Table of Contents

Section 1: Introduction............................................................................................................ 1

Bambi System Drawing............................................................................................................................2

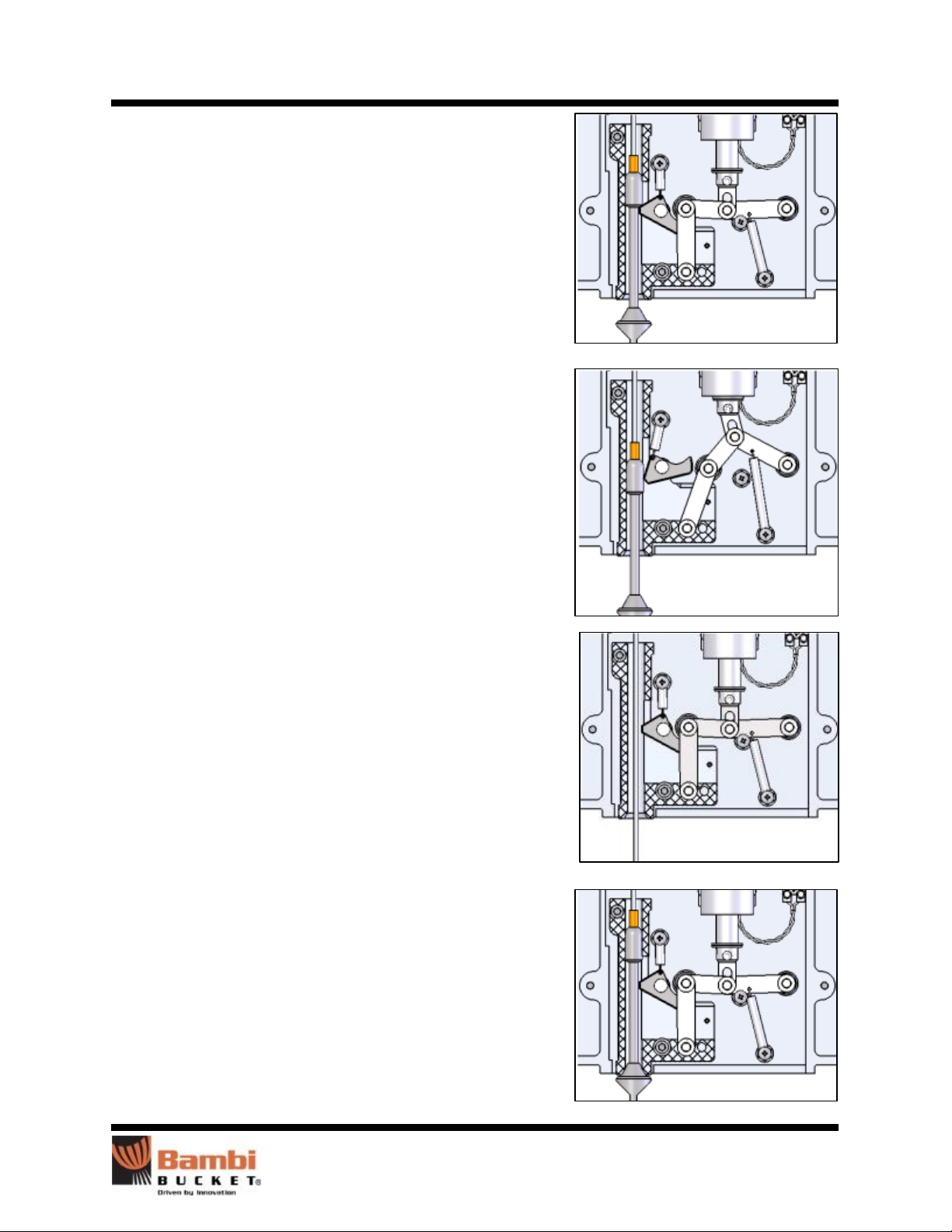

Dump Valve Operation.............................................................................................................................3

Control Head Operation............................................................................................................................4

Section 2: Deploying the Bambi Bucket................................................................................. 7

Attaching to the Cargo Hook....................................................................................................................7

Connecting Power.....................................................................................................................................8

Longlines ..................................................................................................................................................8

Checking Tail Rotor Clearance.................................................................................................................9

Instant Deployment System (IDS)..........................................................................................................10

Section 3: Accessories...........................................................................................................11

PowerFill Snorkel ...................................................................................................................................11

Foam Injection Systems..........................................................................................................................12

Section 4: Making Adjustments.............................................................................................13

Adjusting the Dump Valve Udder ..........................................................................................................13

Adjusting Purse Strings...........................................................................................................................13

Section 5: Packing and Storage.............................................................................................15

Packing the Bucket .................................................................................................................................15

Storing the Bucket...................................................................................................................................17

Section 6: Troubleshooting Guide.........................................................................................19

Valve Troubleshooting............................................................................................................................19

Control Head Troubleshooting................................................................................................................20

Section 7: Repair Assessment Guide....................................................................................23

Overview of Repair Categories...............................................................................................................23

Control Head Repair Criteria..................................................................................................................24

Cables Repair Criteria.............................................................................................................................25

M-Straps/Top Chains Repair Criteria.....................................................................................................26

IDS Repair Criteria.................................................................................................................................27

Bucket Shell Repair Criteria...................................................................................................................28

Cinch Strap Repair Criteria.....................................................................................................................29

Valve Repair Criteria..............................................................................................................................30