Seidel ST 5-100 B User manual

Operation

Manual

ST 5-100 B

SEIDEL STERNMOTOREN UG

(haftungsbeschränkt)

Montage und Vertrieb

2

Contents

Foreword..................................................................................................3

1 Specifications........................................................................................4

2 Engine installation.................................................................................4

3 Propeller mounting................................................................................5

3.1 Propeller............................................................................................. 5

4 Engine cover and hood ......................................................................... 5

5 Ignition system......................................................................................5

6 Fuel mixture..........................................................................................6

6.1 Mixture table....................................................................................... 6

7 Tank installation....................................................................................7

8 Valve clearance.....................................................................................7

9 Engine start...........................................................................................7

10 Carburetor settings..............................................................................9

11 Stopping the engine ..........................................................................10

12 Maintenance and repair..................................................................... 10

13. And finally….....................................................................................11

Warranty statement................................................................................ 12

3

Foreword

Dear customer,

Congratulations on the purchase of the new SEIDEL radial engine ST 5-100 B.

Your engine is a part of the latest generation of radial engines, which are based on

engineering experience more than 30 years.

These motors are manufactured exclusively in Germany, which gives them the seal of

approval

Made in Germany!

Our engines have been developed exclusively for the propulsion of radio controlled

model airplanes and optimized. For use outside the intended use, we can not accept

claims or complaints, nor assume any liability.

Please read these operating instructions before the first start carefully.

If you have any questions or suggestions, do not hesitate to contact us at the

following options:

Phone: +49 (0) 7246 2210

we wish you pleasant flights and always have fun with your SEIDEL radial engine.

Best regards

SEIDEL STERNMOTOREN UG

4

1 Specifications

Engine Type:

4 stroke radial engine

Cylinder:

5

Capacity:

100

Performance (hp/kw):

6 / 4,4

Bore / stroke (mm):

30 / 28,2

Diameter / length (mm):

245 / 190

Weight (kg):

3,3

Recommended propeller:

26×14 two-blade / 24×14 three-blade

Maximum speed (rpm):

5500

Fuel mixture (petrol/oil):

1:50

Ignition type:

electronically, with electronic igntion

timing

Power supply:

11,1 V

Power source:

Lipo 3 cells á 3,7V (in series)

Engine built (month/year):

2 Engine installation

For a secure and reliable mounting, the motor bulkhead should consist of 8-10 mm thick

multi-laminated plywood.

Do not use rubber bumpers!

Variant a) Motor bulkhead with preset side pull:

Mount the motor directly to the motor bulkhead and use for this M5 screws, strength class 8.8

(DIN EN ISO 4759-1) and only self-locking nuts. The screws should protrude at least three

turns of the nut.

Variant b)The motor bulkhead is straight and the side pull is adjusted by shims:

Please provide assurances that the motor is mounted stress-free and without distortion. Use

for this M5 screws, strength class 8.8 (DIN EN ISO 4759-1) and use self-locking nuts.

The screws should protrude at least three turns of the nut.

5

3 Propeller mounting

The propeller is secured by a securing ring which is clamped in a groove in the turn of the

propeller shaft. This retaining ring holds the propeller securely on the shaft, even if the nut

should be solved in the case of an abrupt motor standstill.

The engine must under no circumstances be started when the retaining ring is not

seated properly in the groove completely missing or the nut is not tightened.

3.1 Propeller

The choice of propeller depends on the type of model aircraft. You can use either two-blade,

three-bladed, and four-blade propellers.

Only mount well balanced propeller to ensure a smooth and vibration-free operation.

Operation not balanced propellers leads to engine damage and is therefore not permitted.

Check the propeller. Does the propeller have any cracks, chipped edges or other

damages, the engine must not be started.

4 Engine cover and hood

For optimum temperature conditions - even at full power - have the exhaust ports in total, the

same size as the air intake in order to ensure free circulation of cooling air and to prevent

overheating of the engine.

If necessary, install baffles that direct the cooling air less than five mm above the surface of

the cylinder along.

