

Cuts out of square

Chisel is not square to fence

Square the chisel to the fence

Uneven bottom to mortise

Auger too far in advance of

the chisel

Reposition the auger

Chisel end blued and cracked

auger rubbing against the

auger edge, causing over

heating

Reposition the auger, regrind,

or replace the chisel

Chisel becomes hot near

centre

Bent auger

Straighten or replace the

auger

Chippings build up inside

chisel

Bad clearance. The auger

spiral does not extend far

enough, or resinous timber is

gumming up the inside of the

chisel

Remove the auger and clean

with paraffin periodically

Limitations of Use and Safe Working Practices

Training and instruction is a central requirement of the Provision of Work Equipment

Regulations 1998 (PUWER). No morticing machine can be operated by any person under the age

of 18 without them having first completed an approved course of training. The regulation does

realise that young persons may need to operate one of these machines as part of a course, and

such use is permitted provided that it is carried out under the supervision of a person who has

thorough knowledge and experience of the machine and of its safeguarding requirements.

It is essential that all operators of morticing machines are adequately trained in the use,

adjustment and operation of the machine, this covers in particular:

The dangers associated with the operation of the machine;

The principles of machine operation, correct use and adjustment of the controls;

The safe handling of the workpiece when cutting;

The position of the hands relative to the cutters and the safe stacking of the workpiece

before and after cutting.

Under no circumstances should anyone operate the machine while under the influence of

drugs, alcohol or any medication which may render them drowsy.

Persons who install this machine for use at work have a duty under the Health and Safety at

Work Act 1974 to ensure, as far as is reasonably practicable, that nothing about the way in

which it is installed makes it unsafe or a risk to health at any time during setting, use, cleaning,

and maintenance. This includes such aspects as correct assembly, electrical installation,

construction of enclosures, and the fitting of guards and ventilation equipment. When installing

571 Operation/Maintenance Instructions Page 15 of 19

this machine consideration must be given to the provision of adequate lighting and working

space.

Repairs and maintenance must only be undertaken by competent technicians. Ensure that all

power supplies are isolated before maintenance work begins. Instructions for routine

maintenance work are also included in this manual.

Health and Safety Advice

Dust

Wood dust can be harmful to health by inhalation and skin contact and concentrations of small

dust particles in the air can form an explosive mixture. These concentrations usually occur in

dust extraction equipment which may be destroyed unless explosion precautions have been

taken in the design and installation of the equipment.

Employers have duties under the Factories Act 1961, The Health And Safety At Work Act 1974

and the Control Of Substances Hazardous To Health Regulations 1988 to control wood dust in

the workplace.

Employers should carry out an adequate assessment of the possible risks to health associated

with wood dust particularly when machining hardwoods, and if necessary seek expert advice as

to the method of dust extraction.

Prevention or control of wood dust exposure should as far as is reasonably practicable, be

achieved by measure other than the provision of personal protective equipment.

Further information and references to practical guidance are contained in free leaflets from the

Health & Safety Executive, alternatively specialist help and information can be obtained from:

P&J Dust Extraction

Extraction House, Otterham Quay, Rainham, Kent ME8 8NA

Tel. 0163 423 3933 Fax. 0163 423 4588

Noise

Noise levels can vary widely from machine to machine depending on conditions of use. Persons

exposed to high noise levels, even for a short time, may experience temporary partial hearing

loss and continuous exposure to high levels can result in permanent hearing damage. The

Woodworking Machines Regulations require employers to take reasonably practicable measures

to reduce noise levels where any person is likely to be exposed to a continuous equivalent noise

level of 90 dB(A) or more over an 8 hour working day. Additionally, suitable ear protectors must

be provided, maintained and worn.

Machines identified as generating unhealthy noise levels should be appropriately marked with a

warning of the need to wear hearing protection and it may be necessary to designate particular

areas of the workplace as ‘Ear Protection Zones’. Suitable warning signs are specified in the

Safety Signs Regulations 1995. It may be necessary to construct a suitable enclosure, in which

professional advice should be sought.

Further information and references to practical guidance are contained in free leaflets available

from The Health & Safety Executive.

571 Operation/Maintenance Instructions Page 16 of 19

The list below outlines some of the variables that directly affect the noise level of the machine:

VARIABLE RELEVANT FACTOR EFFECT

Timber Species Hard stiff timber can mean more noise

(approx. 2dB(A) difference when cutting

oak and pine) & more transmitted noise.

