Selkirk SUPERVENT 2100 Instructions for use

1

&&

&&

&

SELKIRK CORPORATION

5030 Corporate Exchange Blvd. SE,

Grand Rapids, MI 49512

1.800.992.VENT (8368)

SELKIRK CANADA CORPORATION

950 South Service Road, Second Floor

Stoney Creek, ON L8E 6A2

1.888.SELKIRK(735.5475)

SUPERVENT 2100 (JM)

SUPERPRO 2100 (ALT)

01/25/21 3010440

&A MAJOR CAUSE OF VENT

RELATED FIRES IS FAILURE TO

MAINTAIN REQUIRED

CLEARANCES (AIR SPACES) TO

COMBUSTIBLE MATERIALS.

IT IS OF THE UTMOST

IMPORTANCE THAT THIS

CHIMNEY SYSTEM BE

INSTALLED ONLY IN

ACCORDANCE WITH THESE

INSTRUCTIONS.

PLEASE READ ALL INSTRUCTIONS

BEFORE BEGINNING YOUR

INSTALLATION.

FAILURE TO INSTALL THIS SYSTEM IN

ACCORDANCE WITH THESE

INSTRUCTIONS WILL VOID THE

CONDITIONS OF CERTIFICATION AND THE

MANUFACTURER'S WARRANTY.

Installer: It is of the utmost importance that

these instructions are left with the

homeowner.

Homeowner: Keep these instructions and

maintenance guide in a safe place for

future reference.

INSTALLATION INSTRUCTIONS

&

MAINTENANCE GUIDE

(CANADA & UNITED STATES)

650°C FACTORY BUILT

INSULATED CHIMNEY

Tested to Standards

CAN/ULC-S629

&

UL 103 Type HT

LISTED

LISTED

2

3

4

4, 5

5

5

5, 6

6

6, 7, 8

8, 9

10, 11

11

11, 12, 13, 14

14

14, 15

15

15, 16

16

17, 18

18, 19

20, 21

19, 20

21

22

23

23

24

TABLE OF CONTENTS

CERTIFICATIONLABELS

TYPE OF APPLIANCES

PRE INSTALLATION GUIDELINES

TOOLS

FRAMING DETAILS

CEILING SUPPORT INSTALLATION

STOVE PIPE ADAPTOR

ATTIC INSULATION SHIELDS INSTALLATION

ELBOWINSTALLATION

WALL SUPPORT INSTALLATION (AWS)

INTERMEDIATE WALL SUPPORT (AIWS)

WALL SUPPORT INSTALLATION (WS)

WALL BAND

CATHEDRAL CEILING SUPPORT INSTALLATION

ROOF SUPPORT INSTALLATION

RAFTER RADIATION SHIELD

ROOF FLASHING INSTALLATION

ROOF GUY KIT INSTALLATION

MASONRY ADAPTER KIT

ADAPTER PLATE

MAINTENANCE AND CLEANING OF CHIMNEY

REPLACEMENT PARTS LIST

CHART 1 - OFFSET CHIMNEY INSTALLATION

CHART 2 - CHIMNEY HEIGHT ABOVE THE ROOF

CHART 3 - CONNECTOR PIPE CLEARANCES - CATHEDRAL SUPPORT

INSTALLATIONINFORMATION

3

ALT / JM

05 / 12 / 20

ALT / JM

05 / 12 / 20

Selkirk Canada Corporation

Stoney Creek, Ontario

Selkirk Canada Corporation

Stoney Creek, Ontario

CERTIFICATION LABELS

4

TYPES OF APPLIANCES

Exceptforinstallationinoneandtwofamily dwellings,afactory-built

chimney that extends through any zone above that on which the

connected appliance is located is to be provided with an enclosure

having a fire resistance rating equal or greater than that of the floor or

roofassembliesthroughwhich theypass. Thespacebetween theouter

wall of the chimney and the enclosure shall be at least 2" (50mm).

Situatethe chimneyinthe structureso thatit canbe installed without

cutting joists, sills, plates or load bearing partitions or members.

Connect only one appliance to a chimney.

