Sedgwick SM255t Troubleshooting guide

SM255t

SPINDLE MOULDER

OPERATION AND MAINTENANCE

INSTRUCTIONS

M. SEDGWICK & COMPANY LIMITED

Stanningley Field Close, Leeds, U.K. LS13 4QG

Tel. +(44) 113 257 0637 Fax. +(44) 113 239 3412

MACHINE SERIAL NO. SM255t-B

SM255t Operation/Maintenance Instructions Page 2 of 32

EC Declaration of Conformity

The manufacturer:

M. Sedgwick & Co. Ltd

Stanningley Field Close, Leeds LS13 4QG

United Kingdom

Telephone +44 113 257 0637

www.sedgwick-machinery.co.uk

Email: admin@sedgwick-machinery.co.uk

declares that the Sedgwick SM255t Spinde Moulder, when installed, maintained and used in

applications for which it was designed, and in compliance with the manufacturer’s

instructions, complies with the provisions of the following European Union legislation,

wherever applicable:

2009/127/EC Machinery Directive

2014/30/EC Electromagnetic Compatibility Directive

BS EN ISO 19085-1:2017 Safety of Machinery. Basic Concepts, General Principles of

Design. Basic Terminology, Methodology.

EN ISO 19085-6:2017 Single spindle vertical moulding machines ("toupies")

EN 60204-1:2018 Safety of machinery. Electrical equipment of machines. General

requirements

Signed for and on behalf of the manufacturer:

Managing Director

M. Sedgwick & Co. Ltd, Jan 2021

SM255t Operation/Maintenance Instructions Page 3 of 32

List of Contents

1.0 Design and Purpose

1.1 Illustration

1.2 Machine Specification

1.3 Shipping Details

2.0 Installation Instructions

2.1 Positioning

2.2 Foundation Drawings

3.0 Connection to a Dust Extraction System

4.0 Electrical Installation

5.0 Switchgear

5.1 The Padlockable Isolator

5.2 Start/Stop Buttons

5.3 Circuit Protection

5.4 Emergency Foot Operated Stop Switch

6.0 Machine Setting

6.1 The Spindle Rise & Fall

6.2 The Loose Top Spindle

6.3 Direction of Rotation

6.4 Table Inserts

6.5 Speed Selection

7.0 Tool Selection

7.1 Tool Setting

7.2 Tool Handling

7.3 Tool Repair

8.0 Machine Guards

8.1 The Main Fence Guard

8.2 The Cutterguard

8.3 The Shaw Guards

8.4 Push Sticks & Push Blocks

9.0 Limitations of Use and Safe & Working Practices

9.1 Warning of Residual Risk

9.2 Warning Labels

9.3 Noise Reduction

10.0 Maintenance

10.1 Cleaning and Lubrication

10.2 Brake Motor Installation & Maintenance

11.0 Parts List

SM255t Operation/Maintenance Instructions Page 4 of 32

Introduction

This Instruction Manual is designed for you in accordance with current UK regulations and EU

law, in particular the European Machinery Directive 206/42/EC.

It describes how to operate the machine properly and safely. Be sure to read carefully and

follow the safety instructions provided as well as any local accident prevention regulations

and general safety regulations. Before beginning any work on the machine, ensure that this

manual, in particular the chapter entitled "Safety" and the respective safety guidelines, has

been read in its entirety and fully understood. This manual is an integral part of the machine

and must always be kept accessible. If the machine is sold, rented, lent or otherwise

transferred to another party, a copy of the manual must accompany it.

All those appointed to work on or with the machine must have fully read and understood the

manual before commencing any work. This requirement must be met even if the appointed

person is familiar with the operation of such a machine or a similar one or has been trained

by the manufacturer. The manufacturer cannot be held liable for damages resulting from a

failure to follow the instructions set out in this manual. Should you have any questions

regarding this manual, please contact the manufacturer.

