Selkirk CF Sentinel User manual

1

SELKIRK CANADA CORPORATION

950 South Service Road, Second Floor

Stoney Creek, ON L8E 6A2

1-888-SELKIRK (735-5475)

Fax: 1-866-835-9624

www.selkirkcorp.ca

2021 CF Sentinel 3009214 02/12/21

(6” to 8” dia.)

FACTORY-BUILT

INSULATED CHIMNEY

Installer: It is of the utmost importance that these instructions are

left with the homeowner.

Homeowner: Keep these instructions and maintenance guide in a safe

place for future reference.

INSTALLATION I NSTRUCTIONS

&

MAINTENANCE G UIDE

Tested to Standard

CAN/ULC-S629

&

UL 103 Type HT

PLEASE READ ALL INSTRUCTIONS

BEFORE BEGINNING YOUR

INSTALLATION.

FAILURE TO INSTALL THIS SYSTEM IN

ACCORDANCE WITH THESE

INSTRUCTIONS WILL VOID THE

CONDITIONS OF CERTIFICATION AND

THE MANUFACTURER'S WARRANTY.

A MAJOR CAUSE OF

CHIMNEY RELATED FIRES IS

FAILURE TO MAINTAIN

REQUIRED CLEARANCES

(AIR SPACES) TO COMBUSTI-

BLE MATERIALS.

IT IS OF THE UTMOST

IMPORTANCE THAT THIS

CHIMNEY SYSTEM BE

INSTALLED ONLY IN

ACCORDANCE WITH THESE

INSTRUCTIONS.

Model CF

LISTED

2

3

4

4

5

5

6

6

6, 7

7, 8

8, 9

9

10, 11

11

12

12, 13

13, 14

15, 16

16

16

17, 18

18

19

20

21

21

22

CERTIFICATIONLABELS

TYPES OF APPLIANCES

PRE-INSTALLATIONGUIDELINES

TOOLS

CFSENTINELJOINTSECURITY

FRAMING DETAILS

CEILINGSUPPORTINSTALLATION

SMOKE PIPE ADAPTER

FIRESTOPJOISTSHIELD

ATTICINSULATIONSHIELDINSTALLATION

ELBOWINSTALLATION

WALLSUPPORTINSTALLATION

WALL BAND

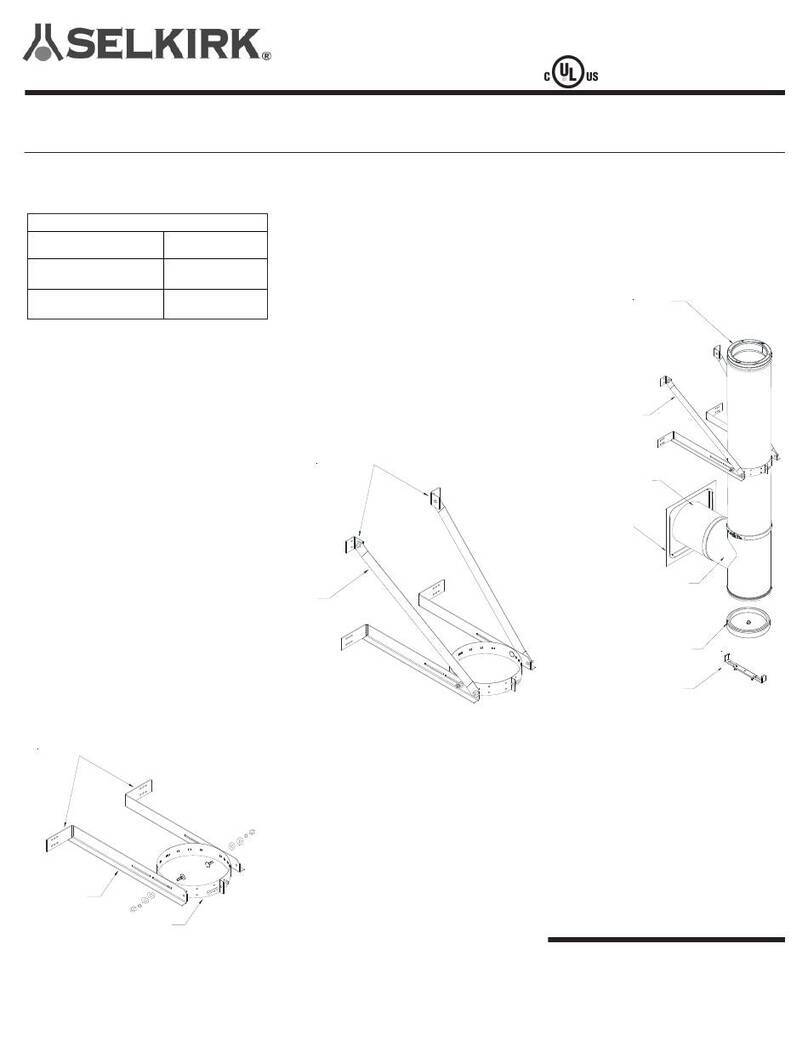

CATHEDRALCEILINGSUPPORTINSTALLATION

ROOFSUPPORTINSTALLATION

ROOFFLASHINGINSTALLATION

ROOFBRACEKITINSTALLATION

ROUNDTOP

SPARK ARRESTER

MAINTENANCEANDCLEANINGOFCHIMNEY

REPLACEMENTPARTSLIST

ANCHORPLATEFORMASONRYFIREPLACE

CHART1-OFFSETCHIMNEYINSTALLATION

CHART2-CHIMNEYHEIGHTABOVEROOF

CHART 3 - CONNECTOR PIPE CLEARANCE

INSTALLATIONRECORD

TABLE OF CONTENTS

3

CERTIFICATIONLABELS

4

10pds.

2pds.

min.

3 pds.

min. 2 pds.

Authorities require that the chimney extend not less than 3 feet

(900mm)abovethehighestpointwhereitpassesthroughtheroof

of a building and not less than 2 feet (600 mm) above any portion

of the building within 10 feet (3 m). See figure 1 and Chart 2.

The ideal location for your chimney is within the building

envelope. In cold climates, the use of external chimneys may

result in operational problems such as poor draft, excessive

condensation of combustion products and rapid accumulation of

creosote. Under these circumstances, the installation of the

chimney within the building is strongly recommended.

If the chimney must be installed on an exterior wall it is

recommended that the chimney be enclosed below the roof line

to protect the chimney from cold outdoor temperatures, this may

helpreducecondensation,creosoteformationandenhancedraft.

Provide an access door by the Tee Plug for chimney inspection

andcleaning. Theexteriorenclosuremaybeinsulated,maintaining

the required minimum air space clearance of 2" (50mm) to any

part of the chimney. Consult local building codes for cold climate

applications.

Do not install the chimney directly at the outlet of the appliance.

Interconnecting smoke pipe is required unless the appliance is

specifically approved for that type of installation.

Use only with an appliance listed by a recognized testing

authority such as Underwriters Laboratories Inc., Underwriters

Laboratories of Canada, Intertek Testing Services, Warnock

Hersey or ICBO.

The flue diameter of gas or oil fired appliances should comply

with the appropriate Installation Codes such as CAN/CSA-B139

or CAN/CSA-B149 when installed in Canada, and the Installation

Codes NFPA 54, ANSI Z223.1 and NFPA 31 in the United States.

WARNING: DONOTPLACE ANY INSULATING MATERIALSOR RUN ANY ELECTRICAL

WIRINGWITHIN THE REQUIRED AIR CLEARANCE SPACESURROUNDING THE CHIMNEY.

MAINTAIN A2"MINIMUM AIR SPACE CLEARANCE BETWEEN

INSULATED CHIMNEYSECTIONSANDCOMBUSTIBLEMATERIALS.

YourCFSentinelchimneyandconnecting stovepipediametershould

be sized in accordance with the appliance manufacturer’s

recommendations.

Plan the installation of your appliance and chimney in such a way that

both your chimney and your chimney connector (stovepipe) run is as

short and straight as possible. By having too long and / or multiple

bend installations you can reduce system draft which can affect the

operation, and or performance of your appliance and or the chimney

system. Thechimney shouldbelocatedwithinthebuildingastoavoid

cutting or altering load bearing members such as joists, rafters, studs,

etc. Ifyouhavetocutoralteranexistingloadbearingmember,special

reframing methods are required which often include doubling of

adjacent members. If such a case arises, contact your local Building

Code Official regarding local regulations and proper installation

methods.

Before commencing the installation ensure that you obtain any

necessary building permits, and that your installation will conform with

all federal and municipal building codes requirement.

Sections of the CF Sentinel chimney which pass through accessible

areasof thebuildingsuch asthroughclosets,storageareas,occupied

spaces or any place where the surface of the chimney could be

contacted by persons or combustible materials must be enclosed in

a chase. The chase may be fabricated using standard building

materials. Drywall mounted on 2” x 4” studs is typically used in this

situation. Except for installation in single and two family dwelling,

factory-built chimneys shall be enclosed with approved walls having

a fire resistance rating equal or greater than that of the floor or roof

assemblies through which they pass. The space between the outer

wall of the chimney and the enclosure shall be at least 2 inches.

TYPES OF APPLIANCES

PRE-INSTALLATION GUIDELINES

If you have a basic knowledge of carpentry and how to use hand

tools, taking on the task of installing your new venting system will

beeasy. However,itisimportantthattheseinstallationinstructions

are followed. If you choose to have your product professionally

installed, we recommend these products be installed by

professionals who are certified in Canada by WETT (Wood

Energy Technology Transfer) or l'APC (l'association des

professionels du chauffage) or NFI in the US.

Be sure that ladders are in good condition and always rest on a

level firm surface.

Be sure that electrically powered tools are properly grounded.

YOUR CHIMNEY HAS BEEN TESTED, AND LISTED USING

ALL OF THE SUPPORTS, SHIELDS, ETC., DESCRIBED HEREIN.

DELETION OR MODIFICATION OF ANY OF THE REQUIRED PARTS OR

MATERIALS MAY SERIOUSLY IMPAIR THE SAFETY OF YOUR INSTALLATION,

AND VOID THE CERTIFICATION AND OR WARRANTY OF THIS CHIMNEY.

FIGURE 1

3 ft.

min.

CANADAAPPLICATIONS

Your CF Sentinel chimney has been tested per CAN/ULC-S629

as an all fuel chimney. As such it is code approved for connection

to solid, liquid or gas fueled residential type appliances and

building heating appliances in which the maximum continuous

flue gases temperatures do not exceed 650°C (1200°F). It has

also been tested and approved to withstand temperatures of up

to 2100°F for three thirty minutes intervals.

The installation should be in accordance with the Installation

Code CAN/CSA-B365 (Solid-Fuel-Burning Appliances and

Equipment) and / or the National Building Code of Canada and

Provincial Building Code, etc. should be consulted.

May also be used with specific factory-built fireplaces listed to

UL 127 and CAN/ULC-S610 when specified in the fireplace

manufacturer's installation instructions.

U.S.A. APPLICATIONS

The CF Sentinel chimney has been tested per UL-103 as "Type

HT". As such it is code approved for connection to solid, liquid

or gas fueled residential type appliances and building heating

appliances in which the maximum continuous flue gases

temperatures do not exceed 1000°F. It has also been tested and

approved to withstand temperatures of up to 2100°F for three ten

minutes intervals.

Theinstallationshould be in accordancewith NFPA211(Standard

for Chimneys, Fireplaces, Vents and Solid Fuel fired Appliances),

and / or local and regional codes such as the International

Mechanical Code and Uniform Mechanical Code, etc.

