Selec SP112 Series User manual

ATSEL HMI User Manual

ATSEL HMI User

Manual

(Version:2.02)

Selec Controls Pvt. Ltd.

ATSEL HMI User Manual

Content

Installation...........................................................................................................................1

Communication Protocol.....................................................................................................3

Address setting....................................................................................................................5

Animation esign..............................................................................................................13

Recipe...............................................................................................................................15

ata Transmission............................................................................................................17

Alarm.................................................................................................................................18

Multi Language..................................................................................................................22

History ata Record..........................................................................................................24

User Encryption.................................................................................................................29

Update Program by U Flash..............................................................................................34

QR Code...........................................................................................................................35

One HMI Multi PLCs..........................................................................................................37

Time Setting......................................................................................................................40

Installment.........................................................................................................................42

System Configuration........................................................................................................49

Internal Register of System...............................................................................................51

Printer Settings.................................................................................................................54

1

ATSEL HMI User Manual

Installation

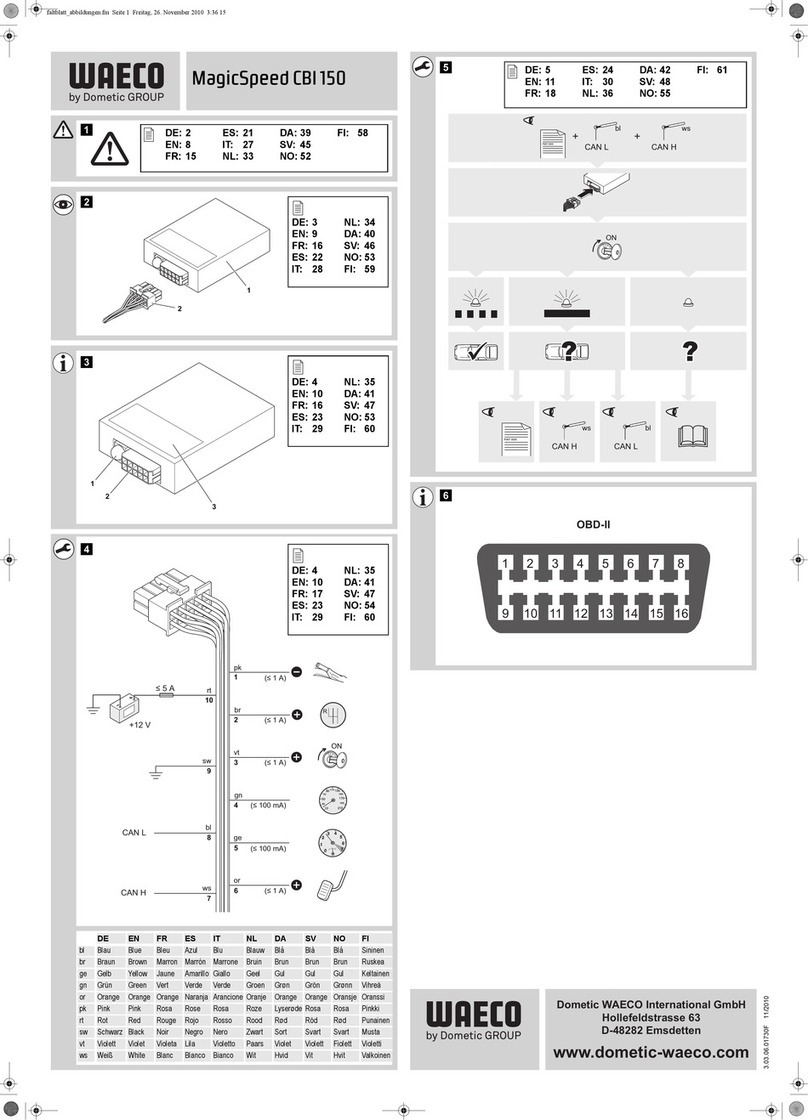

imension for installation opening

SP112 series of HMI(SP112-GT70-S-CE and SP112-GT70-ET-CE)

