3

It is within legal regulation and without restriction, to use a

Seip door operator with any garage door that has been ap-

proved for use with other certified door operators!

Directives and Regulations

The operators TS 75 and TS 100 comply to the latest European di-

rectives and regulations. The declaration of conformity is enclosed

at the end of these instructions.

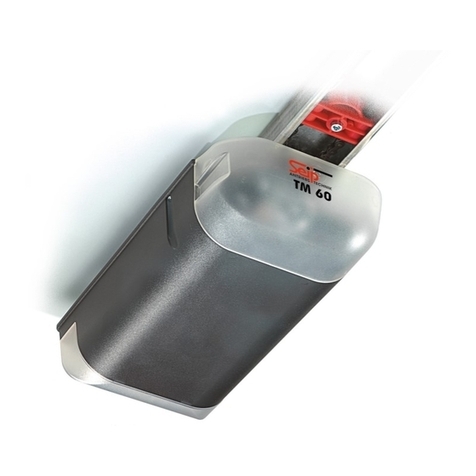

Use of the operators

The operators were designed for the use with up-and-over doors

(tilting and canopy-type) and sectional doors. They can be used

with side-hinged doors using a special conversion-kit.

All garage doors need to be maintained before automation. The

door must be easily opened and closed by hand. A garage door

must not be automated unless it is easy to open and close manu-

ally.

Garage Doors

In January 2001 the European regulations EN12604 and EN12605

became compulsory for garage doors. Before installing an au-

tomatic door operator it must be assured that the garage doors

applies to these regulations (the information can be obtained from

the manufacturers‘ declaration of confirmity). A Seip door opera-

tor may be installed to any door that complies to the regulations.

Should a garage door not be compliant then please refer to the

chapter „older garage doors“.

The installers declaration of conformity

No matter whether a door operator was delivered together with a

garage door or seperately, the installer must issue a declaration of

conformity for the complete installation.

With this declaration the installer assures, that the installation

was made according to the instructions given by the manufactur-

ers (e.g. the installation instructions of the garage door and the

operator). This declaration can only be issued by the installer and

may not be issued from the manufacturer!

If both components comply to the directives and the installation

was made as to the manufacturers instructions the whole installa-

tion will normally be CE-compliant.

Older Garage Doors

When automating an older garage-door the TS-series will still

comply to the regulations - through the automatic force setting

the requested values for forces and reversion will be according to

the regulations.

But it needs to be taken in consideration that most older garage

doors do not meet the regulations EN 12604 and EN 12605

- especially regarding security features. They might still have sharp

edges bearing the danger of severe injuries - for example sectional

doors might not have a finger protection between the sections.

Unfortunately the entire regulations do not mention how to

handle the automation of such an older garage door - the danger

basically is not the automation but the construction of the door.

Therefore we strongly recommend to

- check the garage door for sharp edges bearing danger when the

door is moving; take any necessary action to avoid the dangers

and make the door safer

- check the doors‘ springs and readjust them if necessary

- grease or oil the pivotal points and rollers of the garage door

- check that the door may be easily used by hand

If, however, the dangers cannot be avoided we recommend to use

the automatic pre-warning function of the operator. The opera-

tors‘ lighting will then be blinking for approx. 5 sec. before every

movement of the garage door. People inside the garage will be

warned before the opening and can step back from the garage

door in time.

Instruction for the users

Please instruct the users as follows:

- Use of the hand transmitter

- Use of the emergency release in case of a power failure

- Hand over the separate „User Manual“ to the customer

- Inform the user about the Security Advises in the User Manual

Important Information for the Installer

Information and Remarks