Sedgwick MB Troubleshooting guide

MB/CP

PLANER THICKNESSER

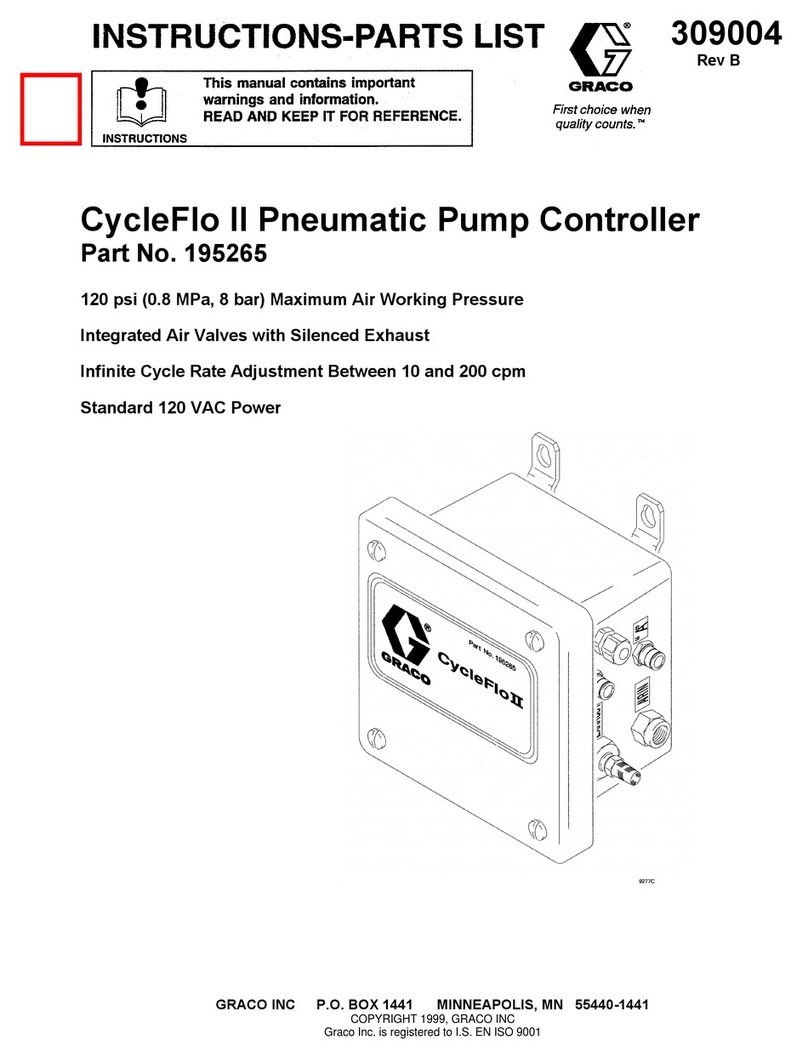

OPERATION AND MAINTENANCE

INSTRUCTIONS

Manufactured in Britain

MACHINE SERIAL NO.

2

DECLARATION OF CONFORMITY

ORIGINAL

Business Name and Full Address of Manufacturer

M. Sedgwick & Co. Ltd. - Stanningley Field Close, Leeds LS13 4QG

Description of product (Commercial Name)

Model MB / CP Planer Thicknesser

Function, Model, Type

Function: Woodworking Machine

Type: Planer Thicknesser

Model: MB / CP

Standards Used

BS EN 861 - 2007 + A2 2012

Place of Declaration

M. Sedgwick & Co. Ltd.

Date of

Declaration

09 May 2017

Name, Address and ID No of Notified Body

TUV SUD BABT Octagon House, Concorde Way, Segensworth North, Fareham PO15

5RL

NB # 0168

No of EC Type Examination Certificate

MAC000012 i01

Declaration

I declare that the machinery fulfils all the relevant provisions of the following

Directives:- Machinery Directive 2006/42/EC, Electromagnetic Compatibility

Directive 2014/30/EU

Person Empowered to Draw Up Declaration

Name:

G. Sedgwick

Position:

Managing Director

Signature:

3

List of Contents

1.0 Design and Purpose

1.1 Illustration

1.2 Machine Specification

1.3 Shipping Details

2.0 Handling Instructions

2.1 Positioning

2.2 Foundation Drawings

3.0 Connection to a Dust Extraction System

3.1 Chip Extraction Hood

4.0 Electrical Installation

5.0 Switchgear

5.1 The Padlockable Isolator

5.2 Start/Stop Buttons

5.3 Two/Three Position Rotary Switch

5.4 Circuit Protection

5.5 Brake Release Switch

5.6 Optional Emergency Foot Operated Stop Switch

6.0 Guarding

6.1 The Front Cutterblock Guard

6.2 The Rear Cutterblock Guard

6.3 The Rear Drive Guard

6.4 The Anti Kickback Fingers

7.0 The Cutterblock / Knife Changing

7.1 The Optional TERSA Monobloc

8.0 Preparation of the Workpiece

8.1 Pilot Checks

9.0 Surface Planing

9.1 Flatting

9.2 Planing Wide

9.3 Bowed Boards

9.4 Edge Planing (Squaring)

9.5 Bevelling or Chamfering

9.6Push Blocks and Push Sticks

10.0 Thicknessing

11.0 Diagnosing Faults in Planing

12.0 Limitations of Use and Safe & Working Practices

12.1 Noise Reduction

12.2 Warning Labels

13.0 Maintenance

13.1 Lubrication

13.2 Cutterblock & Bearings

13.3 Vee Belt and Pulleys

13.4 The Feed Rollers

13.5 Planer Tables

13.6 The Fence

14.0 Parts Illustration

14.1 Parts List

15.0 Wiring Diagrams

4

Introduction

This Instruction Manual is designed for you in accordance with The Supply of Machinery (Safety)

Regulations 1992, and the Supply of Machinery (Safety) (Amended) Regulations 1994, which

implement the European Machinery Directive 89/392/EEC.

It describes how to operate the machine properly and safely. Be sure to follow the safety

instructions provided as well as any local accident prevention regulations and general safety

regulations. Before beginning any work on the machine, ensure that the manual, in particular

the chapter entitled "Safety" and the respective safety guidelines, has been read in its entirety

and fully understood. This manual is an integral part of the machine and must therefore be kept

accessible at all times. If the machine is sold, rented, lent or otherwise transferred to another

party, a copy of the manual must accompany it.

All those appointed to work on or with the machine must have fully read and understood the

manual before commencing any work. This requirement must be met even if the appointed

person is familiar with the operation of such a machine or a similar one, or has been trained by

the manufacturer.