SP112 – 192×138mm

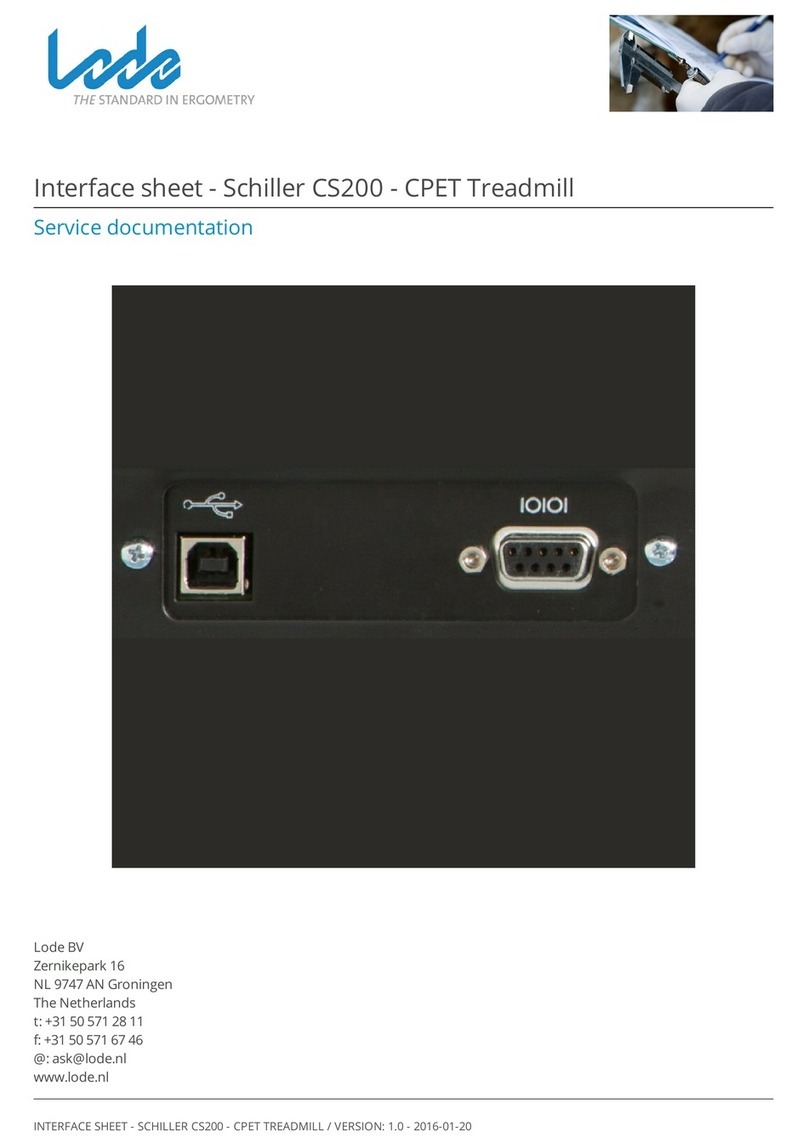

Interface

SP112 interface

Cable layout:back side of the HMI

2

ATSEL HMI User Manual

COM ort connection

For SP112, COM port includes RS232 and RS485. The pins set up as below, pin 7/8 for

RS485 and pin 2/3/5 for RS232.

As for 4 Points terminal, A is set for RS485+,B RS485-, R is when using built-in 120Ω

resistance then to short connection R and A, it will be convenient for long-distance

communication.

Remark

: the pluggable terminal COM1 and the B9 COM1 share the same RS485

series port, thus they can’t be used at the same time.

HMI B9 Male Pluggable terminals

picture

interface

PIN

Pin efinition

interface

PIN

Pin definition

remark

picture

SP112 COM2 1 —— COM1 1 R 120Ω resistance

2 RS232 RX 2 A RS485+(A)

3 RS232 TX 3 B RS485-(B)

4 —— 4 PE Shielded ground

5 GN remark:The pluggable terminal COM1 and the B9

COM1 share the same RS485 serial port.

COM1 6 ——

7 RS485+(A)

8 RS485-(B)

9 ——

3

ATSEL HMI User Manual

Communication protocol

Function brief

Our HMI support many kinds of communication protocols, such as PPI, MPI,

Modbus, smart S7, Mitsubishi, Panasonnic, Omron, etc.