Heat accumulation leads to overheating of the engine with the probable result of a

severe to final engine failure.

5 Ignition system

The ignition is supplied with electrical energy from a LiPo battery type with 11,1 volts

(switched two cells in series).

For security reasons, we recommend the installation of a switch (on / off ignition) indicates

the status of an optical signal and is connected between the power source and the ignition.

This switch should be mounted at a location that is easily visible and accessible in order to

ensure an easy and safe operation.

Similarly allows you to bring the motor if necessary to an immediate standstill of these

switches.

6

General instructions for installation and operation of the ignition and associated parts:

The receiver (RC equipment) must be installed at least 20 cm from the igniton and their

power source.

All cables should be mounted in such a way that they do not come with the muffler or

any other part of the engine in contact, which may become hot. Otherwise, the

insulation could be damaged, which may cause a short circuit and therefore to the loss of the

model.

Do not attach pliers or other tools to remove the spark plug cap. Do not pull the plug wire, but

remove the spark plug by a slight rotation by hand.

Keep a firm hold of the spark plug cap, otherwise known as crack pulses may arise , which

would affect the remote control of your model.

A slight clicking shows you the correct position of the connector on the spark plug.

Please also refer to the operating instructions of the ignition system.

6 Fuel mixture

We recommend for your engine unleaded fuel with an octane rating of 98 or more, and oil

additive or a finished two-stroke engine mixture (e.g. Aspen 2 or Motomix).

As an oil additive to the unleaded petrol Stihl Engine Oil HP Ultra or Castrol RS 2T You can ,

for example, Stihl HP motor oil , engine oil Stihl HP Super , use . All of these oils are fully

synthetic two stroke oils. The brand name may vary in your region.

6.1 Mixture table

Petrol

Fully synthetic oil

Run-in period

1 liter

0,02 liter (2%)

Flight and continuous

operating

1 liter

0,02 liter (2%)

The run-in period should last for two hours. Within this time you should never run the

engine with more than 75% throttle position. Please note for this also the operating

instructions supplied with your remote control, servo travel section and throttle curve.

7

7 Tank installation

The fuel line should be routed so that they do not come into contact with the muffler or any

other part of the engine, which can be hot.

Keep in refueling hose clean and use a filter if necessary.

8 Valve clearance

The valve clearance is in the delivery of 0.1 - 0.15 mm preset.

It is advisable to check the valve clearance every 2-3 hours runtime and adjust if necessary.

A visual inspection of all moving parts (rocker arms, rocker arm shaft, tappets and push rods)

should be performed before each flight.

For an adjustment of the valve clearance of the engine must be cold!

If adjustment is necessary, please proceed with the following steps:

Turn the propeller in the running direction until both valves of the cylinder to be adjusted are

relieved.

Check the game by hand. Is this too large (> 0.3 mm) , loosen the nut on the rocker arm (

counter-clockwise) and turn the Valve Adjusting (clockwise) until the game is in the range of

0.1 mm - 0,15 mm is.

Now tighten the nut on the rocker arm firmly back carefully.

Turn the propeller in the direction two full turns and check the valve clearance again.

Repeat the cycle on all cylinders in succession in the direction (counter-clockwise).

After every second or third flight operations day you should spend a little thick liquid lubricant

on the valve guides. Suitable are the same oils that you use as a fuel additive, see chapter

fuel mixture.

9 Engine start

First, some general information on starting the engine:

In order to prevent unintentional rolling on the model, you secure it with a strap on a fence

post or the like, or ask an aviator colleagues for support.

Make sure that no persons are in front or on either side of the rotating propeller. You too

should leave this area immediately after "cranking" the engine.

8

Make sure that there are no loose objects are within five meters around your model.

Check the propeller for damage (see chapter propeller).

The engine must not be started if the safety ring is not correctly plugged into the groove

provided in the propeller shaft, completely lacking or the propeller nut is not securely

tightened.

When you start the engine, set up your whole attention to it.