If you have a basic knowledge of carpentry and how to use hand

tools, taking on the task of installing your new chimney system will

be easy. However, it is important that these installation instructions

are followed. If you choose to have your product professionally

installed, we recommend these products be installed by profession-

alswho arecertifiedin Canadaby WETT(WoodEnergy Technology

Transfer) or l'APC (l'Association des professionels du chauffage).

PRE-INSTALLATIONS

Your model JM/ALT chimney and connecting stove pipe diameter

should be sized in accordance with the appliance manufacturer’s

recommendations.

Planthe installationof yourappliance andchimneyin sucha waythat

both your chimney and your stove pipe run is as short and straight as

possible. By having too long and / or multiple bend installations you

can reduce system draft which can affect the operation, and / or

performance of your appliance and / or chimney system. The

chimney should be located within the building so as to avoid cutting

or altering load bearing members such as joists, rafters, studs, etc. If

you require to cut or alter an existing load bearing member, special

reframing methods are required which often include doubling of

adjacent members. If such a case arises, contact your local Building

Code Official regarding local regulations and proper installation

methods.

Be sure that ladders are in good condition and always rest on a level

firm surface.

There should be no draft regulators on solid fuel equipment and

smoke pipe connectors.

Be sure that electrically powered tools are properly grounded.

The ideal location for your chimney system is within the building

envelope. In cold climates, the use of external chimney may result in

operational problems such as poor draft, excessive condensation of

combustion products and rapid accumulation of creosote. Under

these circumstances, the installation of the chimney within the

building is strongly recommended.

If the chimney must be installed on an exterior wall it is recom-

mended that the chimney be enclosed below the roof line to protect

the chimney from cold outdoor temperatures, this may help reduce

condensation, creosote formation and enhance draft. Provide an

access door by the Tee Plug for chimney inspection and cleaning.

The exterior enclosure may be insulated, maintaining the required

minimum air space clearance of 2" (50mm) to any part of the

chimney. Consult local building codes for cold climate application.

YOUR CHIMNEY HAS BEEN TESTED, AND LISTED USING ALL

OF THE SUPPORTS, SHIELDS, ETC., DESCRIBED HEREIN.

DELETION OR MODIFICATION OF ANY OF THE REQUIRED

PARTS OR MATERIALS MAY SERIOUSLY IMPAIR THE

SAFETY OF YOUR INSTALLATION, AND VOID THE

CERITFICATION AND OR WARRANTY OF THIS CHIMNEY

Sections of the JM/ALT chimney which pass through accessible

areas of the building such as through closets, storage areas, occupied

spaces or any place where the surface of the chimney could be

contacted by persons or combustible materials must be enclosed in

a chase to avoid personal contact and damage to the chimney. The

chase may be fabricated using standard building materials. Drywall

mounted on 2” x 4” studs is typically used in this situation.

An Attic Insulation Shield must be installed where the chimney

passes into an attic space. It is designed to keep insulation materials

or debris from coming into contact with the chimney. It must

accommodate the amount of insulation as required by the National

Building Code.

Where height restrictions will not permit the use of the Attic Insula-

tion Shield, it is permissible to construct an enclosure with a 2” air

space clearance to the outer pipe all the way to the underside of the

roof deck. In this application you need to install an Attic Insulation

Shield which will act as a Joist Shield on the ceiling side and a Rafter

RadiationShield attheroof level. Afinishingplate canbeused below

the Attic Insulation Shield.

At the level where the chimney penetrates the air/vapour barrier,

special attention is required. Seal the vapour barrier to the Firestop

Spacer or Ceiling Support assembly or Wall Thimble using an

appropriate caulking compound as per the requirement of local

authorities.

Beforebeginningthe installationensurethatyou obtainanynecessary

building permits, and that your installation will conform with all

federal and municipal building code requirements.

WARNING: DO NOT PLACE ANY INSULATING MATERIALS OR RUN

ANY ELECTRICAL WIRING WITHIN THE REQUIRED AIR

CLEARANCE SPACE SURROUNDING THE CHIMNEY.

