ForceDoor FS 600 Mounting instructions

Sectional And Tilting Door Opener

Installation Instructions and User Guide

WARNING

S/N

Please read the manual carefully before installation and use.

The installation of your new door opener must be carried out by a technically qualified

or licensed person.

Attempting to install or repair the door opener without suitable technical qualification

may result in severe personal injury, death and / or property damage.

FS 600 600N

FS 1000 1000N

FS 1200 1200N

FS 600-

Speed

600N

FS 1000-

Speed 10

00N

Important Safety Recommendations...…………………………….……………………………..1

Product Description & Features..............................................................................................2

Pre-Installation Recommendations ........................................................................................3

Installation (Wall Bracket & Door Bracket) .............................................................................3

Installation (Steel Track)………………………………………….…………………………….…..4

Installation (Sectional Steel Track Assembly).........................................................................5

Installation (Aluminium Track)..............................................................................................6-7

Battery backup Assembly (optional)..............................................................7

Programming Instructions....................................................................................................8-9

Terminal Introduction and Application.................................................................................10-11

Manual Disengagement........................................................................................................12

Maintenance……………………………………………………………………………………….12

Technical specifications……………………………………………………………………….....13-14

Parts Listing…………………………………...........................................................................15

Common Fault & Solutions ..................................................................................................16

CONTENTS

FAILURE TO COMPLY WITH THE FOLLOWING SAFETY RECOMMENDATIONS MAY

RESULT IN SERIOUS PERSONAL INJURY, DEATH AND / OR PROPERTY DAMAGE.

1. PLEASE READ CAREFULLY AND ADHERE TO ALL SAFETY AND INSTALLATION

RECOMMENDATIONS.

2. The opener is designed and manufactured to meet local regulations. The installer must be

familiar with local regulations required in respect of the installation of the opener.

3. Unqualified personnel or those persons who do not know the occupational health and

safety standards being applicable to automatic gates and other doors, must in no

circumstances carry out installations or implement systems.

4. Persons who install or service the equipment without observing all the applicable safety

standards will be responsible for any damage, injury, cost, expense or claim whatsoever

any person suffered as a result of failure to install the system correctly and in accordance

with the relevant safety standards and installation manual whether directly or indirectly.

5. For additional safety we strongly recommend the inclusion of Photo Beam. Although the

opener incorporates a pressure sensitive Safety Obstruction Force system the addition of

Photo Beam will greatly enhance the operating safety of an automatic garage door and

provide additional peace of mind.

6. Make sure that the garage door is fully open & stationary before driving in or out of the

garage.

7. Make sure the garage door is fully closed & stationary before leaving.

8. Keep hands and loose clothing off the opener and garage door all the time.

9. The Safety Obstruction System is designed to work on STATIONARY objects only.

Serious personal injury, death and / or property damage may occur if the garage door

comes into contact with a moving object

10. This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play

with the appliance.

11. Waste electrical products should not be disposed of with household waste. Please

recycle where facilities exist. Check with your local authority or retailer for recycling

advice.

12. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard.

- WARNING: Important safety instructions. It is important for the safety of persons to follow

all instructions. Save these instructions.

- Do not allow children to play with door controls. Keep remote controls away from children.

- Watch the moving door and keep people away until the door is completely opened or

closed.

- Take care when operating the manual release since an open door may fall rapidly due to

weak or broken springs, or being out of balance.

- Frequently examine the installation, in particular check cables, springs and mountings for

signs of wear, damage or imbalance. Do not use if repair or adjustment is needed since a

fault in the installation or an incorrectly balanced door may cause injury.

- Each month check that the drive reverses when the door contacts a 50 mm high object

placed on the floor. Adjust if necessary and recheck since an incorrect adjustment may

present a hazard, for drives incorporating an entrapment protection system depending on

contact with the bottom edge of the door.

- Details on how to use the manual release.

- Information concerning the adjustment of the door and drive.

- Disconnect the supply when cleaning or carrying out other maintenance.

- The installation instructions shall include details for the installation of the drive and its

associated components.

IMPORTANT SAFETY RECOMMENDATIONS

1. Automatic safety reverse

Automatic stop / automatic reverse are controlled by our software of circuit boards. We are

circumspect to protect your children, pet or other goods.

2. Soft start / Soft stop

Ramping speed up and down at the start and end of each cycle reduces stress on the door

and opener for longer life, and makes for quieter operations.