1.0 Design and Purpose

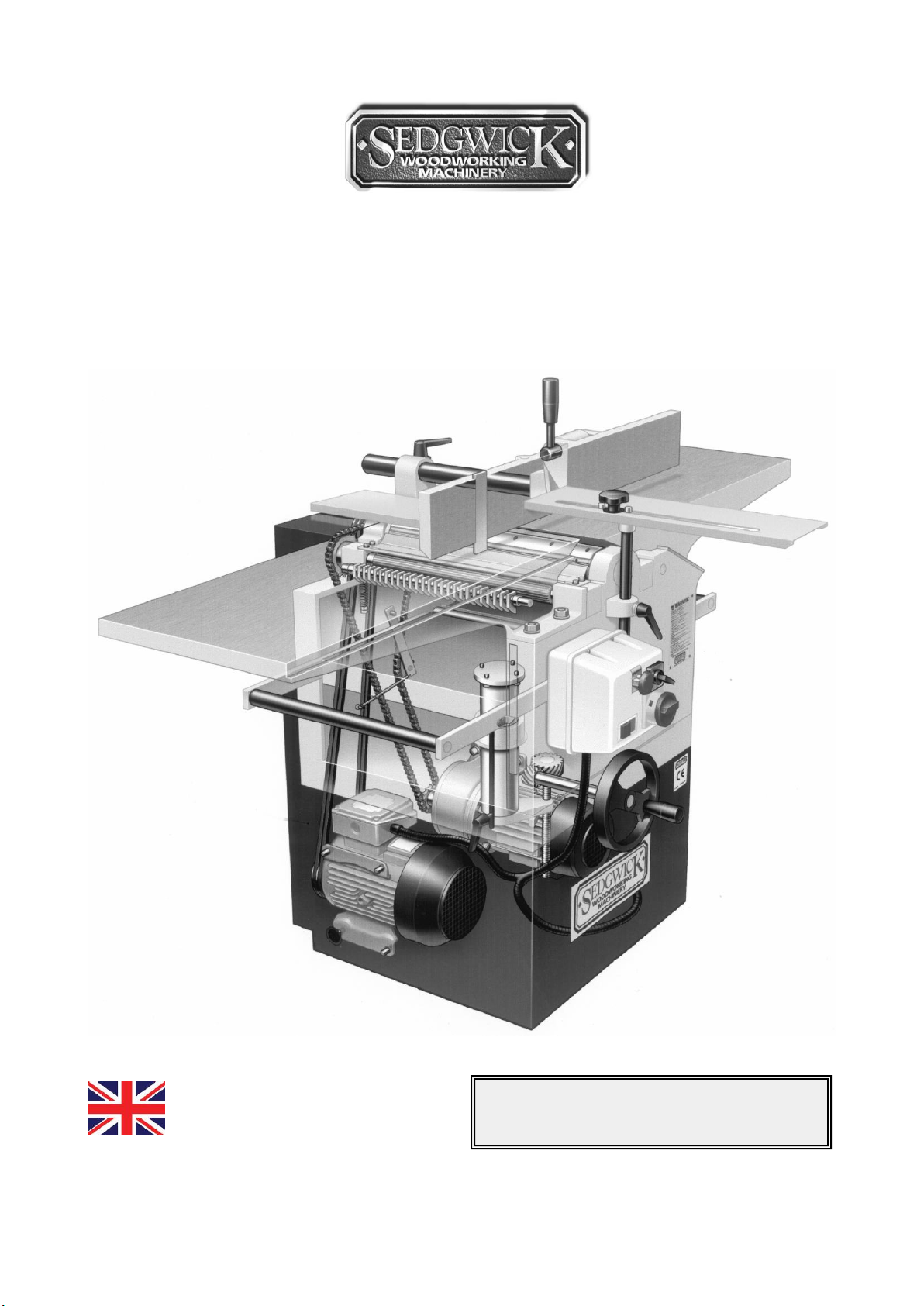

The MB/CP Planer Thicknesser is a dual-purpose machine designed to plane wood and similar

materials by means of a horizontally rotating cutterblock. When surfacing, the workpiece is

passed over the top of the cutterblock and the lower surface is planed. The infeed table of the

surface-planing unit is adjustable in height. When planing material to a set thickness, the wood

is passed underneath the cutterblock, supported by the thicknessing table, and the top surface

is planed.

The following operations can also be performed on the machine, and guidelines on how these

should be performed safely are provided in this manual: flatting, edging, chamfering, and

bevelling.

Any use outside of the machine's intended purpose shall be considered improper

and is therefore not permitted. All claims regarding damage

resulting from improper use that are made against the manufacturer

and its authorised representatives shall be rejected. The operator

shall be solely liable for any damage that results from improper use of the

machine.

It is expressly forbidden to make any unauthorised modifications to the machine.

5

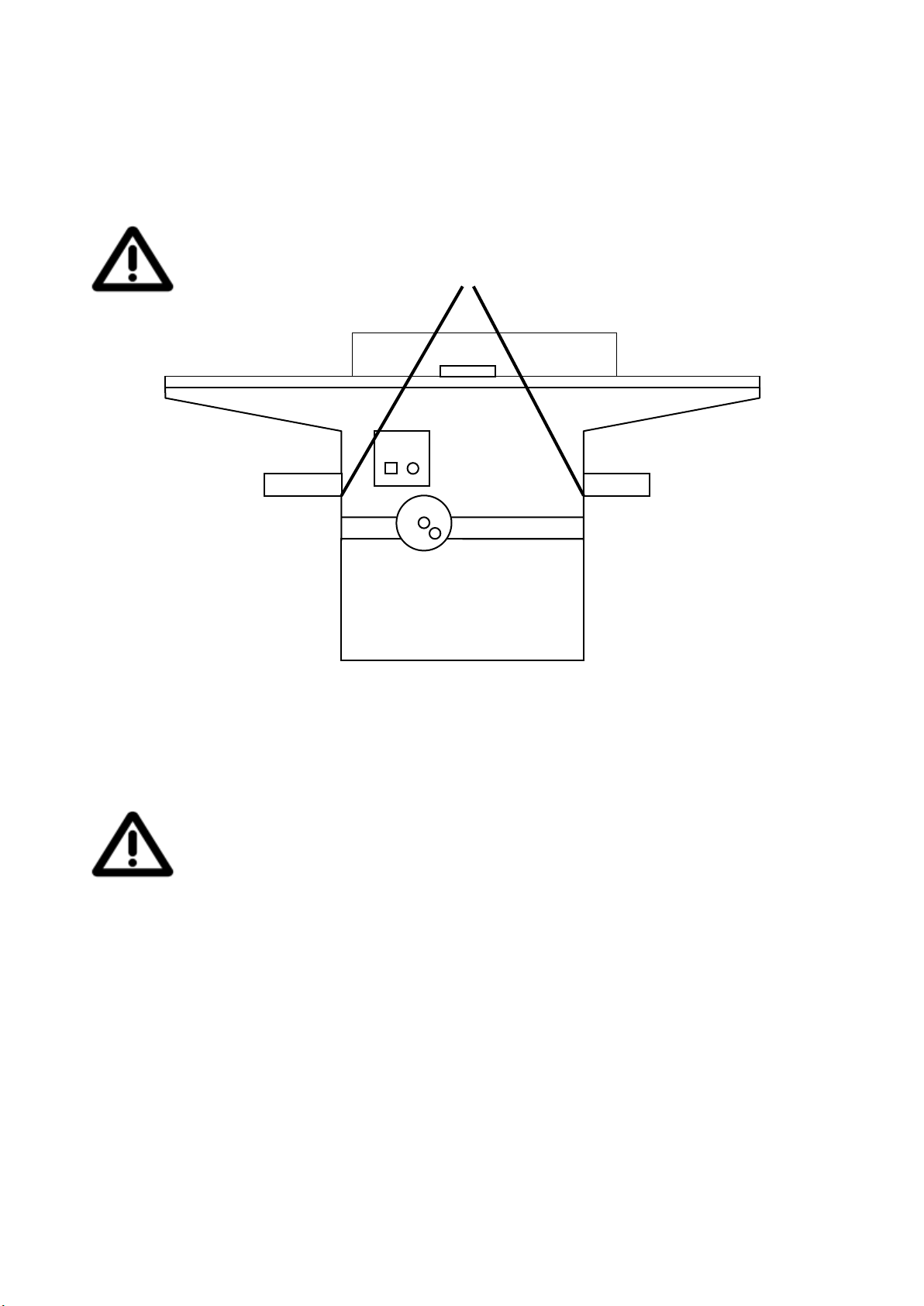

1.1 Illustration

FENCE CANT LOCK

SURFACE TABLE RISE

AND FALL HANDLE

CUTTERBLOCK

GUARD

HORIZONTAL LOCK

4

CUTTERBLOCK GUARD

VERTICAL LOCK

THICKNESSING TABLE RISE

AND FALL

THICKNESSING TABLE

VERTICAL LOCK

MOTOR SWITCHGEAR

REAR MACHINE GUARD

REAR CUTTERBLOCK

GUARD

FENCE LATERAL LOCK

SURFACE TABLE RISE AND

FALL LOCK

6

1.2 Technical Specification

MB

CP

SURFACE CAPACITY

308 mm

410 mm

THICKNESSING WIDTH

308 mm

410 mm

THICKNESSING DEPTH

230 mm

230 mm

SURFACE TABLE LENGTH

1500 mm

1700 mm

INFEED TABLE LENGTH

850 mm

850 mm

SURFACE TABLE HEIGHT

900 mm

900 mm

THICKNESSING TABLE LENGTH

600 mm

600 mm

TABLE LENGTH OVER EXTN ROLLERS

1000 mm

1000 mm

CUTTERBLOCK DIAMETER

102 mm

102 mm

CUTTERBLOCK KNIVES

3 Std (4 TERSA)

3 Std (4 TERSA)

CUTTERBLOCK SPEED

4000rpm

4000 rpm

FEED ROLLER DIAMETER

51 mm

51 mm

FEED SPEEDS

3 PHASE 4.5 & 7m/min

1 PHASE 6 m/min

3 PHASE 4.5 & 7m/min

1 PHASE 6 m/min

FENCE SIZE

900 x 140 mm

900 x 140 mm

TILTING ANGLE OF FENCE

0O–45O

0O–45O

CHIP EXTRACTION OUTLET DIA.

125mm

150mm

VOLTAGE / FREQUENCY

3 PHASE + EARTH ; 400/230 V –50/60 Hz

1 PHASE + N + EARTH ; 230V / 50/60 Hz

CUTTERBLOCK MOTOR RATING

3 PH 3.0Kw IE2 (S1)

1 PHASE 3.0 Kw

3 PH 4.0Kw IE2 (S1)

1 PHASE 3.8 Kw

FEED MOTOR RATING

0.375 Kw

0.375 Kw

MOTOR FULL LOAD CURRENT IN AMPS

3 PH C’BLOCK 6.5A

1 PH C’BLOCK 14.6A

3 PH FEED1.5/1.3A

1 PH FEED 2.8A

3 PH C’BLOCK 8.0A

1 PH C’BLOCK 16.5A

3 PH FEED 1.5/1.3A

1 PH FEED 2.8A

STARTING CURRENT IN AMPS

3 PHASE 39A

1 PHASE 87.6A

3 PHASE 48A

1 PHASE 99A

REQUIRED FUSE SIZE IN AMPS

3 PHASE 20A/ph

1 PHASE 40A

3 PHASE 20A/ph

1 PHASE 40A

REQUIRED CABLE SIZE

3 PHASE 2.5mm2

1 PHASE 4.0mm2

3 PHASE 2.5mm2

1 PHASE 4.0mm2

1.3 Shipping Details

DIMENSIONS - Length x Width x Height

1550 x 950 x 1265

1700 x 1050 x 1275

MACHINE WEIGHT

Total Weight, including Packing Crate

390 Kg

500 Kg

430 Kg

560 Kg

7

Personal Protective Equipment

When working on or with the machine, the following must be strictly observed:

Persons with long hair who are not wearing a hairnet are not permitted to work on or

with the machine.