Width Wide work pieces radiate noise over a

greater area increasing the noise level.

Thickness Thin workpieces generally vibrate more

increasing the noise level.

Length Long workpieces transmit noise away from

the cutting area towards the operator.

Tooling Width of Chisel Noise increases roughly in proportion to

the width of cut.

Tool Sharpness Dull ands worn cutters tend to chatter.

The following noise levels were recorded at a distance of one metre from the machine (operator

side) with a combination block fitted, using varying feed rates and depths of cut.

OPERATION

NOISE LEVEL dB(A) @ 1M

None

67

Cutting

70

The figures quoted for noise are emission levels and not necessarily safe working levels. Whilst

there is a correlation between emission levels and exposure levels, this cannot be used reliably

to determine whether or not further precautions are required. Factors that influence the actual

level of exposure to the work force include the duration of exposure, the characteristics of the

workroom, the other sources of dust and noise, etc., i.e. the number of machines and other

adjacent processes. Also the permissible exposure levels can vary from country to country. This

information, however, will enable the user of the machine to make a better evaluation of the

hazard and risk.

571 Operation/Maintenance Instructions Page 17 of 19

Maintenance and Lubrication

Electrically isolate the machine and ensure that all spindle movement has ceased before

carrying out any maintenance operation.

Since your morticer is constructed of cast iron, which is a porous metal, care should be taken

when cleaning. Use mineral spirits and steel wool on all metal parts. Avoid contact with

anything moist. Don’t set drinks on the tabletop, or leave green wood on it. These will leave

permanent marks.

Waxing the table surface will help resist moisture. Avoid products that contain silicone, anti-slip

additives, or abrasives.

Clean the interior of the machine stand frequently to prevent the accumulation of chips and

sawdust.

Once clean, lubricate moving parts using a lubricant that does not pick up a lot of sawdust. Pay

particular attention to the slides, operating screws and oil nipples (for the oil nipples use a

grease gun filled with oil). Powdered graphite, hard wax or white lithium sprays are ideal. Do

not use an oil-based product. These will collect sawdust and congeal into a gummy substance,

making working parts hard to operate.

Should, after long use, the tables or headstock develop a degree of side play, this can be

rectified by slackening slightly the retaining bolts on the slide concerned, and tapping the slide

until side play is eliminated, but taking care not to interfere with normal movement. Tighten

retaining bolts firmly after adjustment.