Series communication:

COM1(RS485)

SiemensS7-200/smart CPU)

SiemensS7-300 CPU)

All Modbus evices.

COM2(RS232)

Mitsubishi(Fx1, Fx2N, Fx3U)

4

ATSEL HMI User Manual

Panasonnic(Fp)

Omron(CP)

MO BUS(MO BUS-RTU MO BUS ASCII)

Ethernet communication:

MO BUS TCP(Server / client)

S7 communication(S7-200 smart)

Remark

: O ur HMI has set the function buttons for smart running & stop .

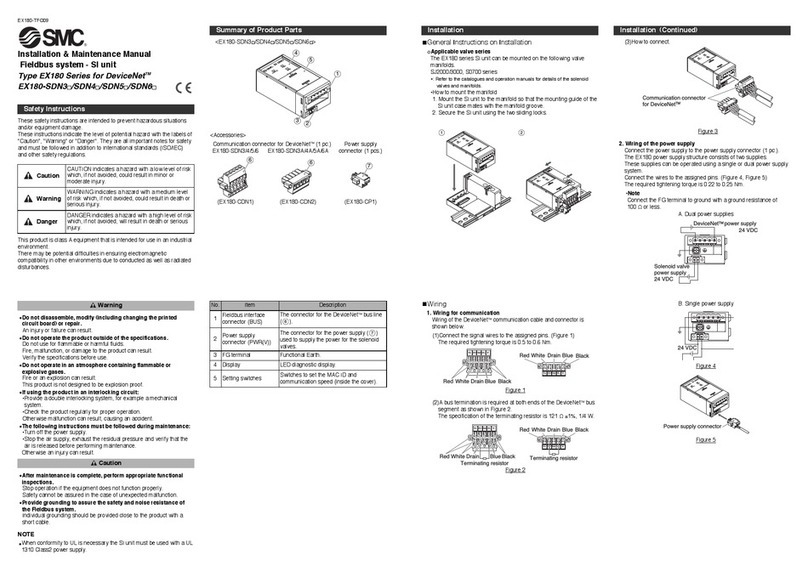

Connect with PLC

SP112 — Siemens

SP112 — Mitsubishi Fx1N/Fx2N ( B9) SP112 — Panasonic Fp

SP112 — Mitsubishi Fx2N/3U (8 pin circular hole) SP112— Omron CP

PPI/MPI

SP112

7 485+

8 485-

3 485+

8 485-

Fx1N/2NSP112

2 X

3 TX

5 GND

2 TXD

1 XD

3 GND

FpSP112

2 X

3 TX

5 GND

2 TXD

3 XD

1 GND

Fx3USP112

SG Shield

2 X

3 TX

SG Shield

4 TX-

1 X-

5 GND 2 X+

7 TX+

500Ω

500Ω

Cp

SP112

2 X

3 TX

5 GND

2 TXD

3 XD

9 GND

4 TS

5 CTS

5

ATSEL HMI User Manual

Address setting

Function introduction

1. RS485(Siemens S7-200)【PPI communication】same as S7 communication

Register

name

Address

format

Input range Remark

I dd.o 0.0~4095.7 bit: input mapping register

Q dd.o 0.0~4095.7 bit: output mapping register

M dd.o 0.0~4095.7 bit: bit memory

S dd.o 0.0~4095.7 bit: Sequence Control Relay

SM dddd.o 0.0~4095.7 word: special bit memory, SM0.0~SM4095.7

V ddddd.o 0.0~10239.7 bit: the bit of variable memory

IW dddd 0~4094 word: input mapping register, each word occupies two byte address

QW dddd 0~4094 word: output mapping register, each word occupies two byte address

MB dddd 0~4095 byte: bit register, each word occupies one byte address.

MW dddd 0~4094 word: bit register, each word occupies two bytes address.

M dddd 0~4092 double word: bit register, each word occupies four bytes address.

SB dddd 0~4095 byte: sequence control relay, each word occupies one byte address.