Pull your hand back after the strong "cranking" of the propeller immediately, because the

engine fires with a small delay.

Alternatively you can use to cranking a cordless screwdriver with suitable cover.

Now the "technical side":

Make sure that the ignition is switched off!

Turn the propeller two or three times in the machine direction (counterclockwise). If the

rotation is very difficult, do now turn the propeller three or four times against the running

direction (clockwise).

If the increased rotational resistance then is still present, remove the bottom two spark plugs

(see chapter ignition coils), to drain the excess amount of oil from the lower cylinders.

Close the choke / keep your finger on the carburetor opening.

Turn ("throw") the propeller 4 to 6 times, to suck in the fuel into the carburetor.

Open the choke / Remove your finger from the carburetor opening.

Turn the propeller three full turns.

Turn on the ignition.

Turn ("throw") the propeller vigorous and pull your hand back immediately, because the

engine would have to start now. Optionally, repeat the process.

Let the engine warm up for about 2 minutes at slightly higher idle speed.

Indicate for a few seconds at full throttle and check the throttle response and your settings on

the remote control. Should give abrupt gas or remove the gas are in the operation of a radial

engine generally be avoided, as this can cause the motor stops.

Keep this in mind: If you fly, you do not move the throttle abruptly.

We recommend that the idle speed by two to three clicks to increase the throttle trim on your

remote control after take-off the aircraft. So the engine does not go out, even if the speed is

reduced due to sudden load changes or the vertical climb. Experience has shown that, in

9

flight, the speed should not drop below 1200 rpm.

After landing, you can reduce the idle speed again for slow rolls on the ground (less than

1200 rpm)

10 Carburetor settings

At delivery, the carburetor is preset with the following values:

Main needle (side air intake): 1 ¼ - 1 ½ turns on (counterclockwise)

Idle needle (side engine casing): 2 ¼ - 2 ½ turns on (counterclockwise)

Turns to the left (counterclockwise) mean by opening the nozzle enriches the mixture.

Turns to the right (clockwise) mean by close the nozzle leaning of the mixture.

If adjustment is necessary, please proceed with the following steps:

Prepare your model to start the engine before (as described in the chapter on starting

engine).

Changing the full gas mixture setting:

Let the engine about two minutes at slightly elevated idling warm up.

Put full power and measure the speed.

Turn the main needle 1/8 turns in or out until you reach the maximum speed.

Beware of the rotating propeller. We recommend stopping the engine before the setting will

be changed.

Changing the idling mixture adjustment:

Let the engine for two minutes at slightly elevated idling warm up.

Measure the speed, which should be between 1000 and 1100 rpm.

If the speed varies, turn the idle needle in 1/8 turns in or out until you have reached a stable

speed.

Check the throttle response during sudden load changes. The rotational speed should not fall

under 1000 - 1100 rpm.

If in doubt, it is always a sure way to make the setting more like a 1/8 turn in the direction of

rich mixture.

10

11 Stopping the engine

The engine can be stopped by manually turning off the ignition (see chapter ignition system).

Alternatively, the ignition cut can also be done by remote control by a switch. In this way, the

motor of you can be parked safely from a distance, e.g. in the unlikely case of a landing

outside the model flying.

12 Maintenance and repair

Your SEIDEL engine will thank you with a long life, if you...

…clean it after every flight with a lint-free cloth.

…the valve guides and rocker studs enjoy some lubricant.

…the motor always operate within the limits and according to instructions in this manual.

…the engine when not in use store cleanly and dryly.

The SEIDEL radial engines are all similar in design and construction. Nevertheless, there are

sophisticated technical products, which require a certain level of technical knowledge by the

user.

Why should minor repairs by the owner only after consultation with us take place, in particular

to maintain the guarantee claim.

All major maintenance should be carried out by us as the manufacturer or through our service

partner.

11

13. And finally…

We have written this manual with care. Please give it your attention before you start

your engine for the first time. Marked with this warning sign posts in the operating instructions

indicate on things, their neglect caused immediate damage to the engine with high

probability.