MAINTAIN A 2" MINIMUM AIR SPACE CLEARANCE

BETWEEN INSULATED CHIMNEY SECTIONS AND COMBUSTIBLE

MATERIALS OR AS ESTABLISHED BY SUPPORT ASSEMBLY.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION

INSPECTION IN YOUR AREA.

Model SuperVent 2100 (JM)/SuperPro 2100 (ALT) chimney has

been tested per CAN/ULC-S629 as an all fuel chimney. As such it

is code approved for connection to solid, liquid or gas fueled

residential type appliances and building heating appliances in which

themaximum continuousflue gastemperaturesdo notexceed 650°C

(1200°F). It has also been tested and approved to withstand

temperatures of up to 2100° F for three thrirty minutes intervals.

The installation should be in accordance with the manufacturer's

installation instructions. Consult the following codes: Installation

Code CAN/CSA-B365 (Solid-Fuel-Burning Appliances and

Equipment),theNational BuildingCodeofCanada and/orProvincial

Building Code, etc.

May also be used with specific factory-built fireplaces listed to

UL 127 and CAN/ULC-S610 when specified in the fireplace

manufacturer's installation instructions.

5

2"

(50mm)

Min

2"(50mm)

Min

2"(50mm)Min

2"(50mm)

Min

14 x 14

355 x 355

143/8x 143/8

365 x 365

143/8x 143/8

365 x 365

143/8x 143/8

365 x 365

143/8x 143/8

365 x 365

6"

(150mm)

7"

(175mm)

8"

(200mm)