1.0 Design and Purpose

The Sedgwick SM255t Spindle Moulder is a hand fed machine designed to profile wood and

other analogous materials. Such operations may include:

1. Straight Moulding e.g., rebating, bevelling, and grooving.

2. Circular Moulding (optional Ring Fence and Cage Guard required).

3. End Grain Work e.g., Tenoning and Finger Jointing (optional Sliding Table required).

The machine is not designed for any other purposes except as set out above. The

operator of the machine shall be solely liable for any damage that results from

improper use of the machine.

The machine should not be modified in any way without the written consent of the

manufacturer. Please also refer to Section 11.0 regarding use of unauthorised spare parts.

SM255t Operation/Maintenance Instructions Page 5 of 32

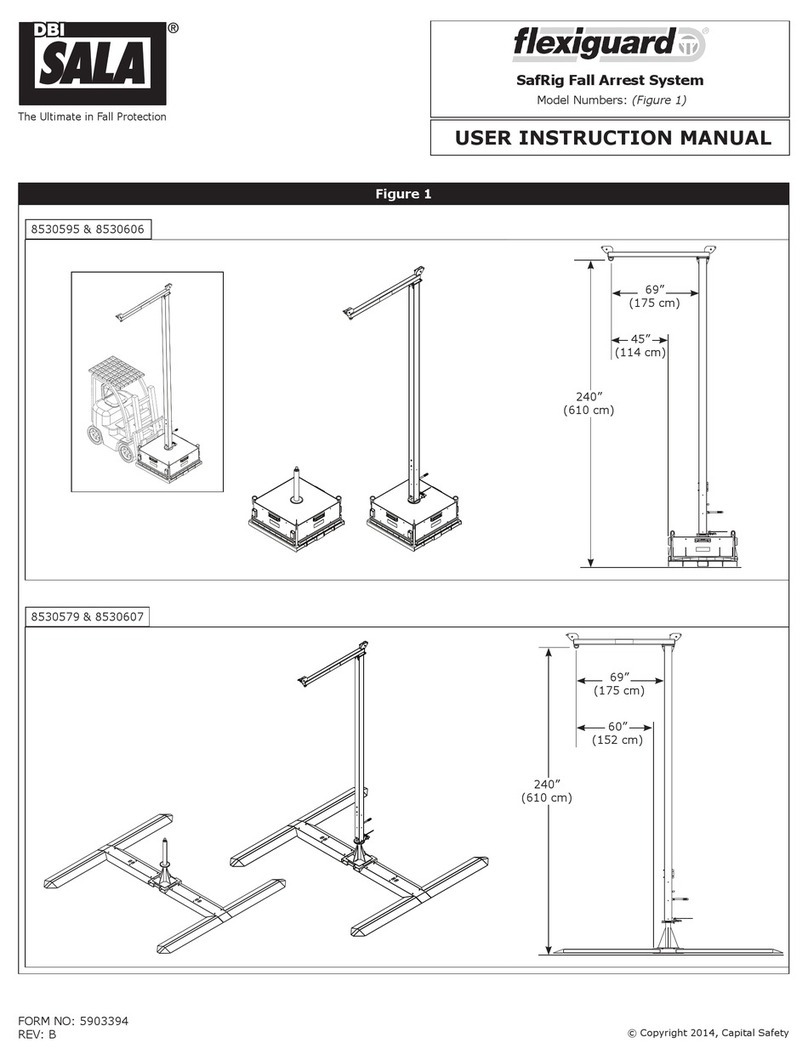

1.1 Illustration

FENCE HOLD DOWN HANDLES

EXTRACTION OUTLETS

CUTTERGUARD SHAW GUARDS

SWITCHGEAR/

ISOLATOR

FENCE PLATES

SPINDLE HEIGHT

INDICATOR

RISE & FALL HANDLE

SPINDLE ANGLE INDICATOR

SPINDLE R & F LOCK

TILT HANDLE

TILT LOCK

FOOT STOP SWITCH

SM255t Operation/Maintenance Instructions Page 6 of 32

1.2 Machine Specification

SM255T

TABLE SIZE L x W

1000 x 750mm

TABLE HEIGHT

880mm

MAX CUTTERBLOCK DIA.