SW dddd 0~4094 word: sequence control relay, each word occupies two bytes address.

S dddd 0~4092 double word: sequence control relay, each word occupies four bytes address.

SMB dddd 0~4095 word: special bit memory, SMB0-SMB29 read only, each word occupies one byte address.

SMW dddd 0~4094 word: special bit memory, SMW0-SMW28 read only, each word occupies two bytes address.

SM dddd 0~4092 word: special bit memory, SM 0-SM 26 read only, each word occupies two bytes address.

VB ddddd 0~10239 Byte: variable memory

VW ddddd 0~10238 word: variable memory, each word occupies two bytes address.

V ddddd 0~10236 double word: variable memory, each word occupies four bytes address.

TV ddd 0~255 word: the current value of the timer.

CV ddd 0~255 word: the current value of the counter.

AIW dd 0~62 word: analog input, each word occupies two addresses.

AQW dd 0~62 word: analog output, each word occupies two addresses.

2. RS485-Siemens S7-300 (MPI communication)

Register Name Address format Input range remark

I dddd.o 0.0~1023.7 bit: input mapping register

Q dddd.o 0.0~1023.7 bit: output mapping register

M dddd.o 0.0~255.7 bit: bit memory

BX :dddd.o 1:0.0~99:32767.7 bit: the bit for the word in B block storage area. The block no. 0-99.

Each block word dddd with range 0-32767 and each word’s bit is 0-7.

IW dddd 0~1022 word: input mapping register, each word occupies two byte address

QW dddd 0~1022 word: output mapping register, each word occupies two byte address

6

ATSEL HMI User Manual

MW dddd 0~254 word: bit memory, each word occupies two bytes address.

M dddd 0~252 double word: bit memory, each double word occupies four bytes address.

BW :dddd 0:0~99:32766 word: B block storage area, block no. 0-99, each block word dddd with

range 0-32766. each word occupies two bytes address.

B :dddd 0:0~99:32764 double word: B block storage area, block no. 0-99, each block word

dddd with range 0-32764. each double word occupies four bytes address.

PIW dddd 0~1022 word: process image input area.

PQW dddd 0~1022 word: process image output area.

3. MO BUS

Register Name Address format Input range remark

0x ddddd 1~65536 bit: output coil.

1x ddddd 1~65536 bit: input coil, read only.

3x_bit ddddd. 1.0~65536.15 bit: the bit input register with 16 bit. Read only

4x_bit ddddd. 1.0~65536.15 bit: the bit output register with 16 bit.

3x ddddd 1~65536 word: the word with 16 bit what be input register. Read only.

4x ddddd 1~65536 word: the word with 16 bit what be output register.

3x_double ddddd 1~65535 ouble word: input register, high-low 16bits upside down with 3x double word,

read only

4x_double ddddd 1~65535 ouble word: output register, high-low 16bits upside down with 3x double word

Note:

d:decimal, the input range is 0~9.

o:octal, and the input range is 0~7.

:block number, the input range is 0-255.

:hexadecimal, and the input range is 0-15.

Word: it means that the register can only be used as a word.

ouble word: it indicates that the register must select 32 bits in the configuration

Bit: it means that the register can only be used as a bit.

Read only: it means that the register can only read but not be written in.

The Register Name supported by different device models may be different and

the range may vary. Please refer to the related technical documents of the

connected devices in detail.

*1 remark:in expanding mode, when input address, using “/” means connection and

using “#” means expanding mode. For example, 2/1#REGxxx means the second

connection No. 1 address REGxxx.