571 Operation/Maintenance Instructions Page 18 of 19

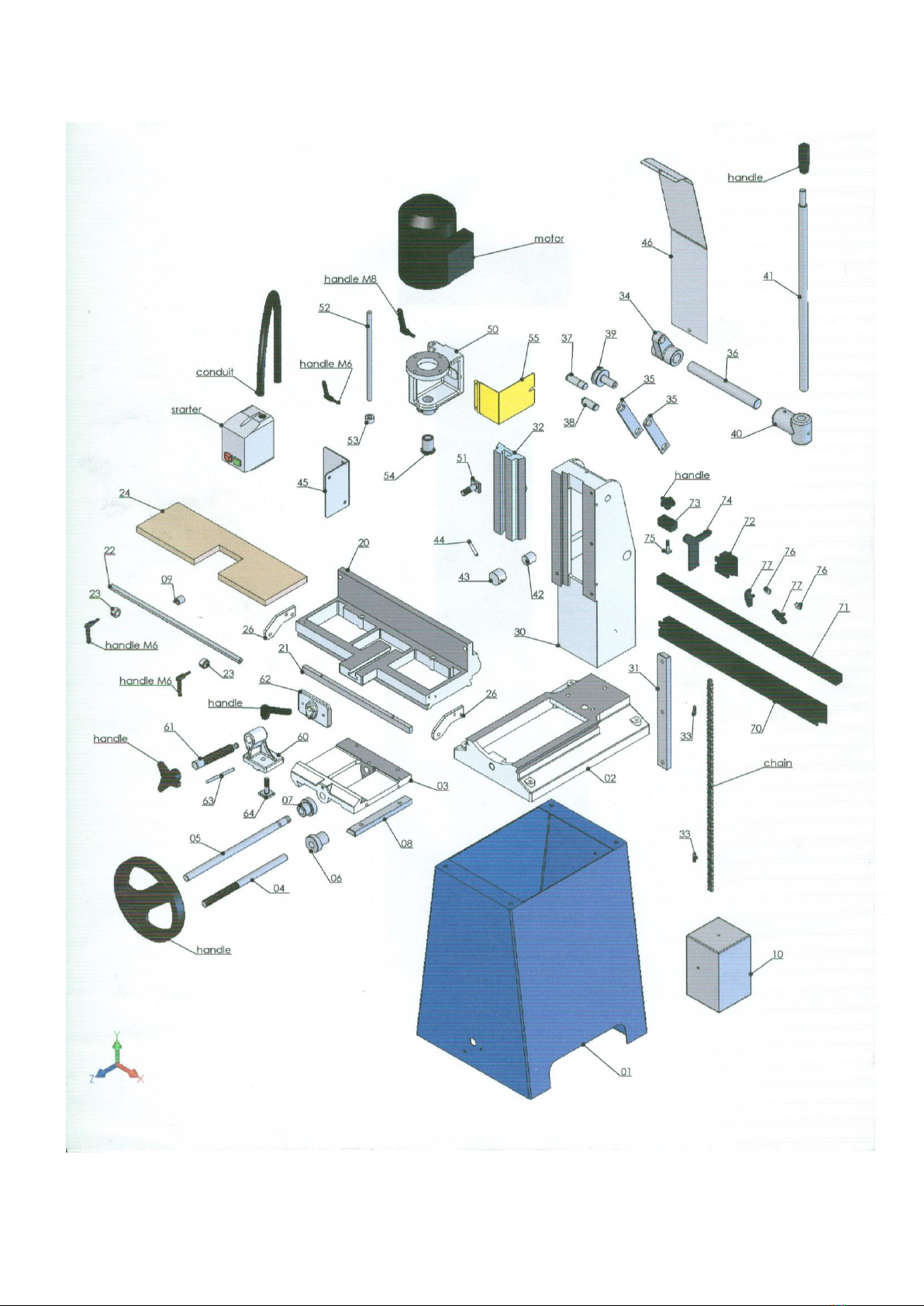

Parts Diagram

571 Operation/Maintenance Instructions Page 19 of 19

Parts List

Base & Cross Slide Assembly

571-42 DEPTH STOP POST

571-01 STAND PTD DK BLUE

571-43 DEPTH STOP CAP

'SEDGWICK' LOGO SCL027

571-44 DEPTH STOP LEVER

571-02 BASE

HANDLE I.580/40 N-8

571-03 CROSS SLIDE

571-45 STARTER BRACKET

571-04 CROSS SLIDE SCREW

571-3 STARTER 415/3/50

SPRING COMP 8DIA X 25

571-1 STARTER 230/1/50

STEEL BALL DIA 5/16INS

571-46 COLUMN COVER

571-05 HANDWHEEL SHAFT

Chisel Head Assembly

HANDWHEEL DIA 250

571-50 CHISEL HEAD

571-06 GEARCUT PINION LONG

MOTOR 1.1KW 3000RPM FLNG MOUNT 3ph

571-07 GEARCUT PINION SHORT

MOTOR 1.1KW 3000RPM FLNG MOUNT 1ph

571-08 CROSS SLIDE VEE STRIP

CHUCK ADJUSTABLE 0-13MM

571-09 LENGTH STOP

CHUCK KEY

571-10 WEIGHT

571-51 TEE BOLT

CHAIN 69 PITCHES EX CONN

SPANNER 24MM SINGLE END

CHAIN CONNECTORS

571-52 DEPTH STOP SHAFT

Table Assembly

571-53 DEPTH STOP COLLAR

571-20 TABLE

LOCKING LEVER M8X20

571-21 GEARCUT RACK

571-54 CHISEL BUSH

571-22 LENGTH STOP SHAFT

571-55 CHUCK GUARD PTD YELLOW

571-23 LENGTH STOP COLLAR

Clamp Assembly

LOCKING LEVER M6X12

571-60 CLAMP BRACKET

571-24 TABLE WOOD

571-61 CLAMP SCREW

571-25 TABLE VEE STRIP

THREE ARM KNOB DIA 16

571-26 LENGTH STOP SUPPORT

571-62 CLAMP PAD

Column Assembly

571-63 CLAMP PAD STEADY

571-30 COLUMN

571-64 CLAMP TEE-BOLT

571-31 COLUMN VEE STRIP

LOCKING LEVER M12

571-32 CHISEL HEAD SLIDE

Setting-Out Attachment Assembly

571-33 ANCHOR PINS

571-70 Setting Out Rail

571-34 CAM LEVER

571-71 Setting Out Rail Inner

571-35 LINKS

571-72 Setting Out Rail Extn Pce

571-36 CAM SHAFT

Wingnut M8x16

571-37 LINK PIN TOP

571-73 Turnover Stop Body

571-38 LINK PIN BOTTOM

571-74 Turnover Stop

571-39 BALANCE PULLEY

571-75 Tee-Bolt

571-40 LEVER BOSS

571-76 Loose Nut

571-41 LEVER

HANDLE I.580/90 N-16

Machine Identification

Your machine has an individual serial number stamped on the top surface of the rear wall of the