3. Auto-Close

Auto- Close ensures peace of mind and keeps your house secure by automatically closing the

door upon entering or exiting the garage.

4. Self learning open and close obstruction force

The amount of opener power for different stages of the door’s travel is learnt during setup and

is constantly re-profiled. Opener force measurement automatically adjustment in a suitable

range.

5. Electronic limit, simple adjustment.

You only need control the limit setup from control panels to adjust it exactly, the simple and

quick process for any peoples.

6. Available terminal for Photo beams & Extra receivers & Wire or wireless wall switch &

Caution light & Pass door protection device.

7. Energy saving - L.E.D courtesy light

3 minutes L.E.D light delay, switching on with each cycle to illuminate your darkened garage.

8. Battery backup available

Openers could be supplied power with our battery backup once the power failure at your

home.

9. Self-Lock in gear motors

Force gear motors will self-lock with our disengagement systems.

10. Manual release

Don't worry about the power failure, the manual release system is a solution for operation the

door at any time.

11. Transmitter technology

Rolling Code technology (7.38 x 1019 Combinations), 433.92Mhz frequency, 4 channels design

to ensure you can control 4 different doors with one transmitter.

12. Lower headroom

With as little as 30mm required between the ceiling and the highest point of the door travel, the

opener can be flush mounted for low headroom applications.

13. Metal bottom plate, stronger and security.

14. O/S/C button (A)

Front panel open / stop / close buttons for operation. (picture below)

15. External mains power fuse (B) (picture blew)

A

B

PRODUCT DESCRIPTION & FEATURES

1. Garage door must be able to be lifted and closed easily by hand and without much effort. A

well balanced & sprung door is critical for proper installation.

2. The garage door opener can’t compensate for a badly installed garage door and should

not be used as a solution for a “hard to open” door.

3. If the unit is being installed on an existing door, make sure any existing locking devices are

removed or warranty will be void.

4. An approved outlet must be installed near where the opener is begin installed.

5. There should be a minimum gap of 30mm between the bottom of the chain drive rail and

the top of the garage door at its closest point. (refer to Fig 1.)

Important note: As for additional safety rules, we strongly recommends the fitting of Photo

Electric safety beams on all installations.

