Selkirk ULTRA-TEMP Instructions for use

Page 1

ULTRA-TEMPTM

510000 - 0214

FACTORY-BUILT

INSULATED CHIMNEY

INSTALLATION

INSTRUCTIONS

&

MAINTENANCE GUIDE

(Canada Only)

A MAJOR CAUSE OF CHIMNEY-RELATED FIRES IS

FAILURE TO MAINTAIN REQUIRED CLEARANCES

(AIR SPACES) TO COMBUSTIBLE MATERIALS

MODEL

IT IS OF THE UTMOST IMPORTANCE THAT THIS

CHIMNEY BE INSTALLED ONLY IN ACCORDANCE

WITH THESE INSTRUCTIONS

PLEASE READ ALL INSTRUCTIONS BEFORE BEGINNING YOUR INSTALLATION. FAILURE TO INSTALL

THIS SYSTEM IN ACCORDANCE WITH THESE INSTRUCTIONS WILL VOID THE CONDITIONS OF

CERTIFICATION AND THE MANUFACTURERS WARRANTY. KEEP THESE INSTRUCTIONS IN A SAFE PLACE

FOR FUTURE REFERENCE

TESTED TO

CAN/ULC-S604

LISTED

(5 to 8 inches dia.)

Page 2

3

3

3

3

3, 4

4

4, 5

5

5

6

6, 7, 8, 9

9

9, 10

10

10, 11

11, 12

12

12, 13

13

13

14

15

15

16

FUELSANDAPPLIANCES.......................................................................................................................

RULESFORSAFETYDURINGINSTALLATION.....................................................................................

GENERALINSTALLATIONRULES..........................................................................................................

TOOLS..........................................................................................................................................................

CHIMNEYSIZING.....................................................................................................................................

FRAMINGDETAILS....................................................................................................................................

CEILINGSUPPORT.................................................................................................................................

ATTICINSULATIONSHIELD....................................................................................................................

FIRESTOPJOISTSHIELD.........................................................................................................................

ELBOWINSTALLATION.............................................................................................................................

ADJUSTABLEWALLSUPPORT................................................................................................

WALLBAND................................................................................................................................................

CATHEDRALCEILINGSUPPORT....................................................................................................

ROOFSUPPORT.......................................................................................................................................

ROOFFLASHING................................................................................................................................

UNIVERSALROOFBRACEKIT.........................................................................................................

ROUNDTOPANDSPARKARRESTER..................................................................................................

STOVEPIPEADAPTER......................................................................................................................

ANCHORPLATE........................................................................................................................................

CHIMNEYOPERATIONANDMAINTENANCE.......................................................................................

OFFSETCHART........................................................................................................................................

CHIMNEYCHARTABOVEROOF..........................................................................................................

REPLACEMENTPARTSLIST................................................................................................................

PRODUCTREGISTRATION/RECORD...............................................................................................

TABLE OF CONTENTS

Page 3

The chimney should be located within the building so as to avoid

cutting or altering load bearing members such as joists, rafters,

studs, etc. If you require to cut or alter an existing load bearing

member, special reframing methods are required which often

includedoublingofadjacentmembers. If suchacasearises,contact

your local Building Code Official regarding local regulations and

proper installation methods.

Model UT chimney requires 2” (50mm) clearance to

combustible material or as established by support

assembly.

Attach flue pipe parts securely to each other, and to the appliance

using three sheet metal screws per joint.

•Be sure that ladders are in good condition and always

rest on a level firm surface.

•Be very careful around electrical wiring and be sure it is

secured at least 2 inches away from any part of the chimney. If

wiring must be relocated, hire a professional electrician.

Do not place any type of insulating materials or run any

electrical wiring within the required clearance air

space surrounding the chimney.

FUELS & APPLIANCES:

Model UT chimney has been designed for connection to liquid

fuel or gas fired residential type appliances and building heating

appliances, in which normally producing flue gases of 540° C

(1000° F) or less. Model UT may also be installed with specific

factory built fireplaces where specified in the manufacturers

installation instructions and identified on the fireplace rating label.

Model UT chimney is listed for use with Selkirk fireplace models.

Before commencing the installation ensure that you obtain any

necessary building permits, and that your installation will conform

with all federal and municipal building codes requirements

affecting the fuel-burning appliance and its chimney. This

chimney is intended for use in accordance with:

- National and Provincial Building Code of Canada,

- CAN/CSA B-149.1-00 Installation Code for Gas Equipment,

-CAN/CSAB-139.00 InstallationCode for OilBurning Equipment;

- Appliance and venting manufacturers’s Installation Instructions.

TOOLS:

Your UT chimney system is designed for installation using

standard building materials and procedures. The following tools/

equipment may be required as well as some others depending

on the location and structure in which the chimney is to be

installed:

Sections of the UT chimney which pass through accessible areas

of the building such as closets, storage areas, occupied spaces

or anyplace where the surface of the chimney could be contacted

by persons or combustible materials must be enclosed in a

chase to avoid personal contact and damage to the chimney.

Enclosures may be fabricated using standard building materials

such as 2” x 4” wood framing with gypsum drywall or plywood

walls and must have a fire rating equal to or greater than the

floors or ceilings through which the chimney passes.

-Safety gloves

-Safety goggles

-Hammer and nails

-Tin snips

-Tape measure

-Scewdrivers and pliers

-Plumb line and level

-Square

-Keyhole say or power jig saw

-Caulking gun and caulking

•Be sure that electrically powered tools are properly

grounded.

If you are knowledgeable in carpentry and mechanically inclined,

you can take on the task of installing your new venting system. It

is important that all pertaining installation instructions and local

codes are followed carefully. If you have any doubt concerning

your ability or knowledge of the appliance being connected to

your chimney system, arrange for a professional installation.

Certified technicians having installed systems many times

before have the knowledge and experience to perform your

installation in a professional and timely manner.

YOUR CHIMNEY HAS BEEN TESTED, AND LISTED

USING ALL OF THE SUPPORTS, SHIELDS, ETC.,

DESCRIBED HEREIN. DELETION OR MODIFICATION

OR ANY OF THE REQUIRED PARTS OR MATERIALS

MAY SERIOUSLY IMPAIR THE SAFETY OF YOUR

INSTALLATION, AND VOID THE CERTIFICATION AND

OR WARRANTY OF THIS CHIMNEY

WEAR SAFETY GLOVES WHEN HANDLING

SHEET METAL PARTS WITH SHARP EDGES

MAINTAIN A 2” (50MM) MINIMUM AIR SPACE CLEARANCE

BETWEEN THE INSULATED CHIMNEY SECTIONS AND

COMBUSTIBLE MATERIALS

The chimney pipe and fittings must be assembled with locking

bands or stainless sheet metal screws, maximum length of 1/2”

(12.70mm) on all interior joints. Locking bands must be used

on all exterior joints.

Supportalloffsets with an offsetsupportand adequate strapping.

RULES FOR SAFETY DURING INSTALLATION:

CHIMNEY SIZING:

The correct chimney size is essential to the efficient operation of

the chimney and the appliance which it serves. Consult the

appliance manufacturer’s installation instructions or your dealer

for proper chimney diameter size. Plan the installation of your

appliance and chimney in such a way that both your chimney

and flue pipe runs are as short and straight as possible. By

having too long and/or multiple bend installations you can reduce

system draft which can affect the operation, and/or performance

of your appliance and/or chimney system.

NOTE: The ideal location for your chimney system is within the

building envelope. In cold climates, the use of external chimneys

may result in operational problems such as poor draft, excessive

condensation of combustion products and rapid accumulation

of creosote. Under these circumstances, the installation of the

chimney within the building is strongly recommended.

If the chimney must be installed on an exterior wall it is recom-

mended that the chimney be enclosed below the roof line to

protect the chimney from cold outdoor temperatures, this may

helpreducecondensation, creosote formationand enhance draft.

Provide an access door by the Tee Cap for chimney inspection

and cleaning. The exterior enclosures may be insulated, main-

taining the required minimum air space clearance of 2” (50mm)

to any part of the chimney. Consult local building codes for cold

climate applications.

GENERAL INSTALLATION RULES:

Page 4

2"

(50mm)

Min

2"

(50mm)

Min

2" (50mm)

Min

2"

(50mm)

Min

1-1/2”

4-1/8”

3”