table. This number can also be found on the front cover of this manual. Always quote your

serial number when applying for spare parts etc.

Other manuals for 571

1

Table of contents

Other Sedgwick Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

PCB Piezotronics

PCB Piezotronics 353B14 Installation and operating manual

laguna

laguna Plasma Level 2 CNC owner's manual

Langmatz

Langmatz EK278 Installation and assembly instructions

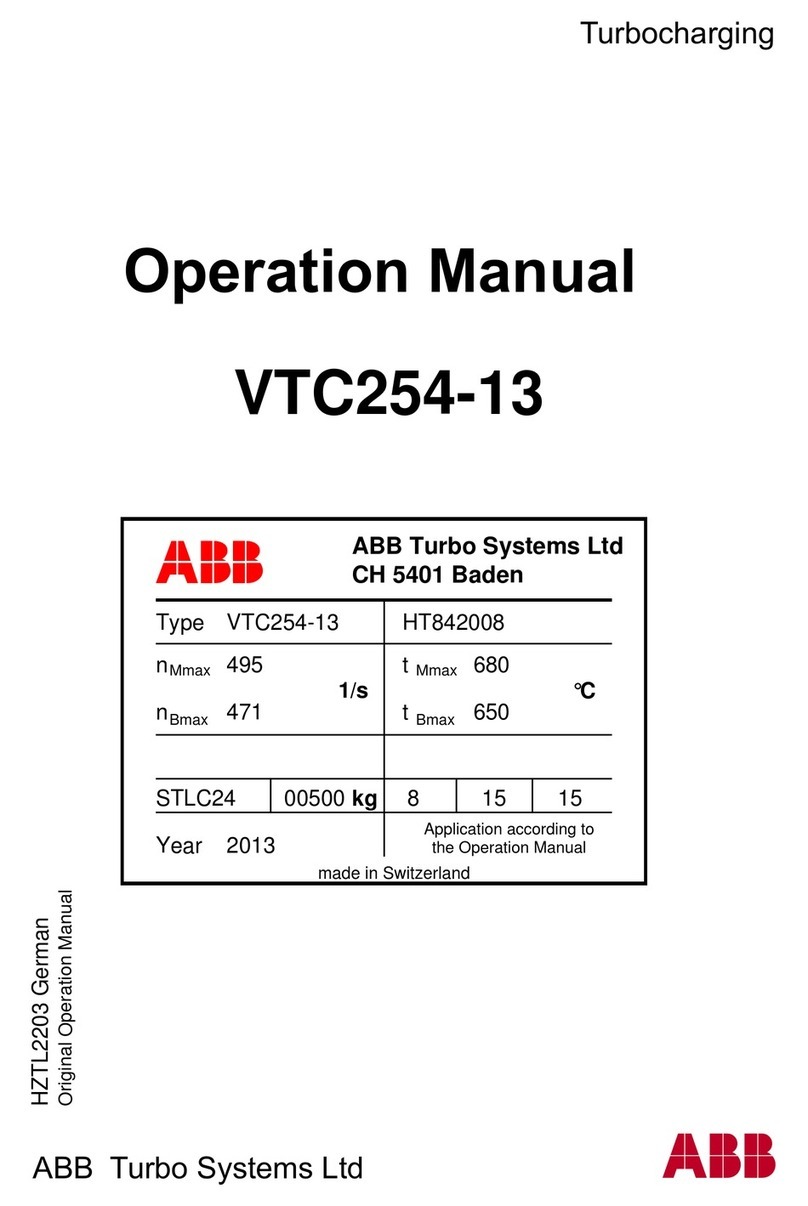

ABB

ABB HT842008 Operation manual

Hitachi

Hitachi P1 Basic instruction manual

Metso

Metso LOKOTRACK LT110C instruction manual