WEAR SAFETY GLOVES WHEN HANDLING

SHEET METAL PARTS WITH SHARP EDGES

CONTACT LOCAL BUILDINGOR FIREOFFICIALS ABOUT RESTRICTIONS AND

INSTALLATIONINSPECTION INYOURAREA.

5

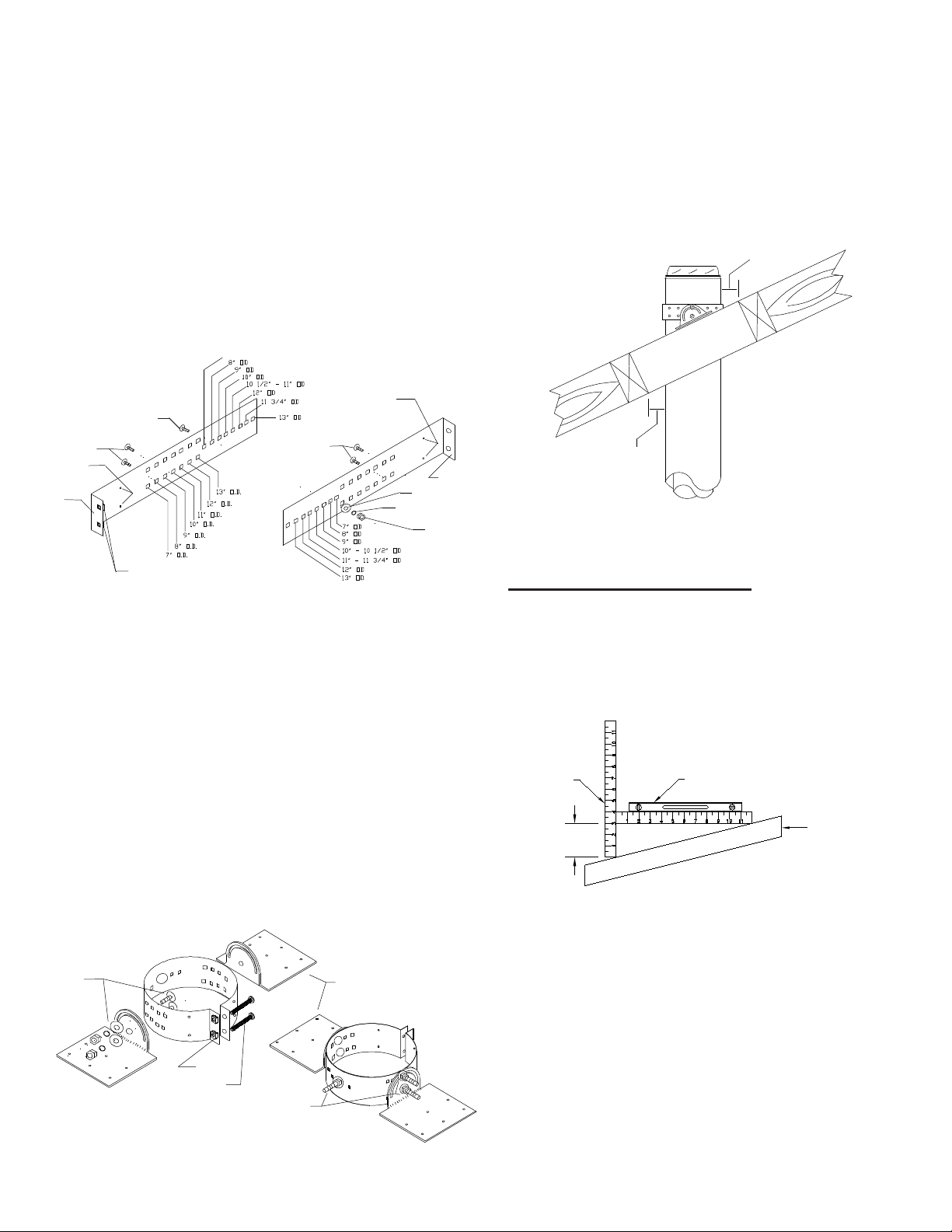

AB

6" 141/4" x 14/4"

362mm x 362mm

8"

7"

141/2" x 141/2"

369mm x 369mm 141/2" x 141/2"

369mm x 369mm

141/4" x 14/4"

362mm x 362mm

141/4" x 14/4"

362mm x 362mm 153/4" x 153/4"

400mm x 400mm 153/4" x 153/4"

400mm x 400mm

17" x 17"

432mm x 432mm 17" x 17"

432mm x 432mm

WebCoupler*

*Not exactly as shown.

Situate the chimney in the structure so that it can be installed

without cutting joists, sills, plates or load bearing partitions or

members.

Connect only one appliance to a chimney.

There should be no draft regulators on solid fuel equipment and

smoke pipe connector.

A minimum smoke pipe connector length of 3 feet (1 m) between

appliance and chimney is recommended.

Your CF Sentinel chimney system is designed for installation

using standard building materials and procedures. The following

tools may be required:

TOOLS

-safety gloves

-safety goggles

-hammer and nails

-tin snips

-tape measure

-screwdriver and pliers

-plumb line and level

-square

-keyhole saw or power jig saw

-caulking gun

Other tools or equipment may be required, depending on your

chimney location and the structure in which it is to be installed.

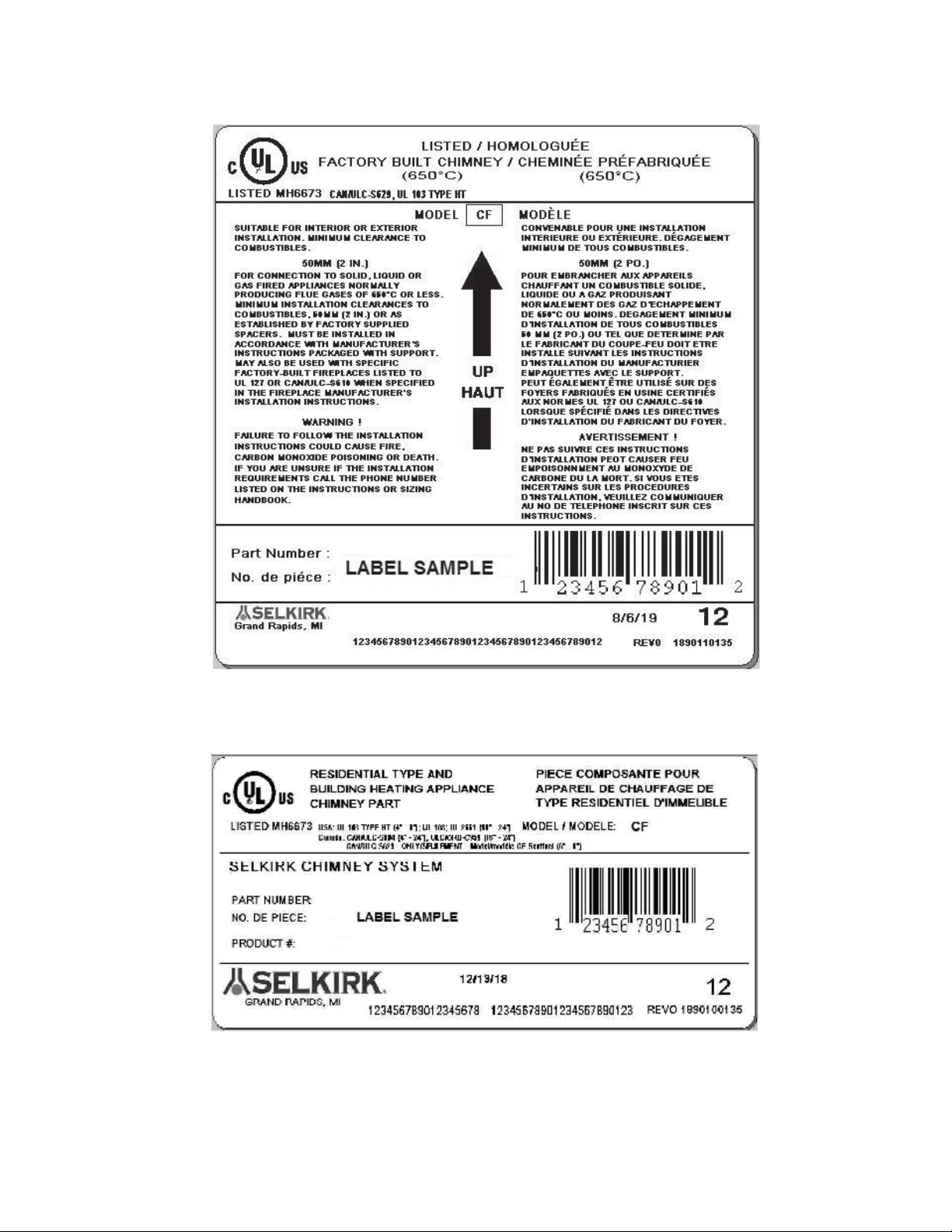

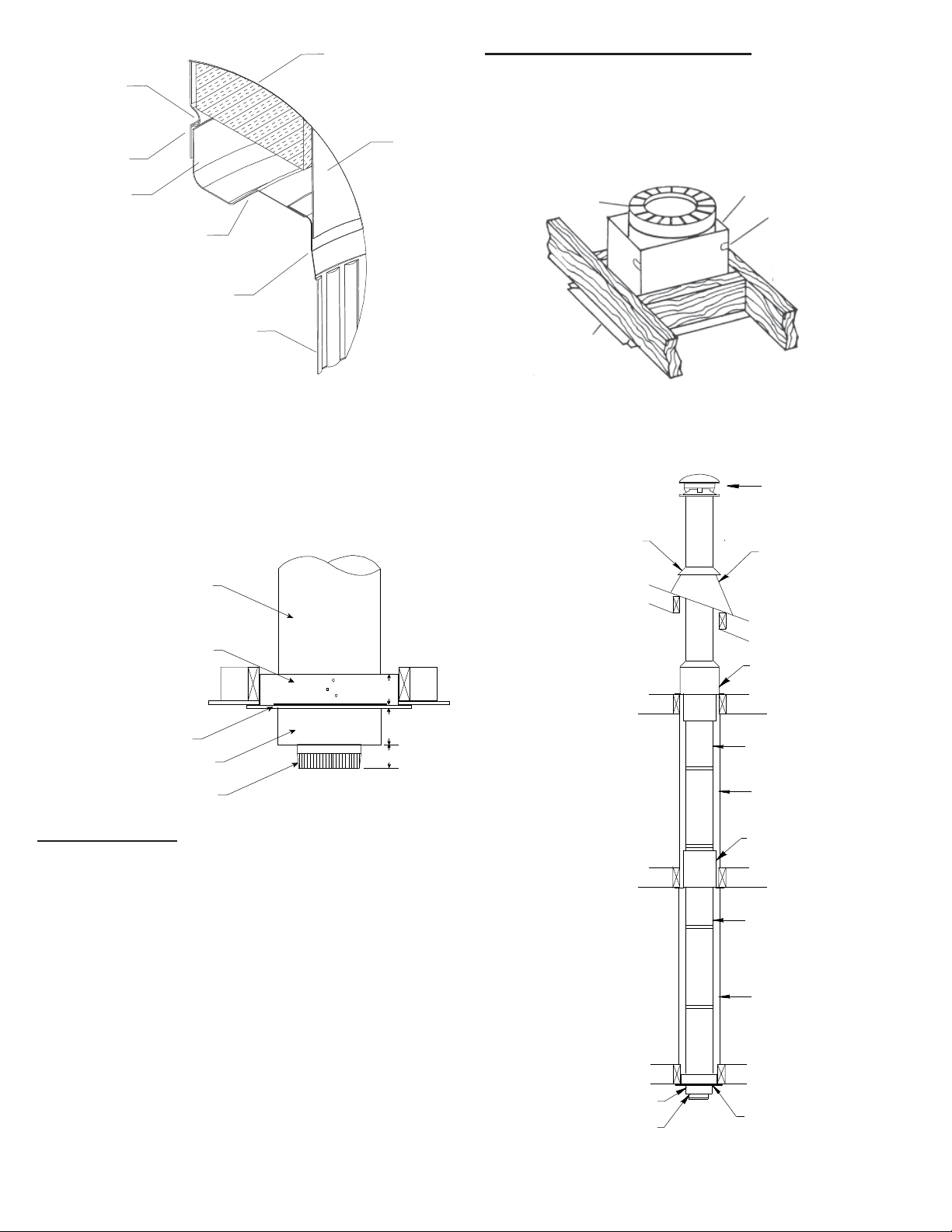

CF SENTINEL JOINT SECURITY:

High internal gas temperatures in a chimney force the internal

pipe to expand or lengthen. This, in turn, may cause the joints

to separate if they are not securely locked. The use of a chimney

cleaning brush may also cause the joints to separate if not

securely locked.