15 x 15

380 x 380

16 x 16

143/8x 143/8

365 x 365

365 x 365

143/8x 143/8

405 x 405

mm

mm

mm

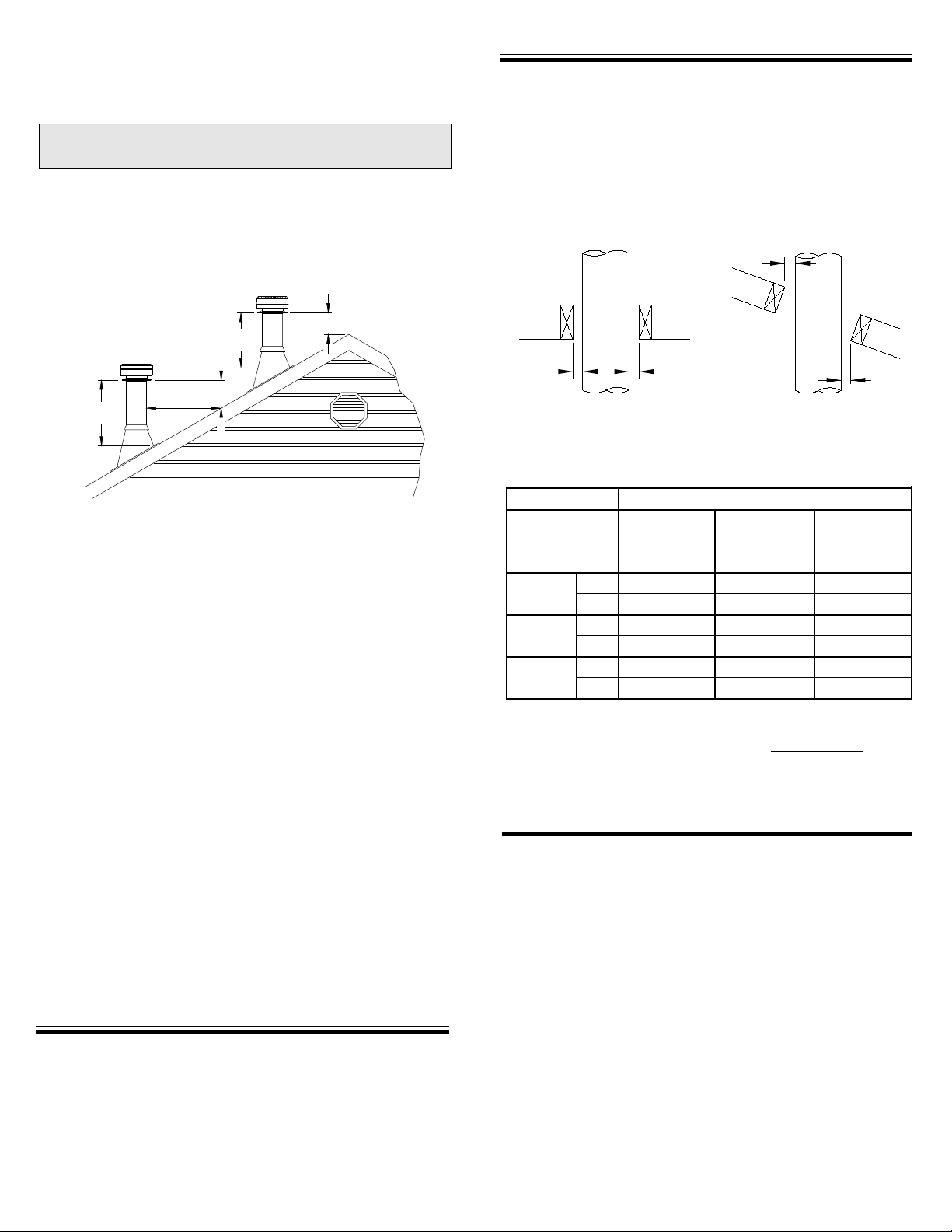

Authorities require that the chimney extend not less than 3 ft

(900 mm) above the highest point where it passes through the

roof of a building and not less than 2 ft (600 mm) above any

portion of the building within 10 ft (3m). See Figure 1and Chart

2 on page 20 of these instructions.

3ft.(900mm)

min.

3ft.(900mm)

min.

2 ft.

(600mm)

2 ft.

(600mm)

10 ft.

(3m)

The use of Locking Bands at all chimney joints is recommended for

added safety and stability when exposed to high winds and as a

precaution against accidental unlocking of lengths when the system

is inspected and swept.

Do not install the chimney directly at the outlet of the appliance.

Interconnectingstovepipe is requiredunless the applianceis specifi-

cally approved for that type of installation.

Use only with an appliance listed by a recognized testing authority

such as CSA, Underwriters Laboratories Inc., Underwriters Labora-

tories of Canada or Intertek Testing Services/Warnock Hersey.

Do not mix and match with other manufacturer's products. Use only

Selkirk's Models JM/ALT listed components.

TOOLS

Your model JM/ALT chimney system is designed for installation

using standard building materials and procedures. The following

tools/equipment may be required as well as some others depending

on the location and structure in which the chimney is to be installed:

FIGURE 1

-Screwdrivers and pliers

-Plumb line and level

-Square

-Keyhole saw or power jig saw

-Caulking gun

-Safety gloves

-Safety goggles

-Hammer and nails

-Tin snips

-Tape measure

WEAR SAFETY GLOVES WHEN HANDLING

SHEET METAL PARTS WITH SHARP EDGES

CHIMNEY SIZING:

In order to achieve safe, optimum performance of the appliance,

service life of the chimney, the chimney must be sized correctly for

the connected appliance. In general, the chimney flue should be the

same size as the appliance flue outlet. The installation should be

done in accordance with the applicable installation codes (eg. CAN/

CSAB149, CAN/CSAB139, NFPA54and NFPA31) andappliance

manufacturer instructions. Plan the installation of your appliance

andchimney in sucha waythat both yourchimney andflue pipe runs

are as short and straight as possible. By having too long and/or

multiple bend installations you can reduce the system draft which

can affect the operation, and/or performance of your appliance and/

or chimney system.