Improper or careless handling or use outside the specifications of this manual will damage

the motor.

Negligence near the rotating propeller can cause serious or even fatal injuries.

If you plan to take the motor in operation, be sure that you are not tired and unfocused.

Follow the instructions and notes in this manual.

Keep all other persons out of the danger zone.

When you get help from someone, make sure that this person knows exactly what to do, how

to do it and also what is to be avoided!

If you follow all the instructions, you will have a pleasant flight with your model and the

SEIDEL radial engine.

In the unlikely event that something does not work properly or are missing, please tell

us.

We will do our best to resolve the issue. As quickly as possible and to your complete

satisfaction.

If everything works and you appreciate your engine, tell your friends!

Also we would be delighted to get a feedback from you.

Thank you.

SEIDEL STERNMOTOREN UG

Montage und Vertrieb

Daimlerstr. 17 Box 20

76316 Malsch

Phone: +49 (0) 7246 2210

info@seidel-sternmotoren.de

www.seidel-sternmotoren.de

12

Warranty statement

Even with careful production and quality control, it may happen that a product does not

function properly. For this case, SEIDEL STERNMOTOREN UG gives a warranty on all

engines. The term of the warranty is 2 years from date of delivery.

The warranty covers all of SEIDEL STERNMOTOREN delivered engines to first time buyers.

If the motor was sold / shipped by a distribution partner of SEIDEL STERNMOTOREN UG,

the warranty applies to whose first time buyers again. Each condition is the submission of the

purchase invoice.

Resale to third parties will void the warranty.

Your rights under the statutory warranty keep their application and are not limited by the

guarantee.

If you want to make your claim under warranty, we ask you to contact us in advance in order

to verify whether and to what extent of warranty coverage and how this can be resolved to

your satisfaction. If necessary, we ask you for returning the motor in a safe and stable

packaging to prevent damage in transit.

Into effect of the warranty won´t be any extension or new enactment of the warranty period.

Excluded from the warranty are:

damage caused by improper use or by not following the instructions of this manual

damage (to the ignition) by short circuit or over voltage (polarity reversal, use of

unsuitable batteries)

damage caused by the use of unsuitable fuel

damage caused by a crash of the flight model

damage during a return from insufficient packing, arise.

Modifications to the engine (valve clearance adjustment and carburetor adjustment

excluded), fitting of parts, disassemble or open the engine will void the warranty.

Please send in a warranty case after consultation with us the motor in a transport-safe

packaging along with this operating manual and a copy of the purchase receipt to the

following address:

Enrico Seidel

Daimlerstr. 17 Box 20

76316 Malsch

Deutschland

Thank you.

___________________________________

State March 2014 Date and signature

Table of contents

Other Seidel Engine manuals

Popular Engine manuals by other brands

Schulz

Schulz MGS 5.5 instruction manual

Volvo Penta

Volvo Penta D1-13 Operator's manual

O.S. engine

O.S. engine O.S.MOTOR OMH-5830-490 Owner's instruction manual

Graco

Graco Premier 240176 instructions

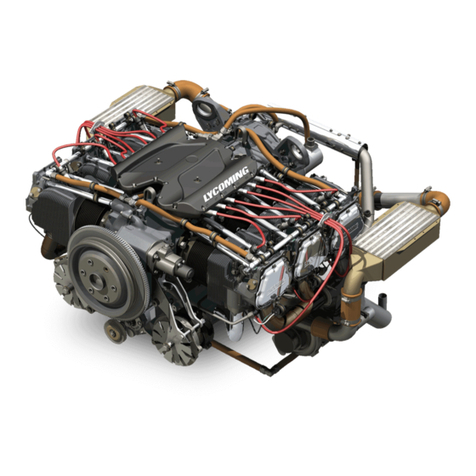

Lycoming

Lycoming TEO-540-A1A Installation and operation manual

Ray Electric Outboards

Ray Electric Outboards E2 Repair manual