Figure 1

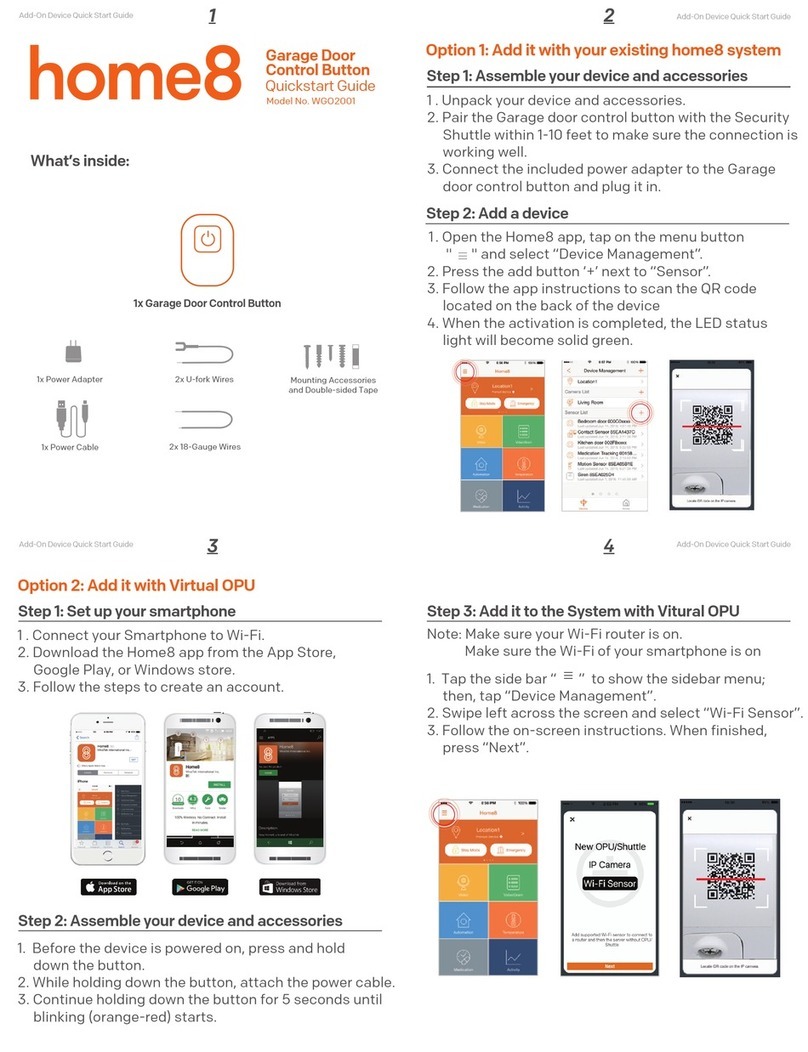

Mount Wall Bracket and Door Bracket (Fig2)

Wall Bracket - Close the garage door and measure the

garage door width at the top and mark the centre. Locate and

mount the wall bracket 2cm-15cm above the door on the

inside wall.

(Depend on the actual installation space).

Door Bracket –Fix the door bracket to a structural part of the

door as close to the top edge as possible.

Figure 2

PRE-INSTALLATION RECOMMENDATIONS

INSTALLATION INSTRUCTIONS

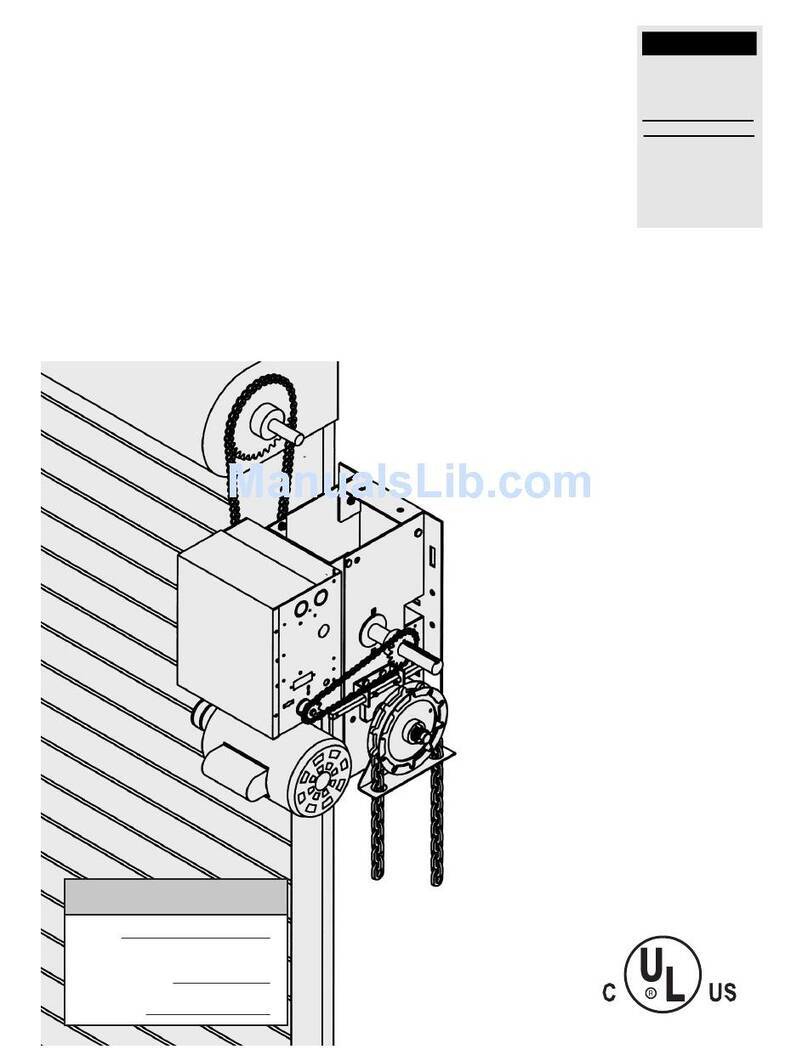

Installation (Steel Track)

Figure 3

STEP1 (Fig.3)

Attach the opener head to the steel track. Assembly the 2 “U” Hanging brack ets

with 6mm nuts supplied.

STEP2 (Fig.3)

Place the steel track and opener head assembly centrally on the garage floor, with

the open head furthest away from the door. Lift the front of the track up to the door

bracket. Insert the pivot pin and secure it with the split pin supplied.

STEP3 (Fig.3, Fig.4)

Lift and support the opener head (with a ladder) so it is

positioned centrally and level. Fix the opener and track

on ceiling by Iron bracket A & B.