INSULATION COMPRESSION OF THE CF SENTINEL

Beforeassembling chimney lengths to one another, the insulation

on the female end (held in place with a plastic retainer) should be

below the outer bead so that it can compress during assembly.

The upper side (male end), should be full of insulation (held in

place with a white paper retainer and a web coupler) to the top of

the length. Once you have assembled the lengths together, a

locking band must be installed. With the insulation being

compressed, this will provide insulation to insulation contact (see

Figure 2).

NOTE: Whentheinsulation retainersmeltorvolatilize duringhigh

temperature operation, the compressed insulation will fill in.

FIGURE 2

Insulation

Locking Band

Locking Band

SeatedAll

Around

InsulationtoInsulation

Contact

InsulationCompressed

Outer Bead

SuspendedLength

Stainless Steel

SheetMetal

Screws FIGURE 4

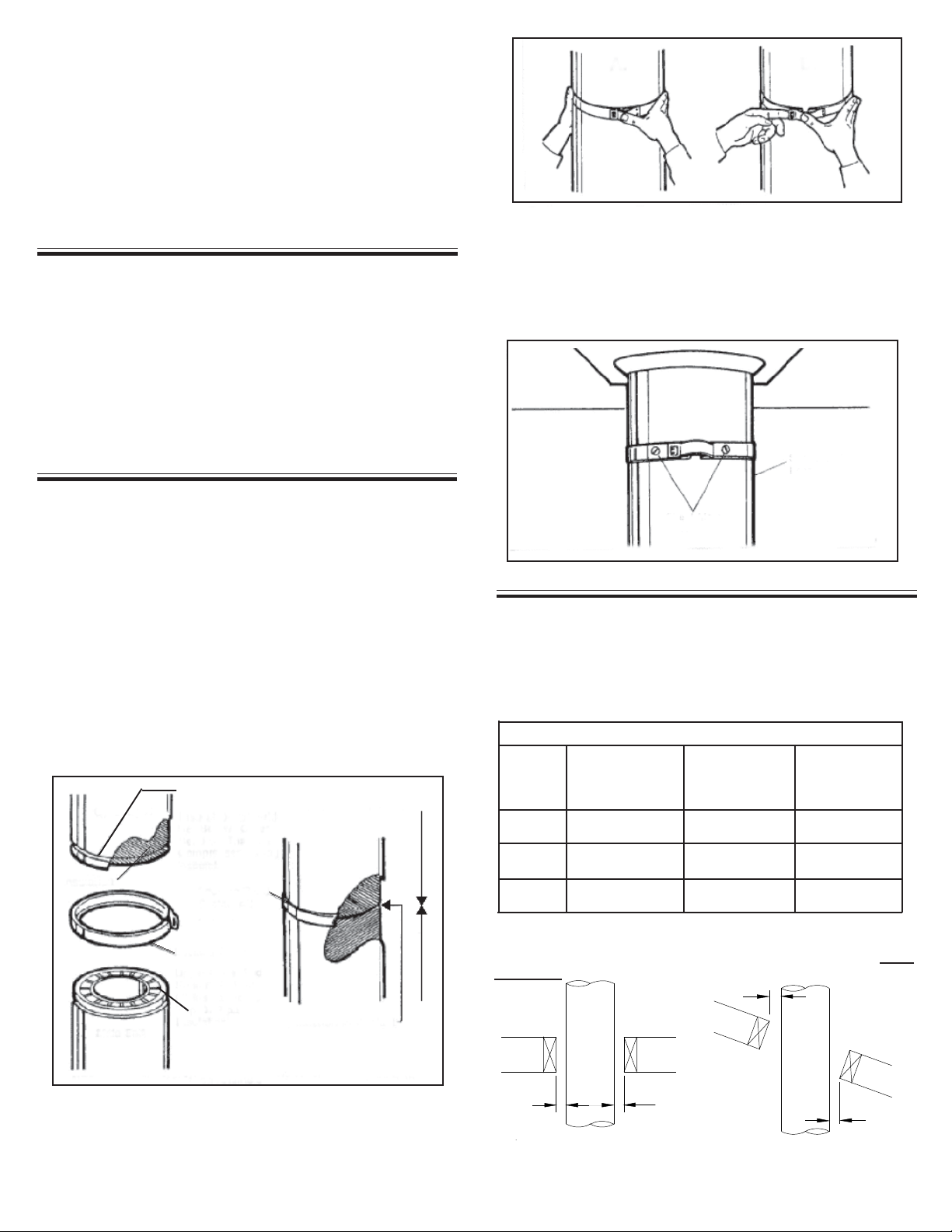

Plan your installation carefully. If possible, position the stove so

that the flue outlet is centered between joists or rafters. Drop a

plumb line to the center of the flue outlet and mark this center

point on the ceiling. Lay out and frame in all openings ensuring

the specified 2” clearance to combustibles is maintained. Refer

to Table 1 or applicable Tables for framing dimensions and mark

the appropriate cutting lines around the center point.

FRAMINGDETAILS:

2. To remove the lockband, the clasp is pushed in and then

unhooked (see Figure 3B). Lift the clasp with a screwdriver if

necessary.

3. When a chimney section is suspended e.g: below a Cathedral

Ceiling Support, the band(s) and the joints must be fastened

using two (2) #6 x 1/2" stainless steel sheet metal screws (see

Figure 4).

FIGURE 3

INSTALLING THE LOCKING BAND:

NOTE: The chimney pipe and fittings must be assembled only

with the locking bands as furnished.

1. The clasp lockbands are simply seated in the beads of the

joints and clipped together (see Figure 2 & 3A). Typical Roof

Joist Framing

FIGURE 5

Typical Joist

Framing

2"Min.

2"Min.

2"Min.

2"Min.

FIGURE 6

TABLE1

*Note: The clearance to combustibles obtained with a correctly

installed Ceiling Support Assembly in the framed opening

specified above has been tested. The 2 inch clearance does

not apply at this location.

*Ceiling

Support Wall

(Support)

Thimble

FramingDimensions

All Other

Framing

Chimney

Flue

Diameter

6

Trim Plate

Ceiling

Support

Nailing Holes

3 Nails per Sides

(4 sides)

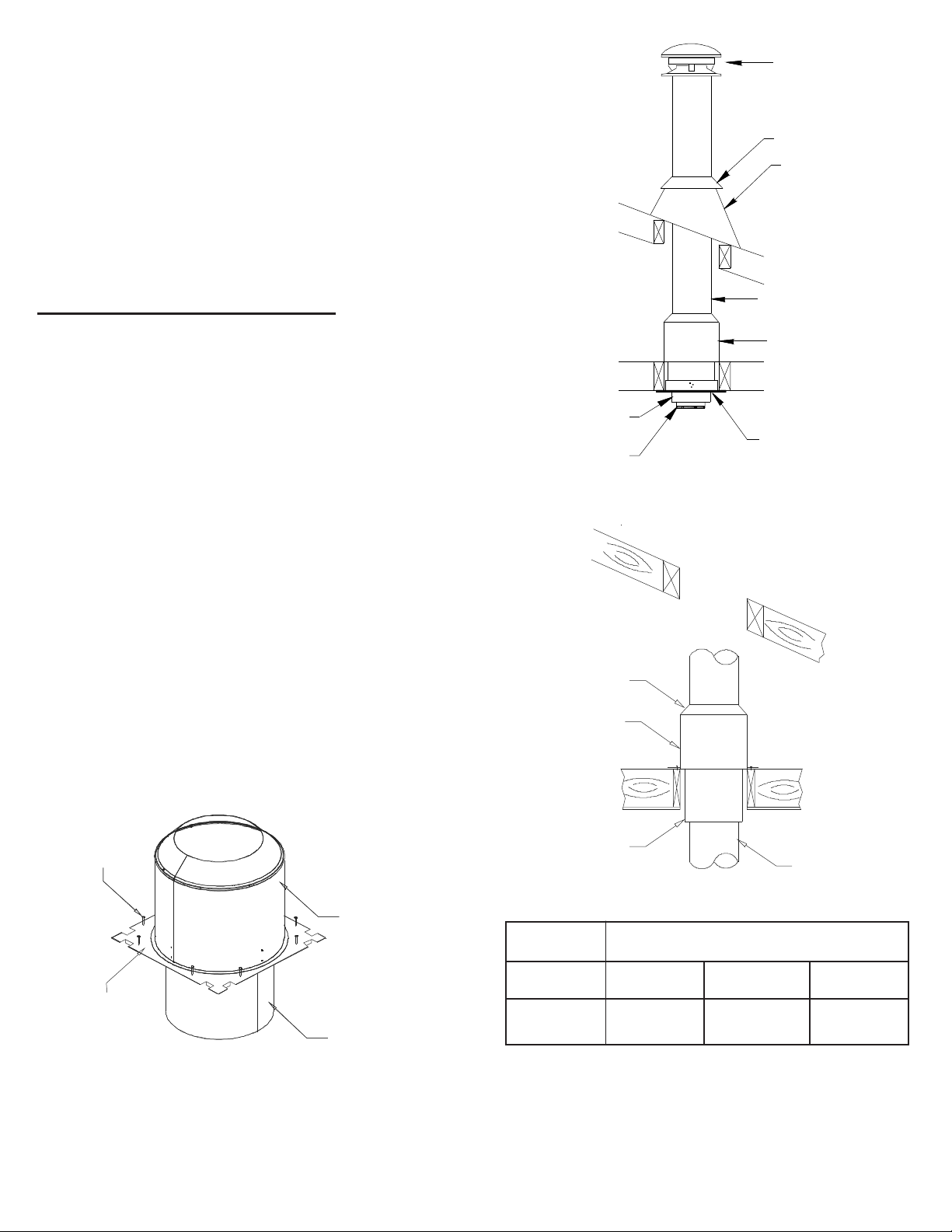

CEILING SUPPORT (CBSP)

- Suitable lengths of Chimney: - The chimney diameter should be

sized to suit the appliance.

- 15oor 30oChimney Elbow: - and suitable supports; resupport

assembly or roof support if required.

- Round Top: - To exclude rain and/or debris into the chim-

ney.

To complete a proper Ceiling Support installation, the following

parts will or may be required:

- Ceiling Support: - Required when supporting chimney with a flat

ceiling.

