1-800-255-5387 • www.premier-mfg.com

PREMIER MANUFACTURING COMPANY Page 6

200 / 200L / 300 Bolt-On Drawbar Eyes

INSTALLATION

Installation Procedure:

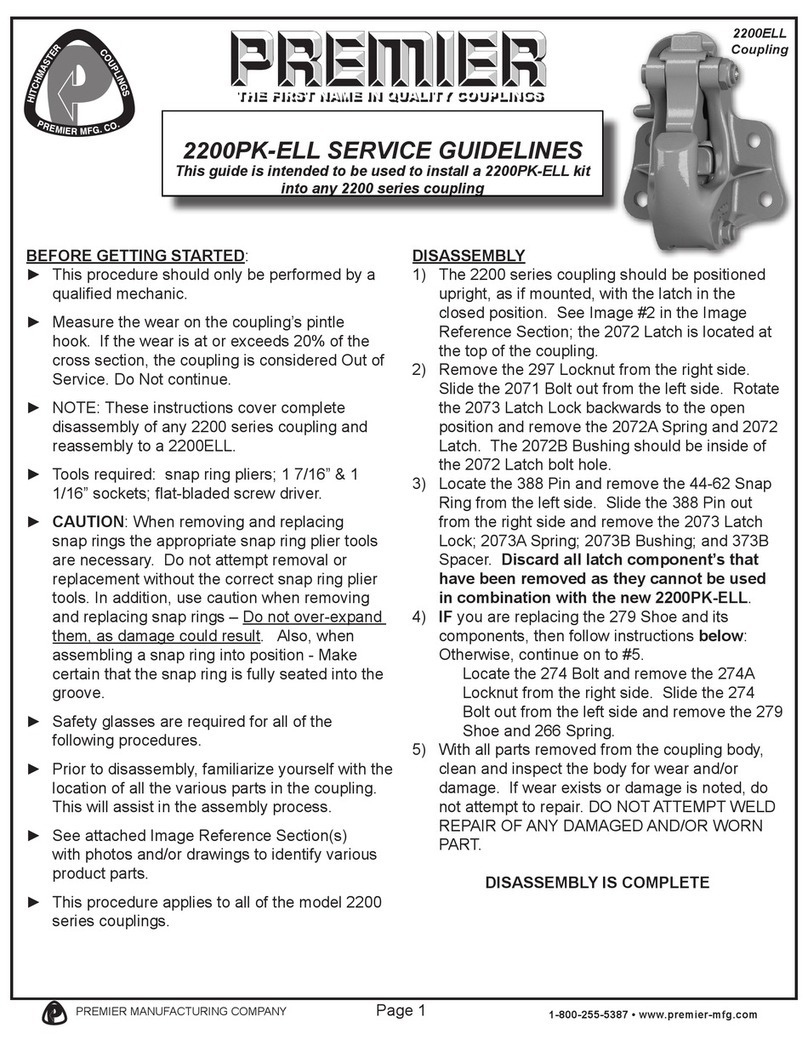

1. The 200, 200L & 300 Drawbar Eye must be

installed to comply with the Federal Motor

Carrier Safety Regulations. Specifically, Section

393.70, Paragraph C: “Towing of Full Trailers.”

Prior to install or operation, consult with local,

state and federal agencies, as there may be

additional applicable laws governing installation

and use of this product.

2. Make certain that the front end structure the

drawbar eye is to be mounted on is of sufficient

strength to withstand the load rating of the

drawbar eye.

3. Using the Standard Installation Drawing,

measure and layout the front end mounting

surface and then drill the holes for the mounting

bolts.

4. Mount the 200, 200L or 300 Drawbar Eye using

either Premier’s 507 Bolt Kit and provided

torque value, or four other 3/4” grade-8 bolts

and grade-C locknuts. Only use new fasteners

when mounting couplings or drawbar eyes and

torque to SAE specifications.

5. An “IMPORTANT WARNINGS!” sticker was

enclosed. This must be attached to the front

end, adjacent to the drawbar eye, and visible for

the end user to read.

1. Visually inspect the drawbar eye for cracks,

impact damage and/or deformation before each

and every use. Do NOT use if any of these

conditions exist.

2. Check all fasteners to make certain that they

are secure before each and every use.

3. If the original cross-section of the eye loop has

been reduced by 20% or more, the drawbar eye

is considered out-of-service and must NOT be

used.

4. This product is designed to be operated within

its free rotation limits. It is the responsibility of

the vehicle designer/end user to ensure that

these limits are not exceeded (do not bind-up/

jackknife).

5. Never weld on any Premier part in order to

repair damaged or worn areas. Field and/or

shop welds are inadequate and may further

weaken the coupling.

6. WARNING: Other inspection and maintenance

procedures are also required prior to the

operation of combination vehicles. Consult

and follow all Federal Motor Carrier Safety

Regulations as well as local, state and federal

guidelines.

7. WARNING: Prior to towing, make certain that

adequately rated safety chains have been

properly connected.

PARTS

Optional Accessories:

- 14005 (1 5/8 in.) Wear Gage: To determine drawbar eye loop wear limits (200/200L).

- 14032 (1 11/16 in.) Wear Gage: To determine drawbar eye loop wear limits (300).

- 507 Bolt Kit: Four 3/4-10 x 2 3/4 in. grade-8 bolts and grade-C locknuts.

INSPECTION / OPERATION / MAINTENANCE

- Never attempt weld repair of damaged or worn drawbar eyes

- Air adjusted drawbar eyes must be used with an air service chamber or

#500 slack adjuster

- Only Grade-8 fasteners properly torqued should be used when attaching

bolt-on drawbar eyes

- Clean and inspect drawbar eyes and eye assemblies for damage or

excessive wear before each and every use

- Structure to which eye is attached must be of sufficient strength to

withstand load rating of eye

- Do not bind-up (Jackknife) any application as stresses can cause damage to products

or components, resulting in failure and detachment of the trailer while in use

- Do not apply lubricants to the coupling hook or drawbar eye loop, as they can cover

up possible damage and accelerate wear

IMPORTANT GUIDELINES that apply to all Premier Bolt-On Drawbar Eyes

ACCESSORIES

- 200 Bolt-On Drawbar Eye

- 200L Bolt-On Drawbar Eye - 300 Bolt-On Drawbar Eye