WARNING: Do not allow children around the door,

opener or supporting ladder serious injury and/or

damage may result from failure to follow this warning.

STEP4 (Fig.3, Fig.5)

Fix the shuttle to assembled by 4pcs 6x23 screws, and

then slide the shuttle towards the closed garage door.

Select and attach the straight arm and bend arm.

Position and bolt the arms to the top edge of the door

using the bolts supplied.

STEP5

Lift the garage door until the shuttle locks into the

drive chain/belt.

Now, ready to program the openers.

Sectional Steel Track Assembly

1. 2-Parts Track:

As Fig.6, slide the Arail into the sleeve, slide the B rail into the sleeve.

3-Parts Track:

As Fig.7, slide the C rail into the sleeve, slide the D rail into the sleeve; slide the E rail into

the sleeve.

2. Cut the plastic thread; pull the screw rod along with inner chain to the end rail position

(Fig.8)

3. As Fig.9, release the nut & spring.

4. Tight the nut to the right position as shown in Fig.10, cut the plastic tape, cut the plastic

thread on sprocket, then whole rail assembled finished.

3 Parts Steel Track

2 Parts Steel Track

F

F

A:1500 mm

B:1500 mm

Sleeve

C:1000 mm

Sleeve

Sleeve

D:1000 mm

E:1000 mm

Installation (Aluminium Track)

Figure 11

STEP1(Fig.12, Fig.13)

Insert the shuttle into the cut-out at the end of the Aluminium track. Be sure it

faces the right direction (the disconnection arm on the shuttle faces towards the

opener head). Slide

the shuttle along the

rail until it locks into

place with the brass

chain coupler. Move

the whole shuttle

assembly to the centre

of the drive rail.

STEP2 (Fig.14)

Using the 6mm hexagon head rail

mounting bolt supplied, slide 2 bolts

in each side of the rail through the

cutouts provided.

STEP3 (Fig.11)

Attach the opener head to the steel

track. Assembly the 2 “U”Hanging

brackets with 6mm nuts supplied.

STEP4 (Fig.11)

Place the Aluminium track and opener head assembly centrally on the garage floor,

with the open head furthest away from the door. Lift the front of the track up to the

door bracket. Insert the pivot pin and secure it with the split pin supplied.

STEP5 (Fig.11)

Lift and support the opener head (with a ladder) so it is positioned centrally and

level. Fix the opener and track on ceiling by Iron bracket A & B.

WARNING: Do not allow children around the door, opener or supporting ladder

Serious injury and/or damage may result from failure to follow this warning.

STEP6 (Fig.11)

Select and attach the straight arm and bend arm. Position and bolt the arms to the

top edge of the door using the bolts supplied. lift the garage door until the shuttle

locks into the drive chain.

Now, ready to program the openers.

Battery backup Assembly (optional)

STEP1 (Fig.15)

Assemble the battery & battery bracket like the photo, fix by screws supplied.

STEP2 (Fig.16)

Join the battery to opener, find the Fig.16.

Figure 15 Figure 16

2. PROGRAMMING HAND TRANSMITTERS

NOTE: Hand transmitters that are supplied with the door opener

are pre-programmed.

a) Press the CODE button. A dot will be indicated in the corner

of the display.

b) Now press the button on the hand transmitter you want to

use, pause for 2 seconds, then press the same button on

the hand transmitter again for 2 seconds.

The dot on the display will flash to confirm the code, then turn off.

Re- peat the process for additional remotes that need to be

stored.

3. DELETING STORED HAND TRANSMITTERS

Press and hold CODE button until a C is indicated on the display.

All stored remotes will be deleted.

1. PROGRAMMING OPEN & CLOSE LIMITS

a) Press and hold SET Button until 1 appears on the display

then release the button.

The door opener is now in Programming Mode.

b) Press and hold the UP until the door reaches the desired

open position.

NOTE: Fine adjustments can be made by toggling UP &DOWN

buttons

c) Now press the SET button to confirm the position. The

display will now indicate the number 2.

d) Next press and hold the DOWN button until the door

reaches the desired close position. For fine adjustments

toggle UP & DOWN buttons.

e) Now press the SET button to confirm the close position.

CAUTION: The door will now cycle open and close to set the

travel limits and force sensitivity adjustments. The door

is now set for normal operation.