- Attic Insulation Shield: - Required where a chimney passes into

an unoccupied attic space.

- Firestop Joist Shield: - Required where a chimney passes from

a lower living space into an upper living space or occupied attic

space

- Roof Flashing Assembly: - Required where the chimney

penetrates a roof.

INSTALLATION PROCEDURES:

TheCFSentinel Ceiling Support will support up to 40feet(12.2m)

of chimney sections, all of which must be installed above the

support. Figures 10 & 11 illustrates the 2 most common types

of Ceiling Support Installation.

Frame (on all 4 sides) a level square opening with the inside

dimensions 14-1/4" (362 mm) square.

With the Lower Bucket removed, place the Ceiling Support

Assembly into the framed opening from below at the ceiling level

(see Figure 7).

The stub end (crimped) of the Smoke Pipe Adapter is intended

to fit inside of the connector pipe from a solid fuel appliance, thus

preventing condensate drips at the chimney connection.

Install inter-connecting stove pipe following appliance

manufactruer's instructions and appropriate building code re-

quirements keeping in mind that the stove pipe run should be as

short and straight as possible and secured in place with a

minimumof 3sheetmetalscrews per joint. Generally, for a wood

burning appliance installation, an 18" minimum clearance to

combustibles must be maintained for the stove pipe. NOTE: The

exception to this is a double wall stove pipe, such as Selkirk's

Model DSP which can be installed at reduced clearances to

combustibles. See separate installation instructions for more

details.

FIGURE8

SMOKE PIPE ADAPTER (SPA)

FIGURE 7

Basecap w/ Built-In

Smoke Pipe Adapter

Chimney

Length

Finish nailing through all the pre-punched holes (12 nails total)

and fasten the finishing plate onto the ceiling with the 4 supplied

black wood screws. Replace the Lower Bucket into the Ceiling

Support (see Figure 8).

Drive one nail, 1-1/2" common or spiral, part way into each of the

four (4) nailing areas of the support. Check that the trim plate is

level and flush (see Figure 7). You may substitute in lieu of nails

#8 x 1-1/2" wood screws.

Lower Bucket

Insert the Lower

Bucket into the

Ceiling Support

BEFORE LOWERING THE FIRST CHIMNEY LENGTH:

The Basecap Assembly with the short crimped Smoke Pipe

Adapter must be inserted into the female end of the first length

(see Figure 9a).

-Insertthe short portion of the short crimped Smoke PipeAdapter

into the Basecap.

- Ensure the Basecap portion is located on the inside of the

exterior casing of the insulated chimney (flush to the bottom of

the inward bead) and the Smoke Pipe portion is located over the

inner liner of the Chimney Length (see diagram 9b).

FIGURE9a

Installed Ceiling Support

All openings should be square (all four sides), plumb and in

perfect alignment with each other (see figure 5).

Forslopingroofsand/orceilings,ensurethattheframingdimension

is measured in the horizontal plane (see figure 6).

7

3"

4-1/8"

2-1/2"

2-1/2"

4-1/8"

3"

FIGURE11

Floor, Ceiling Joist

(Framed all 4 sides)

Lower Bucket

FIGURE9c

TrimPlate

Smoke Pipe Adapter

Lower Bucket

CeilingSupport

Lower the prepared Chimney Length into the Lower Bucket.

Ensure that the Chimney Length rests on the Lower Bucket into

the Ceiling Support (see Figure 9c).

NOTE: Any length of CF Sentinel Chimney can be used.

There is no special "Starter" length required with the

Ceiling Support. Make sure the length is long enough to be

above the floor level or above the Attic Insulation Shield.

Continue adding chimney lengths until a height of about 2 feet

below the next ceiling level is achieved.

Chimney

Length

Inner Liner

of Chimney

Length

Insulation between

Outer Casing and Inner

Liner of Chimney

Length

Basecap Portion

(painted black)

Short crimped Smoke

Pipe Adapter Portion

Outer Casing of

Chimney Length

FIGURE9b

Inward bead of

outer casing

Beveled Portion Up

Crimpedend

Towards Appliance

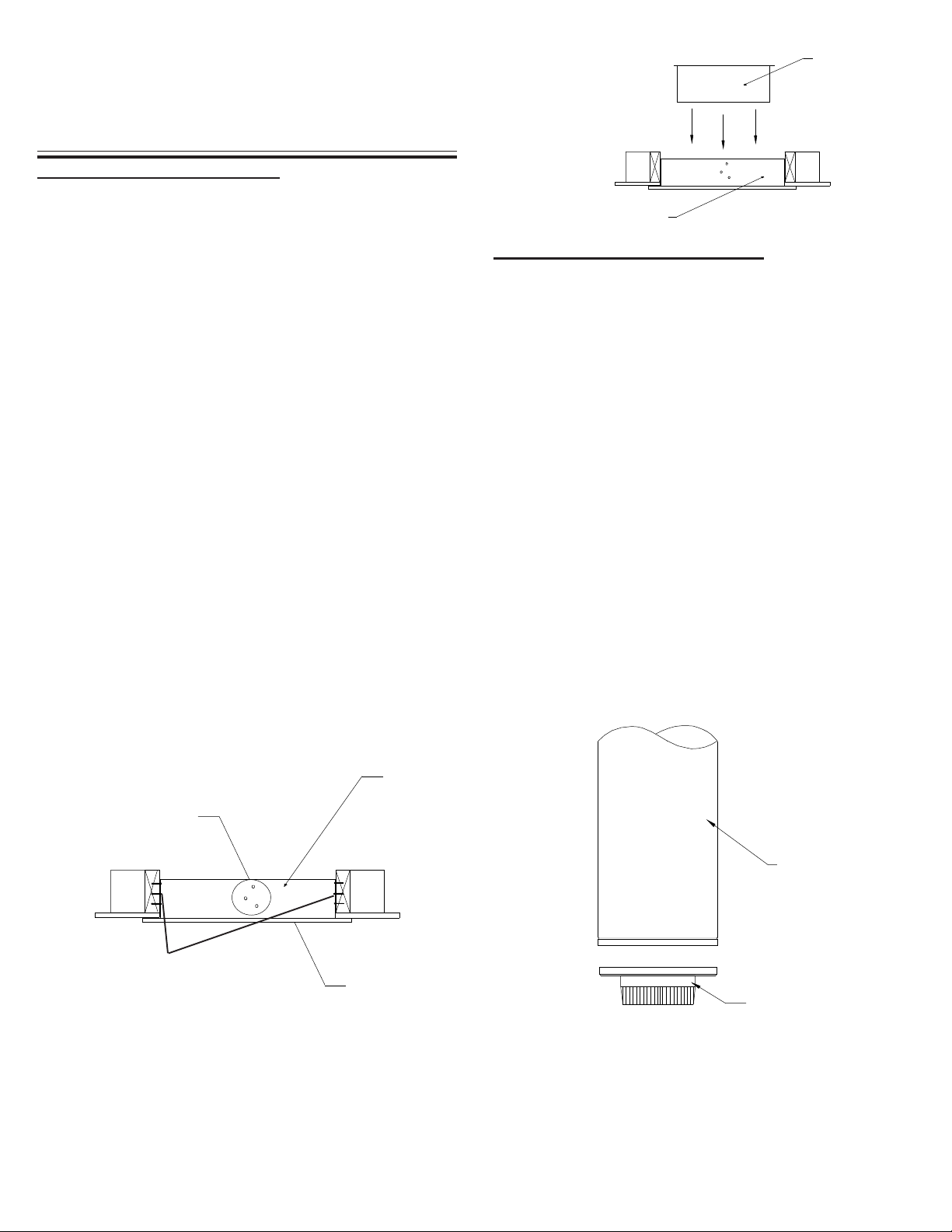

FIRESTOP JOIST SHIELD (JS)

A Firestop Joist Shield (JS) must be installed where the

chimney passes from one living space to another living space as

shown in figure 11. It is designed to provide proper firestopping

between floors and to keep direct radiation from the chimney away

from the joist framing.

RoundTop

StormCollar RoofFlashing

Attic Insulation

Shield

FramedEnclosure2"(50mm)

clearance from chimney to

combustiblewall

ChimneySections

ChimneySections

Living Space

Attic Space

Floor, Ceiling Joist

(Framed all 4 sides)

Floor, Ceiling Joist

(Framed all 4 sides)

Roof Joist

(Framed all 4 sides)

Two Story

Basement Installation

CeilingSupport

Living Space

FramedEnclosure2"

(50mm)clearancefrom

chimney to combustible

wall

Smoke Pipe Adapter

Firestop Joist Shield

FIGURE10

Firestop Joist

ShieldPositioned

intoFramingfrom

below

CloseBox Corners

UsingTabs

ChimneyLength

NailSideFlanges

Securely To Bottom

ofFraming

FIRESTOPPING

Firestopping is required at every joist level. Wherever a chimney

passes through a ceiling or floor, through a wall, or into an

enclosure, it must be firestopped. No firestopping is required in

conjunction with a Ceiling Support installed as shown in Figures

11, the Ceiling Support provides the firestopping.

A fire stop performs the following essential functions for both

dwelling and the chimney:

- Together with a fully framed opening (all four sides), it controls

vertical and horizontal spread of any fire external to the chimney.

- It stabilizes the chimney in the framed opening and defines and

maintains the required AIR SPACE clearance to combustibles.

- It reduces heat losses from the dwelling by blocking vertical air

circulation in the spae around the chimney.

- When located at a ceiling below a roof flashing (or below a roof

support) it helps provide stability for chimney extending above the

roof.

- At the level where the chimney penetrates the air/vapour bariier,

special attention is required. Seal the vapour barrier to the Ceiling

Support, Attic Shield (Joist Shield if the chimney is enclosed in the

attic) or Wall Thimble using an appropriate caulking compound as

per the requirement of local authorities.