7

ATSEL HMI User Manual

4. Mitsubishi FX series

Fx2N

Register name bit/word Address format Max. address Mini. address

X bit OOO 377 0

Y bit OOO 377 0

M bit 3071 0

S bit 999 0

SM bit 8255 8000

T bit 255 0

C bit 255 0

word 7999 0

S word 8255 8000

TV word 255 0

CV word 199 0

32CV word 255 200

Fx3U

Register Name bit/word Address format Max. address Mini. address

X bit OOO 377 0

Y bit OOO 377 0

M bit 7679 0

S bit 4095 0

SM bit 8255 8000

T bit 255 0

C bit 255 0

word 7999 0

S word 8255 8000

TV word 255 0

CV word 199 0

32CV word 255 200

8

ATSEL HMI User Manual

5. Panasonic Fp series

Register Name bit/word Address format Max. address Mini. address

X bit OOO 377 0

Y bit OOO 377 0

R bit 7679 0

T bit 4095 0

C bit 8255 8000

L bit 255 0

T word 99999 0

L word 99999 0

FL word 99999 0

SV word 9999 0

EV word 9999 0

WX word 9999 0

WY word 9999 0

WR word 9999 0

WL word 9999 0

IX word 13 0

IY word 13 0

I word 32 0

6. Omron CP1H

Register Name bit/word Address format Max. address Mini. address

CIO_bit bit dddd. 6143.15 0.0

LR_bit bit ddd. 199.15 0.0

HR_bit bit dddd. 1535.15 0.0

AR_bit bit ddd. 959.15 448.0

M_bit bit ddddd. 32767.15 0.0

CIO word 6143 0

LR word 199 0

HR word 1535 0

AR word 959 448

9

ATSEL HMI User Manual

TC word 127 0

M word 32767 0

Fins

Register Name bit/word Address format Max. address Mini. address

CIO_bit bit dddd. 6143.15 0.0

WR_bit bit ddd. 199.15 0.0

HR_bit bit dddd. 1535.15 0.0

AR_bit bit ddd. 959.15 448.0

M_bit bit ddddd. 32767.15 0.0

CIO word 6143 0

WR word 199 0

HR word 1535 0

AR word 959 448

TC word 127 0

M word 32767 0

7. Address searching function

Click the search function of edition or shortcut key crtl+F then the address search

menu is popped up which can search the bit or word of the internal address and external

connection address, or the current scene and all the scenes, and supports the address

replacement at the same time.

Example

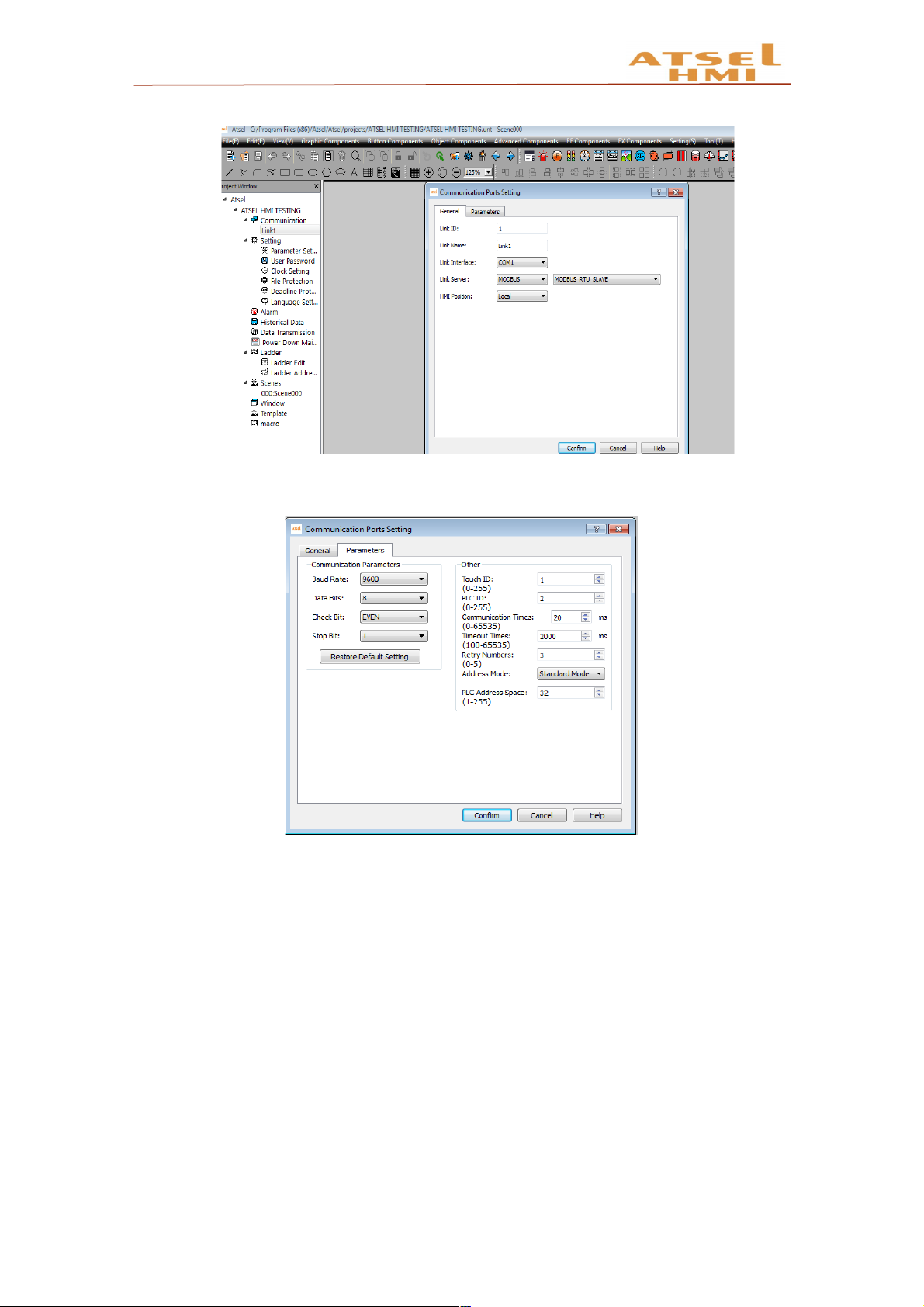

1. HMI’s communication parameters setting: set communication port--- mode

selection--PPI

10

ATSEL HMI User Manual

2. PPI communication parameters setting as showing in below chart.

3. Put a few bit buttons onto the screen and setting the written addresses of these bit

buttons Q0.0, Q0.1.

11

ATSEL HMI User Manual

4. The system block parameter setting interface of S7-200 program software is

shown as the following diagram

5. Connect the HMI to PLC through 485 communication cable and power them

together, then download the corresponding project to HMI. When click the components

on the screen, the corresponding PLC output points will be lighten.

12

ATSEL HMI User Manual

6. Address searching : Click the search function of edition or shortcut key ctrl+F to

pop up the search interface. You can search bit and word in the current scene or all of

the scenes. At the same time, you can replace the selected addresses, double-click the

corresponding addresses to pop-up corresponding control option of corresponding

scene.

13

ATSEL HMI User Manual

Animation design

Function introduction

Picture Dis lay function: To achieve the dynamic display of static pictures through

other ways, such as address control, time setting.

GIF icture: To set dynamic gif pictures. You can set the animation in the library, or

user-defined GIF files.

Bar Gra h: The value of the corresponding address is displayed by the bar graph.

Flow Block: Flow Block is used to simulate in animated pictures the liquid flow

status in pipeline. Whether a flow block is flowing is determined by the status of the

trigger, when the trigger is 1, the flow block is flowing, when the trigger is 0, the flow block

is static. The flowing speed is specified by user.

Dynamic Rectangle and Dynamic Circle: Their function is similar which changes

the position or size of graph according to the value of monitoring address, thus to show

real-time change of the monitor address on a dynamic basis.

14

ATSEL HMI User Manual

Example

1. Shining light (controlled by time)

Put a Picture isplay on scene, in the general page set the Total Status 2, Status

type to auto change with frequency being set 5 x 0.1s. In Label page, add an indicator

pattern from the Gallery to a status screen, in Visibility page set controlled by bit, When

the corresponding bit value to achieve the effective state the indicator pattern will be

displayed.

2. Liquid storage tank.

Put a image of Graphic Components, select a liquid storage tank from Gallery, and

drag into a Bar graph of Object components to cover the liquid area of tank.

3. Rotation motor

First put a picture and set as display when bit control value being 0, put a

similar GIF component and set as display when bit control value being 1. These two

components must be set the same size and same position(Use alignment function). Or

put a picture to be displayed when its bit control value being 0and put a Picture isplay,

set to automatically switch 0.1s, Then select two motor pictures with same shape but

different angle in the Gallery, set to display them when the bit control value being 1.

15

ATSEL HMI User Manual

4. Flow block

Add expand flow block at advanced components and set the corresponding address

for it.

5. Dynamic rectangle, Dynamic circle

In the Object components, add dynamic rectangle or dynamic circle and set the

corresponding address.

ynamic rectangle, for example, the data type is 16-bit integer, and the address is

ynamic circle, for example, the data type is 16-bit integer, and the address is set as

LW1. Then the value of LW1 is the X coordinate of the center of the circle. The value

of LW2 is the Y coordinate of the center of the circle, and the value of LW3 is the

radius of the circle.

Recipe Function

Function introduction

In manufacturing field, recipe describes proportion relation of different recipes, it's

the gather of some variables corresponding parameters setting value during production

process.

For example, a bread factory produces bread, there will be a basic ingredient recipe,

this recipe will list all ingredient lists that used for producing bread (for example

water,flour, sugar, egg, sesame oil etc.)Besides, also list all choosable ingredient lists (for

example fruits, kernel, chocolate chips etc.) These choosable ingredient can be added to

basic recipe to produce various breads. For example,sweet cake will use more

sugars,while low sugar cake will use less sugar. Here, we call the ingredient proportion

relation as recipe.

In ATSEL recipe editor function, one group recipe is one proportion relation. In the

table of editor, customers can match proportion relation among ingredients visually. Click

"Recipe Setting" of tool menu, then you can see recipe configuration dialog box, please

check as below:

1. Create a recipe group and name as bread.

2. Add the ingredients number of bread that is recipe length is 5.

3. Modify ingredients name and matched variable address.

4. Click save recipe and exit.

16

ATSEL HMI User Manual

Example

1. Project target

Realize the adjustment of different kinds of coffee ingredients, so that can complete the

coffee modulation by one key operation.

2. How to achievement

Click recipe control , add a new recipe group and set ingredients number of recipe,

each recipe contains different ingredients proportion, and then save the recipe.

Add the corresponding components and set corresponding variables to project scene,

and group index is modify Internal Register LW60802 can achieve switch-over of recipe

17

ATSEL HMI User Manual

group, If recipe index is Modify Internal Register LW60803 can achieve recipe switch-

over of recipe group.

Numerical input and display address of recipe ingredients is using the internal recipe

register address. Such as the above recipe, there are 8 ingredients, the system internal

address is RWI0-RWI7 from top to bottom if connects corresponding PLC address just

needs to input the corresponding variables, such as VW0, VW2, VW4 etc. Recipe’s

uploading, downloading or saving can be achieved in the function button.

ata transmission

Function introduction

ata Transmission is used for the data exchange between external device and HMI

or between device and device.

Click ata Transmission in Project Manager to pop up the data transmission list as

below.

1. Click "Add", you can add data transmission. At present, maximum number entries is

100. Triggered type is interval trigger and minimum time unit is 200ms, the data types

which can be transfered is bit, word, double word, and the maximum transmission data

size by each trigger is 100(bit, word, double word)

a)Interval: 1~100 (* 20ms )

b)Address type: bit, word, double word

c)Address length: 1~100, the data size of each transmission, unit is the type chosen at

"address type"

d)Source address/ estination address: the transmission direction is from source

address to destination address, this type of chosen register must be same as the address

set in "Address type".

2. After setting, click "confirm", add this set entry into the list.

18

ATSEL HMI User Manual

3.After adding, click close button exit, after downloading the configuration you can do

data exchange according to the set transmission type.

Alarm

Function Introduction

When triggering some events that should not be triggered during the operation of the

device, the system will make warning and record the time and content of the

corresponding events. The alarm is used to set the alarm information. Only the alarm is

configured, the alarm control and the dynamic alarm bar can be used normally.

1. Set the alarm information, firstly set the trigger condition

2. Record the real-time alarm: to show the real-time alarm data, alarm

scrollbar

3. System alarm setting: to set the display mode of overall pages alarm.

This manual suits for next models

2

Table of contents