It is prohibited to wear gloves while working on or with the machine.

When working on or with the machine, the following must always be worn by personnel:

Protective clothes - Sturdy, tight-fitting clothing (tear-resistant, no wide sleeves).

Protective footwear - that protect the feet from heavy falling objects and prevent

sliding on slippery floors

Hearing protection - To protect against loss of hearing.

Residual Hazards

The machine is considered operationally safe when used properly; nevertheless there are some

remaining risks that must be considered:

The machine runs with high electrical voltage.

Electrical energy can cause serious bodily injury. Damaged insulation materials or

defective individual components can cause a life-threatening electrical shock.

Before carrying out any maintenance, cleaning and repair work, switch off the machine and

ensure that it cannot be accidentally switched on again. When carrying out any work on the

electrical equipment, ensure that the voltage supply is completely isolated. Do not remove any

safety devices or alter them to prevent them from functioning correctly.

• Risk of injury when changing the planer knives

• Risk of injury through accidental contact with the rotating cutterblock

• Risk of injury due to ejected workpieces

• Risk of injury from workpiece kickback. (when surface planing)

• Hearing damage as a result of high noise levels

• Health impairments due to the inhalation of airborne particles, especially when working with

beech and oak wood.

The following section offers a guide to transporting, assembling, and installing the machine.

These are all skills that should not be attempted by those who have not received relevant

training.

2.0 Machine Handling

There is a risk of injury as a result of falling parts while transporting, loading or

unloading the machine.

The machine could be damaged or written-off if subjected to improper handling

during transport.

8

Always use a sling within the safe working load of the machine weight. Machine weights are

provided above. Before lifting, place a piece of wood onto the thicknessing bed, sufficiently long

to lock up against the cutterblock (ensure that it does not foul the knives) and both feed rollers.

Wind the bed up using the Thicknessing Rise and Fall Handwheel until the wood is locked firmly

in position. Sling underneath the machine’s thickness table extension rollers. Do not walk or

stand under the machine during lifting.

Never lift the machine by its planer tables. To do so would seriously damage

their alignment.

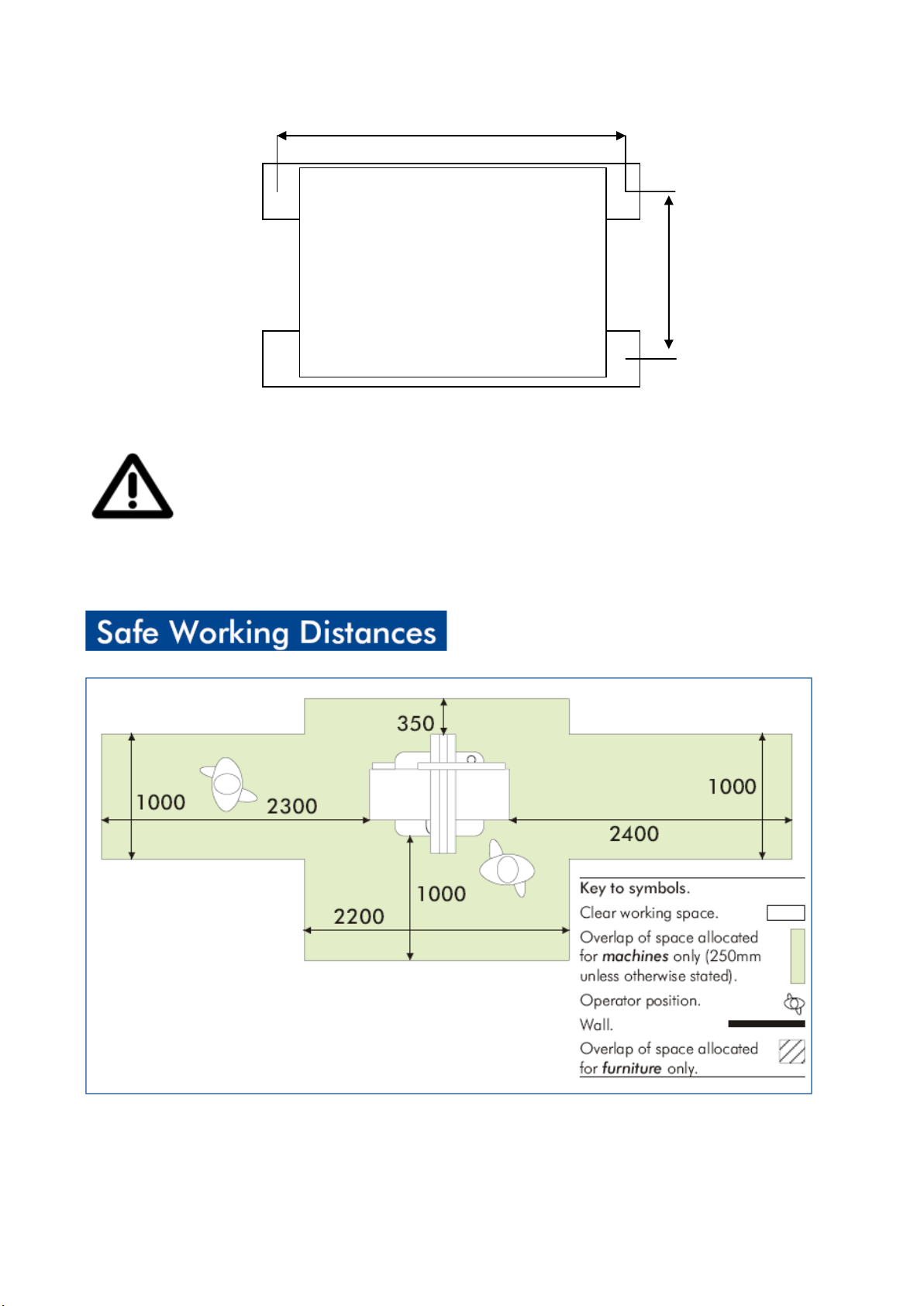

2.1 Positioning

There should be provided around every woodworking machine sufficient clear and unobstructed

space to enable the work being done at the machine to be done without risk of injury to persons

employed. You must also ensure that there is an ample power supply available, together with

good lighting and ventilation.

Only operate the machine in ambient temperatures from +10° to +40° C. If the

instructions are not followed, damage may occur during storage.

The chosen floor space should be in good and level condition to enable the machine to be

anchored at four points. Holes for M10 foundation bolts (not supplied) are provided in the

machine base. Level the tabletop by packing under the feet of the base as required. The

following drawing shows a lay-out of the anchor openings:

9

Unpacking

Dispose of the packaging materials in an environmentally friendly way and

always in accordance with local waste disposal regulations.

Remove the protective grease using turpentine or paraffin. Do not use any solvent, petrol or gas

oil, which might dull or oxidise the paintwork. Lightly oil cleaned surfaces to prevent rusting.

692mm

MB 268mm

CP 370mm

10

Storage

Keep the machine sealed in its original packaging until required for assembly/installation and be

sure to observe the machine handling advice on the outside of the packaging.

Store packed items only under the following conditions

• Do not store outdoors.

• Store in a dry and dust-free environment.

• Do not expose to aggressive substances.

• Protect from direct sunlight.

• Avoid subjecting the machine to shocks.

• Storage temperature: –10° to +50 °C

• Maximum humidity 60 %.

• Avoid extreme temperature fluctuations (condensation build-up).

• When storing for a period longer than 3 months, apply a coat of oil to all machine parts that

might be prone to rusting (corrosion protection). Regularly check the general condition of all

parts and the packaging. If necessary, refresh or re-apply a coat of anti-corrosive agent.

• If the machine is to be stored in a damp environment, it must be sealed in airtight packaging

and protected against corrosion (desiccant).

Disposal

When disposing of the machine, separate all components into material groups in order to

facilitate recycling. The main structure is made of cast iron and steel and can therefore be

safely dismantled and disposed of without risk of pollution.

Used electrical materials, electrical components, lubricants and other auxiliary

substances must be treated as hazardous waste and may only be disposed of by

specialist licenced firms.

3.0 Connection to a Dust Extraction System

This machine must be connected to a compatible dust extraction unit using a

suitable size and grade of vacuum hose.

Wood dust can be harmful to health by inhalation and skin contact, and concentrations of small

dust particles in the air can form an explosive mixture. Prevention or control of wood dust

exposure should as far as is reasonably practicable, be achieved by measure other than the

provision of personal protective equipment.