8

14-1/4 x14-1/4

362 x 362 16-3/4 x16-3/4

426 x 426

15-1/2 x15-1/2

394 x 394

6" 7" 8"

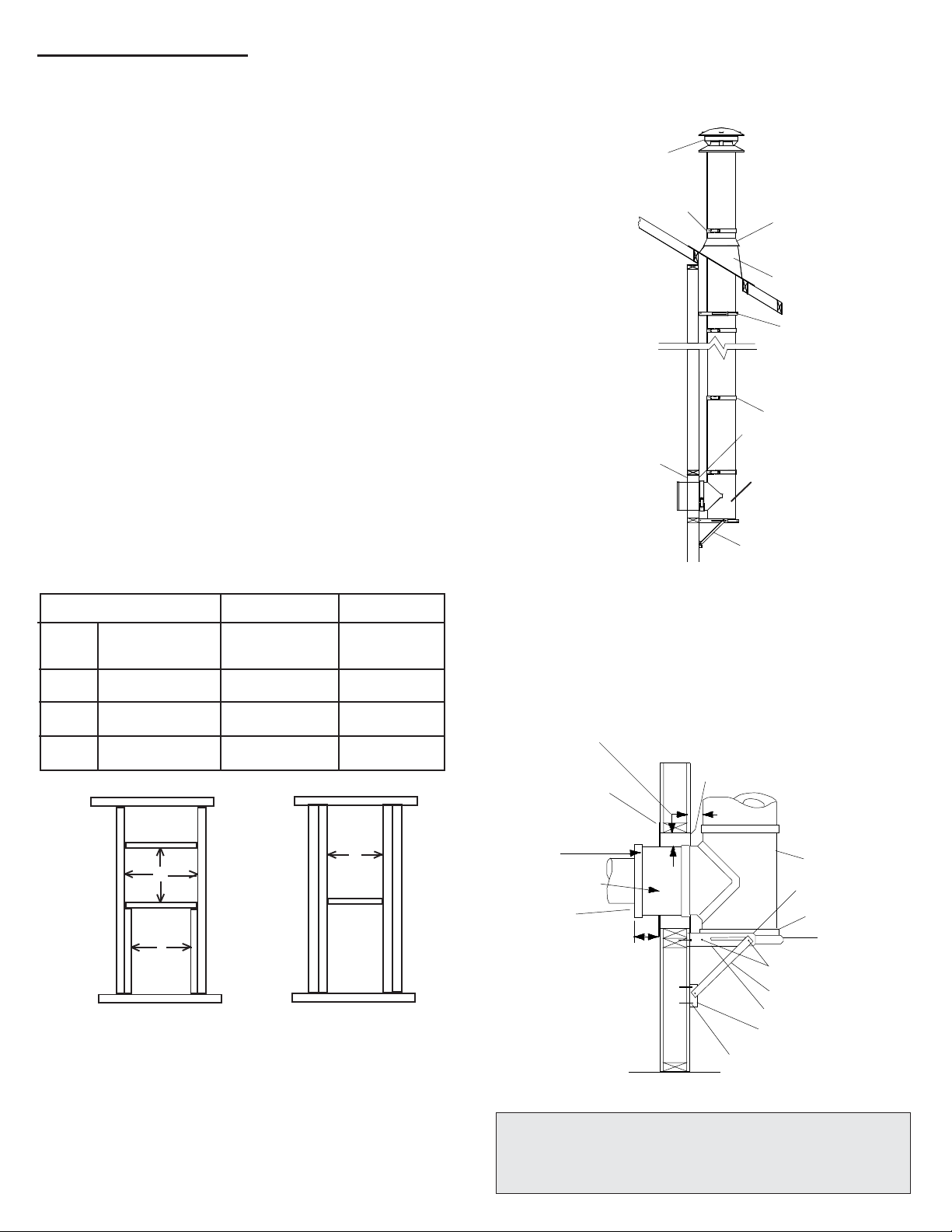

The Attic Insulation Shield (AIS) provides 2 features: it comes

fully assembled with a built-in telescoping bottom shield,

eliminating the need for field assembly.The function of the Attic

InsulationShield(or a complete enclosure) is to keep insulation from

coming into contact with the chimney. Certain insulations made

of cellulose fiber (old newspapers, processed wood) may ignite

and smolder due to heat trapped by contact with the chimney.

When this smoldering fire reaches ordinary wood framing, a

flaming fire may resuilt. However, even without a flame, a

smoldering fire may create noxious gases and cause great

property damage.

An Attic Insulation Shield (AIS) must be installed where the chimney

enters an attic space. The Attic Insulation Shield is designed to

keep insulation materials from coming into contact with the chimney

and will protect up to a 10 inch 250mm) thickness of insulation plus

thedepth of the ceiling joists. If insulation is blown in and adheres

to the chimney pipe, it should be brushed off to eliminate any

possible contact of this material with the chimney when it is in

use.

The height of the AIS must accomodate the amount of insulation

as required by the National Building Code. Where height

restrictions will not permit the use of the Attic Insulation Shield, it is

permissible to construct an enclosure with the required minimum

air space clearance of 2" (50mm) to the chimney all the way to the

underside of the roof deck. In this application you will install a

Firestop Joist Shield (JS) at the ceiling level, with the exception of

a Single Story Installation (see Figure 13).

ATTIC INSULATION SHIELD (AIS)

Nail the AIS base to the framing dimensions with at least 2 per

side using 2d (1") spiral nails or 1" x #8 wood screws.

FramingDimensions

forAtticInsulationShield

DIAMETER

OFCHIMNEY

TABLE2

FRAMED

OPENING

Single Story

Installation

Attic Space

Roof Flashing

SmokePipeAdapter

RoundTop

StormCollar

ChimneySections

Attic Insulation Shield

CeilingSupport

Ceiling Joist

(Framed all 4 sides)

FIGURE13

Roof Joist

(Framed all 4 sides)

Lower Bucket

FIGURE 14 - Attic Insulation Shield

Fully frame a level square opening (all four sides) for 2" ( 50mm)

clearance from the outside of the chimney to the inside of the

frame. Place the Firestop Joist Shield (JS) up into the framed

opening from below the joist framing and nail in place using 1"

spiral nails as per Figure 10. Ensure no insulation or debris is

within the 2" air space clearance around the chimney. This

includes the air spaces between the Firestop Joist Shield (JS)

and the joist framing.

When the chimney is enclosed in the attic area, a Firestop Joist

Shield (JS) must be installed at the ceiling level. If the base of the

Firestop Joist Shield (JS) does not fit flush with the ceiling frame,

measure the distance that the base is sitting below the framing

and trim that amount off the top of the Firestop Joist Shield (JS)

before securing into place.

Attic Insulation

Shield(AIS)

Telescoping

Joist Shield

Nail Base to

Framing

Base (Fire Stop)

FIGURE12

Attic Insulation Shield

Intergrated Storm Collar

Telescoping Joist Shield Chimney Section

Attic space

For proper installation, the attic opening must be fully framed at

2 inches of clearance to the chimney pipe with framing material

of the same dimension as the ceiling joists (as per Framing

Dimension Table 2). The tabs on the base plate of the AIS are

inserted in the framed opening around the chimney. NOTE: This

only applies to the 6" AIS. On the 7" and 8" AIS, the tabs will

require to be flattened out and the AIS centered over the

framed opening.

When an Attic Insulation Shield is required above the Ceiling

Support into an attic as shown in Figure 13, ensure that the base

of the shield is flush with the top of the joist framing and nailed in

place. The telescoping portion of the AIS will eliminate the need

to trim the bottom when installed immediately above this support.

When fully exended, the AIS will also provide joist shielding when

installed in a 2 story main floor or basement applications (see

Figures 11 & 15).

9

SmokePipeAdapter

Elbow

ElbowSupportBand

Locking Bands

Elbow

Ceiling Joist

(Framed all 4 sides)

Floor, Ceiling Joist

(Framed all 4 sides)

RoundTop

StormCollar Roof Flashing

ChimneySections

Roof Joist

(Framed all 4 sides)

Elbow Support Straps

Locking Bands

CeilingSupport

Living Space

Attic Space Attic Insulation Shield

Offset(Elbow)Installation

FIGURE16

Lower Bucket

FramedEnclosure2"(50mm)

clearance from chimney to

combustiblewall

Install a Resupport Assembly on the vertical length just above the

highest elbow. Securely clamp the Support Band to the chimney

just above the locking band at the joint. Attach the Support Straps

to the Support Band assembly and nail the Support Straps to the

framingusing 1-1/2”nailsor#8x1-1/2"woodscrews (2perstraps).

See Figures 17 and 18.

The weight carrying capacity of the support, which depends on

the angle of the straps, and the security of attachment is

adequate for 9 m (30') of Model CF Chimney pipe.

ELBOW INSTALLATION

Framed Enclosure 2" (50mm)

clearance from chimney to

combustible wall

Living Space

Roof Flashing

CeilingSupport

Smoke Pipe Adapter

RoundTop

Storm Collar

Floor, Ceiling Joist

(Framed all 4 sides)

Ceiling Joist

(Framed all 4 sides)

Attic Insulation Shield

Attic Space

Chimney Sections

Two Story

Main Floor Installation

Roof Joist

(Framed all 4 sides)

Lower Bucket

NOTE:Toreducecoldairinfiltrationintothedwelling you can

installtheoptionalUniversalShieldingInsulation(SUSI)

into the Attic Insulation Shield. See separate installation

instructions.

FIGURE15

NOTE: At the level where the chimney penetrates the air / vapour

barrier,specialattentionisrequired. Sealthevapourbarriertothe

Ceiling Plate of the Ceiling Support, Wall Thimble or Attic

Insulation Shield using an appropriate caulking compound as per

the requirement of local authorities.

StainlessSteel

SheetMetal

Screws

FIGURE18

Two pairs (four) of 15oor 30oelbows may be used in an interior

installation to provide an offset in order to avoid cutting of joists and

to clear other obstructions.

Locking bands must be used at each joints. For added security

when forming an offset, it is required to fsten the joints using two

(2) X6 x 1/2" stainless steel sheet metal screws through the pro-

punched holes in the locking bands (see Figure 16).

The maximum permissible angle with solid fuel CF installation is 30

degrees. Combiningoffsetsforgreaterangleisnotpermitted. The

vertical run of chimney above an offset must be supported using an

Interior Resupport Assembly. Each Interior Resupport Assembly

will support 30 feet (9 m) of chimney and the maximum length of

chimney allowed between the elbows is 6 feet.

See Chart 1 for Offset Chimney Installation at the back of these

instructions for more information.

Never install an elbow in a joist area. Chimney sections must

pass vertically through a framed joist areas.

During installation provide supplementary support for the offset

section to avoid undue stress on connected elbows.

SupportBand

Straps

Locate Support

BandBelow

Locking Band at

Joint

Bend Straps

Over Framing,

Nail Securely

FIGURE17

10

EF

F

E

11-1/2" (292mm)

12-3/4" (324mm)

14" (356mm)

14-1/2" (369mm)

15-3/4" (400mm)

17" (432mm)

10-5/8" (270mm)

11-7/8" (302mm)

13-1/8" (334mm)

6"

7"

8"