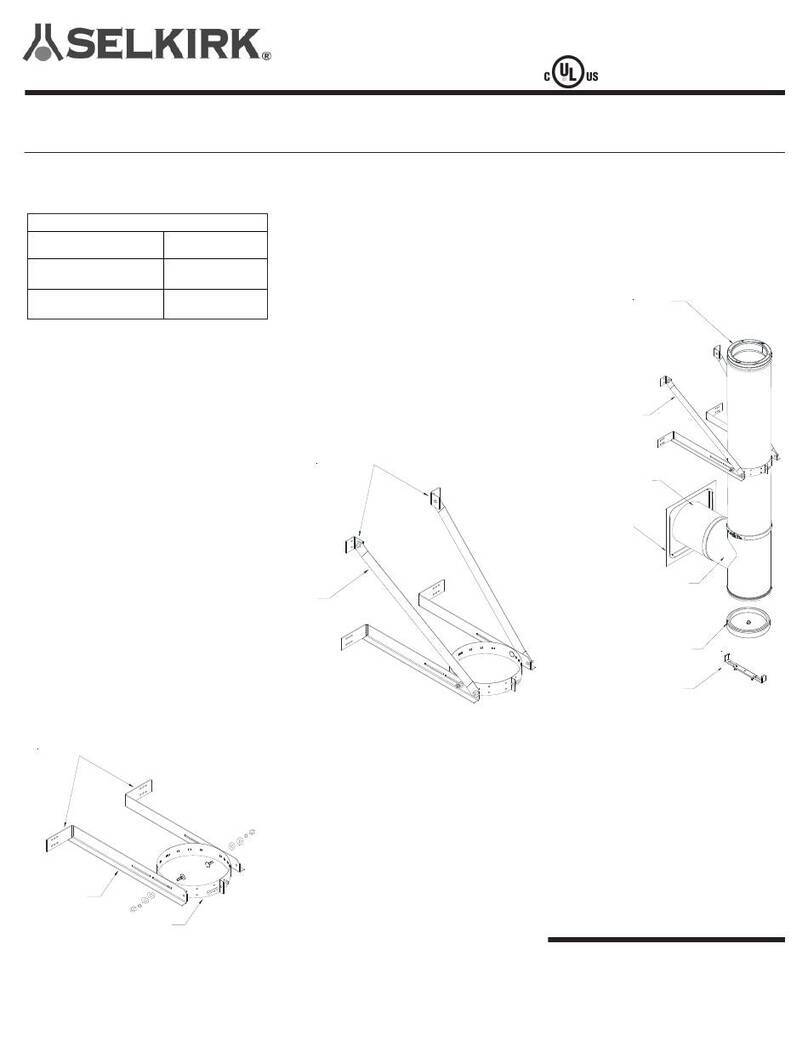

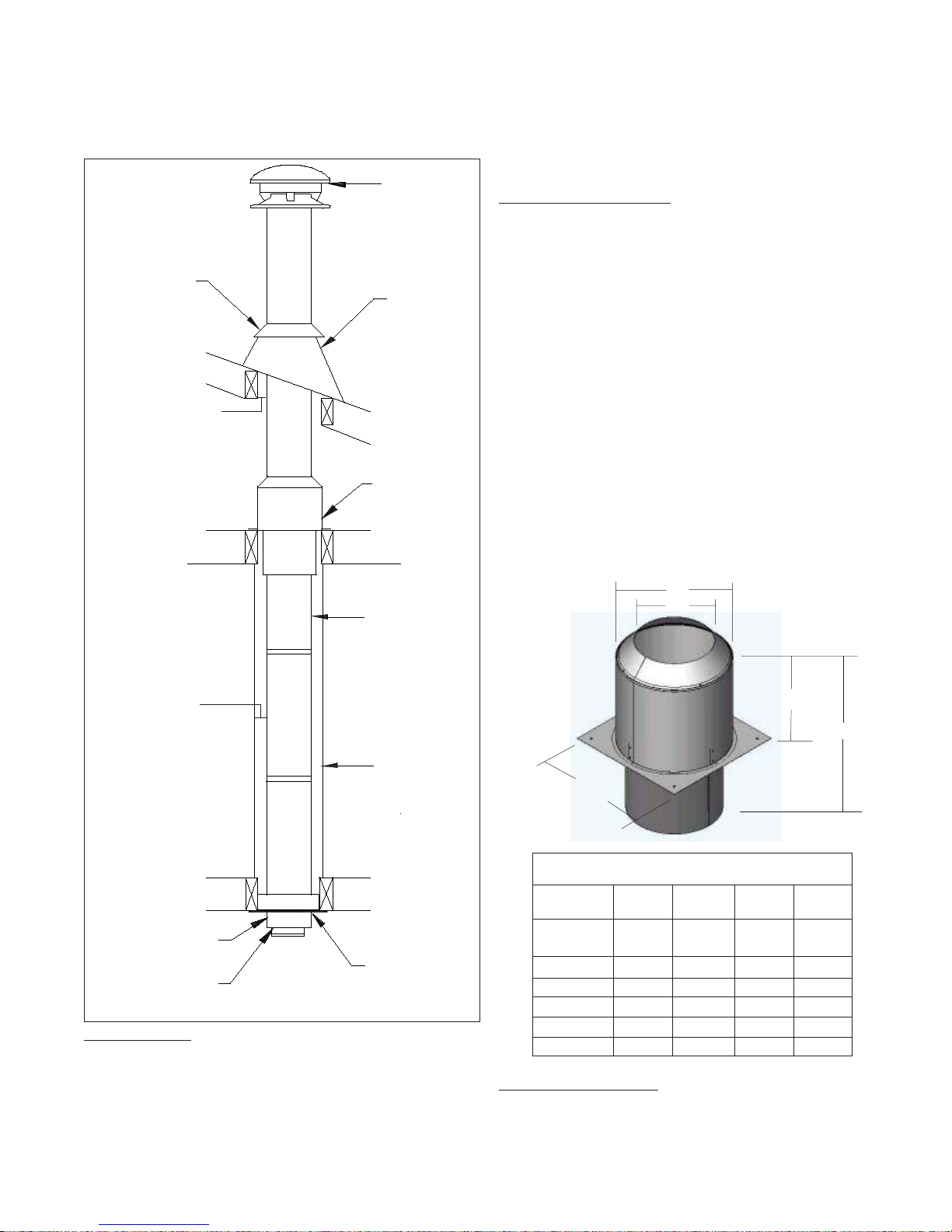

INSTALLATION PROCEDURES:

CEILING SUPPORT

To complete a proper Ceiling Support installation, the following

parts may be required.

- Ceiling Support: For joist supported chimney system.

- Attic Insulation Shield: Where a chimney enters an open attic

space.

- Firestop Joist Shield: Installed where the chimney passes from

one living space to another living space or as specified in the

listed factory-built fireplace installation instructions.

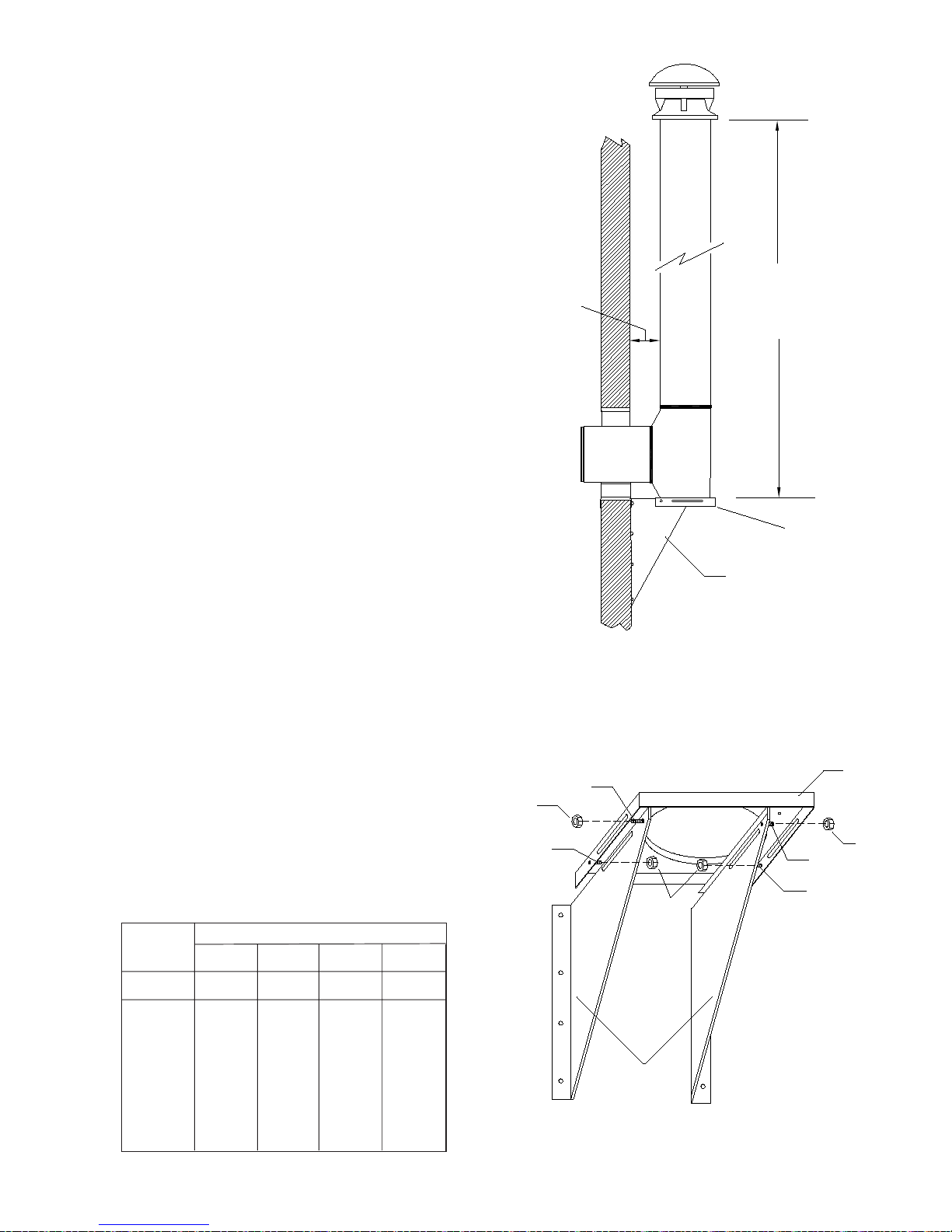

Authority require that the chimney extend not less than 3ft (900

mm ) above the highest point where it passes through the roof of

a building and not less than 2ft (600 mm) higher than any portion

ofa buildingwithin 10ft (3m) horizontally. See Figure 1 and Chart

2 in the back of these instructions.

FRAMING DETAILS:

Plan your installation carefully. If possible, position the appliance

so that the flue outlet is centered between joists, rafters or studs.

Drop a plumb line to the center of the flue outlet and mark this

center point on the ceiling. Lay out and frame all openings

ensuring the specified 2” clearance to combustibles is main-

tained. All openings should be square, plumb and in perfect

alignment with each other (see Figure 2). For angled roofs, en-

sure that the framing dimensions are measured on the horizon-

tal plane (see Figure 3).

FRAMING DIMENSIONS FOR MODEL UT

TO MAINTAIN 2 INCH AIR SPACE CLEARANCE

MODEL UT

Chimney Inside

Diameter:

All other framing*

CeilingSupport*

*All framing dimensions may be up to 1/2” more, but not less than the above values.

Table 1

The following instructions will assist you in the installation of your

chimneywitha CeilingSupport. Thissupportwill holdup to15.25m

(50’) of chimney sections, all of which must be installed above the

support.

1. Frame a level square opening (all four sides). Inside dimen-

sions should conform to Table 1.

2. With the Lower Bucket removed, place the upper bucket

assembly into the framed opening from below.

3. Ensure that the support plate is level and flush and drive one nail,

1-1/2” common or spiral, part way into each of the four (4) nailing

areas of the support. You may substitute nails with #8x1-1/2” wood

screws.

4. Finish nailing through all prepunched holes (12 nails total) and

fasten the finishing (support) plate to the ceiling (see Figure 4).

5. Replace the Bucket Section from above. Connect the proper

sized Stove Pipe Adapter to the first chimney length. Lower this

chimney section down into the bucket section, with the male end

pointing upwards as indicated by the arrow on the chimney label.

6. Additional chimney lengths above the support are simply

stacked on, twist locked with a 1/8 clockwise turn and secured

with a locking band at each chimney joint. A locking band is

supplied with every chimney length and must be used on all

chimney joints, interior or exterior. Stainless steel sheet metal

screws (maximum length of 12.70mm (1/2”) may be substituted

on interior joints.

7. Finish the chimney to its required height.

8. If an offset is installed in the system, an Offset Support must be

installed as shown in Figure 7.

9. If the chimney extends 5 feet (1.5 m ) or more above the roof,

additional lateral support is required, such as the Universal Roof

Brace Kit.

3 ft.

(900mm)

min.

2 ft.

(600mm)

10 ft.

(3m)

2ft.

(600mm)

3 ft. (900mm)

min.

FIGURE 1 - Roof Flashing: Required when the chimney penetrates a roof.

- 15° , 30° or 45° Elbow Kits (2 per box with locking bands and

elbow support).

- Suitable lengths of chimney: Available in 6”, 12”, 18”, 24” and

36” lengths. A 48” length is available in 6” and 8” only.

- Round Top

- Stove Pipe Adapter

Chimney Length

Lower Bucket

Upper Bucket

The Ceiling Support is intended for installation below a finished

or unfinished ceiling.

Figure 4

CathedralSupport

Support Plate

Stove Pipe Adapter

Figure 3

Typical Roof Joist

Framing

Figure 2

Typical Joist Framing

5” 6” 7” 8”

10 1/4”

12 1/4”

11”

11 1/4”

N/A

13”

12 1/4”

N/A

14”

10 1/4”

12 1/4”

12”

Page 5

280 x 280 305x 305 330x 330 356 x 356

A

B

C

D

“A” DIM.

“B” DIM.

“C” DIM.

“D” DIM.

“E” DIM.

E

FIGURE 5

CeilingSupport

- Together with a fully framed opening (all four sides) it controls

vertical and horizontal spread of any fire external to the chimney.

- It stabilizes the chimney in the framed opening and defines and

maintains the required two inch AIR SPACE clearance to combustibles.

- It prevents heat losses from the dwelling by blocking vertical air

circulation in the space around the chimney.

- It helps provide stability for chimney extending above the roof.

ATTIC INSULATION SHIELD

The function of the Attic Insulation Shield (or a complete enclo-

sure) is to keep insulation from coming into contact with the chim-

ney. Where height restrictions will not permit the use of the Attic

Insulation Shield, an enclosure from the attic joist to the roof joist

will be sufficient. All chimney enclosures must maintain the re-

quired minimum air space clearance of 50mm (2”) to the chim-

ney (see Figure 5).

For proper installation, the attic opening should be fully framed

at 2 inches clearance to the chimney pipe with framing material

of the same dimension as the ceiling joists as per Table 2. The

tabs on the base plate of the AIS are inserted in the framed

opening around the chimney. Nail the AIS base to the framing

dimensions with at least 2 nails per side using 2d (1”) spiral

nails or 1” x #8 wood screws.

The Attic Insulation Shield allows for a depth of insulation of 10

inches plus the depth of the ceiling joists. If insulation is blown

in and adheres to the chimney pipe, it should be brushed off to

eliminate any possible contact of this material with the chimney

surface.