Employers have duties under the Provision of Use of Work Equipment Regulations 1998 (PUWER)

and the Control Of Substances Hazardous To Health Regulations 1988 to carry out an adequate

assessment of the possible risks to health associated with wood dust particularly when machining

hardwoods, and if necessary seek expert advice as to the method of dust extraction.

The minimum recommended air volume required to effectively exhaust this machine at

20m/sec is 1105 CMH for the MB and 1445 CMH for the CP.

11

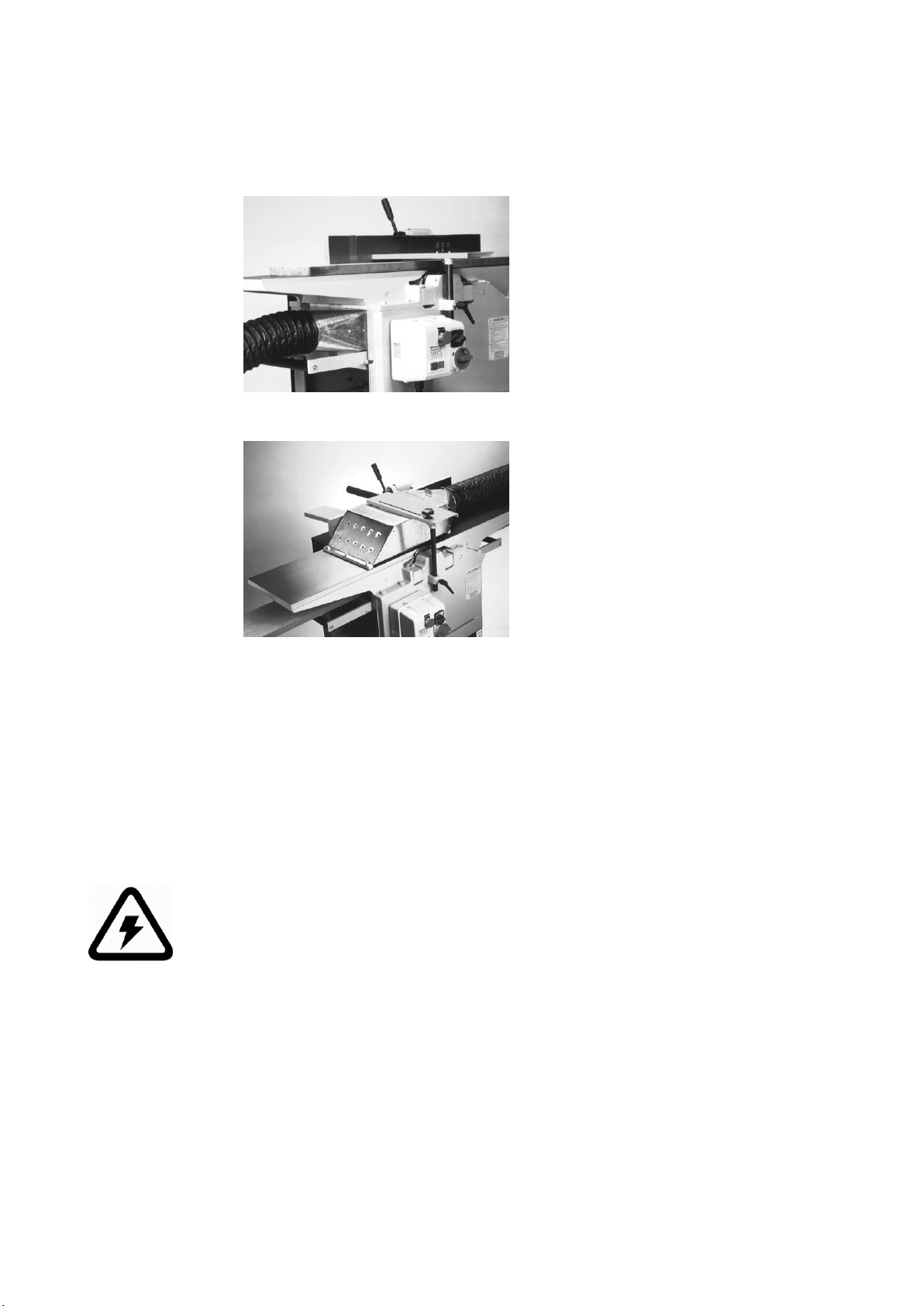

3.1 Chip Extraction Hood

A chip extraction unit is supplied as a standard feature of this machine, and guidance for its use

is as follows:

For Surfacing The hood is designed to sit on the

thicknessing bed, and should be inserted

hollow side up, with the exhaust outlet

below the fixed outfeed table. The lug

on the underside of the hood, attached

to the exhaust outlet, should locate

against the end of the thicknessing bed,

with care being taken that the anti-

kickback fingers are not fouled when

the bed is wound up.

For Thicknessing

Position the fence to the rear of the

surfacing table. Place the hood centrally

over the cutterblock, hollow side down,

with the exhaust outlet pointing toward

the in-feed table rise and fall handle.

Bring the bridge guard down over the

hood and lock it in position between the

two welded straps.

The diameter of the connection point is 125/150mm and reducers are not recommended.

Further information and references to practical guidance are contained in free leaflets from the

Health & Safety Executive, alternatively specialist help and information can be obtained from

the following:

P&J Dust Extraction Otterham Quay, Rainham, Gillingham, Kent ME8 8NA

4.0 Electrical Installation

All electrical wiring should be carried out by a fully qualified electrician and in

strict observance of the safety instructions.

Please follow these directions when connecting to the mains:

The motor and control gear have been wired in at the factory and tested before despatch. It

is prohibited to open the switch box on the machine without the express authorization of the

manufacturer. Violating this stipulation could invalidate the machine’s warranty. All that is

required is to connect the power supply to the ISOLATOR box on the machine stand.

First check that the supply details on the motor nameplate correspond with the site supply. If

the motor is operated on a voltage outside (plus or minus 6%) of the spot voltage, then

premature failure will occur.

12

Refer to the machine specification sheet at the front of the operator’s handbook to establish

the correct size of cable required. Undersize cable will lead to voltage drop at the motor

terminals.

Do not attempt to wire single-phase machines into a 13-amp plug socket.

Ensure that there is no voltage at the supply lead before connecting.

It is important to check rotation of the cutterblock which should be clockwise when viewed

from the starter side of the machine. If necessary you can change the rotation by swapping

any two of the brown wires from the supply side on the terminal block.

Should you encounter problems on start up check for the following likely causes:

PROBLEM

LIKELY CAUSE

CORRECTIVE ACTION

Fails to start

Main supply switched off

Overload tripped

Fuse blown

Loose wire

Coil failure

Check main switch

Reset overload

Check and replace fuses (check all three on three

phase)

Check all connections

Check circuit of hold in coil

Overload trips

during starting

Low voltage

Low voltage

Low voltage

Three phase machines

only: 1 fuse blown

Machine jammed

Check supply-voltage both on no load and on

moment of switch on. Allowed variation +/minus 6%

Check that correct cable size has been used to

install the machine. Change if necessary.

Long runs of cable can cause voltage drop. Check

that voltage is not outside the minus 6% tolerance.

Re-site the machine nearer supply or increase the

cable size to compensate.

It is possible for 3 phase machines to operate with

only 2 phases of the supply. This will create an

overload situation and will eventually cause

premature failure, this is known as single phasing.

Check all fuses.

Check spindle is free to rotate, clean as necessary.

Slow

acceleration

Low voltage

For a motor (particularly a single-phase permanent

capacitor motor) to reach its required starting

torque a healthy line voltage is essential.

13

5.0 Switch Gear

5.1 The Padlockable Isolator

With this switch in the OFF position the machine is effectively isolated

from the supply to allow personnel safe access for maintenance or

repair work and to prevent dangerous restarts. In order to prevent

unauthorised use of the machine the switch can also be secured in the

OFF position using a padlock.

To operate the machine first turn the isolator to the ON position.

5.2 Start / Stop Buttons

The cutterblock motor is then started by pushing the green (power on) button on the starter

panel, and stopped using the red (power off) button. The mushroom headed lock-off stop

switch, once pressed will remain locked in the off position. To restart the machine it is

necessary to release the off button by twisting it in a clockwise direction.

5.3 Two/Three Position Rotary Switch

The feed rollers are driven via a separate gearbox motor, which is

controlled using the rotary switch below the isolator. A single phase

machine has only two positions: ON and OFF. A three phase machine

has three:

Position 0 –OFF

Position I –Slow Run (4.5m/min)

Position II –Fast Run (7 m/min)

5.4 Circuit Protection

In case of a mains failure the starter is fitted with no volt release protection and will not restart

without being switched on again. The starter is also fitted with an overload protection device.

An electrical overload occurs where an electric motor is subjected to a greater load than it was

designed for. This can be caused by short circuit, by incorrect installation, or by misuse

(including poor machine maintenance). The inbuilt breaker will therefore help prevent damage

to the motor should such a situation occur. The motor cannot be restarted until the breaker has

reset itself.