F

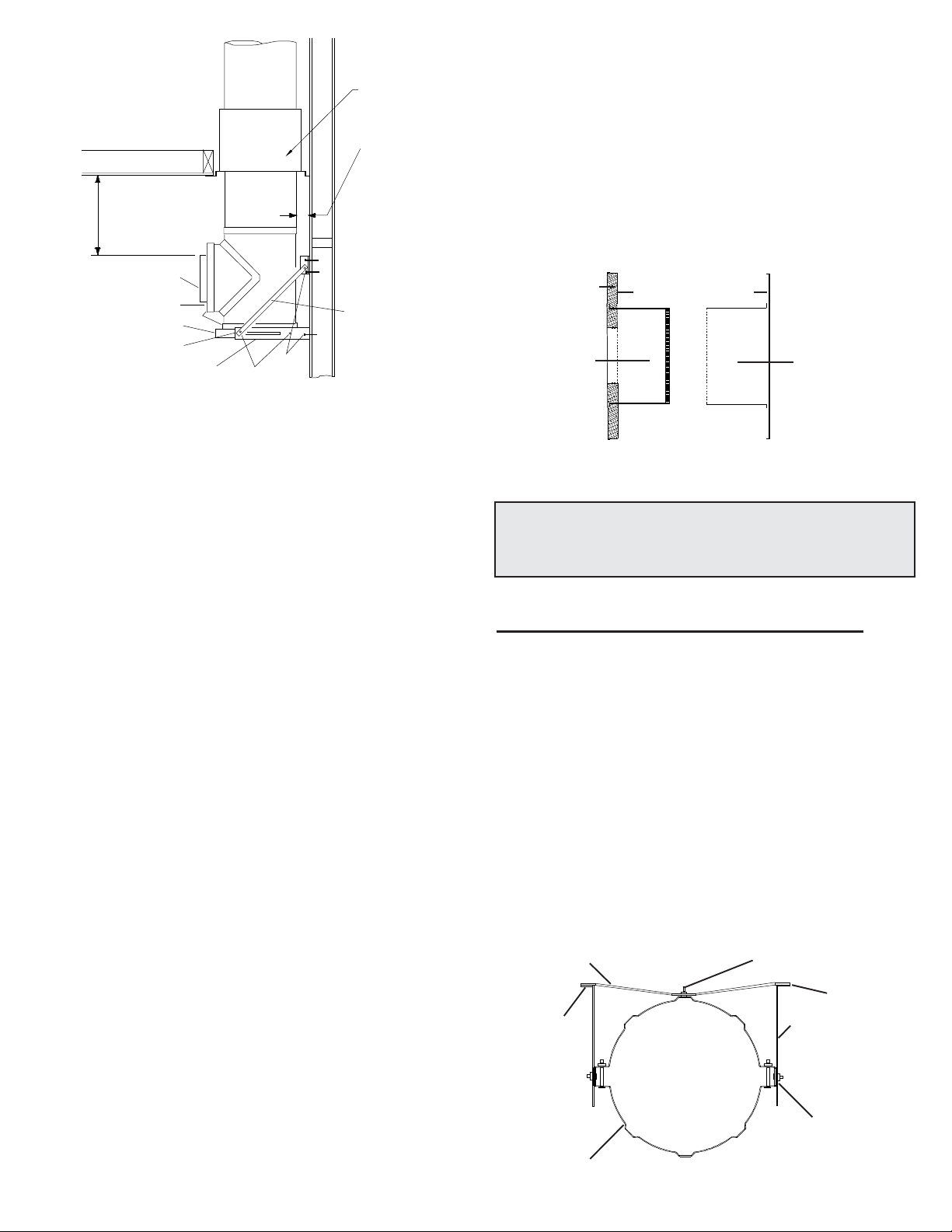

WALL SUPPORT (WSP)

To complete a proper Wall Support installation, the following parts

may be required:

- Wall Support Package: - Intended for a through-the-wall installa-

tion where the chimney has a lateral connection.

- Adjustable Roof Flashing: - Required when the chimney

penetrates a roof or a roof overhang.

- Insulated Tee: - Required when the chimney is installed through

and along a vertical wall either on the exterior or interior.

- Wall Bands: - Required to provide lateral support to the chimney.

- Suitable lengths of chimney: - The chimney diameter should be

sized to suit the appliance.

- Interior Wall Plate and Exterior Wall Plate: - Required when going

through a combustible wall.

- Insulated Wall Thimble: - Required to satisfy through-the-wall

installation where framing an opening may not be practical.

- Round Top: - To exclude rain and/or leaves into the chimney.

The CF Sentinel Adjustable Wall Support will support up to 40 feet

(12.2 m) of chimney, all of which must be above the support.

1. Determine the center line of the lateral connection (horizontal

length through the wall) and frame in your opening to the dimen-

sions specified in Table 3. For a non-combustible wall (concrete

blockor pouredfoundation),cutahole 1/8"greaterthantheoutside

diameter of the chimney as per Table 3. DO NOT PLACE ANY

LOOSE INSULATION around the horizontal chimney length within

the framed opening when using a Wall Plate Spacer or Insulated

Wall Plate Spacer. Maintain the required minimum 2" (50mm) air

space clearance to combustible materials.

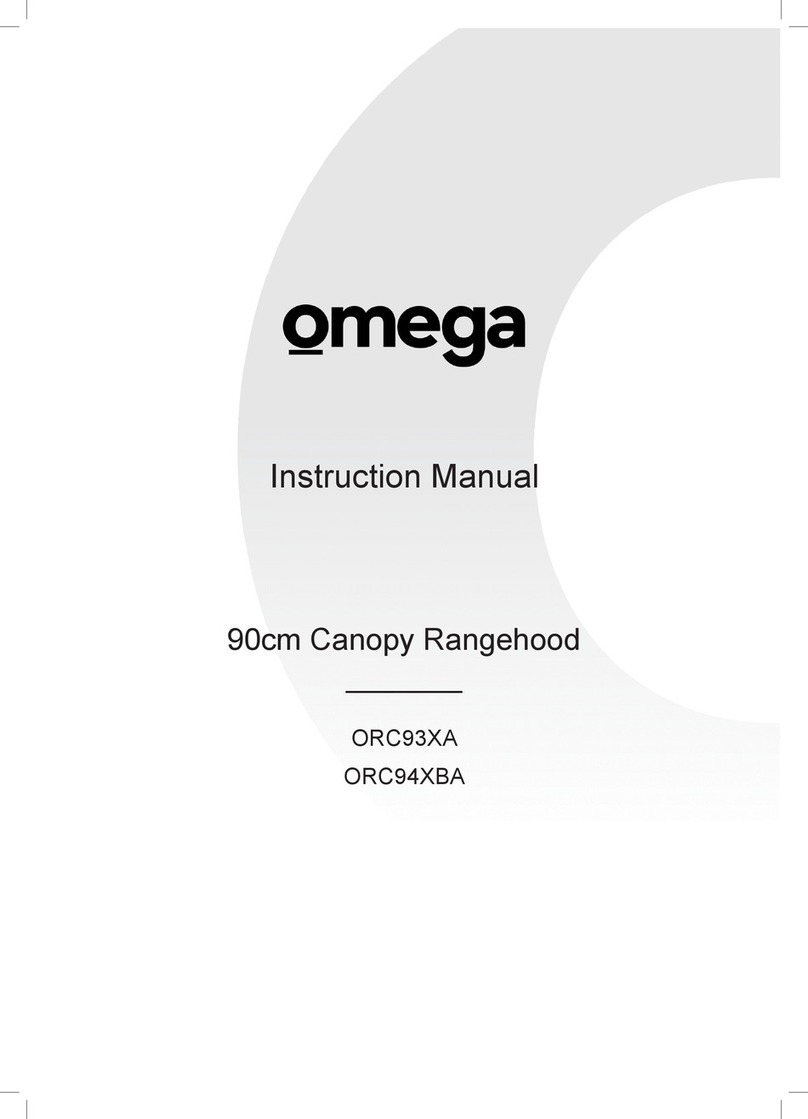

2. Assemble braces, brackets and angles to the base plate using 1/

4" nuts and bolts, with braces up or down as necessary (DOWN IF

CHIMNEY GOES THROUGH WALL) as per Figure 19 & 20a and if

it is an interior wall support installation (Figure 20b).

3. Nailbracketsand angles to framing temporarily making sure that

the base plate is level (and positioned to allow for the installation

of the wall plates, if the chimney goes through the wall).

TABLE3

Chimney

Size Hole

Non Combustible Framed Opening

Combustible Framing

For Bracing

A.

Framingforthroughthewall

InsulatedTee

B.

FramingforTeefacingaway

fromthewall

6. If the Tee is located on an outdoor wall, place the exterior wall

plate over the horizontal Tee branch, and attach an appropriate

insulated chimney length to the Tee branch. Secure in place with

the supplied locking band. Ensure that the clasp of the locking

band is facing down to prevent any water from collecting in the

lockingbandiflockingbandispositioned on the exterior of the wall.

NOTE: Interior or Exterior Plates can be substituted with the

Insulated Wall Thimble. In a combustible wall the opening must

be framed in (see Table 3).

Round Top

Storm Collar

Roof Flashing

Wall Plate Spacer

Wall Band

Locking Band

Exterior Wall

Plate (Louvered)

Insulated Tee

Angle Bracket

FIGURE19

4. Mark, and drill 5/32" pilot holes in the framing for the lag screw

location, or install masonry anchors in proper locations.

5. Remove nails, install lag screws or anchor bolts in all the holes

and tighten all bolts in the assembly.

FIGURE20A

ExteriorWallSupport Installation

Base Plate

Bolts

Angle Brace

Wall Bracket

Wall Angle secured to studs

with lag screws

Lag screws

Insulated Tee

Locking Band

Tee Plug with lugs

Exterior Wall Plate (louvered)

Maintain 2"

(50mm)

Min. clearance

Wall Plate Spacer

Locking

Band

9" Pipe Section

Min.

3" (76mm) Min.

39" (990mm) Max.

NOTE: THE CHIMNEY MUST EXTEND AT LEAST

3” (75 MM) INTO THE LIVING SPACE WHERE THE

SMOKE PIPE ADAPTER WILL BE ATTACHED TO THE

CHIMNEY BRANCH.

Locking Band

Smoke Pipe

Adapter

11

NOTE: If complete framing of the vertical wall opening is not

practical, the Wall Plate Spacer and the Exterior Wall Plate must

be substituted with an Insulated Wall Thimble (see Figure 21). It

is designed for use in accommodating unframed openings while

maintaining thechimney'srequired50mm(2")airspaceclearance

to combustibles.

- Install the Wall Thimble before installing the Wall Support

assembly.

- Ensure that the proper framing dimensions is respected below

the opening to accommodate the Wall Support (see F "Framing

for Bracing" in Table 3).

Interior Wall Support Installation

FIGURE20B

Insulated Wall Thimble

FIGURE21

Tee Plug retained by twist lugs

WallBracket

BasePlate

LockingBand

SmokePipeAdapter

BaseCap

Bolt Lag

Screws

AngleBrace

Refer to the Installation

Codes for clearance to

single wall pipe.

Normally 18" (450mm)

minimum clearance is

required for solid fuel

fired appliance.

2" (50mm)

Minimum

Clearance

Interiorportionof

InsulatedWall

Thimble

Exteriorportionof

InsulatedWall

Thimble

Telescoping adjustment

from 6" to 11"

InsulationBlanket

NOTE: To reduce cold air infiltration into the dwelling

you can install the optional Universal Shielding Insula-

tion (SUSI) into the Insulated Wall Thimble. See sepa-

rate installation instructions packaged with the SUSI.

WallBand

FIGURE22

1-3/4"CarriageBolt

Strap Under

WallBracket

Perforated Straps

LagScrews

Support Band

WallBracket

Pivot Screw In Slot

WALL BAND INSTALLATION (WB)

1. The required 2" (50mm) minimum clearance is established by

the 1-3/4" center (carriage) bolt. Place the 1-3/4" carriage bolt

through the center offset of the band half nearest the wall. Place

single hole ends of the perforated straps over this bolt. Install nut

tight against strap so that straps are horizontal (as per Figure 22).

2. Clamp the two halves of the support band around the chimney

pipe using the long bolts through the band end tabs. First install

the pivot screws.

3. Place the wall brackets (long slotted parts) over the pivot

screws projecting out from the end tabs and hand tighten.

4. Line up the perforated straps and wall brackets, then mark

position on wall for lag screws or anchors to go through both the

straps and brackets.

9. After checking fit, secure Tee to integral basecap of base plate

with a locking band. Install the Tee Plug and turn the two (2) twist

lugs.

10. Use a non-hardening high-temperature sealant (500oF) to

seal around the exterior portion of the horizontal chimney length

where it enters one of the following: Exterior Wall Plate, Insulated

Wall Thimble or a concrete wall.

11. NOTE: Only CF Sentinel chimney must extend through-the-

wall. Use the Wall Plate Spacer (or the interior portion of the

Insulated Wall Thimble) on the interior wall to center and support

the horizontal extension. Remember that the chimney pipe

length selected must extend at least 3" (76mm) beyond the wall

and must be centered in the wall opening. The maximum length

of pipe out from the wall is 39" (990mm).

12. Chimney lengths above the Tee are simply stacked and

secured in place with the supplied Locking Bands.

13. To ensure chimney stability above the wall support, Wall

Bands must be used at every 8 to 12 feet (2.4 to 3.6m) intervals

above the support.