150mm

MAX PROFILING CUTTER DIA.

255mm

MAX CUTTER WEIGHT

7Kg

MAX RETRACTABLE TOOL SIZE

180 x 65mm

SPINDLE DIA.

30mm (Optional 11/4”)

SPINDLE LENGTH

180mm

SPINDLE SPEEDS rpm

3000/4500/6000/8000

SPINDLE STROKE

90mm

FENCE PLATES (H x L)

150x425mm

DUST EXTRACTION OUTLETS

125 & 100mm

TOTAL AIR VOLUME REQUIRED

(Straight work)

1 100

VOLTAGE/FREQUENCY

3 PHASE+EARTH; 400/230v –50/60

Hz

1 PHASE+N+EARTH; 230V - 50/60 Hz

MOTOR RATING

3 PHASE 5.5Kw IE2 (S1)

1 PHASE 3.8Kw

MOTOR FULL LOAD CURRENT IN

AMPS

3 PHASE 8.0A

1 PHASE 16.5A

STARTING CURRENT IN AMPS

3 PHASE 48A

1 PHASE 99A

REQUIRED FUSE SIZE IN AMPS

3 PHASE 20A/ph

1 PHASE 40A

REQUIRED CABLE SIZE

3 PHASE 2.5mm2

1 PHASE 4.0mm2

1.3 Shipping Details

DIMENSIONS (m/c only) LxWxH

1120x760x1440mm

NETT WEIGHT

425 kg

SM255t Operation/Maintenance Instructions Page 7 of 32

2.0 Machine Handling

The following section offers a guide to transporting, assembling, and installing the machine,

which should be done following an adequate risk assessment. Movement, adjustment, or

installation of the machine should not be attempted without proper training in the handling

of heavy machinery.

There is a risk of physical injury when moving the machine. The machine could

be damaged or written-off if not handled properly during transportation.

Always use a sling within the safe working load of the machine weight. Machine weights are

provided above. Sling underneath either side of the machine table, ensuring that you do not

catch the starter etc. Take care not to lift the machine by the slide bar on the front of the

machine table (if fitted) as damage to this will inhibit the movement of the sliding table. Do

not walk or stand under the machine during lifting.

Upon arrival, check that the machine has not suffered any damage during transit. Reuse or

recycle any packaging materials (e.g., wooden pallet) and where not possible to do so,

dispose of them in accordance with local refuse requirements.

2.1 Positioning

First ensure that there is ample power supply available, together with good lighting and

ventilation.

Second ensure that there is sufficient unobstructed space around the machine to enable the

work being done at it to be done without risk of injury to persons employed.

The chosen floor space should be in good and level condition to enable the machine to be

anchored at four points. Holes for M10 foundation bolts (not supplied) are provided at either

corner of the inside of the fabricated body. Remove the machine’s side guard, score marks

through these holes, drag the machine out of the way, and drill the necessary holes and

insert fixing plugs. Finally, make sure that the machine is not rocking. Pack under the feet of

SM255t Operation/Maintenance Instructions Page 8 of 32

the base if it is. This will keep the machine from rocking and generating vibration during the

cut.

2.2 SM255t Foundation Drawings

Remove the protective rust preventative using turpentine or paraffin. Do not use any solvent,

petrol, or gas oil, which might dull the paint or oxidise the paintwork. Lightly oil cleaned

surfaces to prevent rusting.

2.2 Storage

Keep the machine sealed in its original packaging until required for assembly/installation and

be sure to observe the machine handling advice on the outside of the packaging.

Store under the following conditions:

• Store indoors in a dry and dust-free environment.

• Do not expose to toxic substances or direct sunlight.

•Store in ambient temperatures and ensure environment is not damp; avoid exposure to

condensation.

