3 ICE EX04-18 Heat I&O Manual 06/2020 Rev.1

WARNING

• If the information in these instructions are not followed exactly, a re may result

causing property damage, personal injury or loss of life.

• Read all instructions carefully prior to beginning the installation. Do not begin

installation if you do not understand any of the instructions.

• Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury or loss of life.

• Installation and service must be performed by a qualied installer or service

agency in accordance with these instructions and in compliance with all codes and

requirements of authorities having jurisdiction.

INSTALLER: Afx the instructions on the inside of the building adjacent to the pressure

transmitter panel.

END USER: Retain these instructions for future reference.

Table of Contents

Chapter 1: Description & Specifications

1.1 Foreword .............................................................................................................................4

1.2 General Description.............................................................................................................4

1.3 Features ...............................................................................................................................5

1.4 Standards .............................................................................................................................5

Chapter 2: Installation & Operation

2.1 Unpacking and Inspection...................................................................................................5

2.2 Preparation Before Installing...............................................................................................5

2.3 Mechanical Installation Of The Heat Exchanger ................................................................6

2.4 Electrical Installation...........................................................................................................6

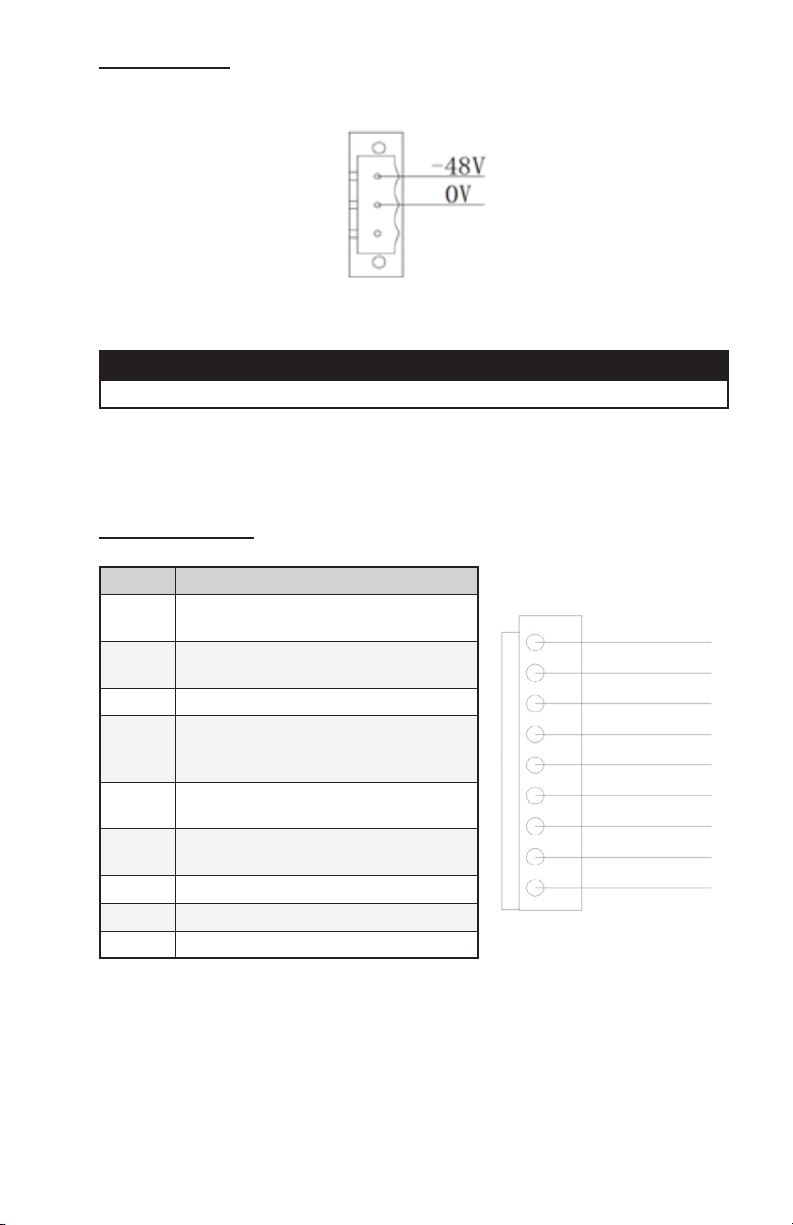

2.5 Power Input Cables .............................................................................................................6