FIRESTOP JOIST SHIELD

A Firestop Joist Shield must be installed where the chimney

passes from one living space to another living space. It is

installed from either above or below the joist. Nail the Firestop

Joist Shield using 1-1/2” common or spiral nails, into the framed

opening outlined in Table 1.

Bucket Section

Floor, CeilingJoist

(Framed all 4 sides)

LIVINGSPACE

*Follow Appliance instructions for proper clearance. If clearance is not given, use

460mm(18”) min.

*Stove Pipe Adapter

Framed

Enclosure

2” (50mm)

clearance from

chimney to

combustible wall

Chimney Lengths

50mm (2”) minimum air

space clearance to

combustible material

ATTICSPACE Attic Insulation

Shield

50mm (2”) minimum air

space cleance to

combustible material

Round Top

CeilingJoist

(Framed all 4 sides)

Stom Collar

FIRESTOPPING:

Firestopping is required at every joist level. Wherever a chimney

passes through a ceiling or floor, through a wall, or into an enclo-

sure, it must be firestopped. No firestopping is required in con-

junction with a Ceiling Support installed as shown in Figure 5,

the Ceiling Support provides the firestopping. Firestopping per-

forms the following essential functions for both the dwelling and

the chimney.

FIGURE 6

Roof Flashing

Warning: The chimney lengths and its fittings must be assembled

with metal-to-metal joints as furnished. Do not use tape or any

sealing compound (such as tar, mastic, putty or silicone) at the

outer joints. Sealers in the joints may cause the insulation to

accumulate moisture and may cause corrosion or freezing failures.

FRAMING DIMENSION CHART

FOR ATTIC INSULATION SHIELD

DIAMETER OF

CHIMNEY

FRAMED

OPENING

Table 2

5”

11 x 11

6”

12 x 12

7”

13 x 13

8”

14 x 14

7 -1/4”

11”

10“

13“

18 -1/2”

8 -1/4”

12”

10“

14“

18 -1/2”

9 -1/4”

13”

10“

15“

18 -1/2”

10 -1/4”

14”

10“

16“

18 -1/2”

Page 6

X X X X

X X X X

X X X

127mm 152mm 178mm 203mm

183

(7-3/16”) 210

(8-3/16”) 233

(9-3/16”) 259

(10-3/16”)

280 x 280

11” x 11” 305 x 305

12” x 12” 330 x 330

13” x 13” 356 x 356

14” x 14”

Table 3

Table 4

Chimney Size 5” 6” 7” 8”

Minimum Framed Opening for

Combustible Wall

Minimum Round Hole

Diam. For Non-Combustible Wall

The female end of the elbows are not lanced in order to ensure

proper alignment of the chimney system can be maintained.

Install and position the insulated elbow on the vertical chimney

length in the required direction. Fasten the elbow to the chimney

length with the supplied locking band.

Place the required offset chimney length(s) (see Offset Chart for

appropriate length(s)) on the elbow. Turn it clockwise to lock it in

place and install the supplied locking band.

Install the remaining offset elbow to return the chimney back to

the vertical position. Again secure in place with the supplied

locking band. *Locking bands and/or stainless steel sheet metal

screws can be utilised with a maximum length of 12.70mm (1/2”)

only on all chimney joints forming an offset.

During installation provide supplementary support for the offset

section to avoid undue stress on connected elbows.

Install an Elbow Support on the vertical length just above the

highest elbow. Securely clamp the support band to the chimney

length just above the locking band at the joint. Attach the support

straps to the support band assembly and nail them to the framing

using 1-1/2” nails or #8 x 1-1/2” wood screws (2 per straps) as

per Figure 7.

Never install an elbow in a joist area. Chimney sections must

pass vertically through framed joist areas.

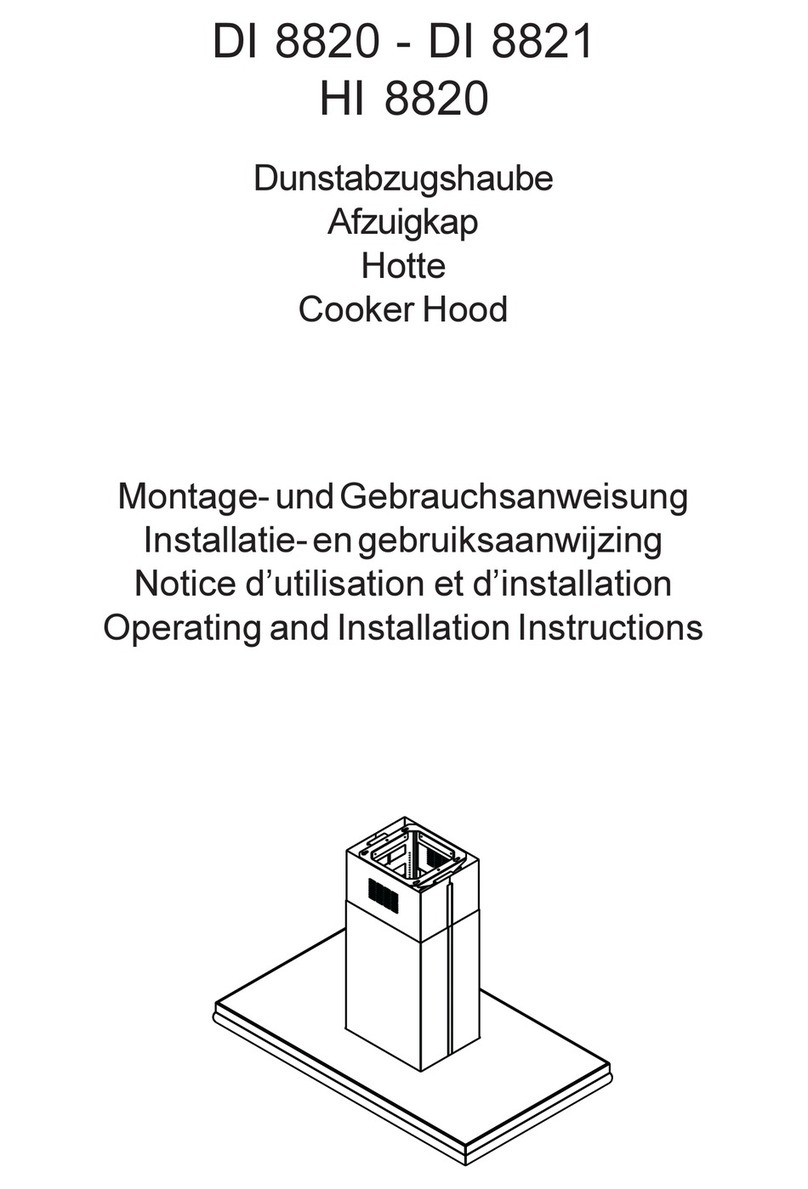

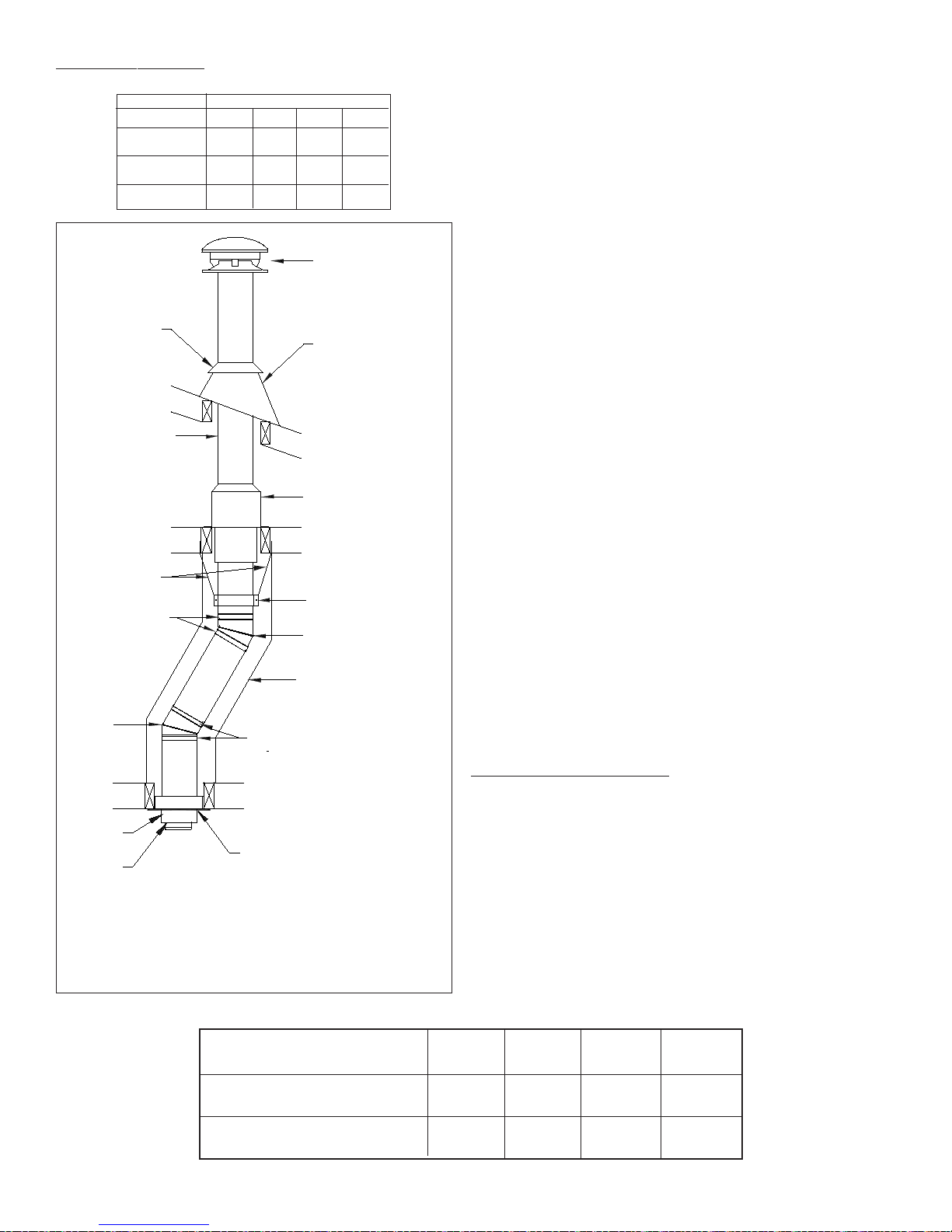

ELBOW INSTALLATION

Elbow Kits (2 elbows, 1 offset support and 4 locking bands).

FIGURE 7

Attic Insulation Shield

Storm Collar

Elbow Locking Bands

Intermediate/Elbow

Support Straps

Locking Bands Elbow

CeilingSupport

Roof Flashing

If the offset length is more than 1.2m (4’), an intermediate support

must be employed at 1.2m (4’) intervals. Maximum offset length

4.8 m (16’), the intermediate support must be used in conjunction

with an offset support.