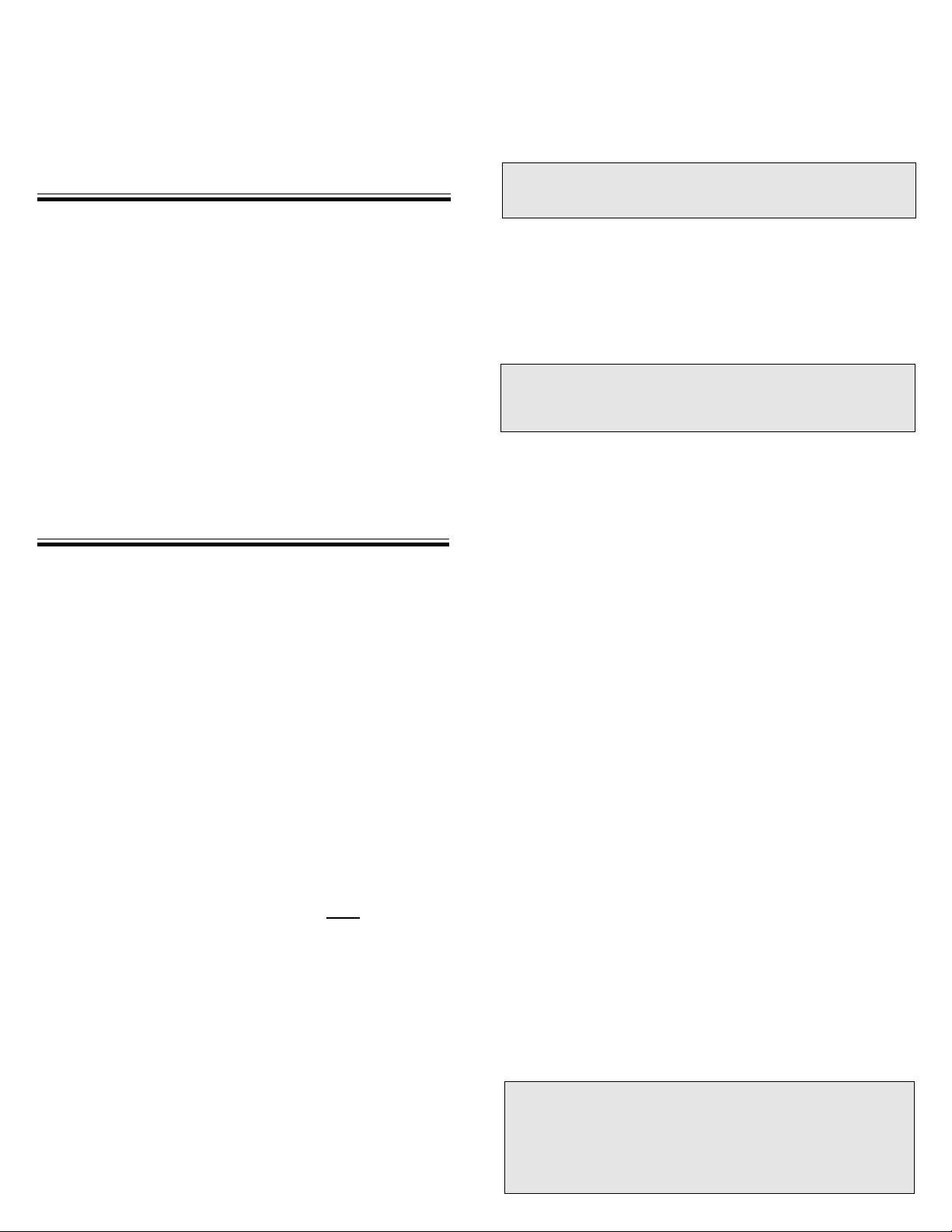

Plan your installation carefully. If possible, position the stove so

that the flue outlet is centered between joists or rafters. Drop a plumb

line to the center of the flue outlet and mark this center point on the

ceiling. Layoutandframeinall openingsensuringthespecified 2"(50

mm) clearance to combustibles is maintained. Refer to Table 1 and

applicable Tables for framing dimensions and mark the appropriate

cutting lines around the center point. All openings should be square,

plumb and in perfect alignment with each other (see figure 2).

For sloping roofs (cathedral/vaulted ceiling), ensure that the framing

dimension is measured in the horizontal plane (see figure 3).

FRAMING DETAILS

* The clearance to combustibles obtained with a correctly installed

Decorator Ceiling Support or Wall Thimble in the framed opening

specified has been tested. The 2" clearance does not apply at these

locations. When cutting the inside "finished" surface of your wall or

ceiling cut a "round hole" to the framing dimension in Table 1.