• If storing for a period of several weeks, apply a coat of oil to all machine parts that might

rust before storing and check condition before operating for the first time after being in long-

term storage.

2.3 Disposal

If disposing of the machine, separate all components into piles of the same material e.g.,

steel, to recycle. The main structure is made of cast iron and steel and can therefore be

safely dismantled and recycled. Always comply with local environmental regulations when

disposing of machinery.

Be aware of your environmental obligations. Carefully consider the disposal of

any electrical components e.g., motors, starters, and ensure any lubricants etc.

are treated as hazardous waste and disposed of safely in accordance with

environmental laws.

SM255t Operation/Maintenance Instructions Page 9 of 32

3.0 Connection to a Dust Extraction System

All employers are duty bound under the Factories Act 1961, The Health and Safety at Work

Act 1974 and the Control of Substances Hazardous to Health Regulations 1988 to control

wood dust in the workplace.

Wherever possible this should be achieved by measures other than the provision of personal

protective equipment.

To effectively exhaust these machines, they should be connected to a dust extraction unit

with a minimum air volume with the chart below. A 125mm-dia outlet is located at the rear of

the fence horseshoe. A 100mm-dia outlet is provided for extraction below the cutter-well.

Always switch the dust extraction system on before switching on the machine.

SM255t Operation/Maintenance Instructions Page 10 of 32

4.0 Electrical Installation

Electrical wiring should only be carried out by a fully qualified electrician taking

in account the following safety instructions.

•The motor, starter, and isolator have been wired in at the factory and tested before

despatch. All that is required is to connect the power supply to the isolator.

•Check that the supply details on the motor nameplate correspond with the site

supply.

•It is important that the correct cable size is used to avoid a voltage drop at the

motor terminals. If the motor is operated on a voltage outside, plus or minus 6% of

the spot voltage, then premature failure will occur.

•Do not wire single-phase machines into a 13 amp plug socket.

•It is important to check rotation of the spindle which should be anti-clockwise when

viewed from the front of the machine.

Should you encounter problems on start-up check for the following likely causes:

Symptom

Check

Machine does not start at all.

Isolator is switched to ON and all STOP buttons are out.

Overload button is reset.

Starter coil/contactor is operational.

There are no loose connections.

There are no fuses blown.

Supply is reaching the starter.

Supply is reaching the motor.

Voltage between the phases at starter and motor.

Motor runs but trips.

Overload setting in starter.

Current drawn without load applied.

Current drawn under load.

Supply voltage without load and on moment of switch on.

Allowed variation plus/minus 6%.

Supply voltage under load.

Supply voltage with motor off.

Supply to all three phases at isolator, starter and at motor.

Note that it is possible for 3 phase machines to operate

with only 2 phases of the supply. This is known as single

phasing. Check all fuses.

Motor attempts to start then

trips.

The machine is not jammed, and the spindle is free to

rotate.

Winding resistance of each motor phase (values should all

balance).

Insulation resistance between windings and earth.

The correct cable size has been used to install the

machine (long runs of cable can cause voltage drop).

SM255t Operation/Maintenance Instructions Page 11 of 32

4.1 Three Phase Wiring Diagram

SM255t Operation/Maintenance Instructions Page 12 of 32

4.2 Single Phase Wiring Diagram

SM255t Operation/Maintenance Instructions Page 13 of 32

5.0 Switch Gear

5.1 The Padlockable Isolator

With this switch in the OFF position the machine is effectively isolated from the

supply to allow personnel safe access for maintenance or repair work and to

prevent dangerous restarts. To prevent unauthorised use of the machine the

switch can also be secured in the OFF position using a padlock.

To operate the machine first turn the isolator to the ON position.

5.2 Start / Stop Buttons

The motor is then started by pushing the green (power on) button on the starter panel and

stopped using the red (power off) button. The mushroom headed lock-off stop switch, once

pressed will remain locked in the off position. To restart the machine, it is necessary to release

the off button by twisting it in a clockwise direction.