8. If the Tee and the Chimney will be fully enclosed in a chase or

shaft or the wall is non-combustible, the exterior wall plate need

not be used.

7. Place this whole assembly (Insulated Tee, Chimney Length

and Exterior Wall Plate) into the wall opening and onto the base

to check centering and clearances. Make sure there are no

interferences. If the Tee is outdoors, keep in mind that the louver

openings in the Exterior Wall Plate must be down to keep the rain

out.

Firestop Joist

Shield Installed

at Ceiling

Level

- If wall thickness is less than 6 inches, trim round inner shield

accordingly.

- Install thimble before installing the Wall Support assembly.

- Insert the 2 halves from opposite sides of the wall. The painted/

insulated section is to be installed from the interior side. Secure

using the supplied black screws.

- The unpainted/exterior half has the larger diameter shield and

simply slides over the interior half. Fasten to wall with suitable

fasteners.

- Seal the perimeter of the exterior plate using an appropriate

exterior sealant.

12

The bottom chimney length(s) must protrude into the living space

so that proper clearances are maintained from the stove pipe

connector to the lower side of the ceiling (see Chart 3 in the back

of these instructions for more details). Do not offset the CF

Sentinel chimney below the Cathedral Ceiling Support Box.

Install additional chimney lengths with locking bands until the

required height above the roof is achieved. NOTE: As previously

mentioned, when a chimney is suspended below the box, locking

bands and joints must be fastened using two (2) #6 x 1/2"

stainless steel sheet metal screws (as per Figure 4).

CathedralCeiling

SupportInstallation

FIGURE23

StormCollar

Roof Brace Kit

RoundTop

RoofFlashing

SmokePipeAdaptor

CF Sentinel chimney to be a

minimum distance of 4"

(101.6mm) below Support Box

Support Band

ROOF SUPPORT (URSA)

50mm(2")MinimumAir

SpaceClearance

DecorativeAdapter

CathedralSupportBox

Install the Support Band on the chimney length at the desired

position by assembling the support bands using the 2 carriage

bolts and nuts. NOTE: A minimum of 4" of an insulated

chimney length must protrude below the Cathedral Support

Box for stability (see Chart 3 at the back of these instructions

for more details). Snug nuts to bolts, do not over-tighten so that

the band deflects the chimney outer casing. Secure the band to

the chimney outer casing by screwing the eight (8) stainless

steel sheet metal screws through the draw band and into the

outercasing (for ease of attachment use a 3/32" hole). Lower the

chimney length down through the opening in the bottom of the

Support Box, so that the Support Band makes contact with the

bottomoftheSupport Box (See Figure 23).NOTE: The maleend

NOTE: If the chimney penetrates an overhang (soffit) cut an

opening with 2" clearance all around and install a Joist Shield on

theundersideoftheoverhang. Iftheatticisopentotheoverhang,

close off the access with suitable building materials ensuring that

a 2" (50mm) air space is maintained. From above install a roof

flashing and storm collar by following the Roof Flashing installa-

tion section. If the overhang is not deep enough to allow the

chimney to be fully installed within the overhang, it will be

necessary to cut away the overang. Ensure that a 2" (50mm)

clearance all around the chimney is respected. Framing and

flashing the sides of the opening will be required. Install a Wall

Band at this level.

To complete a proper Cathedral Ceiling Support installation, the

following parts are required:

- Cathedral Ceiling Support: - Includes a painted black support

box, a two-piece support band, 4 painted ceiling trim angles (2

short, 2 long), decorative sleeve, smoke pipe adapter and

hardware package.

- Roof Flashing Assembly:- Required when the chimney pen-

etrates a roof.

- Suitable lengths of chimney: - The chimney diameter should

be sized to suit the appliance.

- Round Top:- To exclude rain and/or leaves into the chimney.

The CF Sentinel Cathedral Ceiling Support will support a total of

15feet (4.6m)ofchimney,ofwhich10ft(3m)canbesupportedbelow

the box. When a chimney is suspended below the box, the locking

bands and joints must be fastened using two (2) #6 x1/2" stainless

steel sheet metal screws (drill 3/32 holes) as per Figure 23.

CATHEDRAL CEILING SUPPORT (CCB)

The Cathedral Ceiling Support Box is manufactured to an overall

outerdimension of 1/8" (6mm) less than the minimum dimensions

specified in the Framing Details section (Table 1) and 17-1/2"

(444mm) in height.

After framing in your opening to the dimensions specified in the

Framing Details section, slide the Cathedral Support box into the

joist opening. Once the box is at the desired level, ensure that

theboxislevelandnailtheboxtotheframing using three 2" spiral

nails or #8 x 1-1/2" wood screws per side. The excess material

sticking above the roof can either be trimmed off before attaching

the box to the framing or, after it is installed, the corners can be cut

and the excess material folded down and secured onto the roof

deck.

DecorativeAdapter

May be installed flush on

the lowest side of the

ceiling

Followappliance

instructionsfor

properconnector

clearance

NOTE: To stop cold air infiltration into the dwelling you

can install the optional Universal Shielding

Insulation (SUSI) into the Cathedral Ceiling Support.

See separate installation instructions

packaged with the SUSI.

ofeachchimneylengthmustbepointingupwardsasperthearrow

on the chimney label.

Install the 4 painted ceiling trim angles with the supplied fastening

screws to finish off the Support Box at the ceiling level.

5. Install lag screws or anchors and tighten pivot nuts. When all

bolts and straps are secured in place around the chimney, the

chimney will be stabilized against horizontal displacement.

The Universal Roof Support Assembly (URSA) is designed to

providesupportand maybeused onafloor,above aceilingorroof

and adjusts to any roof pitch. It may also be used above an offset

to support the offset or as a supplementary support when the

chimney or vent height exceeds that of the primary support.

Where permitted, it will provide support above freestanding

appliances and open cathedral ceiling installations.

The Universal Roof Support Assembly (URSA) accommodates

most models of chimneys with outer diameters ranging from 7"

through 13".

The URSA will support up to 30’ (9.0m) of chimney of which 20’

(6.9m) may be suspended beneath it.

13

ElevatorBolts

SupportPlate

(Ref.Step 3)

Securingholes to

Pipe

ElevatorBoltsfor

SupportPlate

(Ref.Step 3)

ElevatorboltThrough

AppropriateHole

(Ref.Step 1)

Tab

Figure 24

1/4”Nut

LockWasher

Large

Washer

Tab

Universal Band

Figure 25a

ElevatorBoltwith

LargeWasher,

lockWasherand

Nut

SupportPlate

1/4”x2” SSBolt

Figure 25b

2”Clearance

CageNuts

CageNut

2”Clearance

Figure 26

7. Center the assembly in the opening. Adjust Plates to the

pitch of the roof and tighten the nuts (see Figures 25b & 26).

8. Install six wood screws (#10 x 2-1/2”) per plate with the

innermost going into rafters or headers.

9. Add additional lengths of pipe as necessary, above and/or

below.

10. Complete installation of the Flashing, Storm Collar and

Round Top as per main installation instructions.

Securing

holestoPipe

ElevatorBoltwith

LargeWasher,

lockWasherand

Nut

To Install:

1. Place the two halves of the URSA Band as shown in Fig.24.

Insert elevator bolts through the single row of holes identified

with the outside diameter of the chimney being installed, (Ex.

-for an8” ODchimney,placethe elevatorboltthroughtheholes

identifiedfor8” OD). Theflatheadoftheboltshouldbeoriented

opposite the direction the formed tabs are pointed. Secure the

center bolt with washers and nut (see Figure 24).

2. Form the Band into a circle and loosely connect both tabs

using the supplied 2” bolts into the 2 cage nuts (see Figure

25a).

3. Attach the Support Plates to the band with flat head bolts (2

sets per plate) washers and nuts. The bolts should pass

through the holes in the band corresponding to the pipe

outside diameter and secured loosely (see Figure 24 & 25A).

NOTE: 2 sets per Support Plates.

4. Place assembly around the length of pipe and loosely tighten

the tabs with the screw and nut referenced in Step 2. Move

the assembly to the desired height location on the pipe.

Firmly tighten bolt and nut to secure the band around the

pipe.

5. Secure URSA to the length of pipe by using four (4) 1/8” x 1/

2” stainless steel self-tapping screws (provided) through the 2

securing holes found closest to the tabs on the band (see

Figure 24).

6. The URSA is mounted directly on the roof sheathing with its

SupportPlateresting over rafters or a framed opening to form

a solid base. Frame a rectangular roof opening to ensure a

good distribution of weight load. Be sure to allow for a

minimum of 2” airspace clearance to combustibles as shown

in Figure 26. Reference the main chimney installation

instructions for frame specifications and other details.

Level

Roof

Pitch is 3/12

3"

12"Ruler

FIGURE27 RoofPitchCalculation

Ensure that you have the proper roof flashing by checking your roof

pitchusingalevelandtworulers(seeFig.22)orbyusingaroofpitch

card.

The FRA-A flashing is for roof pitches from 0/12 to 6/12.

The FRA-P flashing is for roof pitches from 7/12 to 12/12.

ROOF FLASHING: (FRA)

Frame a RECTANGULAR opening to suit the pitch of the roof and

ensure that a 2" (50mm) minimum clearance is maintained to

combustibles.

In new construction, slide a Roof Flashing Assembly suitable to

your roof pitch over the chimney.

On an existing roof, center and install the flashing before extending

thechimneyabovethe roof. Do not nail the flashing to the roof yet.

NOTE: Prepare roof area by removing shingle nails and cutting

roofingmaterialallowing 2" clearance to the chimney. Slide the top

edge(nearesttheroofpeak)ofthe flashingsuitablefortheroofpitch

under the roofing shingles. At least half of the flashing sides

should be UNDER the shingles and the lower end OVER the

shingles to provide a watershed. Trimming off the shingles may

be neccessary around the

14

If the chimney extends 5 feet or more above the roof deck, a

Universal Roof Brace Kit is required (see Figure 35).

ROOF BRACE KIT (URBK)

of the flashing for a better fit. Ensure that the chimney is level and

plumb before nailing flashing to the roof. Nail flashing to the roof

deck(undertheshingles)alongtheupperedgeanddowneachside

with 12 nails with neoprene washers or cover the nails with a

suitable non hardening waterproof caulking . Seal the shingles to

the plate in the same manner. As a precaution, apply a bead of

caulking along all seams of the flashing above the roof as per

Figure 28.

Shingles

Flashing

Nails

RoofFlashingInstallation

Apply a bead of

silicone caulking

along back seamApply a

bead of

silicone

caulking

alongseam

of cone

On steep roofs, it is recommended that an ice deflector or cricket

fabricated from heavy-gauge galvanized steel be installed. The

wedge-shaped deflector is installed against the chimney on the

upper slope. Its function is to split ice and snow as they slide

down the roof, preventing damage to the chimney. This is not a

supplied item. Contact a sheet metal fabrication shop in your

area for your custom ice deflector.

The flashing and storm collar should be painted to match the roof

shingles. This will extend its life and improve the appearance.

The chimney may be painted also with a HEAT RESISTANT

paint. ToimproveadhesiontotheCFSentinelchimney,degrease,

clean, prime before painting. Follow the paint manufacturer's

instructions.

Apply non-hardening high temperature silicone caulking just

above the top of the flashing cone where it meets the chimney

outer casing. Slide the tab end of the storm collar into the slot

end. DONOTBENDTHE TAB OVER YET. Slide the collar down

the chimney until it contacts the flashing and the caulking. Bend

the tab back over the slot for a snug fit. Apply additional caulking

above the storm collar as required.