To complete a proper Decorator Ceiling Support installation, the

following parts may be required:

-Decorator Ceiling Support (DCS): Required when supporting a

chimney through a flat level ceiling.

- Stove Pipe Adaptor (ASE): Transition from the chimney to flue pipe.

- Attic Insulation Shield (AIS): Required where a chimney passes

from a lower living space into an upper living or an attic space.

- Universal Shielding Insulation (JUSI): To reduce cold air infiltra-

tion into the dwelling when installed in conjunction with the Attic

Insulation Shield.

- Rafter Radiation Shield (RRS): Required when the chimney is

enclosed immediately below the roof line.

-Roof Flashing Assembly(IncludingStorm Collar): Requiredwhen

the chimney penetrates a roof.

INSTALLATION PROCEDURES

FIGURE 3

Typical Roof

Joist Framing

FIGURE 2

Typical Joist

Framing

*Decorator

Ceiling

Support

*Wall

(Support)

Thimble

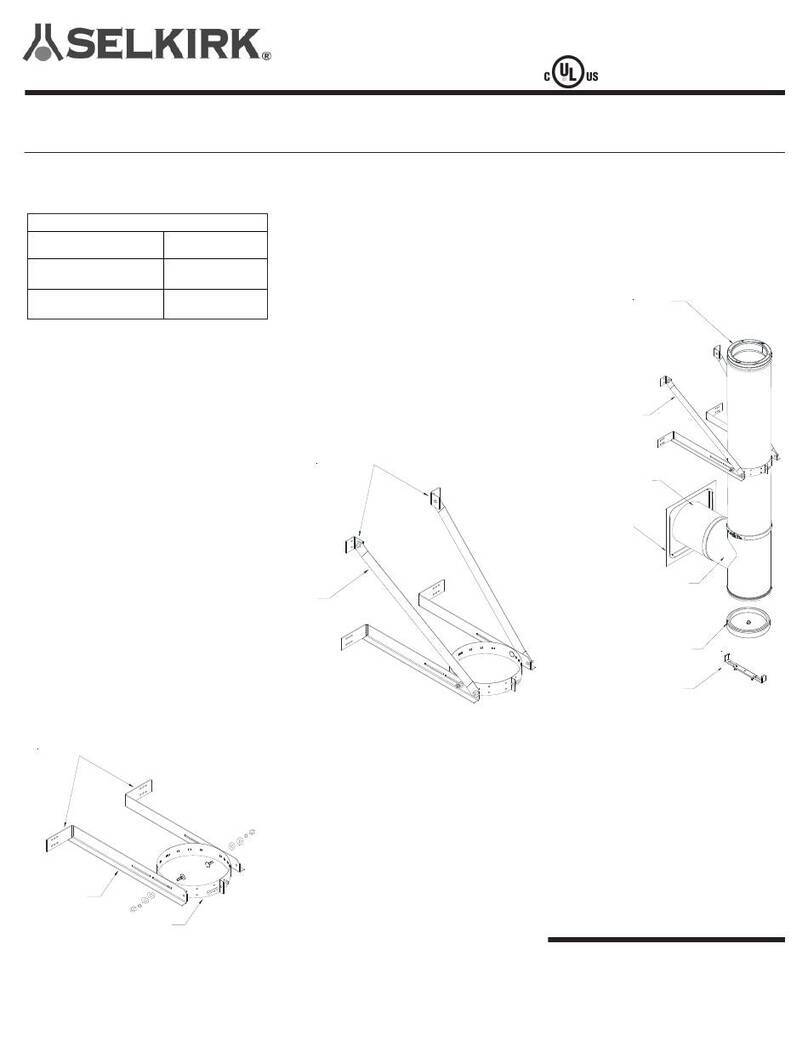

Framing Dimensions Table

All Other

Framing

Chimney Flue

Diameter

TABLE 1

DECORATOR CEILING SUPPORT (DCS)

in.

in.

in.

Other manuals for SUPERVENT 2100

1

This manual suits for next models

1

Table of contents

Languages:

Other Selkirk Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual