Mounting The Operator

1/ Close the door, measure the centre of the door and mark this position on the

door and the frame header. Note: check that the door-frame header is securely

fixed at the centre and make good with additional fixings if necessary.

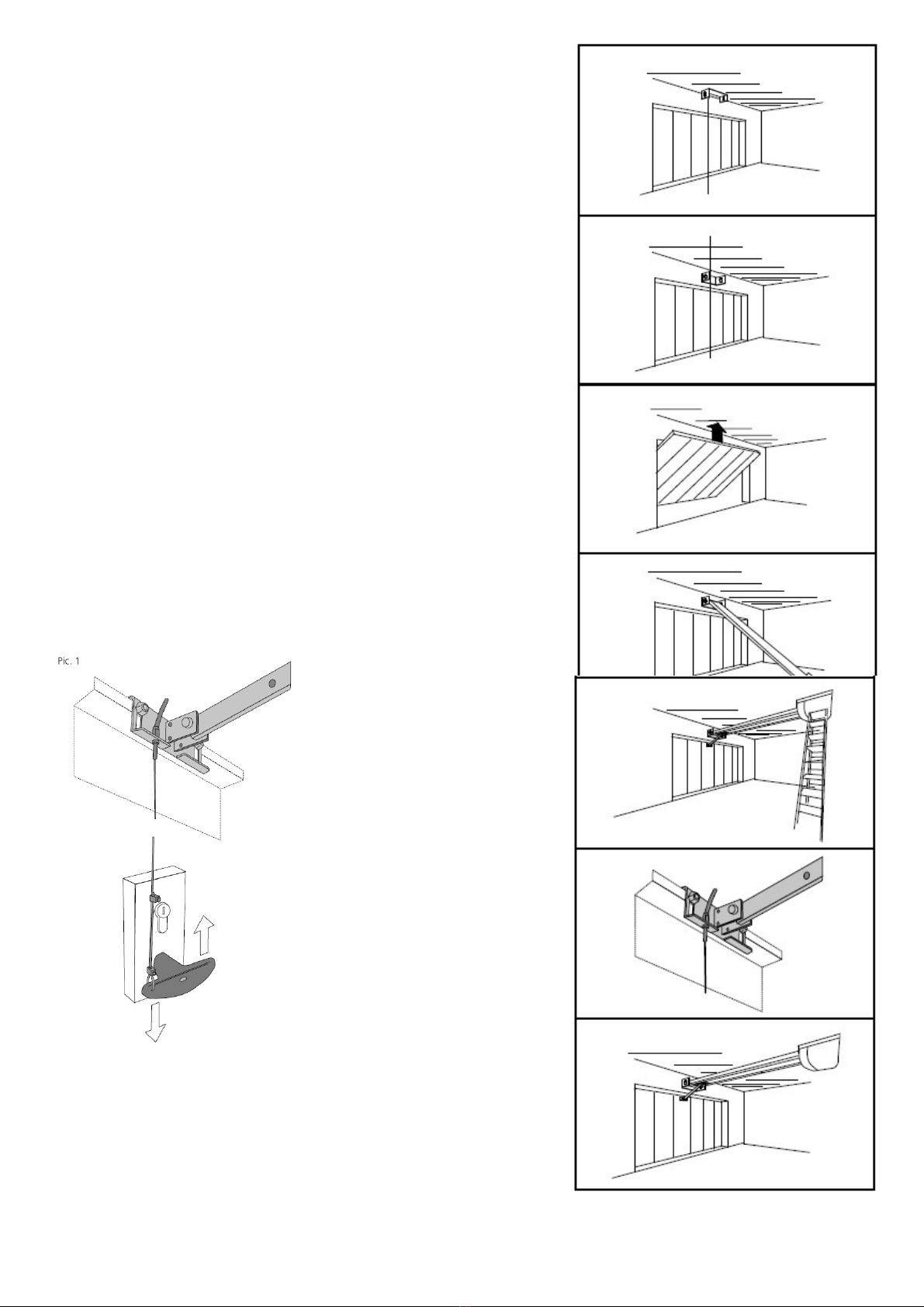

2/ Fix the C-rail fixing bracket to the lintel, door header, or ceiling, as shown in

Fig 1 or 2 The ideal position is 50 - 100mm above the top edge of the door.

3/ Place a carton on the floor to protect the motor casing and attach the C-rail to

the front fixing bracket as shown in Fig 4

4/ Raise the motor head and support it either by using a strap from the beams or

a pair of steps as in sketch as shown in Fig 5

5/ Open the door and align the C-rail track with the centre of the door and adjust

the motor height to give a clearance of approx 30mm to 60mm between the C-rail

track and the face of the door. The motor head may now be fixed to the ceiling

with the brackets provided. (for model TM80 refer fig 3 on page 7 of the

manufacturers installation manual for fixing details) Note: If you have a high

ceiling it may be necessary to extend the motor fixing brackets.

6/ Disengage the black sliding trolley from the chain drive (by pulling the manual

release cable forward) and slide the trolley along the track towards the door.

7/ Fix the door arm bracket to the top edge of the door as shown below. Four M6

self tapping screws & washers are provided for use on steel doors. For timber or

G.R.P. doors use M8 x 40mm coach screws & washers.

