Contents

ii

Switching between analog output and

waveform output ...................................... 92

Setting the rectifier for analog output ....... 93

3.8.2 D/A Output ..........................................95

Setting D/A output parameters ................. 95

Example uses .......................................... 97

Examples of analog output ...................... 98

Example waveform output ..................... 101

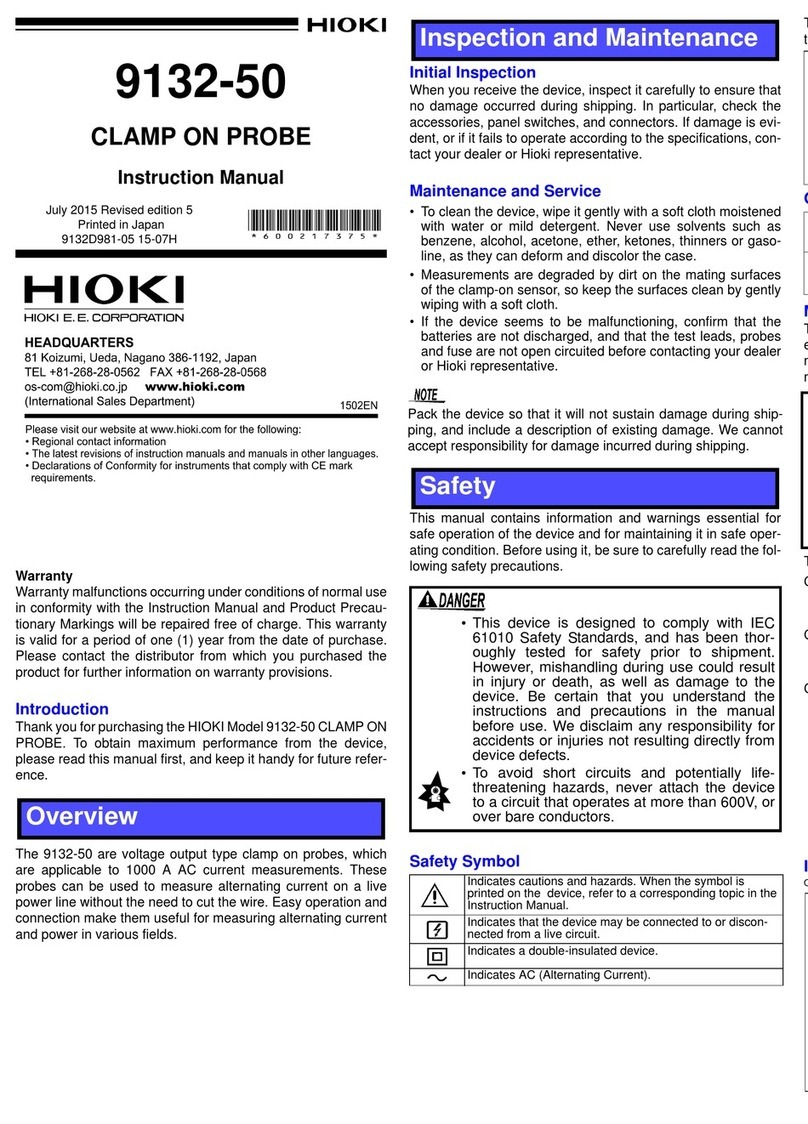

3.9 Using a Current Sensor ....................102

Before connecting a current sensor ....... 103

Connecting a Type 1 current sensor ...... 104

Connecting a Type 2 current sensor ...... 104

Setting external current sensor input ..... 106

Using an external CT ............................. 107

3.10 Other Functions ................................108

3.10.1Fixing Display Values (Display Hold) 108

Activating display hold ........................... 108

Canceling the display hold state ............ 108

3.10.2Displaying Peak, Minimum, and Maxi-

mum Values (Maximum Value Hold) 109

Displaying maximum values .................. 109

Displaying minimum values ................... 109

Returning to the instantaneous value display

............................................................... 109

Clearing maximum and minimum values 109

3.10.3Disabling Control Keys (Key Lock) ..111

Enabling the key lock state .................... 111

Canceling the key lock state .................. 111

3.10.4Initializing the Instrument

(System Reset) .................................112

3.11 When PEAK OVER, o.r, or the Unit

Indicator Flashes ..............................114

3.11.1If the PEAK OVER U or PEAK OVER I

Lamp Lights Up ................................114

3.11.2When o.r (over-range) Is Displayed .115

3.11.3When the Unit Indicator Flashes .....116

Chapter 4 Connection to a PC

117

4.1 RS-232C Settings and Connection

(Before Using Command

Communications) .............................118

Setting the RS-232C communications speed

................................................................ 119

Connecting the RS-232C Cable ............. 120

4.2 LAN Settings and Connection

(Before Using Command

Communications) .............................122

Setting the LAN’s IP address ................. 123

Setting the LAN’s subnet mask .............. 124

Setting the LAN’s default gateway .........125

Displaying the LAN’s MAC address ....... 126

Connecting the instrument to a computer

with a LAN cable ....................................127

4.3 Operating the Instrument from a

PC's Browser ................................... 129

Operating the instrument remotely .........130

4.4 GP-IB Interface Settings and Connection

(Before Using Command

Communications) .............................................131

Connecting the cable to the GP-IB connector

................................................................................................... 132

Setting the GP-IB address ............................... 133

4.5 Canceling the Remote State

(Activating the Local State) .............. 134

Canceling the remote state ....................134

Chapter 5 Specifications 135

5.1 Environmental and Safety Specifications

.......................................................... 135

5.2 General Specifications .....................136

5.3 Measurement specifications ............139

5.4 Functional Specifications .................156

5.5 Calculation Formulas Specifications 161

Voltage channel and sum value calculation

formula ................................................... 161

Current channel and sum value calculation

formulas .................................................163

Power channel and sum value calculation

formulas .................................................164

Power channel and sum value calculation

formulas .................................................167

5.6 Wiring Specifications ....................... 168

Wiring diagrams for direct input

(connections to instrument’s terminal block)

................................................................ 168

Chapter 6 Maintenance and

Service 177

6.1 Trouble Shooting ............................. 177

6.2 Error Indication ................................ 179