Sacksafoam II Model 8044 Operations Manual (Version C)

Table of Contents

Section 1: Sacksafoam II Overview 1

Introduction to Model 8044 ...........................................................................................1

System Description .......................................................................................................2

Unpacking .......................................................................................................2

Section 2: Installation 3

Installation Procedures .................................................................................................3

Section 3: Testing 7

Testing the Sacksafoam ...............................................................................................7

Dry Test ..........................................................................................................7

Wet Test .........................................................................................................8

Section 4: Safety 9

Preflight Safety Check ..................................................................................................9

Section 5: Controller Box 10

Control Box Description ..............................................................................................10

Controller Box Functions ............................................................................................11

Controller Connector Pin Descriptions .......................................................................12

Section 6: Operations 13

Operating the System .................................................................................................13

Container Size ..............................................................................................14

Model SF2-8044 Run Times .........................................................................14

Section 7: Maintenance 15

Maintenance and Servicing ........................................................................................15

Flushing Procedure ......................................................................................15

Servicing .......................................................................................................16

Section 8: Parts 17

Parts and Diagrams ....................................................................................................17

Control Panel ................................................................................................17

Control Panel (Continued) ............................................................................18

Control Panel (Continued) ............................................................................19

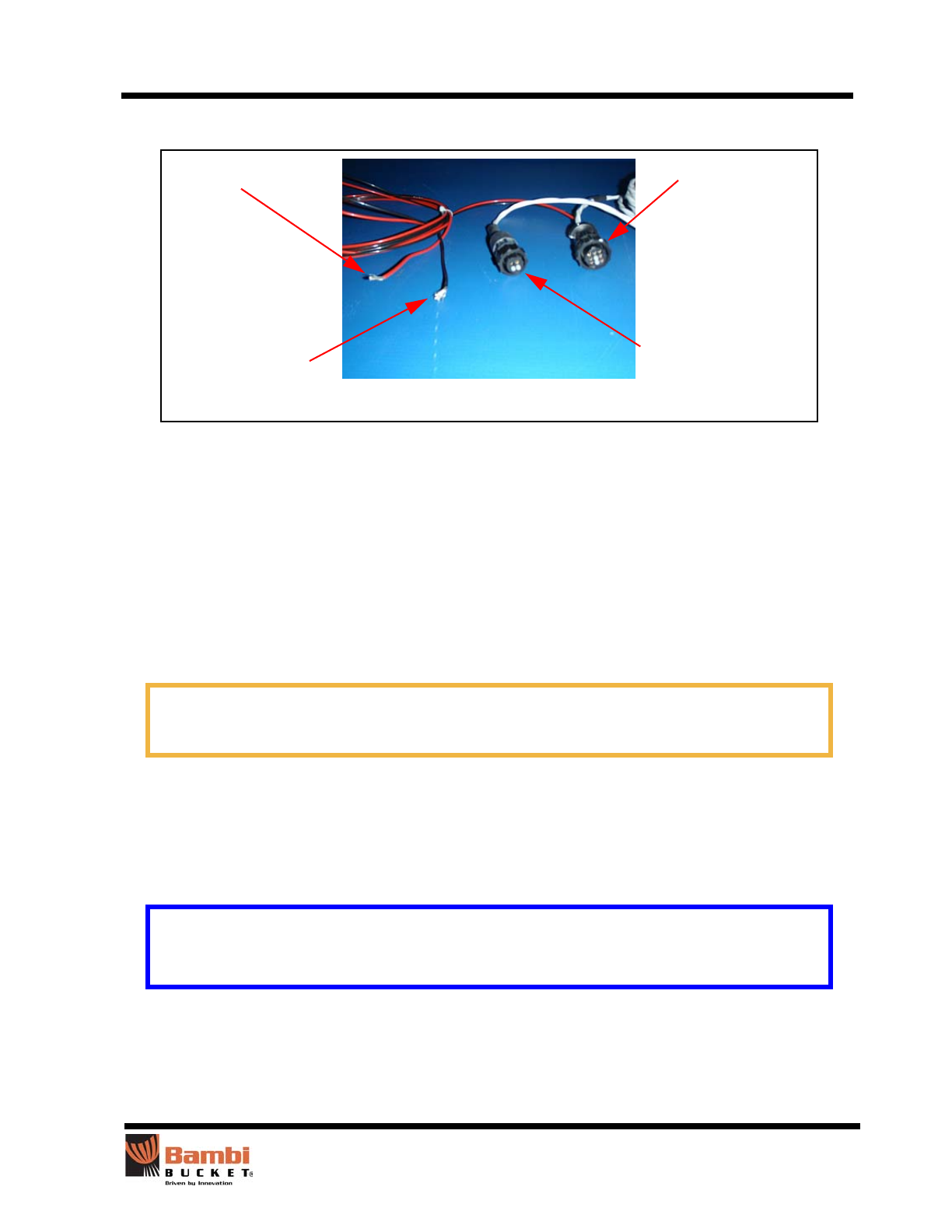

Wiring Harness (Bambi) ...............................................................................20

Section 9: Warranty 21