8/ Disable the original manual latching system on the door, (the motor will

automatically secure the door at the top when closed)

Note: Our Securi-Dor AP2000 multi-point locking system may be fitted to provide

additional security by automatically engaging the door's original manual latches

when closed.

Emergency Release Device

If your garage door is the only entrance you must provide a means of

opening the garage door from outside in the event of power failure.

Seip operators feature a Bowden cable operated emergency door-release device

to allow manual operation in case of power failure, this can be operated either

from inside the garage, or from outside by means of the original locking door

handle if you have a "vault type" garage (no personal access door)

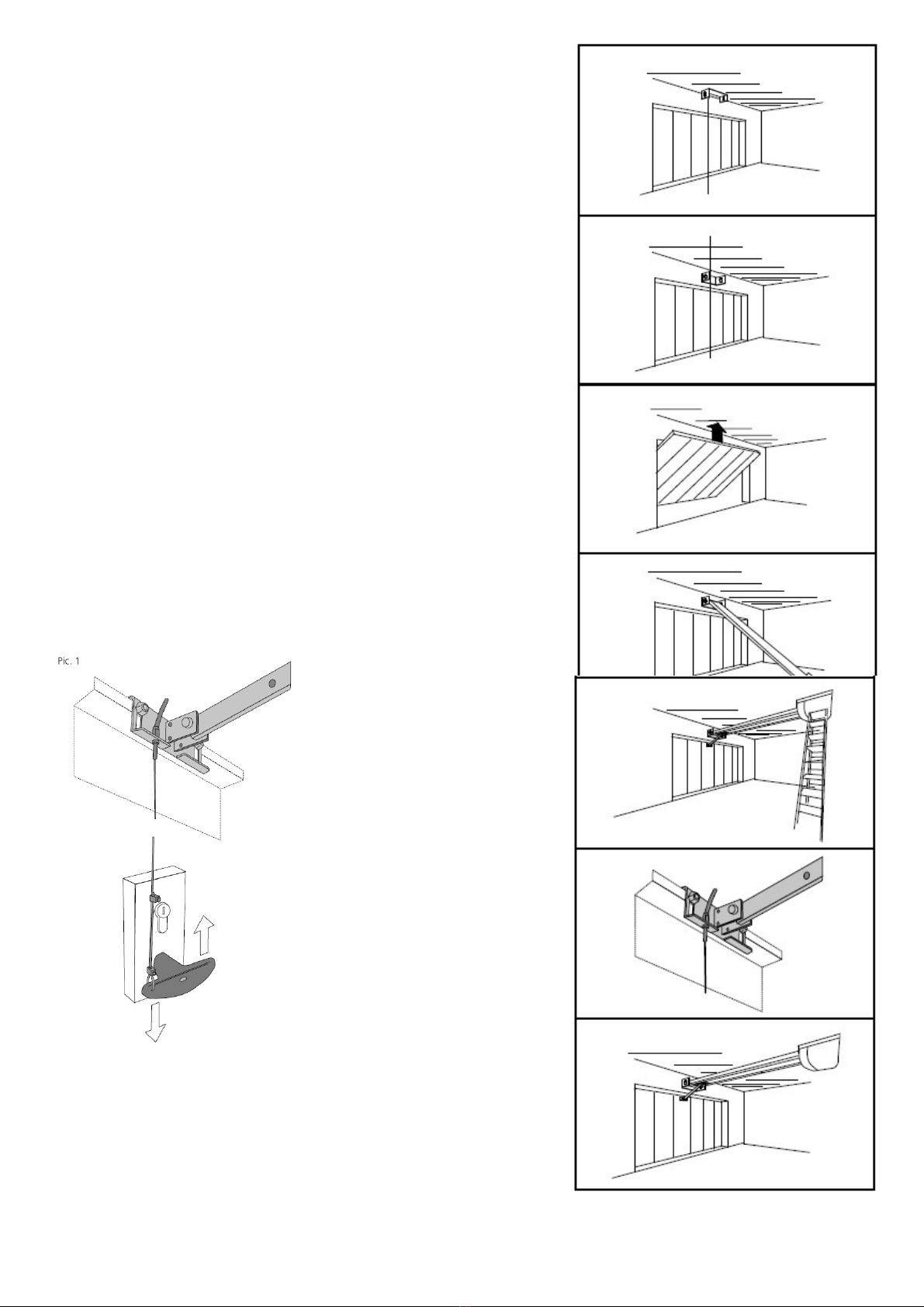

To enable the door to be released from

outside with a key the emergency

release cable should be connected to

the original locking door handle as

follows:

Connect the emergency release cable

to the back of the door's original handle

so that when the handle is unlocked and

turned from outside it pulls the cable

downwards. The sketch (Pic1) is only a

guide as door handles vary according to

the make of door.

Note: Do not leave the garage and

close the door until you have

tested the operation of the

emergency release from outside.

Get someone to test for correct

operation of the handle & cable etc.

while you are inside.

If your garage has a personal

entrance door it is not necessary to

connect the emergency release cable

to the door handle as above

Note: we do not recommend using the red pull toggle supplied by the factory.

We recommend that you fit 4mm red sleeving (supplied) over the cable instead

and secure the end of the emergency release cable to a fixed point on the back

of the door garage, this will enable manual operation from inside by pulling the

cable.

Page 2 of 4

Fig 1

Fig 2

Fig 3

Fig 5

Fig 6

Fig 7

Fig 4