Adjusng with a PC

With the »EASY Starter« engineering tool (expanded version, »EASY Advanced«“ or »Engineer

HighLevel« soware licence needed) can be used to adjust the Lenze Smart Products. The

relevant version can be easily downloaded from hp://www.lenze.com . As the sengs are

very simple and clear, there is an easy-to-use dialog box, which can be opened directly via the

navigator. The corresponding buon is directly accessible in the navigaon bar. Analogously to

other product sengs, the parameter values can be archived.

Starng and stopping smoothly and gently

An acceleraon ramp and – in contrast to a convenonal starter – a deceleraon ramp can be

set for Lenze Smart Products. This ensures that the conveyed material is handled in a dened

and jerk-free manner..

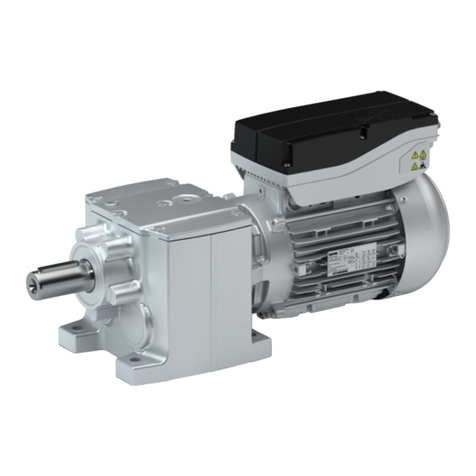

Contactor and motor protecon funcons integrated

The Lenze Smart Products can be started and stopped by mean of digital inputs. It is also

possible to switch between dierent speeds and rotang direcons. Up to 5 dierent speed

modes (e. g. creep speed and normal speed in both direcons as well as stopping) can be used

for a motor. Reversing-contactor changes and pole changes are thus a thing of the past.

In addion, motor-protecons devices are not needed as monitoring of temperature, short

circuits, earth faults and phase failures has already been integrated.

Easy installaon

Connecon takes place completely from the outside by means of connectors.

The Lenze Smart Products come with an especially clever connecng technology – Phoenix

Contact QUICKON. Electrical installaon is therefore very easy without special tools and

requires less than one minute.

In addion to the QUICKON connector, the M15 connecon customary on the market is

available.

As a standard feature, the digital inputs and outputs are connected at M12 sockets of the type

currently available on the market.

Already exisng signal cables can oen be reused.

Worldwide and ecient

The drive can be used worldwide:

•In all 3-phase networks with a supply voltage of 400 ... 480 V and a mains frequency of

50 ... 60 Hz

•At ambient temperatures of -30 ... +40 °C

•Is suitable for many approvals

The Lenze Smart Motor fulls the requirements as described in the highest eciency

requirement for IES2.

If very lile torque is needed in the paral-load operaonal range, the integrated energy

saving funcon can be used to opmize the energy absorpon of the drive.

Product informaon

Product descripon

9