PROGRAMMING INSTRUCTIONS

4. OBSTRUCTION FORCE ADJUSTMENT

CAUTION: the obstruction force adjustment is set automatically

during programming. Normally no adjustment is necessary.

a) Press and hold the SET button until 3 appears on the

display then release the button.

The unit is now in force adjustment mode.

b) Press the UP button to increase the force setting or the

DOWN button to decrease the force setting. The

Maximum force is 9 and the minimum is 1.

c) Press SET to confirm your setting

NOTE: The force is set on 3 as standard in factory.

5. AUTOMATIC CLOSING

NOTE: We recommend that Safety Photo Beams be used in any

installation where the Auto Close function is enabled.

a) Press and hold UP button until a horizontal bar is indicated

on the display. Now press UP button once to set the auto

close time (in minutes).

b) Press UP button to increase the time, or DOWN button to

decrease the time.

The Maximum time is 9 minutes. To disable Auto Close, set

time to zero (0).

c) Press SET button to confirm the set.

6. PHOTO ELECTRIC SAFETY BEAM

NOTE: Make sure the photo beam has been correctly installed

and use Normally Closed contacts to the accessory terminals of

the opener (Fig. 17, Fig.18)

Also note that the photo beam function must be disabled if

NO photo beams are fitted, otherwise the door cannot be

closed, and the LED will blink once time as an indication.

a) Press and hold the DOWN button until 11 appears on the

display. To enable the photo beam option press UP again,

the display will indicate a H(enabled) or press DOWN

button to disable (display 11) the option.

b) Press SET to confirm the set.

7. OPEN / STOP / CLOSE TERMINALS

The O/S/C facility can be used for an external push button switch

to operate the opener. The switch must have voltage free

normally open contacts (Fig. 20)

Increase Force

Decrease Force

IneaseA/C time

Decrease A/C time

Auto Close enabled

Auto Close disabled

Photo Beam enabled

Photo Beam disabled

Photo beam connection (optional) –Fig.17,Fig.18

Switch control connection (optional) –Fig.17

Figure 17

Figure 18

Other terminal introduction and application

1.The O/S/C interfaces available. (Fig. 19, Fig. 20)

Add a new O/S/C button to open or close the door.

2. Flash light function. (Fig. 19, Fig. 20)

There are corresponding interfaces for this function and provide 24v-35v flash light voltage.

Connect the flash light with DC 24v-28v, current≤100mA. When use AC 220V power flash

lights, please match an adapter, and wiring as required

3. Pass door (SD) protection (Fig. 19, Fig. 20)

This function ensure that the door can’t be opened unless the small pass door is closed.

The door panel won’t be damaged.