5.3 Circuit Protection

In case of a mains failure the starter is fitted with no volt release protection and will not restart

without being switched on again. The starter is also fitted with an overload protection

device. An electrical overload occurs where an electric motor is subjected to a greater load

than it was designed for. This can be caused by short circuit, by incorrect installation, or by

misuse (including poor machine maintenance). The inbuilt breaker will therefore help prevent

damage to the motor should such a situation occur. The motor cannot be restarted until the

breaker has reset itself.

5.4 Brake Release Switch

Machines fitted with an electro-magnetic brake unit are also equipped with a ‘Brake

Release’ switch. This switch makes it possible to release the brake mechanism, allowing the

operator to rotate the spindle when changing or adjusting the cutting knives. To operate the

switch first turn the isolator to ON, release the mushroom headed lock-off stop switch, and

turn the brake release to ‘BRAKE RELEASE’. It is not possible to start the motor with the switch

in this position. To start the motor, turn the switch back to the RUN position.

5.4 Emergency Foot Operated Latching Stop Switch

This switch is provided for use in emergency situations only. We do not

recommend that it is used in lieu of the stop switch on the front of the starter

panel. The foot switch once pressed will remain locked in the off position. To

restart the machine, it is necessary to release the switch by pulling it

towards you.

SM255t Operation/Maintenance Instructions Page 14 of 32

6.0 Machine Setting

Details on the correct setting of the guards, fences, and other safety devices, are detailed in

the following sections of this manual. Prior to these operations however the following checks

should be carried out:

1. Isolate the machine before setting up or making any alterations.

2. Ensure that the arbor mounting, cutterblock and cutters are clean and free from grease,

rust preventative, rust and wood residue etc.

3. Check visually for any cracks or distortion in the cutters and replace any suspect

components.

4. Check that the cutters are mounted correctly for anti-clockwise rotation when viewed

from the front of the machine.

5. The fence assembly and spindle guards are securely fastened to the table.

6. The timber is free of grit, nails or other foreign bodies.

7. The table is free of spanners, rules etc., and that all tools are returned to their rightful

place.

ENSURE THAT ALL STOCK IS CLEAR OF THE BLADE BEFORE START-UP

ENSURE THAT THE SPINDLE HAS REACHED FULL SPEED BEFORE PRESENTING THE WORKPIECE TO

IT. IT IS ESSENTIAL THAT THE MACHINE IS SWITCHED OFF WHEN LEFT UNATTENDED.

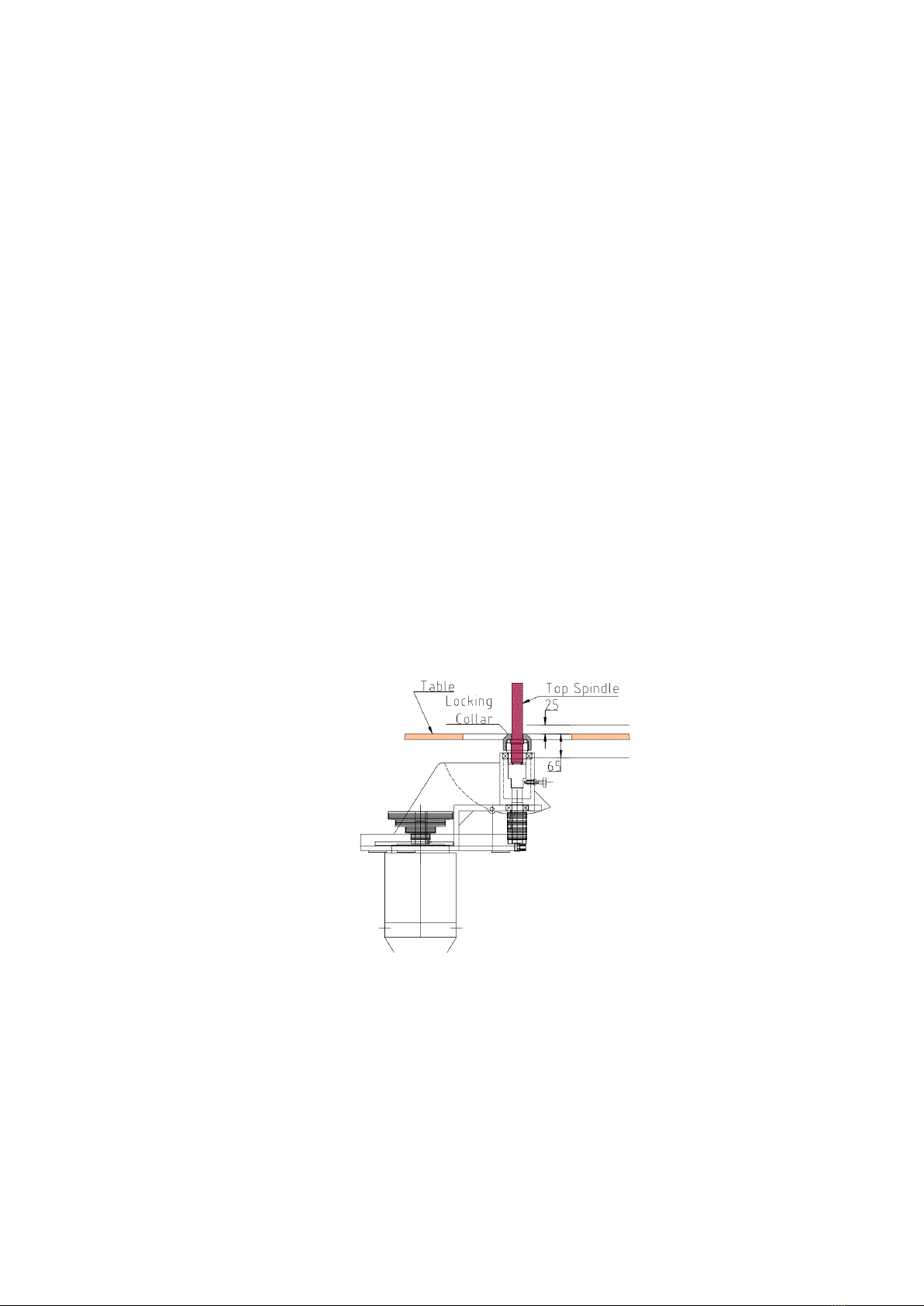

6.1 The Spindle Rise and Fall and Tilt

To adjust the spindle height, first untighten the Spindle Lock positioned directly behind the

handwheel. Rotate the handwheel clockwise for up, and anti-clockwise for down.

The range of adjustment is =25mm above the Table and -65mm below referenced to the

Locking Collar surface from which the cutter blocks may be mounted.

Always make final adjustments to the spindle height against gravity and re-tighten the

Spindle Lock prior to start-up.

Stiffness in the rise and fall movement could be caused by:

1. The Spindle Lock not releasing or being released.

2. Dirt or rust between the barrel and the bearing housing.

3. A lack of lubrication.

4. Badly worn gears (usually the result of an effort to force the rise and fall mechanism

when stiff).

5. Dirt between the gear teeth.

6. Offcut wedges between the slideways.

SM255t Operation/Maintenance Instructions Page 15 of 32

On the Sedgwick SM255t the complete motor and spindle sub-assembly tilts independently

of the Rise and Fall mechanism. The tilt action rotates about the centre line of the spindle at

the locking collar surface, the operator therefore maintains the same depth of wood cut

irrespective of whether a new height of cut is chosen.

The operator is provided with stops at =%, 0 and -45 degrees. At the zero stop the operator

must hand withdraw the Zero Stop Plunger to enable further tilt, either in the +5 or -45

direction.

6.2 The Spindle Unit

The loose top spindle onto which the cutters are mounted is attached to the main spindle by

a draw bar. To remove the loose top spindle, first isolate the machine. Open the cabinet

door. Using the two 19mm spanners, one set on the flats of the loose spindle, the other on the

bolt head at the bottom of the spindle pulley, untighten the bolt. This enables the loose top

spindle, complete with cutters, spacing sleeves, and lock nut to be removed as a unit from

the machine without disturbing their setting. Use only the spanners supplied with the

machine. Never add extra leverage as this strains the bolts and leads to excessive wear.

If several months pass between spindle changes it is good practice to wipe a light film of oil

over the spindle base before installing it in the arbor.

SM255t Operation/Maintenance Instructions Page 16 of 32

6.3 Direction of Rotation

The machine spindle is designed for one direction of rotation only. The rotation should be

anticlockwise when viewed from the top.

It is most important that the tooling is fitted to the machine to operate in the correct direction

of rotation. The operator shall ensure that the workpiece is fed to the tools against the

direction of spindle rotation. To reduce the risk of kickback, always start the machine before

presenting the workpiece. Ensure that the machine is switched off when left unattended.

6.4 Table Inserts

Use the table rings provided to reduce the gap between the table and the spindle to a

minimum. Correct use of the table rings to give the smallest possible hole reduces the risk of

the workpiece dipping and catching the edge as it passes over the gap.

6.5 Speed Selection

The relationship between the tool diameter, the cutting length and the maximum rotational

speed of the spindle is important. This can be determined from the following graph:

To obtain the different spindle speeds required for the various diameters and types of cutter

equipment simply alter the position of the drive belt again the pulley ratio.

This unit is totally enclosed within the main frame and is accessed via the door on the front of

the machine’s body.

It is important that all spindle motion has ceased, and the machine has been electronically

isolated before opening this door.

SM255t Operation/Maintenance Instructions Page 17 of 32

The motor is face mounted to a hinged platform, which is adjustable for position along a slot

in which the locking lever runs. To change the selected speed the lever must be unlocked,

and the motor plate pulled forward to release the tension on the drive belt. The poly-vee belt

may then be relocated on the pulleys, the motor plate pushed away to re-tension the belt,

and the lever re-locked. Always ensure that the belt is fully engaged within the full set of

grooves for each speed setting on both motor and spindle pulleys before starting the

machine.

7.0 Tool Selection

Only tools conforming to EN847-1:1997 and marked MAN should be fitted to this machine

(refer to manufacturer’s sales literature).

Only use tooling with the manual feed cutter blocks usually mark with ‘MAN’.

LIMITED CUTTER PROJECTION TOOLING

Where possible, always use limited cutter projection tooling.

The following information is contained in the HSE Information Sheet ‘PUWER 98: Selection of

tooling for use with hand-fed woodworking machines’:

Limited cutter projection tooling (sometimes referred to as chip thickness limitation

tooling) significantly reduces:

● the severity of injury if a machine operator’s fingers contact the rotating tool;

● the risk of workpiece kickback.

Most accidents at woodworking machines are due to the operator’s hands or fingers

encountering the rotating cutters. Amputation usually results. Between 1993 and 1996

there were 165 injuries (amputations and severe lacerations) at machines where

limited cutter projection tooling could have been fitted. It is estimated that limited

cutter projection tooling would have reduced the seriousness of injury in 90% of these

accidents. By reducing the risk of kickback, this type of tooling can also help prevent

many other serious injuries.

SM255t Operation/Maintenance Instructions Page 18 of 32

On round form tools, limited cutter projection should be achieved by restricting the

projection of the cutter beyond either:

●the round profile of the tool body

● or a ‘limiter’ (also called a deflector or counter knife) which mirrors each cutter

Note: Limited cutter projection tooling should be used in addition to the normal

guards, protection appliances (jigs etc) and safe working practices, not as an

alternative.