Round Top

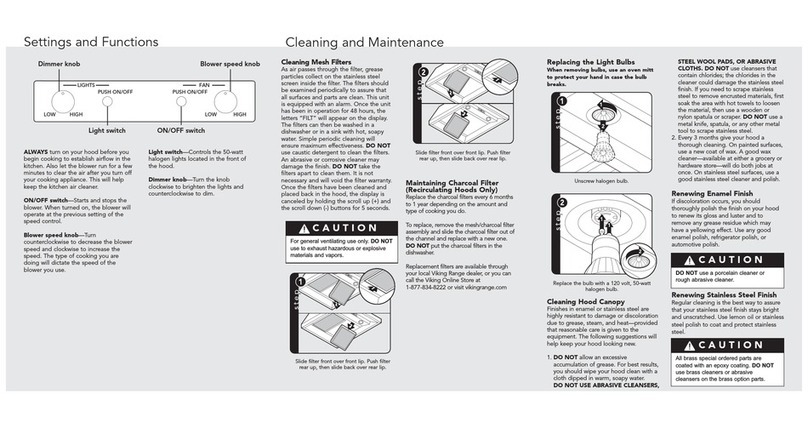

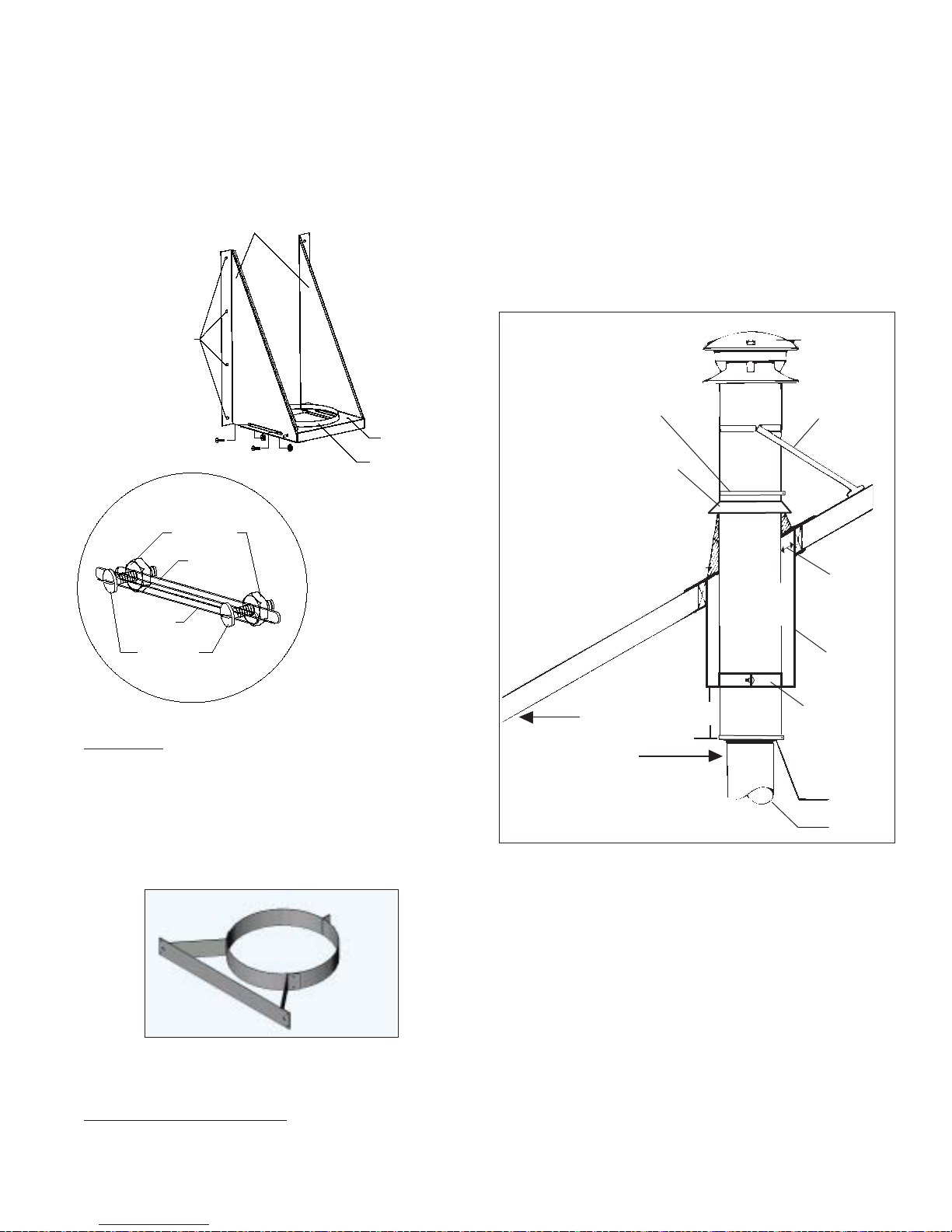

ADJUSTABLE W ALL SUPPOR T

As previously mentioned, the ideal location for your chimney

system is within the building envelope. An Adjustable Wall

Support is required when the above mentioned location is not

possible.

The adjustable Wall Support will allow for an adjustment of 2” to

6” from a vertical wall. Threaded studs are factory installed on

both side brackets and the support plate for fast and easy

assembly (see Figure 9).

One pair only of (two) 15 or 30 or 45 degree elbows may be used

to provide an offset in order to avoid cutting of joists and to clear

other obstructions. The vertical run of chimney above an offset

must be supported with an elbow support. Each elbow support

will support 10m (30’) of chimney. If the offset length is more than

1.2m (4’), an intermediate support (plumbing straps not supplied)

must be installed at 1.2m (4’) intervals in conjunction with an offset

support. Maximum offset length is 4.8m (16’). See Figure 7 and

the Offset Chart for assistance in selecting your offset.

15° Elbow Kit

30° Elbow Kit

45° Elbow Kit

MODEL UT

Framed Enclosure 2”

(50mm) clearance from

chimney to combustible

wall

Elbow Support Band

Roof Joist

(Framed all 4 sides)

Chimney Section

Lower

Bucket

Stove

Pipe

Adapter

Floor,Ceiling Joist

(Framed all 4 sides)

5” 6” 7” 8”

Page 7

2

2.5

3

3.5

4

4.5

5

5.5

6

74

73

71

69

66

62

58

52

45

63

62

60

59

56

53

50

45

39

56

55

53

51

49

46

43

38

34

49

48

47

46

44

42

39

35

30

The following steps will assist you in the installation of the

Adjustable Wall Support. Figure 13 shows a typical Wall Support

installation.

To complete a proper Wall Support installation, the following

parts may be required:

-Adjustable Wall Support: Intended for a through-the-wall

installation where the chimney has a horizontal connection.

-Suitable Lengths of chimney: Installed above the support.

-Through-The-Wall Length: Attaches to tee branch.

-Insulated Tee w/Plug

-Insulated Wall Thimble:Required to pass through a combustible

wall.

-Wall Band: Required to provide lateral support to the chimney.

-Round Top: To prevent rain and/or debris from entering in the

chimney.

-Stove Pipe Adapter:To connect from the chimney to appliance’s

flue pipe.

-Roof Flashing: Required when the chimney penetrates a roof or

a roof overhang.

2. For a non-combustible wall (concrete block or poured

foundation), cut a hole 5mm (3/16”) greater in diameter than the

outside diameter of the chimney as per Table 4.

1. Determine the centre line of the horizontal connection (length

through the wall) and frame an opening to the dimensions

specified in Table 4.

3. After framing in your opening to the dimensions specified in

the Framing Dimensions in Table 1, install the outer half (with the

unfinished square plate) of the Insulated Wall Thimble in the

outsidewallopening. Secure inplaceusing appropriatefasteners

through the pre-punched holes.

4. Install the inner half (with black plate) of the Insulated wall

Thimble in the inside wall opening, ensuring that the shield slides

into the shield of the outer half. Once in place and flush against

the wall, fasten with appropriate fasteners through the pre-

punched holes.

Distancefrom

Wall to

Chimney 5” ID

Chimney 6” ID

Chimney 7” ID

Chimney 8” ID

Chimney

H(feet)

Max. Height H (feet)

Max. Height H(feet)

Max. Height H(feet)

Max. Height

D (inches)

Wall/Chimney

Table 5 - Wall Support Chimney Height Chart

The maximum chimney height above an Adjustable Wall Support

is indicated in Table 5 and illustrated in Figure 8, all of which

must be above the support.

FIG. 8 - See Table 1 for Maximum Chimney

Heights based upon Chimney Diameter and

Distance from Wall

“H”

Max.

Chimney

Height

“D”

Distance

from Wall to

Chimney

Support Bracket

Support Plate

5. Assemble the side Brackets (point of triangle facing down) to

the Support Plate (flange up) by inserting the threaded studs into

the oblong slots. Install the supplied nuts on the threaded studs.

(see Figure 9 & 10).

Support Side

Brackets

Support Plate

Threaded Stud

Support Bracket

Threaded Stud

Nut

Support

Plate

Nuts

Nut

Support Bracket

Threaded Stud

Support

Plate

Threaded

Stud

FIG. 9 - UNDERSIDE VIEW OF

THREADED STUDS AND NUTS

Never offset an exterior chimney.

Page 8

Insulated Wall Thimble

Telescoping adjustment

from 6” to 11”

Insulation

Blanket

Interior Inner

Half of

InsulatedWall

Thimble

Exterior Outer

Half of

InsulatedWall

Thimble

Figure 11

Insulated Wall

Thimble

Combustible Inside Wall

76mm (3”) min.

660mm (26”) max.

Insulated Chimney

Length

Min. Clearance to

Combustibles (50mm)

Fig. 13 - Wall Support

Installation

Lag Screws Into

Structure Bracket

Support Plate

Wall Support Kit

Locking Band

Insulated Tee

Full Enclosure

Recommended.

Both Indoors

and Outdoors

Use Locking

Bands on All

Joints

Wall Band Every

8 Feet

9. Place the insulated Tee on the support plate ensuring that the

male coupler of the Tee is facing up and the flange on the top of

the plate slides into the female coupler. Insert and secure theTee

Capwith theattachedretainer clips(see Figure12). In earthquake

zones, secure the Tee to the flange on the support plate by

installing 2 stainless steel sheet metal screws as per figure 12.

10. For extension of the Tee, slide an appropriate insulated

Chimney Length through the Wall Thimble and attach it to the

horizontal branch of the Insulated Tee with the supplied locking

band. Make sure the nut and bolt are facing down to prevent any

water from collecting in the locking band. The insulated length

must protrude at least 76mm (3”) through the wall into the room

as per Figure 13.

Stud and Nut

located to front

of Support

Bracket

Support

Brackets

Threaded Stud

and Nut

located at

rear of

Support Plate

Pre-

Punched

Holes of

Support

Bracket

Flange Up

Holes for Retainer Clips

FIG.10-FRONTVIEWOFWALLSUPPORTASSEMBLY

Support

Plate

6. Ensure that the Wall Support is level, and secure to the wall

through the pre-punched holes located on the sides of each of

the wall support brackets using (8) #14 x 1-1/2” hex head lag

screws or #10 x 1-1/2” wood screws. You can drill 5/32” pilot

holes for the lag screws.

7. Once in its final position and all clearances have been met,

tighten each of the nuts on the threaded studs.

8. Attach the two (2) retainer clips to the bottom of the support

plate and fasten with the supplied nuts and bolts using the two

(2) holes on top of the support plate (see Figures 10 & 12).

FIG. 12 - SECURINGOFTEE CAP

Support

Plate Retainer

Clip

Tee Cap

Earthquake zones

secure Tee to the

Support Plate

with stainless

steel screws

Insulated Tee

WARNING: Tee Cap and Retainers must be installed.

Failure to install retaining clips could cause fire,

injury or death.

Wing Nut

11. Use a non-hardening high-temperature sealant (500oF) to

seal around the horizontal length where it enters the wall thimble

or the concrete wall.

12. Chimney lengths above the InsulatedTee are simply stacked

on and locked with a 1/8 clockwise turn. Locking bands must be

used on all joints.

13. For lateral stability of the chimney above the support, a Wall

Band must be used every 8 feet, and at least one Wall Band

must be installed. Interior chimneys must use the Firestop Joist

Shield (JS) in place of Wall Bands if extending through floor /

ceiling penetrations.

Page 9

76mm

(3”) min.

-Suitable lengths of chimney

-Stove Pipe Adapter

-Trim Collar

-Round Top

Flashing Minimum

50mm 2”

air space

clearance

Universal

Roof

Brace Kit

Storm Collar

Locking

Band

Stove

Pipe

Adapter

Follow

Appliance

Instructions

for proper

connector

clearance

Support

Band

Cathedral

Ceiling

Support

FluePipe

Round Top

Figure 17

NOTE: The male coupler of the chimney length must be pointing

upwards as per the arrow on the chimney label.

The bottom chimney length should protrude into the living space so

that proper clearances are maintained at the adapter (see Figure 17).

The Cathedral Ceiling Support Box is manufactured to an over-

all outer dimension of 12” x 12” (305mm x 305mm). Therefore,

thesuggestedframingtofittheboxis12-1/4”x12-1/4”(311x311mm).

suspend the chimney below the roof. To complete a proper

Cathedral Ceiling Support installation, the folllowing parts may

be required:

-Cathedral Ceiling Support /w 4 painted ceiling trim angles

-Roof Flashing w/ Storm Collar

The following instructions will assist you in the installation of

your chimney with a Cathedral Ceiling Support. This support will

hold up to 30’ of chimney, of which 15’ can be suspended below

thebox. Chimneyjoints madebelowthe supportmustbe secured

with locking bands.

Wall Band

WALL BAND

The Wall Band is used along an outside wall at 8 ft intervals for

lateral stability. Secure the Wall Band bracket to the wall using

two 6d or 2” spiral nails. For concrete walls use suitable masonry

fasteners.The nut and bolt supplied will fasten the band around

the chimney.

Figure 16 After framing in your opening to the dimensions specified above

and in Table 1, slide the Cathedral Support Box into the joist/

rafter opening. Once the box is at the desired location, ensure

the box is level and plumb. Nail the box to the framing using four

2” spiral nails or equivalent per side. The excess material stick-

ing above the roof can either be trimmed off before attaching the

box to the framing or, after it is installed the corners can be cut

and the excess material folded down onto the roof deck.

Install the Support Band on a chimney length at the desired

CATHEDRAL CEILING SUPPORT

A Cathedral Ceiling Support is available for 5” and 6” diameters

chimney only. For other diameters, a roof support can be used to

NOTE: Invertingthebrackets(bracketsmounted abovethesupport

plate) can be accomplished by inserting extra bolts through the

oblong slots of the support side brackets and the support plate

as per Figures 14 and 15. Secure with nuts. In this position, the

range of adjustability is limited to 5” from the wall.

Nuts

Slot on

Support

Bracket

Support Brackets

Pre-Punched

Holes of Support

Bracket

Support Plate

w/ Flange Up

Front Hole for

Retainer Clip

Slot on

Support

Plate

Bolts

FIG. 15- SLOTAREAS

WITH BOLTSAND NUTS

ASSEMBLYOFSUPPORT

BRACKET AND

SUPPORTPLATE

FIG. 14-FRONTVIEW OF

WALLSUPPORT

ASSEMBLYWITH

BRACKETSMOUNTED

ABOVETHESUPPORT

PLATE

Page 10

158

7

6

4

32 910

1

26

453 78910

11

11

3”

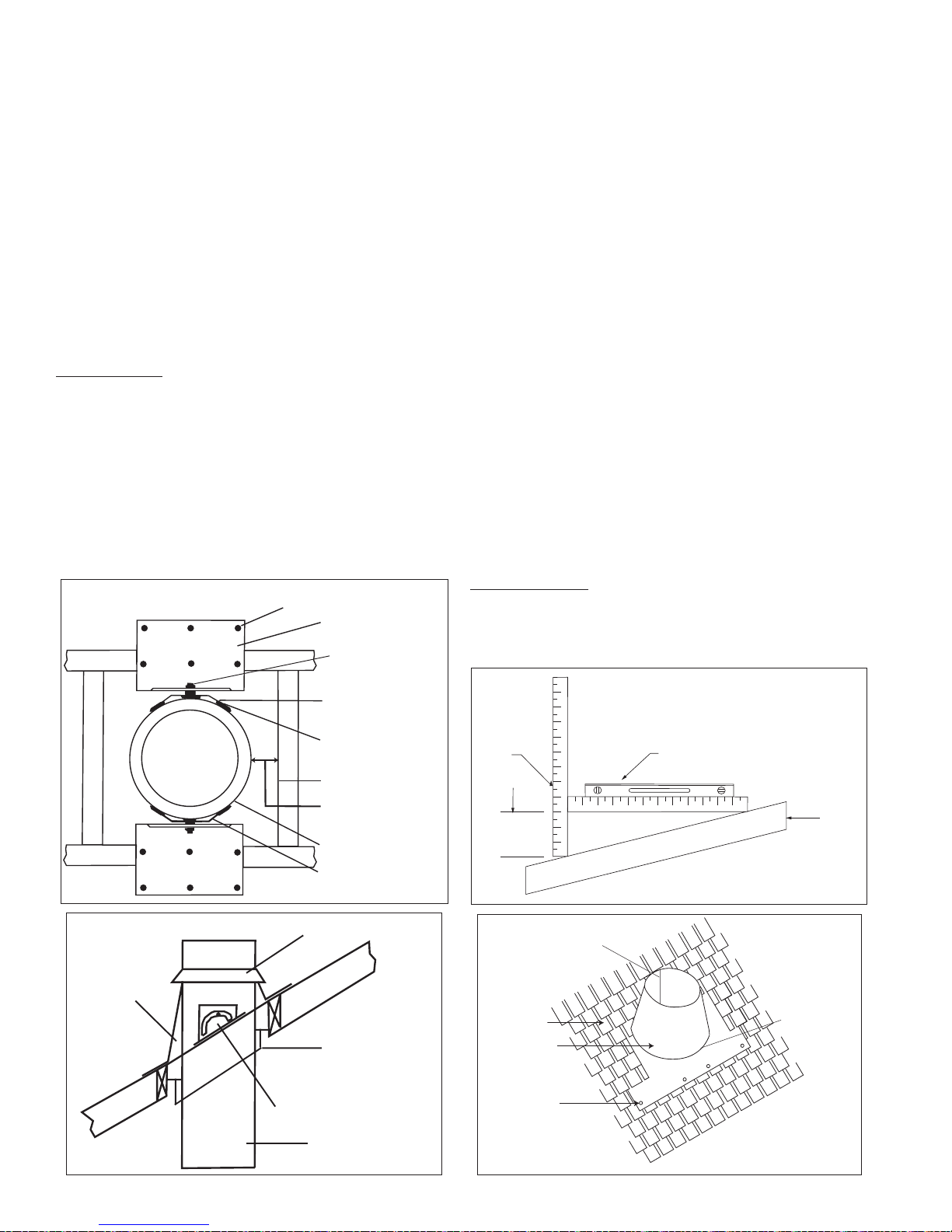

ROOF SUPPORT

5. Using the bent chimney plate as a template, drill 3/32" holes in

the outer casing of the chimney (do not penetrate more than 12

mm (1/2'’) into the chimney). Attach the plate with the small

sheet metal screws provided.

6. Install the second plate in a similar manner on the opposite

side of the chimney length.

The following instructions will assist you in the installation of

your chimney with a Roof Support. This support will hold up to

9.0 m (30') of chimney of which 6.0 m (20') may be suspended

beneath it.

Figure 18

Figure 19

ROOF FLASHING:

Ensure that you have the proper roof flashing by checking your

roof pitch using a level and two rulers (see Figure 20) or by

using a roof pitch card.

12” Ruler Level

Roof Pitch is 3/12

Figure 21

Figure 20

Flashing

Storm Collar

Roof Support

50mm (2”) min.

clearance

Insulated Chimney

Length

Shingles

Nails

Flashing

Framed Opening

Chimney Plate

Carriage Bolt

50mm (2”) min.

clearance

Chimney length

Bend to fit curve of

chimney

Roof Bracket

Large wood screws provided

Small sheet metal

screws (provided)

1. Frame a rectangular roof opening to provide a 50mm (2") mini-

mum clearance from combustible materials (See Figure 18).

2. Bend both chimney plates at the vertical slots to fit the outside

curvature of the chimney length (Figure 18).

7. Attach the Roof Brackets to the chimney plates. Centre the

assembly in the roof opening, ensuring that a 2” clearance to

combustible is maintained.

8. Adjust Roof Brackets to the roof pitch and tighten nuts. Attach

to the roof with six (6) large wood screws per bracket

with the inner-most screws going into the rafters or headers

(See Figure 18 & 19).

9. Additional chimney lengths above the support are simply

stacked on and locked with a 1/8 clockwise turn.

10. Locking Bands must be used on all exterior joints.

11. Finish the chimney to its required height. If the chimney

extends 1.5 m (5') or more above the roof, a Universal Roof

Brace Kit is required (see Figure 22).

3. Determine the chimney plate position on the chimney casing

(See Figure 19).

4. Install two (2) carriage bolts per chimney plate in the square

holes.

position by tightening the support band with the bolt and nut.

Secure the band to the chimney outer casing by screwing four

stainless steel sheet metal screws through the support band

andinto theoutercasing. Lower thechimney lengthdownthrough

the opening in the bottom of the support box, so that the Support

Band makes contact with the bottom of the Support Box (see

Figure 17).

Install additional chimney sections and lock together by turning

clockwise until the two sections lock together tightly. Locking

bands must be used at all joints. Continue in this manner until

the required height above the roof is achieved.

Chimney sections installed below the Cathedral Support are

locked together from below by turning counter-clockwise until

tightly locked together with each joint being secured by locking

bands which are provided. Do not offset the chimney below the

Cathedral Support.

Roof

Apply a bead of

silicone caulking

along the seam

where the plate

meets the cone.

Apply a bead of

silicone caulking

along the back

seam of the

cone

Page 11

4

4

5

5

18

21

23

27

UNIVERSAL ROOF BRACE KIT

If the chimney extends 5 feet (1.5m) or more above the roof deck,

a Universal Roof Brace Kit is required. The Universal Roof Brace

Kitcontains2 telescopic legs,brackets, band strap andhardware

package. The band strap is wrapped around the chimney and

the two telescopic legs bolted to the roof brackets.

The Flashing and Storm Collar may be painted to match the roof

shingles. This will extend its life and improve the appearance. The

chimney may be painted also with a HEAT RESISTANT paint. To

improve adhesion to the chimney, degrease, clean and prime

before painting. Follow the paint manufacturer’s instructions.

Continue adding chimney lengths until the proper height is

achieved (see Figure 1 and Chart 2). Install a Round Top. The

Round Top prevents entry of moisture which might lead to prema-

ture deterioration of the chimney.

On metal or steep roofs, it is recommended that an ice deflector

or “cricket” fabricated from heavy-guage galvanized steel be

installed. The wedge-shaped deflector is installed 2” from the

chimney on the upper slope. Its function is to split ice and snow

as they slide down the roof, preventing damage to the chimney.

This is not a supplied item. Contact your dealer or a sheet

metal fabrication shop in your area for your custom ice deflector.

This also should be painted with a suitable metal paint by

following the paint manufacturer’s instructions.

Once you have marked and located the area where the chimney

will come through the roof, center, position and prepare the roof

area by removing shingles, shingle nails and cutting the roofing

material. Frame a RECTANGULAR opening to suit the pitch of

the roof and ensure that a 2” (50mm) clearance is maintained to

combustibles on all four (4) sides. This is done before extending

the chimney above the roof. Do not nail the flashing to the roof at

this time as ajustments may be required.

Slide the top edge (nearest the roof peak) of the flashing under

the roofing shingles. At least half of the flashing (top and sides)

should be UNDER the shingles and the lower end OVER the

shingles to provide a watershed. Trimming off the shingles may

be neccessary around the cone of the flashing for a better fit. On

existing roof application, lower a chimney length into the flashing

opening and twist lock in place and secure with a Locking Band.

Ensure that the chimney is level and plumb before nailing the

flashing to the roof.

Nail the flashing to the roof deck (also under the shingles) along

the upper edge and down each sides with 12 nails with neoprene

washers or cover the heads with a suitable non hardening

waterproof caulking. Seal the shingles to the plate in the same

manner. As a precaution, apply a bead of caulking along all

seams of the flashing as per Figure 21.

Apply a non-hardening high temperature silicone caulking just

above the top of the flashing cone where it meets the chimney

casing. Slide the Storm Collar through the applied caulking and

place into its final position to ensure a waterproof joint. Apply

additional caulking above the Storm Collar as required.

Two (2) pockets must be formed to attach the telescopic legs

(use Figure 23 and the Selection Chart below as guide).

Tab “A” is formed at one end by bending the strapping band

(clearing the first hole). The number of holes counted away from

Tab “A” (including the first hole) will identify the location of the

first pocket. Attach at this location the “U” bracket by inserting a

bolt through and securing with the supplied nut.

To formTab “B”count the holes away from the“U”bracket. At this

location a bolt is inserted into the holes creating the other pocket.

Fasten the larger diameter section of the telescopic leg to the

“U” bracket using the bolt and nut.

FIGURE 22

Eye Bolt

Clamp

Storm Collar

Flashing

Locking Band

Nut & Bolt

RoundTop

BandStrap

TelescopicLeg

Nails

FIGURE 23

UT/ST

Inside Diameter # Holes from "Tab A" for

the "U" Bracket # holes from "U" Bracket

to bolt hole in tab "B"

Hole/Tab Selection Chart

"U" Bracket

(1st Pocket)

Tab "A"

Tab "B"

Bend the strapping of

Tab "A" and "B" to form

2nd pocket and cut off

excess material

5”

6”

7”

8”

Page 12

B

C

A

4. Always secure all single wall flue pipe joints with a minimum

of 3 screws.

5. Obtain proper attachment parts for the appliance end and for

the entry to the chimney.

6. Locate or support the flue pipe to avoid contact of damage.

7. Caps or plugs for single wall tees should be secured

against falling out and designed so they can’t leak creosote

or rain.

The band is clamped around the chimney and the two legs

bolted to the roof. Position the band approximately two thirds of

the way up the chimney height. The preferred location for the

band is next to a joint, immediately above or below a locking

band and fasten the other telescopic leg to Tab “A” and Tab “B”

using the bolt and nut provided.

Secure the bottom end of each telescopic legs to the roof brack-

ets and the roof brackets to the roof with supplied hardware as

shown in Figure 24. The two legs of the brace assembly should

form an angle of about 60 degrees to give support to the chimney

in all directions. Keep bottom ends equal distance from the

chimney and at approx. at the same elevation, on the high side of

the sloped roof. Ensure that the lags are anchored in rafters and

not just the roof deck. Seal the roof with a suitable non-hardening

waterproof sealant. After the legs are attached securely to the

roof brackets and to the band, tighten the eye bolt which locks

the two tubes together fixing the position of the telescopic legs.

Figure 24

SPARK ARRESTER

Use a spark arrester if you have a shingle roof or live in a for-

ested area. If the chimney is used for venting a gas appliance,

use a spark arrester to keep birds out.

The Spark Arrester is made of flexible expanded metal mesh.

Each size is cut to fit the appropriate size Round Top.

Wearing safety gloves, fit the bolt with one nut and place the

mesh between the dome and the skirt of the round top. It should

be midway between the inner wind band and the outer edges.

Do not place the screen directly against the wind band.

Once the Screen is wrapped around the band, secure it in place

with the 2nd bolt and nut.

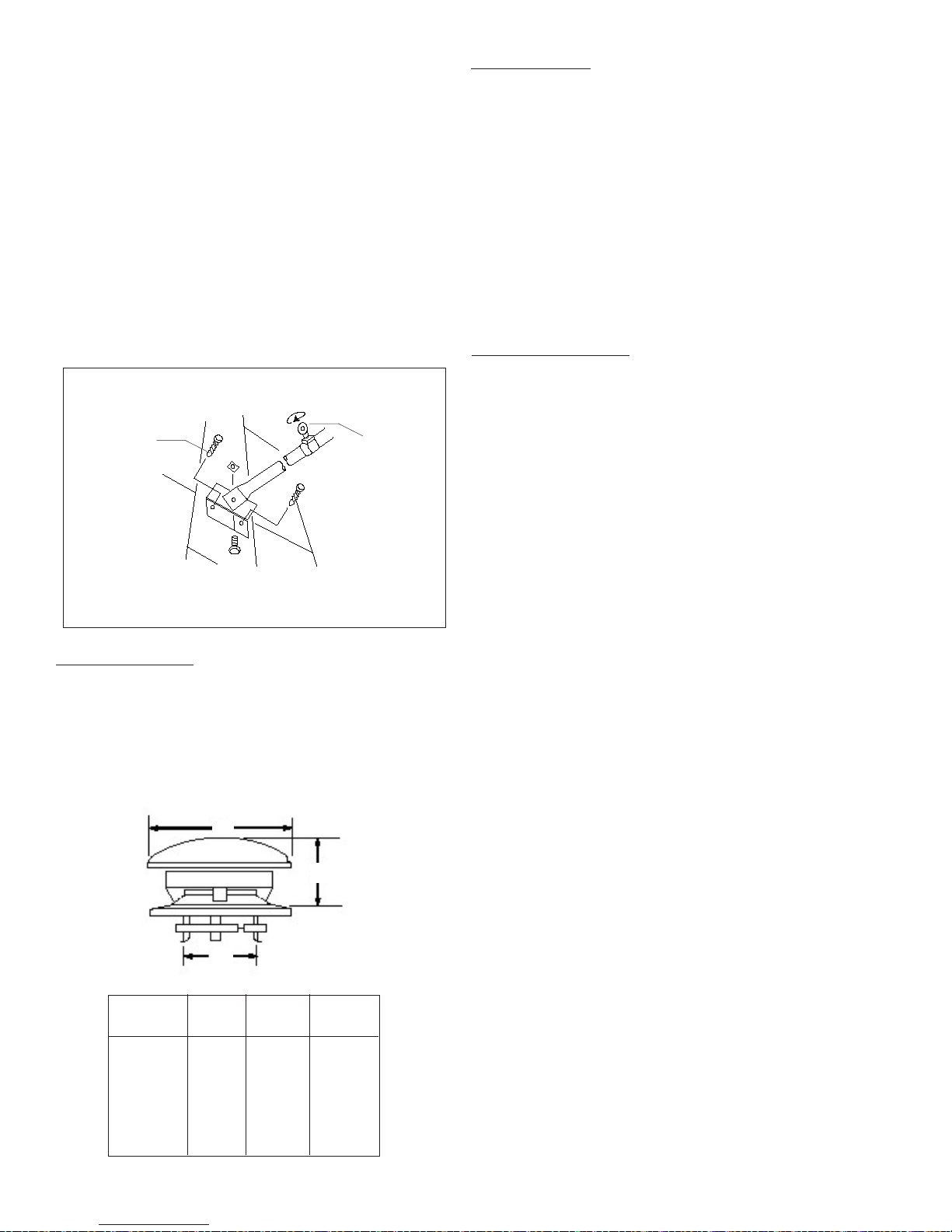

TYPE HT ROUND TOP

Attach the Type HT Round Top to the chimney by sliding it over

the chimney length. ensure that the three (3) vertical tabs are

located on the outside of the chimney length and that the

Round Top sits flush on the top surface of the length. Wrap the

band snug to the bottom of the 3 tabs and secure in place with

the supplied nut and bolt.

The connection of a single wall base tee or single wall flue pipe

or double wall flue pipe to the insulated chimney must be secured

with the screws supplied in the Support carton. The use of a

stove pipe adapter is recommended with the first length, this will

provide a positive connection between the insulated chimney

and the appliance connector. The Stove Pipe Adapter is inserted

into the female end of the first insulated chimney length and

extends beyond the ceiling support approximately 32mm (1-1/

4”). For a Cathedral Support and Wall Support application, the

stove pipe adapter is inserted into the female end of the exposed

chimney length and extend into the room and held in place with

the finishing collar secured with 4 screws which is used to

attach the stove pipe adapter to the finishing collar.

Install inter-connecting flue pipe following the appliance

manufacturer’s instructions, and appropriate building code

requirements keeping in mind that the flue pipe run should be

as short and straight as possible. All joints should be secured

in place with three (3) sheet metal screws.

Besides following the appliance instructions for flue pipe, other

rules that should be taken into account:

To comply with the National Building Code of Canada the single

wall base tee can be installed with a 229mm (9”) minimum air-

space clearance between connnecting single wall material and

combustibleproductsprovided thattheflue gastemperaturedoes

not exceed 400° C (750° F) (most oil fired appliances). Other-

wise, the minimum air space clearance must be 450mm (18”).

Refertothe applianceinstallationinstructions for theproper chim-

ney requirements.

STOVE PIPE ADAPTER:

Connect only to low heat (liquid fuel or gas fired) appliances

with continuous flue gas temperatures below 540° C (1000° F).

When installing a factory-built fireplace refer to the fireplace in-

stallation instructions for the proper chimney requirements.

1. Never enclose single wall flue pipe, even at 18 inches clear-

ance.

2. Never run it through ceilings or floors, or windows.

3. Don’t use single wall flue pipe outdoors.

Ensure that

the lags are

anchored in

rafters rather

than the

sheathing

Tighten the

eye bolt which

locks the

two tubes

together fixing

the position of

the telescopic

legs

Roof Bracket Secured to Roof

Chimney

Dia.

5”

6”

7”

8”

FIGURE 25

A

7”

8”

9”

10”

B

10”

12”

14”

16”

C

5”

5-1/2”

6-1/4”

7”

Page 13

With a new chimney installation, the chimney should be inspected

at least once every 2 weeks during the heating season to deter-

mine if a creosote or soot buildup has occured. When familiar with

the appliance and chimney characteristics, the chimney should be

inspected at least once every 2 months during the heating season.

If creosote or soot has accumulated, it should be removed to

reducethe riskofachimneyfire. Depending onthe rateof buildup,

as you learn what is going on in the chimney, you can adjust your

cleaning schedule.

If you have any doubts about your ability to clean the

chimney, or if the deposits are very heavy and hard to remove, call

a certified chimney sweep. Do not try to burn them off.

If chemical cleaner is used to assist in cleaning your chimney,

make sure it is a product which is non corrosive to the chimney

liner. The optimal method for cleaning a chimney is by a

mechanical brushing of the chimney in conjunction with a

complete evaluation of the system by a certified chimney sweep.

The National Fire Code of Canada states: “Every chimney flue

and flue pipe shall be inspected and cleaned annually or as

often as maybe necessary, to keep the chimney and flue pipe

free from dangerous accumulations of combustible deposits”.

CHIMNEY FIRES AND WHAT TO DO ABOUT THEM:

Your Selkirk chimney is not intended or designed for use as a

combustion or fire chamber. If the fire in your appliance has

gotten out of control, or if you suspect a chimney fire for any

reason, follow these steps:

1. Immediately close all dampers and/or air entrance to your

appliance.

2. Alert your family to the possible danger.

3. Inspect your appliance and chimney for possible fires, if in

doubt, alert your Fire Department.

4. Do not use salt or water on the fire. Salt is corrosive and water

will cause a dangerous steam explosion. You may be able to

control the fire by using ashes, sand or baking soda, since baking

soda is an ingredient used for dry chemical fire extinguishers.

5. Donotcontinue to useyourappliance until itandyour chimney

have been thoroughly inspected by a certified service technician.

6. After a chimney fire, when it is safe to do so, check internal

locations such as the attic and under the roof and keep watching

for two or three hours. There may be delayed smoldering and

subsequent ignition even if the fire inside the chimney has been

controlled.

The Anchor Plate can be used for adapting the UT chimney to a

“Listed” Factory-Built Fireplace certified for use with Model UT.

Follow the installation instructions accompanying the fireplace.

NOTE: Itis ofutmostimportance thatthe AnchorPlatebe installed

in accordance with the manufacturers installation instructions

accompanying the “listed” Factory-Built Fireplace.

MODEL UT ANCHOR PLATE

CHIMNEY OPERATION AND MAINTENANCE:

The need for chimney maintenance depends on the kind of ap-

pliance and how it is operated. Gas and oil-burning appliances

need very little, but wood-burning appliances may need a great

deal of chimney maintenance.

IMPORTANT

Burning wood produces creosote, soot, and fly ash which tend to

collect in chimney flue and on termination parts causing reduced

flow of gases through the chimney. Check top weekly for exces-

siveaccumulationof thesenormal combustionproductsand clean

as necessary. If the spark arrester becomes clogged with creo-

sote, it should be cleaned or replaced.

®

www.selkirkcorp.com

Selkirk Canada Corporation

P.O. Box 526, Depot 1

Hamilton, ON L8L 7X6

Toll Free: 1.888.SELKIRK (735.5475)

Selkirk Corporation

5030 Corporate Exchange Blvd.

Grand Rapids, MI 49512

Toll Free: 1.800.433.6341

Page 14

AABBAB

AB

13-3/4"

18-7/8"

22-3/4"

28"

N/A

37-1/2"

44"

53-1/2"

58-7/8"

68-3/8"

N/A

3-5/8"

6-1/8"

8-1/2"

11-5/8"

N/A

16-5/8"

20-7/8"

25-1/2"

28-3/8"

33-1/4"

N/A

3"

5-1/4"

8-1/8"

11-1/8"

13-3/4"

16-1/8"

20-1/4"

24-7/8"

28-3/8"

32-5/8"

26"

13-1/4"

17-5/8"

22-7/8"

27-7/8"

33-1/4"

37-1/2"

43-3/4"

53-3/8

58-3/8"

68-1/2"

54"

AABBAB

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

AB

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

4-3/8"

7-3/4"

11-7/8"

16"

20-1/2"

23-7/8"

28-1/2"

36-1/4"

40-1/8"

47-7/8"

41-1/2"

12"

15-5/8"

19-3/4"

23-7/8"

27-3/4

31-3/8"

36-7/8"

44-3/8"

49-1/4"

56-1/2"

45-5/8"

AA

BBAB

AB

5/8"

1-3/4"

2-3/4"

4-1/8"

N/A

6-3/8"

8-3/8"

11-1/4"

13"

16-1/8"

N/A

7-1/2"

13-3/8"

17-7/8"

23-7/8"

N/A

34-1/8"

41-5/8"

52"

57-3/4"

68"

N/A

5/8"

1-5/8"

2-7/8"

4-3/8"

5-3/8"

6-3/8"

8-1/8"

10-5/8"

12-1/8"

14-3/8"

10-3/4"

7-1/2"

12-1/2"

18-1/8"

24"

29-3/4"

34-1/8"

41-1/4"

52"

57-5/8"

68"

53-1/4"

5/8"

1-7/8"

3"

4-1/8"

5"

6"

7-1/2"

9-7/8"

11"

13-3/8"

10"

8"

13-5/8"

18-1/2"

24-3/8"

30-1/2"

34-7/8"

42"

52-1/2"

58-1/2"

68-3/4"

53-1/2"

3-1/8"

2"

3"

4"

5-1/4"

6-1/4"

8"

10-1/8"

11-7/8"

15-1/8"

10-1/8"

8-1/8"

14-1/4"

18-3/4"

24-5/8"

30-3/8"

35"

42"

52-5/8"

58-1/2"

68-3/4"

54-3/8"

4-1/8"

7-1/8"

9-5/8"

12-1/2"

15-3/4"

18"

21-5/8"

27-1/2"

30-1/2"

35-3/4"

27-1/2"

15-1/4"

20-1/8"

24-1/4"

29-3/8"

34-7/8"

39"

45-1/4"

54-1/8

59-1/8"

68-1/2"

55-3/8"

4-1/4"

7-1/8"

9-1/2"

12-1/2"

15-1/2"

18-1/4"

21-7/8"

27-1/8"

30-1/2"

36-1/8"

28-1/2"

16-1/8"

21-3/4"

25-3/8"

30-5/8"

35-7/8"

39-1/2"

46"

55-3/8

60-1/2"

69-5/8"

56-5/8"

5-1/2"

9-3/4"

13"

17-1/4"

21-3/4"

25-5/8"

30-5/8"

38-1/8"

42-3/4"

50-1/2"

38-1/4"

14"

18"

21-3/4"

25-3/8"

29-7/8”

32-3/4"

38-1/8"

45-1/8"

49-1/4"

57-3/8"

46-1/2"

5-3/4"

9-1/2"

13"

17"

21-5/8"

24-5/8"

29-5/8"

38-1/8"

41-7/8"

49"

38-1/2"

15-1/8"

19-1/4"

22-1/2"

27"

31”

34-1/2"

39-7/8"

47"

51-1/2"

59-3/8"

48-7/8"

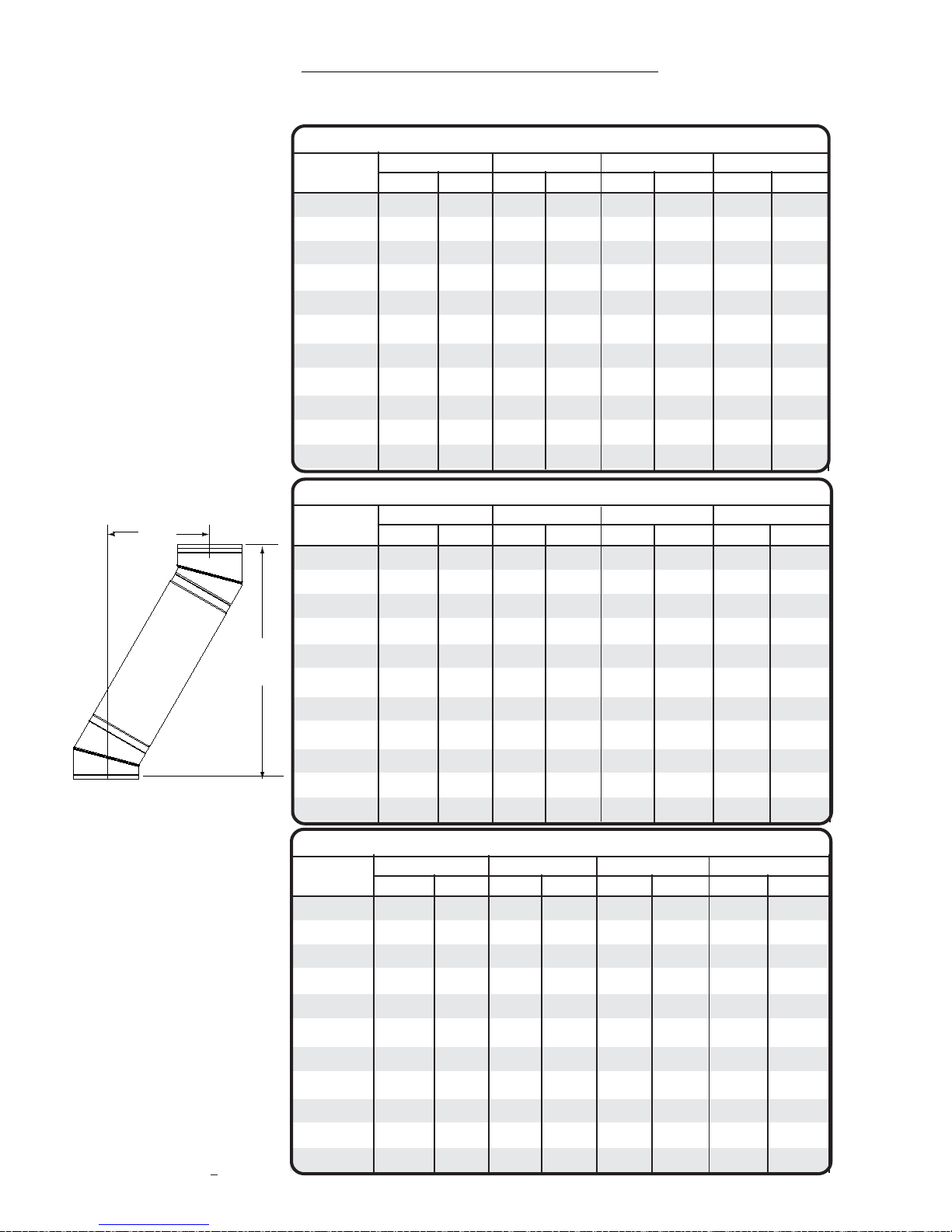

45o OFFSET CHART

Chimney

Lengths 7"Diameter

6"Diameter 8"Diameter

5"Diameter

30o OFFSET CHART

Chimney

Lengths 7"Diameter

6"Diameter 8"Diameter

5"Diameter

none

6"

12"

18"

24"

12" + 18"

36"

12" + 36"

18" + 36"

12”+18"+36"

48"

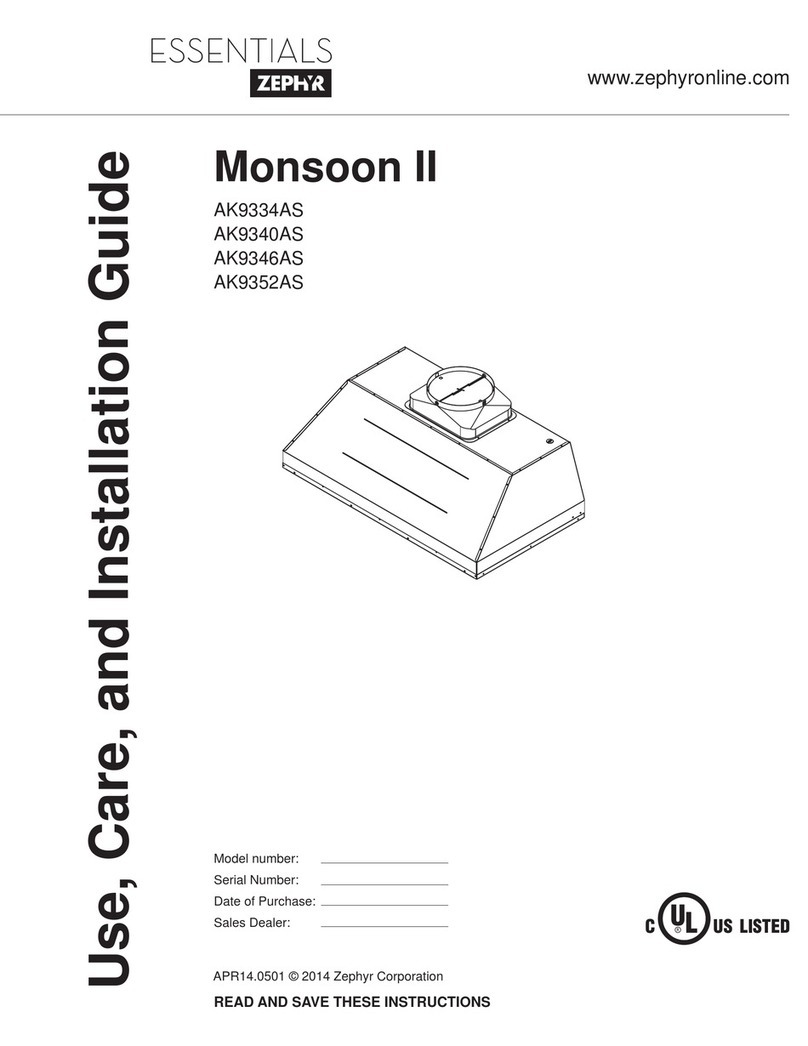

OFFSETCHART CHIMNEYINSTALLATION

It may be necessary to offset the chimney in order to clear a joist or an obstacle. The three (3) charts below will assist you in selecting

the proper combination of elbow angle and chimney length(s) that will provide the necessary degree of offset within an available height.

1. Select the column with the proper

chimney diameter of your system.

2. Determine the distance of the off-

setrequired by droppingaplumb line

for an accurate measurement. The

offset is measured at the chimney

centre line as per the "A" Offset

measurement in the diagram below.

3. On the chart, find the predeter-

mined distance (under the "A" col-

umn) required for the 15oelbow. For

greater offset, use the 30oor 45o

offset charts.

4. After finding the offset, look at the

“B”(height)measurement in the chart

to find the specified height. The

appropiate "chimney lengths" re-

quired in between elbows is found in

the left hand side column on the

chart.

NOTE:

• UltraTemp chimney can be

offsettedusing 15o, 30oor45oelbows.

Combining offsets for a greater angle is

not permitted.

• One pair of (two) 15o, 30oor

45oelbows may be used per interior

installation.

• Neverinstallan elbow in ajoist

area. Chimney sections must pass

vertically through framed joist areas.

• Each elbow support will sup-

port 30 feet of chimney.

•An intermediate support must

beusedat4feet intervals in conjunction

with an elbow support.

•The maximum length of

chimney allowed between elbows is

16 feet.

All measurements in inches.

Construction tolerances + one inch.

Offset

“A”

"B"

Height

none

6"

12"

18"

24"

12" + 18"

36"

12" + 36"

18" + 36"

12"+18”+36"

48"

15o OFFSET CHART

Chimney

Lengths 7"Diameter

6"Diameter 8"Diameter

none

6"

12"

18"

24"

12" + 18"

36"

12" + 36"

18" + 36"

12"+18" 36"

48"

5"Diameter

Page 15

44

42

40

38

36

*36

*36

*36

*36

*36

54

51

48

45

42

39

36

*36

*36

*36

64

60

56

52

48

44

40

36

*36

*36

74

69

64

59

54

49

44

39

*36

*36

84

78

72

66

60

54

48

42

36

*36

94

87

80

73

66

59

52

45

38

*36

104

96

88

80

72

64

56

48

40

*36

114

105

96

87

78

69

60

51

42

*36

124

114

104

94

84

74

64

54

44

*36

134

123

112

101

90

79

68

57

46

*36

144

132

120

108

96

84

72

60

48

36

*36

*36

*36

*36

*36

*36

*36

*36

*36

*36

1/12 2/12 3/12 4/12 5/12 6/12 7/12 8/12 9/12 10/12 11/12 12/12

*UT-36

*UT-24

*UT-18

*UT-12

*UT-06

*T-ITP

*T-EL15KIT

*TEL30KIT

*T-CSB

*T-AWS

*T-CCSK

URSP

*T-LB

*T-AD

DESCRIPTION

DESCRIPTION

*T-IWT

*T-WB

URBK

*T-AP

*T-AIS

*T-JS

*T-FS

*T-RT

*T-FF

*T-FA

*T-FAA

*T-SC

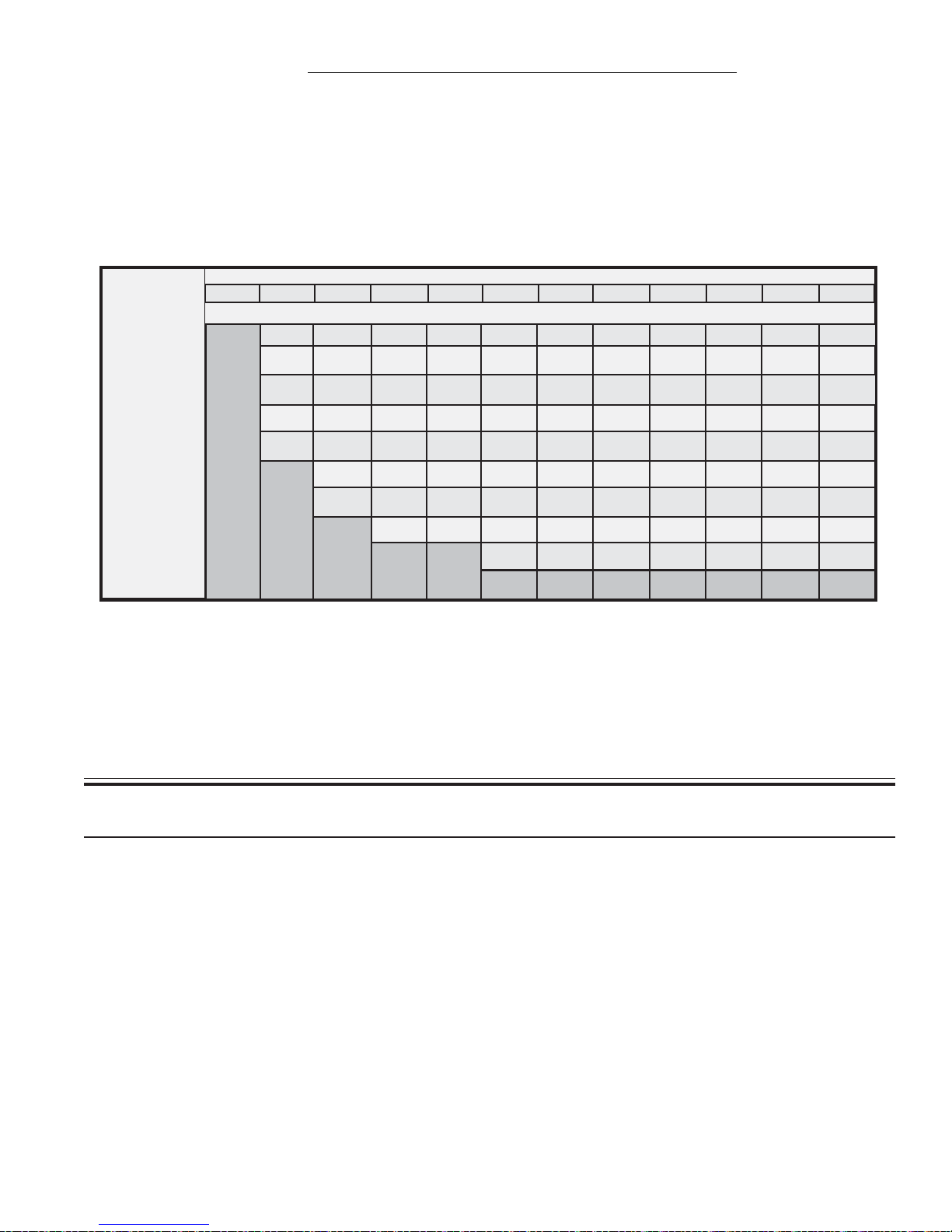

Requirement # 1 :

The code requires that the chimney must extend at least 3 feet (900mm) above the highest point of the roof that

it penetrates.

Requirement # 2 :

It must also be 2 feet (609mm) above any roof, wall or other obstruction within a horizontal distance of 10 feet (3m).

The following Chart is to assist you in determining the minimum chimney height you will require above the roof. You may need

to add to this height as nearby buildings, trees and other parts of the house roof could interfere with airflow over and around

the top of the chimney and affect its performance. If you think a nearby obstacle could affect draft, you might want to install

one or more additional lengths.

CHART 2 - CHIMNEY HEIGHT ABOVE THE ROOF

DISTANCE

FROM PEAK

10 Ft

9 Ft

8 Ft

7 Ft

6 Ft

5 Ft

4 Ft

3 Ft

2 Ft

1 Ft

CHIMNEY HEIGHT ABOVE ROOF (INCHES)

PITCH OF ROOF

* Defaulted to 36" to meet requirement #1. Both requirements (#1 and #2) must be met.

• If the chimney extends more than 5 feet or more above the roof, a Universal Roof Brace Kit is required.

•All lengths above the roof must havelocking bandsatalljoints. Thiswill eliminate the risk of sections becoming undonebelowtheroofline when

the Round Top is removed when inspections and cleaning of the system is being done.

All measurements are in inches with the exception of "distance from the peak" being in feet.

REPLACEMENT PARTS LIST

ULTRATEMP

PARTNO. ULTRATEMP

PARTNO.

36" Chimney Length

24" Chimney Length

18" Chimney Length

12" Chimney Length

6" Chimney Length

Tee with Insulated Plug

15o Elbow Kit

30o Elbow Kit

Ceiling Support

Adjustable Wall Support

Cathedral Ceiling Support Kit

Roof Support

LockingBand

Stove Pipe Adapter

InsulatedWallThimble

WallBand

Universal Roof Brace Kit

Anchor Plate

Attic Insulation Shield

Firestop Joist Shield

Firestop Spacer

Type HT Round Top

Flat Roof Flashing

1/12 - 7/12 Roof Flashing

8/12 - 12/12 Roof Flashing

StormCollar

* Specify chimney diameter (5, 6, 7 & 8 inches)

Page 17

Keep in a safe place for future reference

CHIMNEYMODEL:_____________________________

TYPEOFAPPLIANCE:__________________________

INSTALLATIONDATE:__________________________

DESCRIPTIONOFINSTALLATION(ChimneyandPipeConnectorConfiguration)_________________________________

___________________________________________________________________________________________________

___________________________________________________________________________________________________

PURCHASED FROM:

DEALERNAME:________________________________________________

Address:______________________________________________________

City:_________________________________________________________

Province:______________________________________________________

INSTALLED BY:

TECHNICIANNAME:____________________________________________

Address:______________________________________________________

City:_________________________________________________________

Province:______________________________________________________

INSTALLATION INFORMATION

Please register your Chimney with the Manufacturer.

Mail to: Selkirk Canada Corporation,

Product Registration, P.O. Box 256, Depot 1, Hamilton, ON L8L 7X6

Register Online @: www.selkirkcanada.com

Name: ________________________________________________________________________________

Address:______________________________________________________________________________

City:__________________________________________________________________________________

Province:_______________________________________ Postal Code:__________________________

Chimney Model:__________________________________ Installation Date:______________________

Technician Name:__________________________________ Address:____________________________

PRODUCT REGISTRATION

Table of contents

Other Selkirk Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Electrolux

Electrolux Westinghouse WRF610WA Installation and operation manual

Windster

Windster RA-76 Series Operation manual

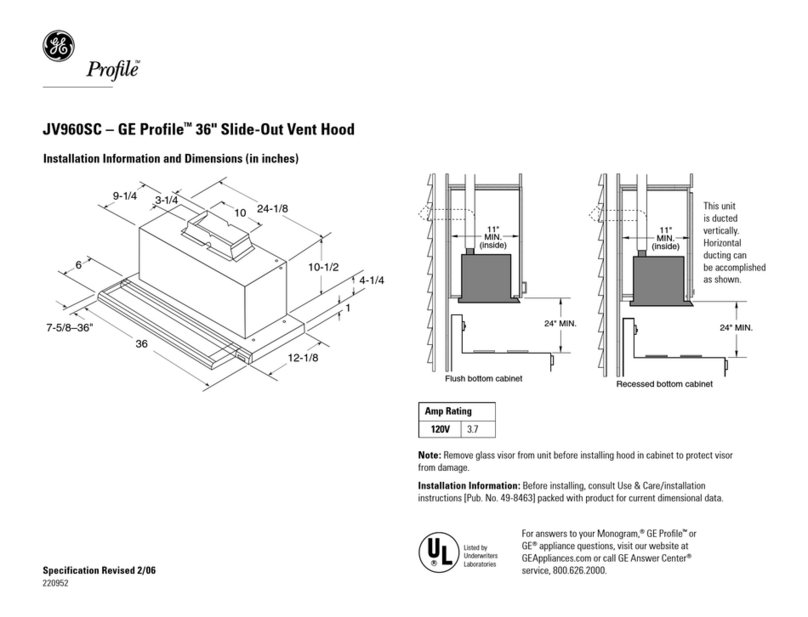

GE

GE JV960SCBR Specification sheet

Gorenje

Gorenje S1 WHC943A1XGB manual

GE

GE Cafe CV966TSS Dimensions and installation information

Logik

Logik L60CHDB17 Instruction & installation manual