5.5 Brake Release Switch

Machines fitted with an electro-magnetic brake unit are also equipped with a ‘Brake Release’

switch. This switch makes it possible to release the brake mechanism, allowing the operator to

rotate the cutterblock when changing or adjusting the cutting knives. To operate the switch first

turn the isolator to ON, release the mushroom headed lock off stop switch, and turn the brake

release to ‘BRAKE RELEASE’. It is not possible to start the cutterblock motor with the switch in

this position. To start the cutterblock motor turn the switch back to the

RUN position.

5.6 Optional Emergency Foot Operated Stop Switch

This switch is provided for use in emergency situations only. We do not

recommend that it is used in lieu of the mushroom headed lock-off stop

switch on the front of the starter panel.

14

6.0 Guarding

All guards should be checked at the beginning of each working shift for damage etc.

6.1 The Front Cutterblock Guard

The yellow pillar mounted guard at the front of the machine is known as the bridge guard. It is

designed for use when surfacing, and it is important that all operators are familiar with its use.

Investigations show that most accidents occur because the guard is not properly adjusted or, in

most cases, is not mounted on the machine. The guard is provided with two hand locking

arrangements, one for the vertical plane and one for the horizontal. This guard should be

maintained through regular cleaning and lubrication, and if it becomes distorted through misuse

then it should be replaced.

6.2 The Rear Cutterblock Guard

To the rear of the fence is mounted a hinged guard which is known as the rear cutterblock

guard. This is designed to guard that part of the cutterblock that is on the side of the fence

remote from the bridge guard. There is no need for its removal from the fence.

6.3 The Rear Drive Guard

The rear drive guard should only be removed for maintenance and cleaning.

6.4 The Anti-Kickback Fingers

The anti-kickback fingers are an essential safety feature of the thicknessing function. Their

purpose is to drop and lock into the face of the workpiece in the event of kickback, thereby

preventing it being ejected from the machine. The movement of the fingers may in time become

restricted due to a build-up of waste, and their freedom to move freely should be regularly

checked and cleaned as necessary.

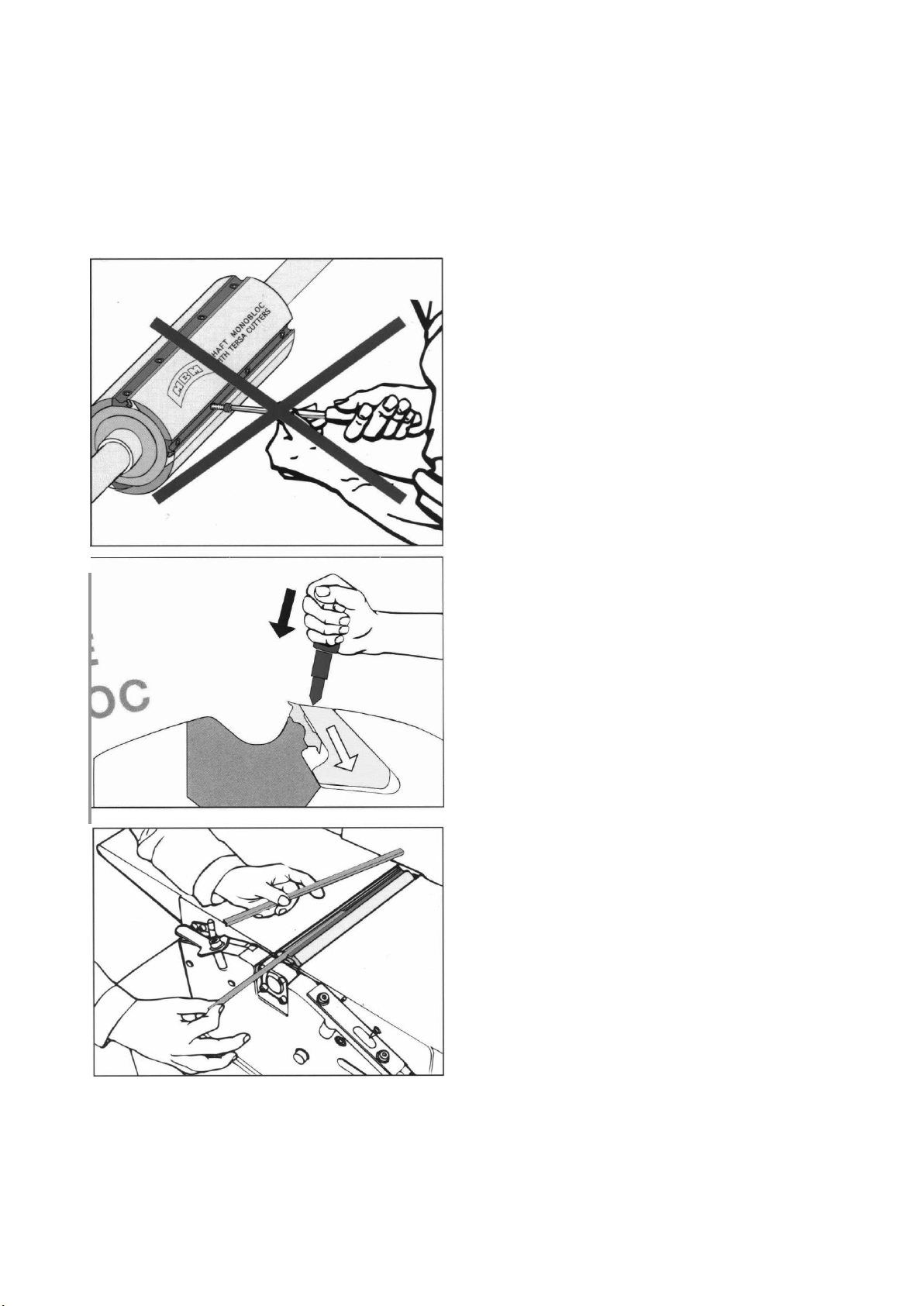

7.0 The Cutterblock

The concept of the TERSA cutterblock is to allow the automatic clamping of the cutters using

centrifugal force. The exactness of the position is +/- 0.02mm, guaranteed on all the sharp

edges and on the whole length of the planing shaft. For correct use of the tool it is

recommended that a suitable product is used to occasionally clean the support runner of the

cutters.

To replace the knives on your MB/CP the following guidelines should be followed:

Planer knives are razor sharp. Please handle them with the utmost care,

especially when turning the cutterblock by hand.

First isolate the machine at the mains. It is not sufficient just to shut off power at the machine.

Next put up a notice saying “cutters being changed”, in case you have to leave the machine for

any reason and someone else might try to use it not knowing the knives are loose. Clean off any

15

chippings and dust from the machine tables and move the fence and front cutterblock guard out

of the way.

Points to check on the cutterblock are

1. Excessive wear of the block surface.

2. Damage or distortion to the block.

3. Damage to the threads on the retaining screws. Rounded corners within the allen heads.

4. The condition of the bearings - check for movement and listen for noisy bearings.

AT NO STAGE SHOULD YOU ATTEMPT TO

UNTIGHTEN THE CUTTERBLOCK SCREWS.

TO DISENGAGE THE CUTTERS WITHIN THE

BLOCK FIRST DISCHARGE THE GIBS USING THE

BRASS HAMMER PROVIDED.

SLIDE THE BLUNT KNIFE FROM OUT OF THE

SIDE OF THE CUTTERBLOCK AND EITHER

REINSERT IT WITH AN UNUSED SIDE UP OR

REPLACE IT WITH A NEW ONE.

16

THE CUTTERS WILL AUTOMATICALLY CLAMP

ON START UP. IN ORDER TO ENSURE THAT

THEY ARE CORRECTLY SEATED THICKNESS A

300 OR 410mm WIDE PIECE OF TIMBER

INTENSIVELY ACROSS THE FULL CUTTING

SURFACE.

8.0 Preparation of the Workpiece

In preparation for all processes, examine the workpiece carefully for faults that may affect the

machining process, particularly foreign bodies such as nails, staples etc. There are many

different kinds of timber, with many different working characteristics. A skilful wood machinist

must consider the grain direction, the shape of the timber, whether it is bowed or twisted, and

the positions of defects such as knots, wavy edges etc. He should also consider any other

peculiar characteristics of the material, such as salicaceous or calceous deposits, which could

cause severe blunting and chipping of the cutters. If a number of abrasive pieces are to be

planed, use the ends of the cutter rather than the middle if possible.

8.1 Pilot Checks

Details on the correct setting of the guards, fence etc., together with the use of the necessary

safety devices, are detailed in the following sections of this manual. Prior to operation however

the following checks should be carried out (first isolate machine):

1. The blades are not cracked or distorted.

2. The cutterblock runs free (check by slowly turning it by hand).

3. The cutterblock guards are secure.

4. The timber is free of grit, nails or other foreign bodies.

5. The tables are free of spanners, rules etc., and that all tools are returned to their rightful

place.

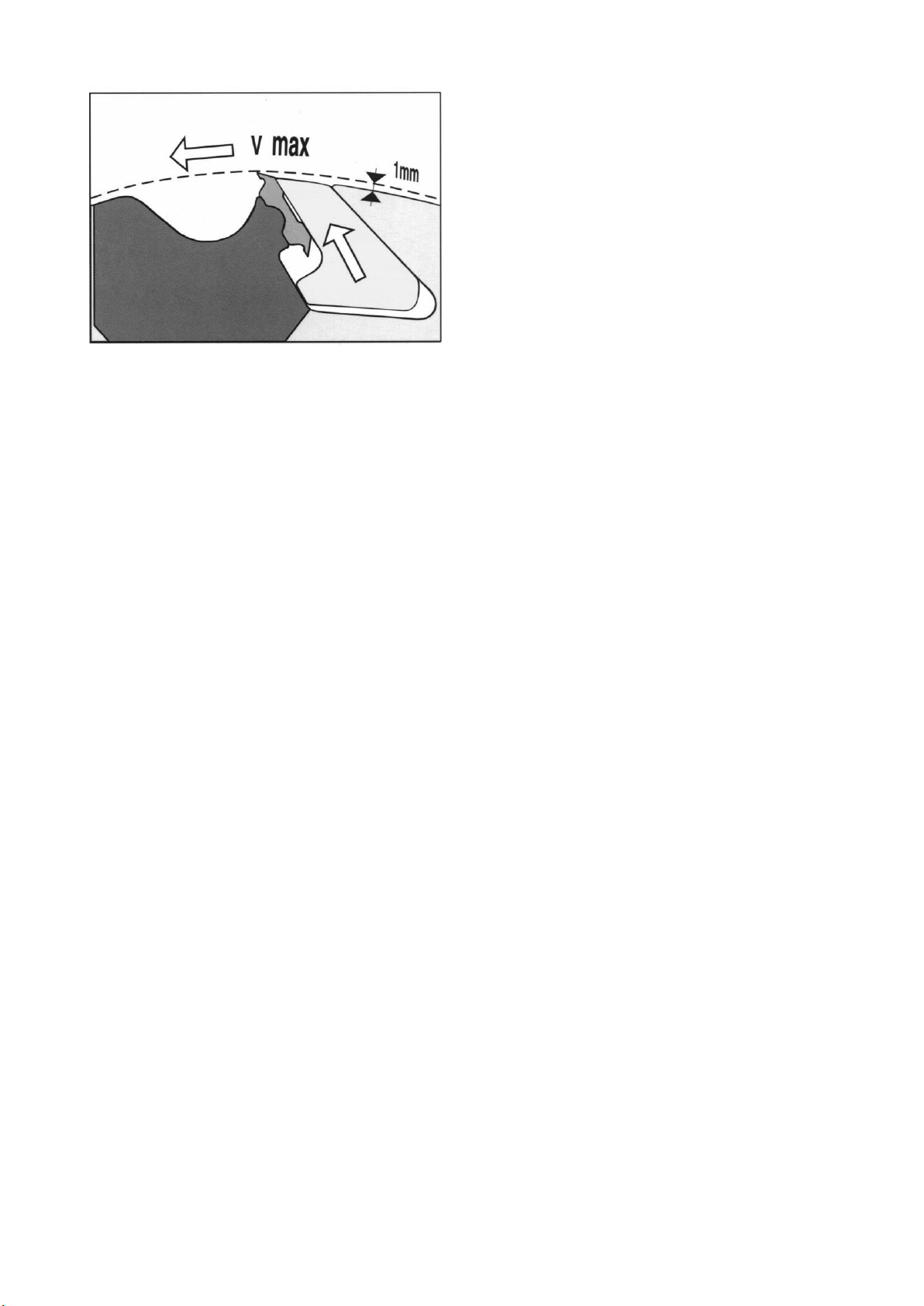

9.0 Surface Planing

Caution: Ensure that all stock is clear of the blades before start-up.

When surfacing, the depth of cut is set by adjusting the height of the infeed table, using the

Surface Table Rise and Fall Handle.

Unlock the Surface Table Rise and Fall Lock prior to making any adjustment, and re-tighten once

set.

The outfeed table is already set level with the cutting circle of the cutterblock.

The sawn finish and the straightness of the timber determine the amount of cut required. For

normal working it is good practice to set the amount of cut to 1.5mm. When planing rough

sawn or bowed timber the amount of cut can be increased to 3mm, so as to obtain a clean finish

with one pass over the cutters.

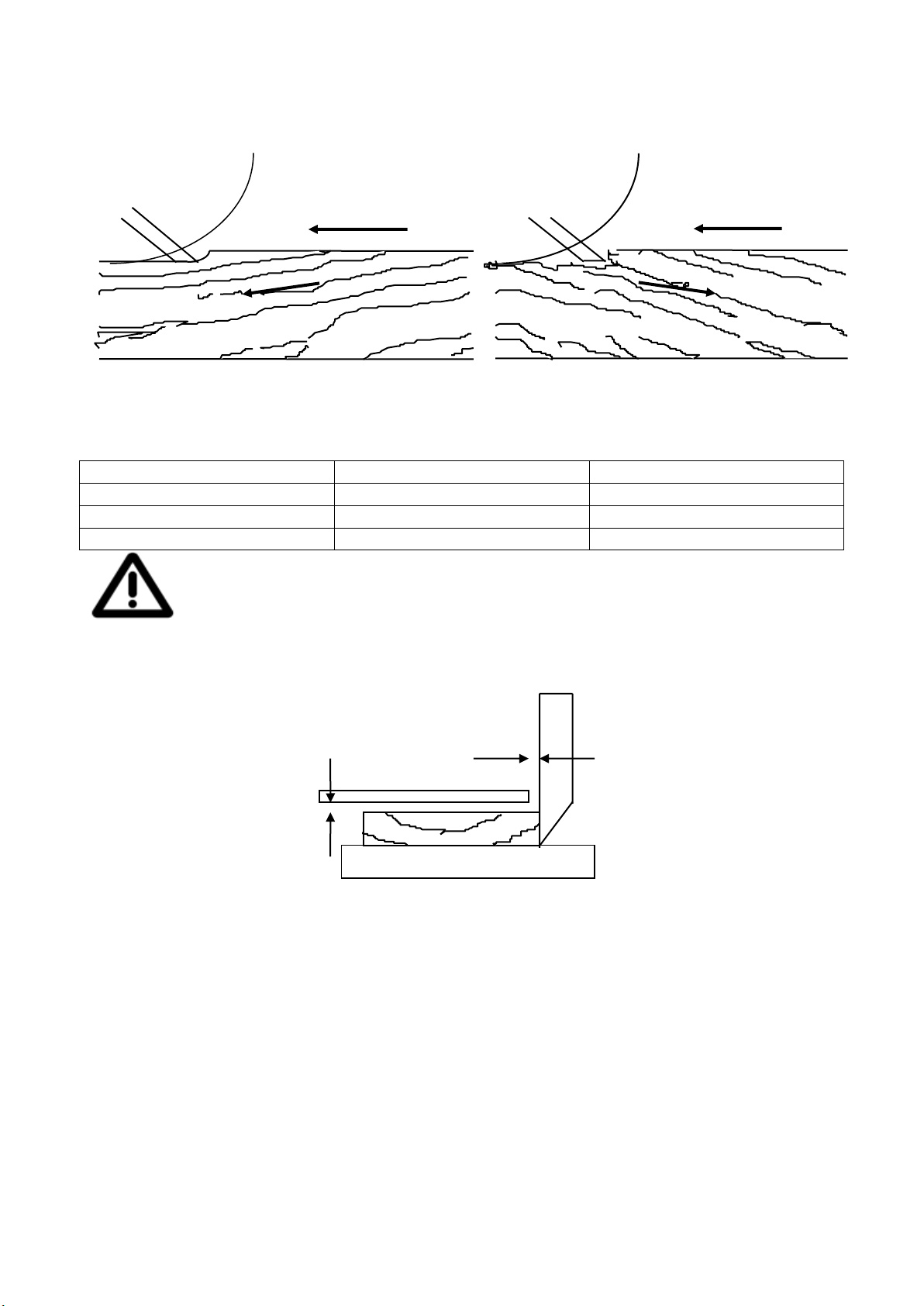

The timber should be fed in with consideration to the grain direction. The following illustration

shows how timber fed through the cutters against the grain will cause it to tear out, producing a

17

ragged finish. Always feed with the grain running down towards the front of the table when

in the planing mode, and the opposite when thicknessing.

Correct Incorrect

Feed Feed

Slope of grain

Slope of grain

9.1 Flatting

Workpiece dimensions:

Length

< 250mm

Only work with a push stick

>1500mm

Extn rollers or 2nd person reqd

Width

Max 308 (MB) or 410mm (CP)

Thickness

Min 10mm

If a workpiece is smaller than 10mm it may split if the depth of cut is too large

(4mm). The finished planed workpiece must not be thinner than 6mm.

When flatting, the wood is passed below the bridge guard, which should be within 10mm of the

timber and 10mm of the fence, as shown below:

10mm

Bridge Guard

10mm

Workpieces longer than the in and out-feed surfacing tables should be supported, e.g. by

extension tables or roller supports. Unless very thick material is being planed, flatting should be

the safest of operations on a hand fed planer, provided that all necessary precautions are taken.

In an attempt to justify the incorrect use of the bridge guard (many wrongly pass the timber

between the end of the guard and the fence) machinists often assert that the left hand has to

jump the guard as the wood is passed over the cutters, the consequent interruption in the

progress of the cut preventing the production of accurate work. It is also claimed that the left

hand must exert pressure on the wood immediately over the cutterblock. Only in the case of

flatting short pieces of wood might it be necessary to pass the wood between the end of the

bridge guard and the fence in order to maintain adequate control. In this event, the wood should

be fed up and over the cutters by means of a push block as described in the relevant section of

18

this manual. Small pieces are the most difficult to control, so consider, do you really need to

face and edge them?

The HSE has published guidelines on the ergonomically correct use of hand fed planers, some of

which is reproduced here:

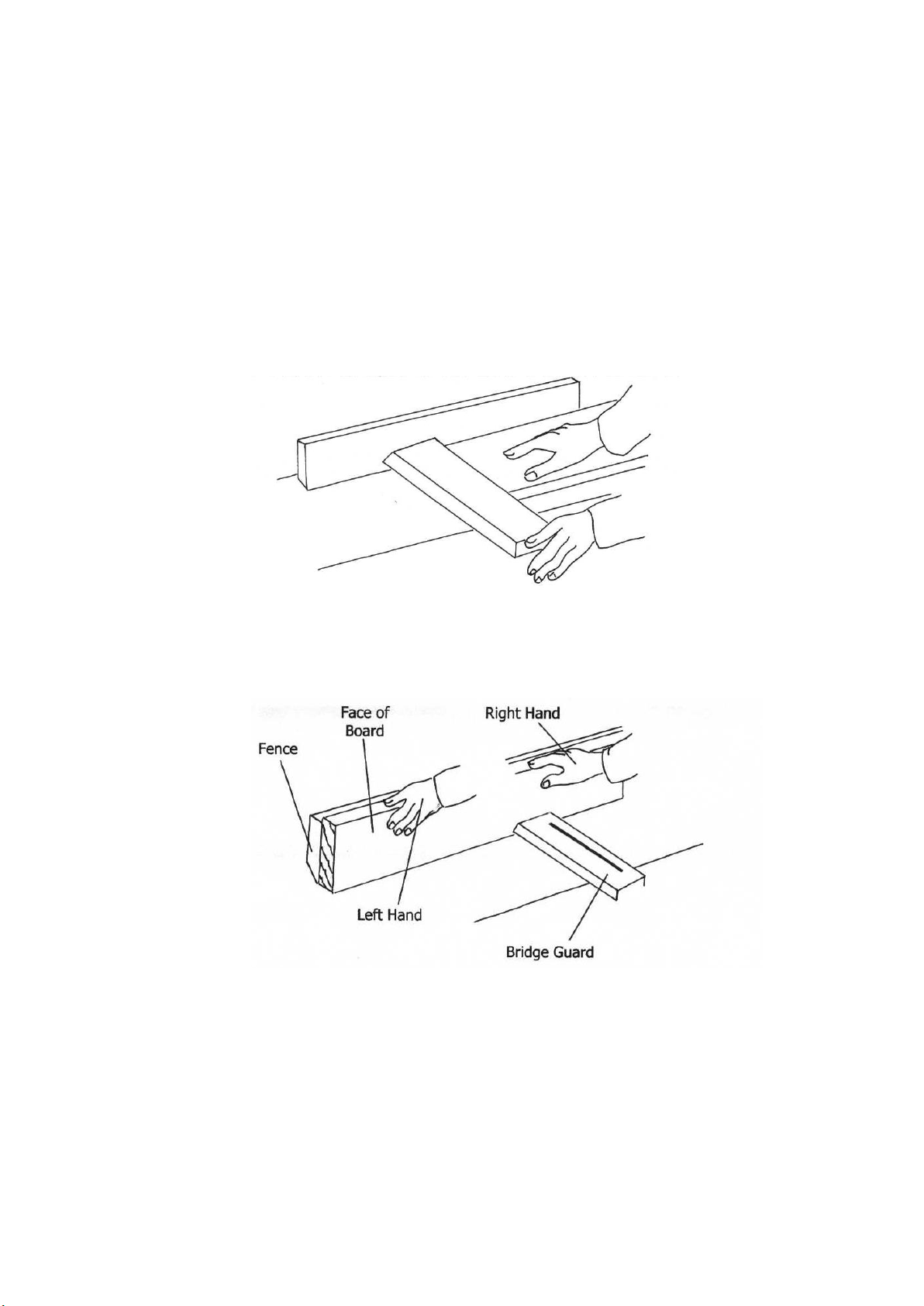

Hand positioning

Preparatory: Using the left hand, with the guard resting on the outfeed table, adjust the guard

horizontally up to the fence and then lift the guard to just accommodate the thickness of the

workpiece. Push the workpiece with the right hand only a little under the guard and let the

latter rest upon the workpiece. This stage should not be carried out while the cutterblock is in

motion.

The work should be fed by the right hand, and if the knives are sharp and the tables are properly

set the main functions of the left hand are to assist feeding by drawing the wood along the

delivery table towards the end of the cut, and to remove the planed piece.

19

When flatting a workpiece of more than 75mm thickness the bridge guard must be lowered on to

the table and adjusted horizontally to the workpiece. The workpiece should be straightened,

with flat hands beside the guard, along the fence.

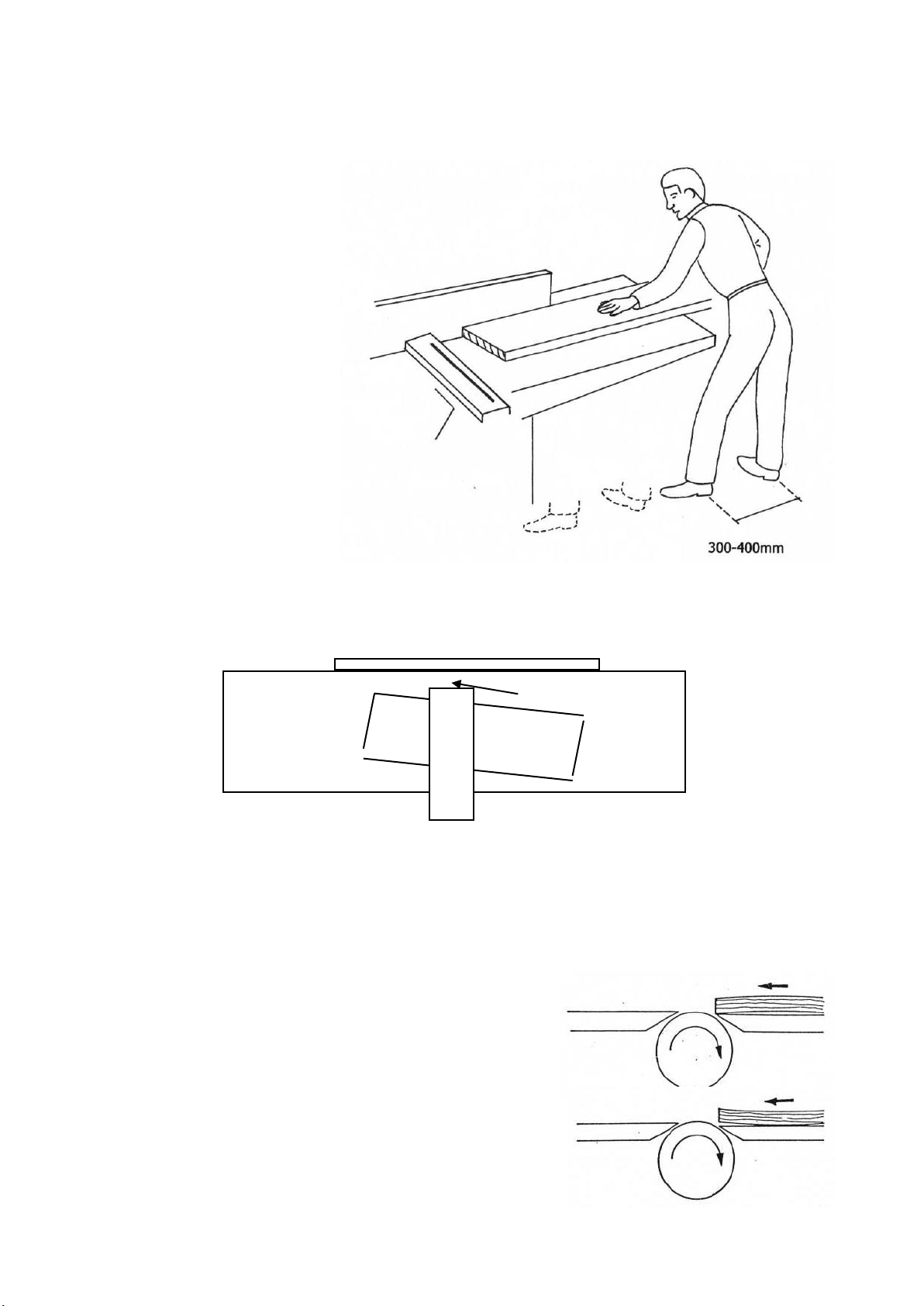

Foot positioning

It is important that a good

firm and balanced base is

made and maintained by the

feet during planing. The feet

should move forward with the

work piece giving good control

of the work piece as

illustrated in positions 1 and

2:

9.2 Planing Wide Boards

Wide boards should be fed at an angle to reduce initial impact and the risk of throwback.

Fence

10mm max

Wide board

Bridge Guard

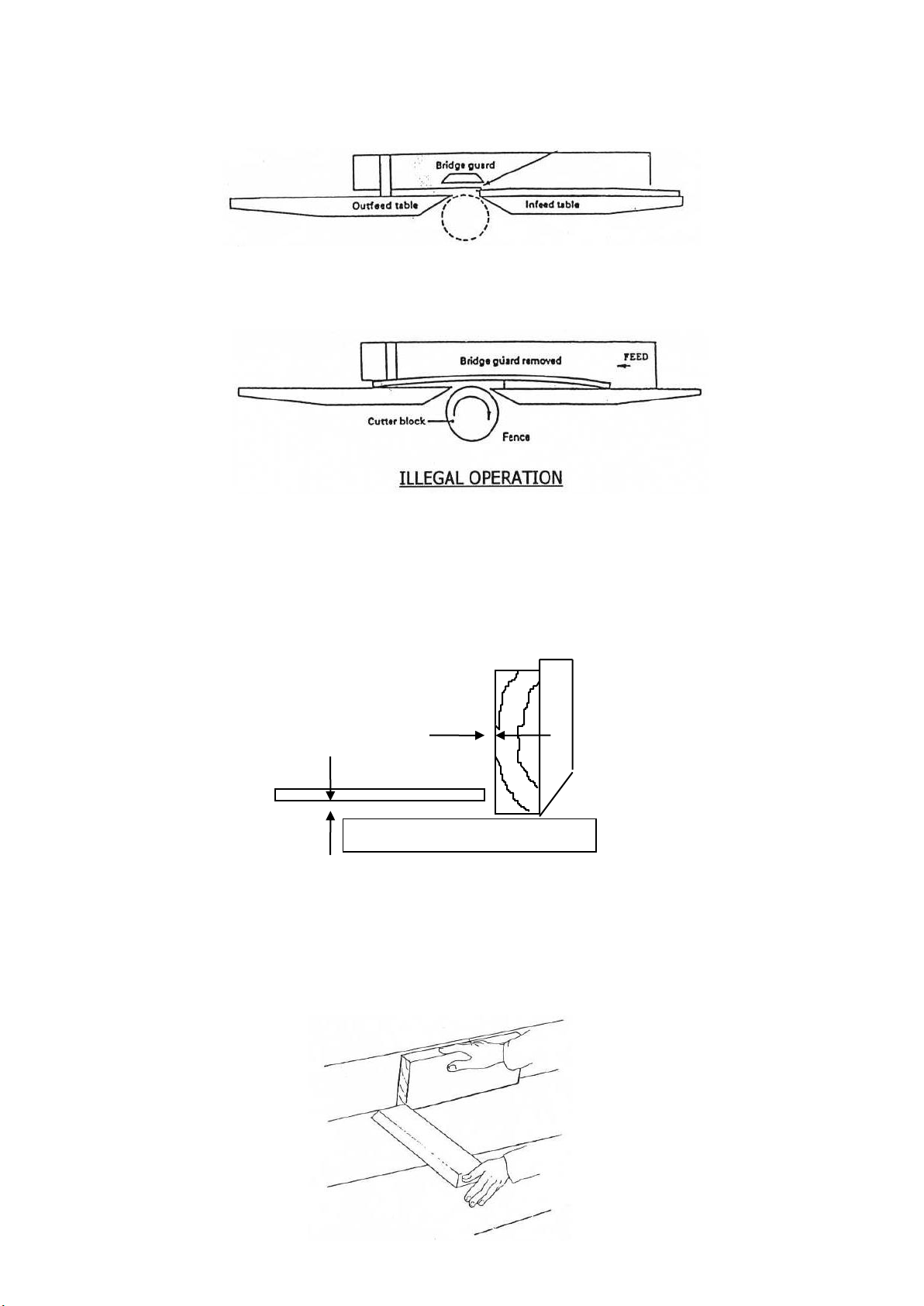

9.3 Planing Bowed Boards

Slightly bowed boards may be planed by the method shown below, but care must be taken to

ensure two point contact on the infeed table to avoid throwback. Badly bowed boards should not

be planed in this method and should be cut up for jobs requiring shorter lengths.

Always plane the board hollow side down, as shown

Working round side down causes timber to rock,

thus making it very difficult to obtain a straight parallel

face.

20

The bridge guard must always be in position when planing bowed boards, as shown:

It is illegal to operate the surface planer without the bridge guard. The long accepted way of

placing the front portion of timber on the outfeed table and taking several cuts off the other

end then reversing the timber should not be used.

9.4 Edge Planing (Squaring)

When edging, the wood is passed between the end of the bridge guard and the fence. The bridge

guard should be adjusted both horizontally and vertically to leave only 10mm from both the feed

table and the workpiece, as shown below:

10mm

Bridge Guard

10mm

When edge planing, follow these guidelines regarding the correct positioning of hands:

Preparatory: Place the workpiece against the fence and move it with the right hand forward to

about the front edge of the infeed table lip. With the left hand bring the guard up to the

workpiece. The guard should be positioned as previously shown. This stage should not be carried

out while the cutterblock is in motion.

This manual suits for next models

9

Table of contents

Other Sedgwick Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT608965 Operation manual

ELWE

ELWE 3B SCIENTIFIC U8497460 operating manual

Spirax Sarco

Spirax Sarco U Series Installation, operation and maintenance manual

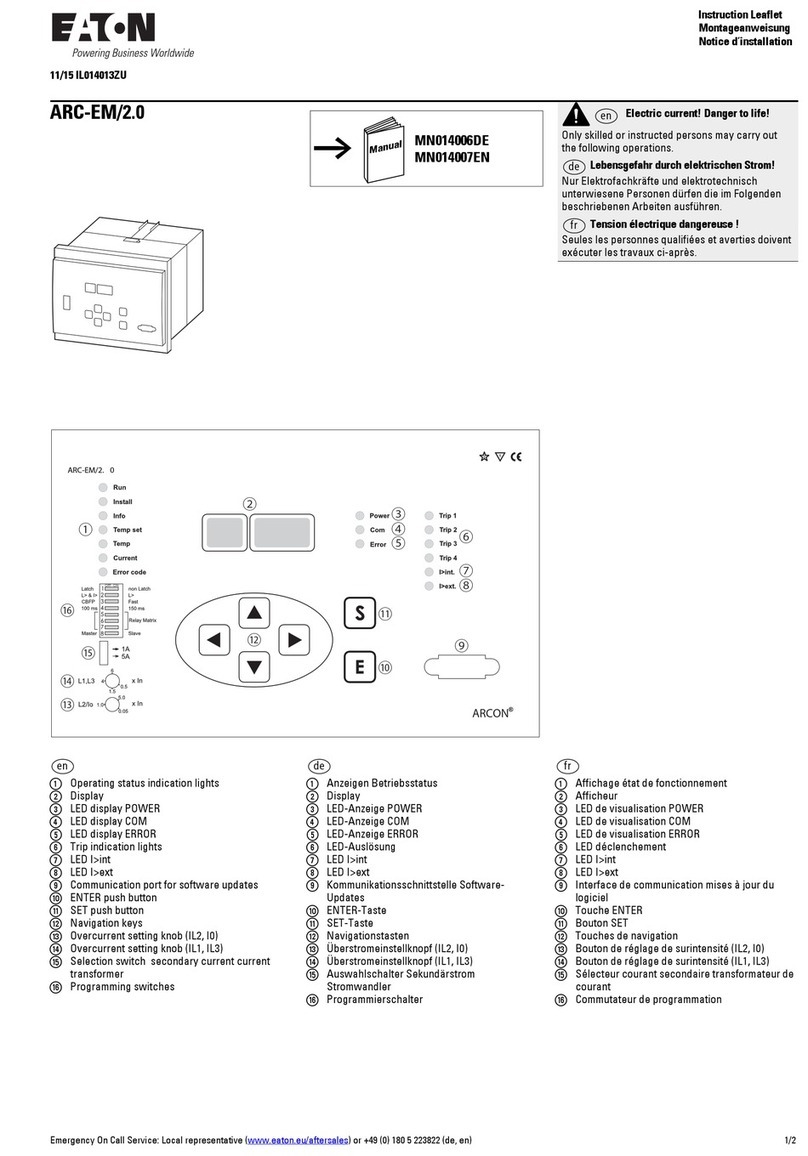

Eaton

Eaton ARCON ARC-EM/2.0 Instruction leaflet

FLENDER

FLENDER COUPLINGS N-EUPEX 3103en Assembly and operating instructions

Infranet Technologies

Infranet Technologies M2M CONTROL CX320 Technical manual