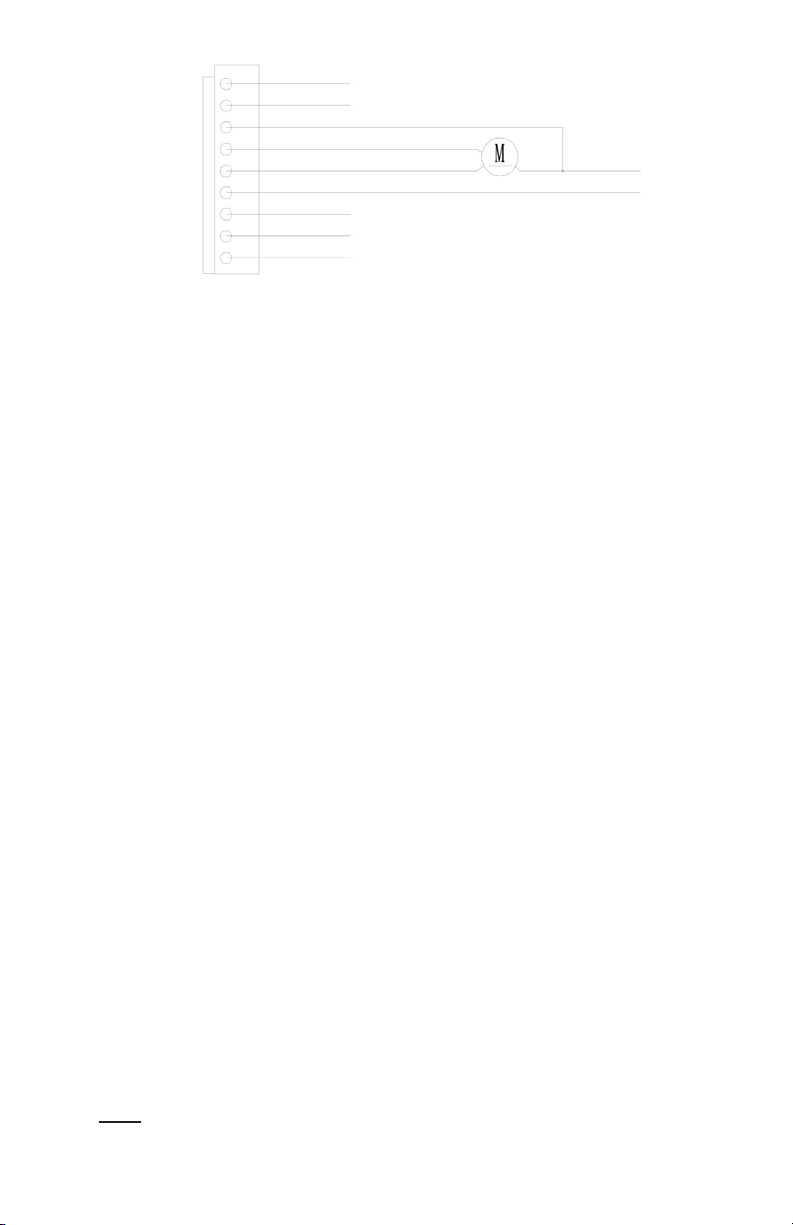

2.6 Monitoring...........................................................................................................................7

2.7 Hydrogen Discharge/Emergency Fan Connection (optional) .............................................7

2.8 Installation Checklist...........................................................................................................8

2.9 Startup .................................................................................................................................8

Chapter 3: System Function Introduction

3.1 Function...............................................................................................................................8

3.2 Operating Control Mode .....................................................................................................8

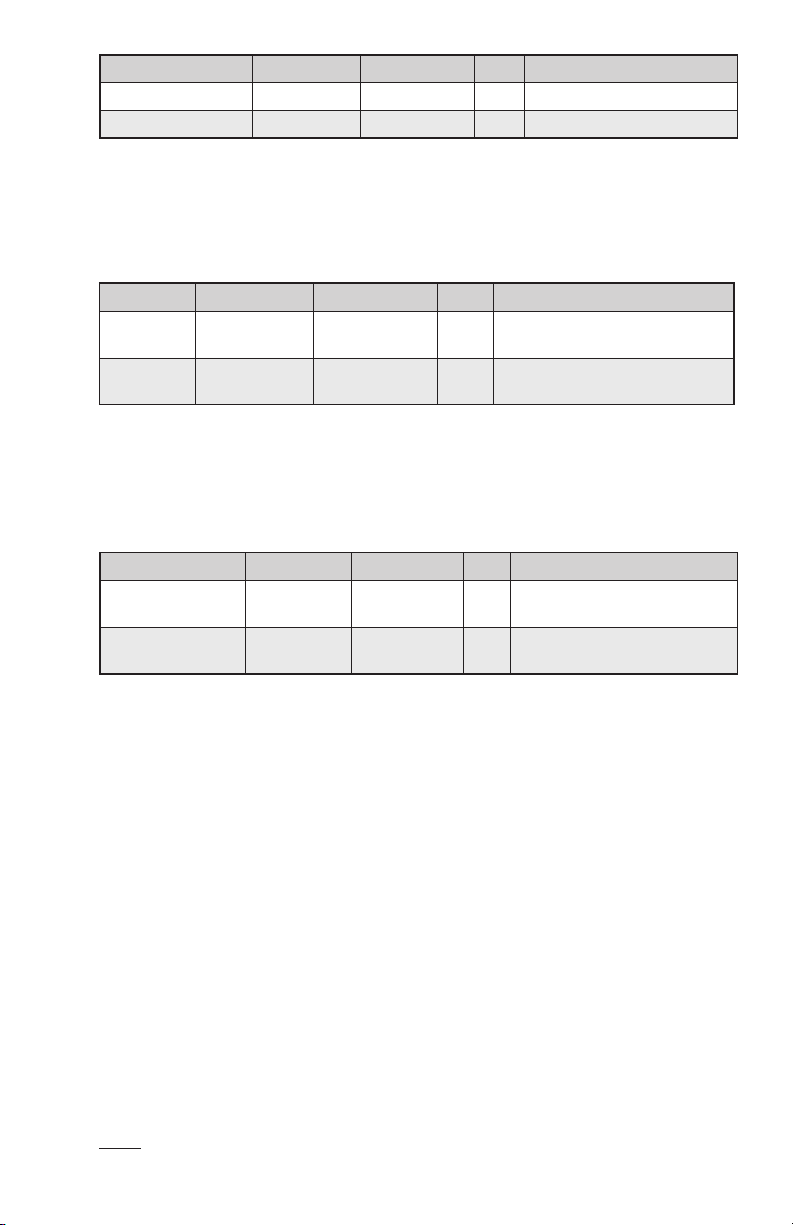

3.2.1 Cooling Control ......................................................................................................8

3.2.2 Heating Control.......................................................................................................9

3.3 Alarms .................................................................................................................................9

3.4 Hydrogen Discharging/Emergency Fan (optional) .............................................................9

3.5 Monitoring...........................................................................................................................9

3.6 Self Test.............................................................................................................................10

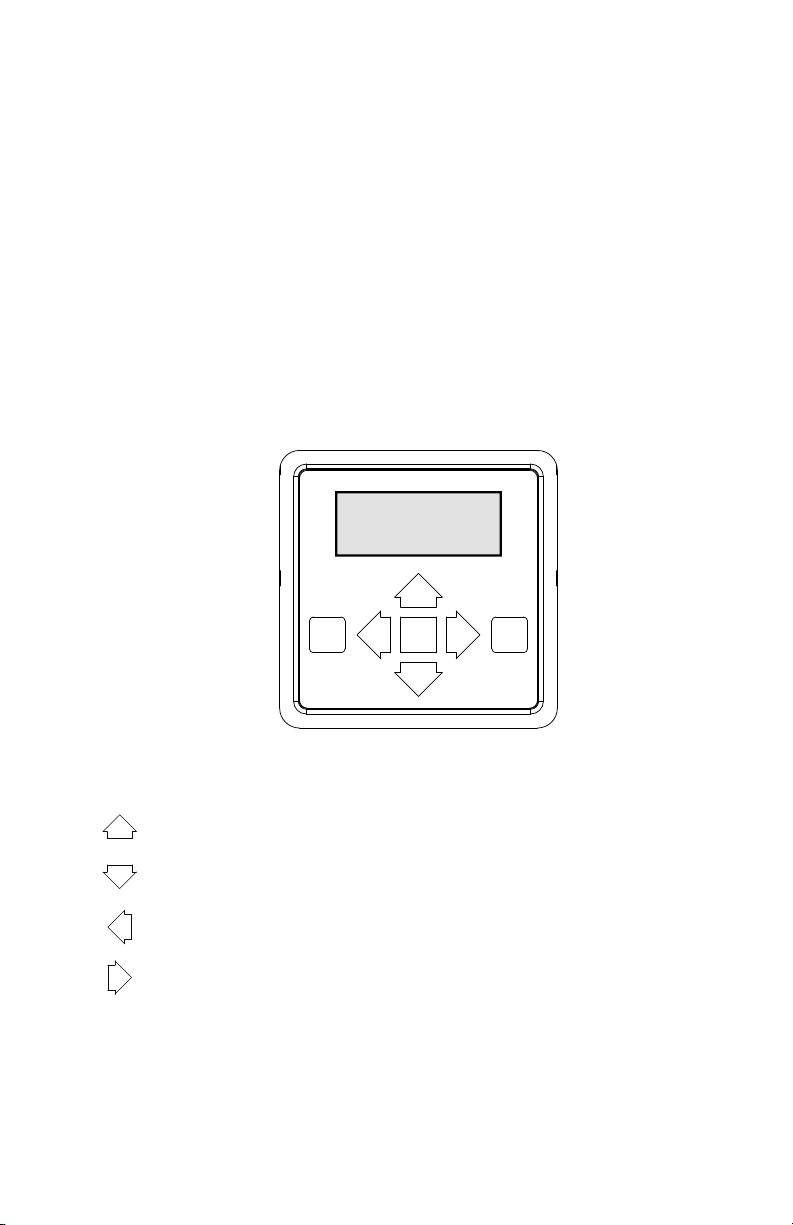

3.7 Operational Menu..............................................................................................................10

Chapter 4: Maintenance

4.1 Filter ..................................................................................................................................11

4.2 Fan.....................................................................................................................................12

4.3 Controller...........................................................................................................................12

4.4 Heater ................................................................................................................................12

4.5 Heat Exchanger .................................................................................................................12

4.6 Maintenance Checklist ......................................................................................................13

4.7 Disposal.............................................................................................................................13

Chapter 5: Troubleshooting

5.1 Troubleshooting Guide......................................................................................................13