Figure 19

Figure 20

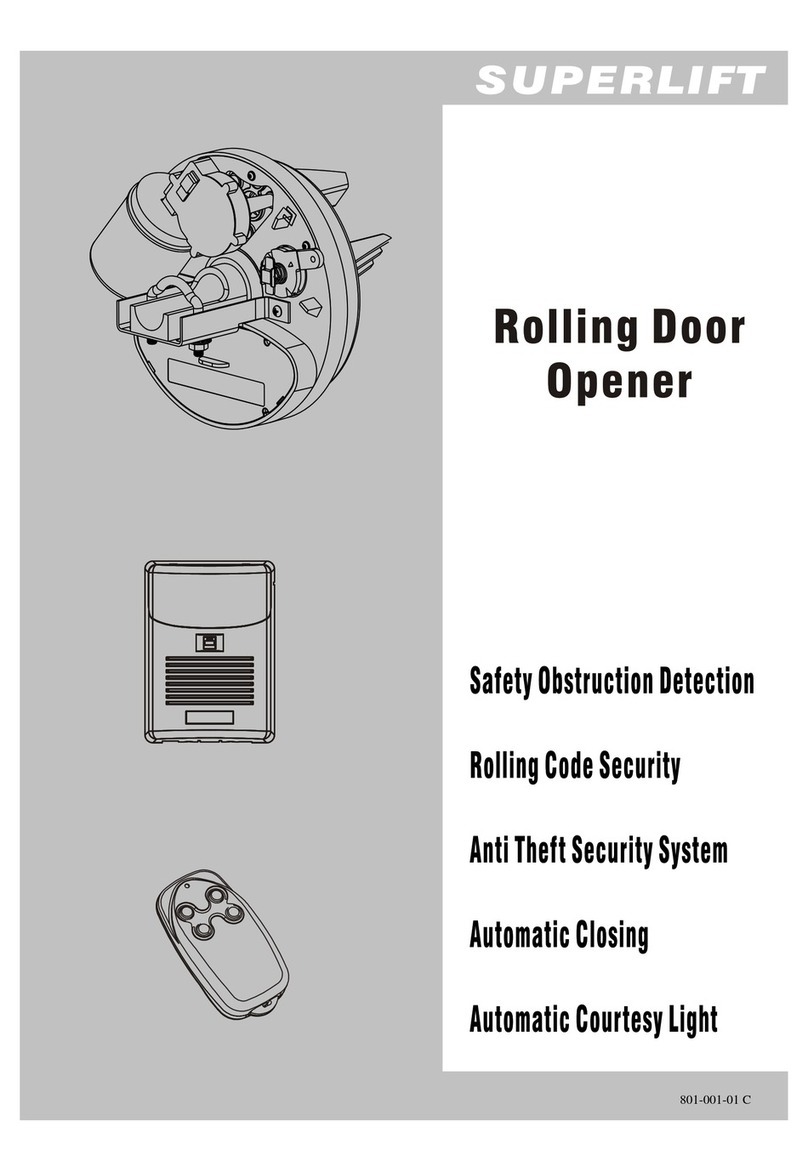

The opener is equipped with a manual release cord to disengage shuttle and move door by

hand while holding the handle down (Fig 21). Pull on the handle to disengage the shuttle. To

re-engage the door simply run opener in automatic mode or move door by hand until the trolley

engages in the chain shuttle.

In some situations that a pedestrian door is not in state, it is recommended that an external

disengagement device should be fitted (Fig 22).

1. No particular maintenance is required for the logic circuit board.

Check the door at least twice a year if it is properly balanced, and all working parts are in

good working condition or not.

Check the reversing sensitivity at least twice a year, and adjust if it is necessary.

Make sure that the safety devices are working effectively (photo beams, etc.)

2. Light bulb replacing:

Notice: Make sure the power supply has been cut off before replacing the light bulb. And

ensure the voltage of the new light bulb is in accordance with the local voltage and the

power is within 25 Watt.

Demount the screws on the lamp cover. Take the lamp cover away then twist off the old

L.E.D light anti-clockwise. Fix the new L.E.D light and lamp cover.

Notice: A rude operating door can affect the life of the automatic opener due to incorrect

loads, and will void the warranty.

Manual disengagement

Maintenance

Figure 21

Figure 22

FS 600

FS 1000

FS 1200

Input voltage

220 - 240V / 110 - 127V, 50–60 Hz

Max. pull force

600 N

1000 N

1200 N

Max. door area

10.0 ㎡

15.0 ㎡

18.0 ㎡

Max. door weight (Balanced)

80 kg

100 kg

140kg

Max. door height

2400 - 3500mm

2400 - 3500mm

2400 - 3500mm

Drive

Chain / Belt

Chain / Belt

Chain / Belt

Opening / Closing Speed

160mm / Second

160mm / Second

140mm / Second

Drive mechanism

Chain / Belt

Chain / Belt

Chain / Belt

L.E.D

24V / 15pcs LED bulbs

Limit setting

Electronic

Electronic

Electronic

Transformer

Overload protection technology

Radio frequency

433.92 Mhz

433.92 Mhz

433.92 Mhz

Coding Format

Rolling code (7.38 x 1019 Combinations)

Standard transmitter

2 X

2 X

2 X

Code Storage Capacity

20 different codes

Caution light terminal

Included

Included

Included

Working temperature

-40℃- +50℃

-40℃- +50℃

-40℃- +50℃

Safety Protection

Soft start & Soft stop, photo cell option, caution light option

Protection level

IP20

IP20

IP20

Technical specifications

FS 600

FS 1000

FS 1200

FS 600-Speed

FS 1000-Speed

Input voltage

220 - 240V / 110 - 127V, 50–60 Hz

Max. pull force

600 N

1000 N

Max. door area

10.0 ㎡

15.0 ㎡

Max. door weight (Balanced)

80 kg

100 kg

Max. door height

2400 - 3500mm

2400 - 3500mm

Drive

Chain / Belt

Chain / Belt

Opening / Closing Speed

200mm / Second

200mm / Second

Drive mechanism

Chain / Belt

Chain / Belt

L.E.D

24V / 15pcs LED bulbs

Limit setting

Electronic

Electronic

Transformer

Overload protection technology

Radio frequency

433.92 Mhz

433.92 Mhz

Coding Format

Rolling code (7.38 x 1019 Combinations)

Standard transmitter

2 X

2 X

Code Storage Capacity

20 different codes

Caution light terminal

Included

Included

Working temperature

-40℃- +50℃

-40℃- +50℃

Safety Protection

Soft start & Soft stop, photo cell option, caution light option

Protection level

IP20

IP20

FS 600-Speed

FS 1000-Speed

Item Qty Description

1 1 Control Panel Cover

2 1 Opener Middle Cover

3 1 LED light Cover

4 1 PCB(1)

5 1 PCB(2)

6 1 DC Gear Motor

7 1 Motor Shaft Sleeve

8 1 Transformer

9 1 Transformer Plate

10 1 Steel Bottom Base

11 1 Reference Switch

12 1 Sprocket Support

Item Qty Description

13 1 Switch Cover

14 1 C Rail - Steel

15 2 U Hanging Bracket

16 1 Track Bracket -1

17 2 Mounting Bracket

18 1 Chain or Belt

19 1 Chain Wheel

20 1 Wheel Bracket

21 1 Track Ending Bracket

22 1 Wall Bracket

23 1 Door Bracket

24 1 Bent Arm

Item Qty Description

25 1 Straight Arm

26 1 Track Bracket - 2

27 1 Trolley Assy - Bottom

28 1 Trolley Assy - Top

29 1 Trolley Arm

30 1 Release Cord

31 1 Caution Card

32 1 Release Handle

33 2 Transmitter

34 1 Transmitter Bracket

35 1 Wire Connection

35

34

33

32

31

30

29

28

27

26

25

24

23

22 21 20 19 18

17

15 13

12

10

7

6

5

3

Parts Listing

1

2 4

8

16

9

11

14

Fault appearance

Fault cause

Solutions

No any working for openers

1. Power supply

2. Plug wire are loosing

1. Check the power supply from electronic plug on

openers.

2. Carefully open the opener cover, check all plug wire on

control boards.

Not working for opener,

Display shows

Faulty learning on “Up”

Or “Down” limit travelling

Lean “Up” and “Down” limit travelling again follow the manual

Door is up moving only.

Do not work in down moving and the

display show

Photo cell function has been effective

but without connecting any photo cell device.

Turn off the photo cell function if there is no any

photo cell device connected.

( Refer the instruction manual)

Up and Down moving is reversed

Reversed plug wire between gear motor and

board

※Power off firstly, open the cover and reverse the plug

wire between gear motor and board. Re-set limit

travelling.

Door was Automatic reversed 15-40cm

before the door closed completely

In operation with automatic reversed

function. Because of some old

doors with not good balanced spring

or some block on it’s moving.

1. Check the door springs or any block position.

2. Re-set the limit travelling

3. Increase the force number for automatic reverse.

Transmitter is not working

1. Flat battery

2. Antenna is loosed or not well extended.

3. Interference around nearby

1. Replace new battery.

2. Extend the antenna on the opener

3. Get rid of interference

Cannot code in the new remotes

1. Stored remote code has been full

2. New remote is not compatible with

opener

1. Press “code” button over 8 Sec until LED

displays “C”, deleted all stored codes, code in new remotes

again.

2. Choose our remotes only.

Display shows

Opener does not work.

1. loosing for gear motor plug wire

2. Damage for gear motor

3. Damage for control board

1. Re-insert plug wire on gear motor

※2. Replace new gear motor

※3. Replace new control board

Display shows

After Opener was moving several

centimeters only

1. Hall sensor wire plug was loosing between

hall sensor and board.

2. Hall sensor or board is damage

1. Check the wire plug

※2. Check the hall sensor

※3. Replace control board

Remark: Only the professional person who are qualified to carry out the installation with ※marked.

Common Fault & Solutions

This manual suits for next models

4

Table of contents

Popular Garage Door Opener manuals by other brands

Chamberlain

Chamberlain LiftMaster SCS300K user manual

Chamberlain

Chamberlain B550 owner's manual

Craftsman

Craftsman 139.53939D owner's manual

PRIORY

PRIORY EUROPA operating & maintenance manual

American Garage Door Supply

American Garage Door Supply Supralift II installation manual

CAME

CAME KRONO quick start guide