7.1 Tool Setting

For safety reasons the cutterhead should whenever possible be mounted to run from

underneath the stock so that the stock will cover the cutterhead and shield your hands. Set

the cutterblock as low on the spindle arbor as possible. Always use cutters that are a

matched pair and mount them directly opposite each other ensuring that they have the

same projection and are dynamically balanced. Most problems experienced on spindle

moulding machines arise from out of balance cutters, with the resulting bad feature of

excessive vibration, which tends to produce a poor finish on the article being machined.

Ensure that the correct number of spacers is used to effectively clamp the cutters.

7.2 Tool Handling

Care should be exercised when handling tools, wherever practicable use a tool carier or

wear protective gloves.

7.3 Tool Repair

Repair of tools should be carried out in accordance with the manufacturer’s instructions.

People who carry out repair of tools should be adequately trained and have knowledge of

the design requirements (eg BS EN 847-1: 1997) and levels of safety to be achieved.

SM255t Operation/Maintenance Instructions Page 19 of 32

7.4 Tool Changing

Raise the spindle to the maximum height and lock off the rise and fall using the lever next to

the rise and fall hand wheel (clockwise to lock). Using a 30mm spanner and M8 hex key

untight the hex bolt from the top of the arbor and remove the bolt and spindle nut and put

them safely to one side. Fit the cutter block by sliding it onto the arbor (check the rotation of

the block) and using the spaces and the spindle nut to clamp the cutter inplace. Tighten the

spindle nut and hex nut. Make sure that it is tighten securely.

8.1 The Main Fence Guard

The Sedgwick SM255t Spindle Moulder incorporates a plain table and a cast-iron ‘Horseshoe’

type fence guard.

Adjustment and Use

For coarse adjustment, the complete fence assembly freely moves as one. The two Fence

Hold-Down Handles effectively clamp the assembly to the table through slotted holes in the

horseshoe. The table has been drilled and tapped for several different locations. The fence

plates can be independently adjusted by releasing the locking levers at the sides of the

horseshoe, and operating the hand-wheels at the rear, remembering then to re-tighten them

once adjusted.

The gap between the two halves of the straight fence must be wide enough to give

clearance for the cutterblock yet narrow enough to limit unnecessary exposure of the

cutters. Similarly ensure that the leading end of the workpiece does not foul the edge of the

take-off half of the fence. These risks may be eliminated using a false fence.

A ‘false fence’ is a board fixed to the two half fences and spanning the gap between them,

it is cut away just sufficiently to allow the cutters to project by the necessary amount. The

exact size of false fence required will depend upon the work being done and it may be

SM255t Operation/Maintenance Instructions Page 20 of 32

necessary to fit a different false fence for every job carried out. Care should be taken in the

making of a false fence. It is recommended that the cutter opening shall be made by a

controlled screw adjustment on the fence on to the cutter and not by pushing the fence on

to the cutter by hand.

The following faults in fences can occur and should be checked:

A) Fences out of alignment. Chippings packed behind the front fence plate and back

fence can cause this.

B) Fences are parallel but not level with one another. Use the fine adjustment screws to

bring them level.

C) Fences are not square against the table. Chippings at the base of the fence plate

can cause this.

8.2 The Cutterguard

The yellow hood on top of the horseshoe assembly is designed to enclose the cutting area

just above the workpiece. It is important that this is always secured in position when using the

horseshoe as it provides protection from ejected cuttings or cutters which might be thrown

off the workpiece or cutterblock while in operation.

Check that the hood is securely in position before switching on.

8.3 The Shaw Guards

The Shaw Guards are a valuable aid when machining straight work where the moulding

extends over the full length of the workpiece. They serve the dual-purpose of steadying the

workpiece, preventing vibration which could cause kick-back, and enclosing the cutting

area.

Work of this type is done with the aid of the straight fence, and in most cases the workpieces

are of regular rectangular section throughout their length. The workpieces can, therefore, be

guided in the volume formed between the Table, Shaw Guard, and fence. The vertical and

Table of contents

Other Sedgwick Industrial Equipment manuals