Continue adding chimney lengths until the proper height is

achieved (See figure 30). Install the Round Top as per the

instructions under the Round Top section.

Figure 28

TheUniversalRoof Brace Kit (URBK)willprovidelateralsupport

to the chimney above the roof line. The URBK is required when

the chimney extends 5 feet (1600mm) or more above the roof

penetration. The URBK contains Telescoping Legs, Support

Band, Roof Angle Brackets and hardware package.

The Universal Roof Brace Kit (URBK) accommodates most

models of chimneys with outer diameters ranging from 7"

through 13".

SingleRowof Holesusedto assemble

SupportBandtoODofthe Chimney

DoubleRowof Holes used

toattachTelescoping Legs

toSupportBand

Figure 29

Support Band Holes Identifier

SupportBandElevator

boltThroughAppropriate

Holesofbothhalves

Figure 30

1/4”Nut

LockWasher

Large

Washer

Form

Tab

Assembly of Universal

Support Band (2 Halves)

CageNuts

Singlerow

selectionholes

usedtoform

SupportBand

A. Measure the outside (OD) diameter of your chimney.

B. From the single row holes (see Figures 29 and 30), select

the hole in each halves that corresponds to the outside

diameter identified with the chimney being installed. Place

the two halves together. Insert an elevator bolt through the

chosen holes (Ex - for an 10” OD chimney, place the elevator

boltthrough theholesidentified for10”OD). The elevatorbolt

should be oriented opposite the direction the formed tabs are

pointed. Secure the center bolt with washers and 1/4”

flanged nut (see Figure 31). NOTE: On smaller diameter

chimney the excess band material can be cut off.

Elevatorboltfor

TelescopingLegs

ThroughAppropriate

Holesofbothhalves

Doublerowsselection

holesusedto

attachTelescopingLegs

NOTE: Upperor Lower

rowcanbe utilized

SecuringHoles

toChimney

(Only1

required)

SingleRowof Holesusedto assemble

SupportBandtoODofthe Chimney

DoubleRowof Holes

usedtoattach

TelescopingLegsto

SupportBand

SecuringHoles

toChimney

(Only1

required)

C. Form the band into a circle and loosely connect tabs using

the supplied 2” bolts into the 2 cage nuts located on1 form

tab.

15

Figure 31 Topview assembly of Support Band -

Elevator Bolt, Washers and Nut

FlangedNut

FlatWasher

SupportBand

Halves

Elevator

Bolt

D. From the double rows of holes (upper or lower row) select the

hole in each halves that corresponds to the OD of the

chimney. Insert 2 elevator bolts (1 per side) through both

holes.

LockWasher

CageNuts

E. Position the Support Band approximately two thirds of the

way up the chimney height (see Figure 35). The preferred

location is next to a joint, immediately above or below a

Locking Band. Secure Support Band by tightening the 2”

bolts.

NOTE: Only one chimney joint should be above a Roof Brace

Kit, the addition of a secondary one may be required.

F. Assemble the telescoping legs by sliding the supplied hose

clamp over larger diameter leg and then inserting smaller

diameter leg into larger diameter leg. Temporarily hold legs

together by tightening the hose clamp over the cut section of

larger diameter leg (see Figure 32). Repeat for the other

telescoping leg assembly.

SmallerDiameter

TelescopingLeg

CutSection of Larger

TelescopingLeg

LargerDiameter

TelescopingLeg

PilotHole for

SecuringScrew

HoseClamp

Figure 32

Assembly of Telescoping

Legs with Hose Clamp

ElevatorBolt

Angledendof

TelescopingLeg

FlatWasher

LockWasher

FlangedNut

ElevatorBolt

Angledendof

Telescoping Leg

FlatWasher

LockWasher

FlangedNut

Figure 33

Assembly of Telescoping

Legs to Support Band

FlangeNut

SmallerDiameter

Telexcoping Leg

RoofShingles

Rafteror framing

structure

1”Bolt

AngleBracket

2”Lag Screws

Figure 34

Securing

Angle Bracket

G. Attach each of the telescoping legs (angled end) to the 2

elevator bolts on the Support Band with supplied washers

and nut (see Figure 33).

H. Attach one end of each telescoping leg assembly to each of

the Angle Brackets using one (1) 1/4-20 X 1” bolt and nut (see

Figure 34).

2”Lag Screws

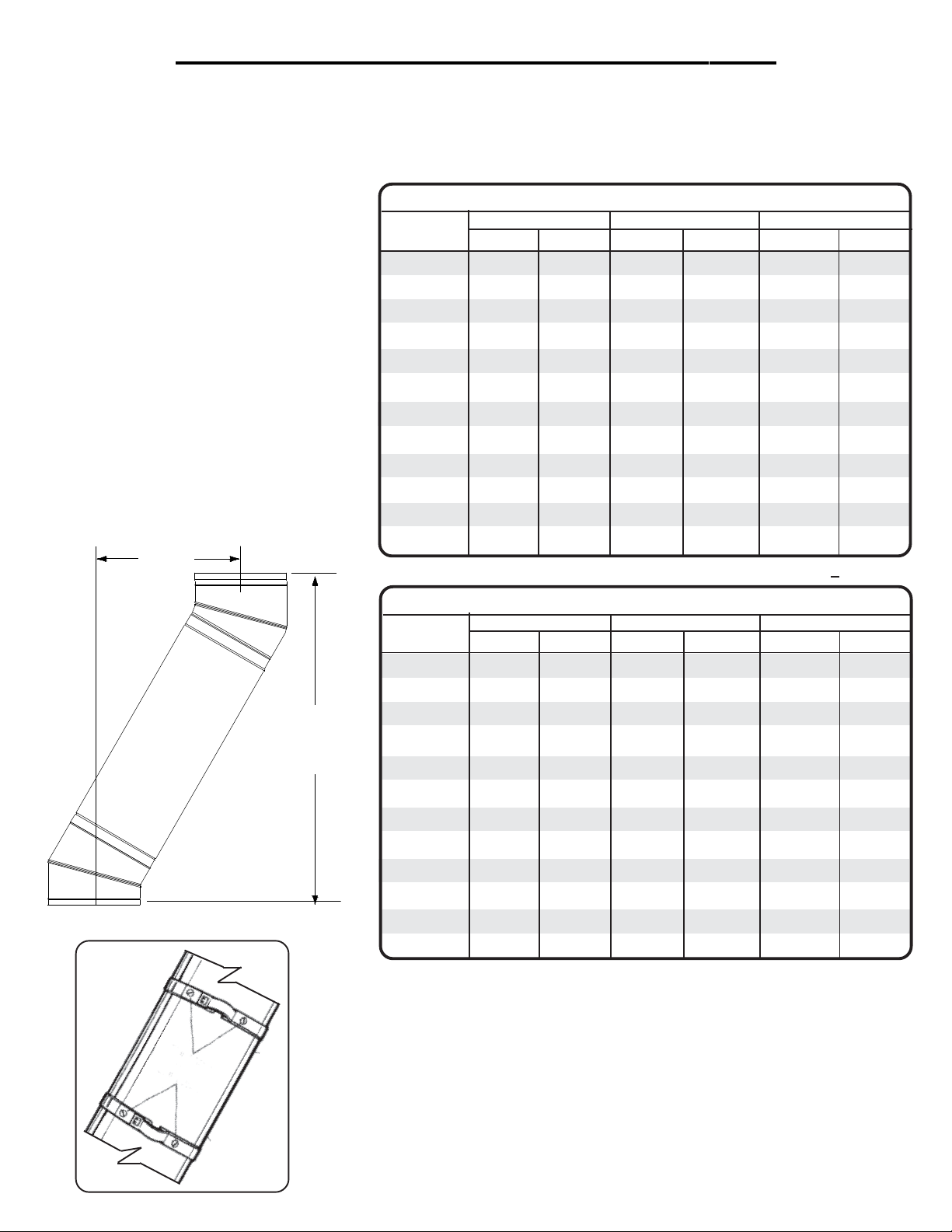

K. The two telescoping legs should form an angle of about 60°

to give support to the chimney in all directions. The angle of

the telescoping legs should not be more than 45° from

horizontal when fastened to the roof (see Figures 33 & 34).

I. Determine the location of the two Angle Brackets on the roof

structure. Ensure the fasteners are into rafters or framing and

not just roof sheathing. Secure the Angle Brackets to the roof

structure using two (2) 1/4 X 2” lag screws per brackets (see

Figure 28). Seal the roof with a suitable non-hardening

waterproof caulking.

J. Make sure the chimney is level and plumb. Check all required

dimensions and angles, adjust if necessary. For added

security, you may lock in place the telescoping legs by using

1/8” x 1/2” stainless steel self tapping screw (supplied)

through the pilot holes found near the hose clamps (Figure 32).

Secure the Support Band to length of pipe by using four (4) 1/

8” x 1/2” stainless steel self-tapping screws (supplied) through

the2securing holes found closesttothetabson the band (See

Figure 29). Cover screw heads with a suitable caulking.

16

SPARKARRESTER(SA)

Use a spark arrester if you have a shingle roof or live in a forested

area. If the chimney is used for venting a gas appliance, use a

spark arrester to keep birds out.

For 6" to 8" diameters a pre-formed spark Arrester is available.

1.Placethe pre-formedSparkArresterdirectly overthedomeand

skirt of the Round Top (Figure 40).

2. Ensure the flanged end of the Spark Arrester is on top of the

dome and the bottom folded edge overlaps the skirt.

ROUNDTOP(RTS)

1. Place RTS Top over an installed chimney Length so that the

three legs slide down over the outside of the chimney (see Figure

36.

2. Press down evenly on the lower skirt so that the skirt seats

tightly on the upper edge of the chimney Length (see Figure 37).

3. Be sure the RTS Top is level. Place the Cinch Band over the

Length and all legs so that the Cinch Band rests evenly on the

turned-out flanges (see Figure 38).

4. Firmly tighten the Cinch Band with screw and nut provided

(Figure 39). To remove the RTS Top, simply loosen the Cinch

Band and slide RTS Top off the Length.

FIGURE36 FIGURE37

FIGURE38 FIGURE39

RoundTop

SupportBand

LockingBand

AngleBracket

2”Lag screws

10’

MAX

2/3rd

OF HT.

Hose

Clamp

Figure 35

Placement of Universal

Roof Brace Kit

NOTE: Do periodic inspection of all fasteners including the hose

clamps as high winds can cause the chimney system above the

roof to vibrate and in time loosen some of the fasteners.

Spark

Arrester

Ifclogged:

If the Spark Arrester becomes clogged with creosote, it should be

cleaned or replaced. Remove Round Top by removing cinch band.

Lightly tap away (from the outside of the SparkArrester) any creosote

residue. If necessary use a soft bristle brush for assistance. If

Spark Arrester is to be removed from the Round Top, release the

bottom edge of the Spark Arrester from the skirt edge and raise

Spark Arrester from Round Top.

Round Top

Cinch Band

CF

Chimney

Length

FIGURE40

17

“Creosote and Soot - Formation and

Need for Removal”

MAINTENANCE AND CLEANING OF

THE CHIMNEY:

The need for chimney maintenance depends on the kind of

appliance and how it is operated. Gas and oil-burning appliances

need very little, but wood-burning appliances may need a great

deal of chimney maintenance.

How you burn wood in your stove or fireplace directly affects the

formation of creosote. Use more dry kindling and paper first to

warmupthe chimney system to a temperature between 350 to500

F. Burn hot, bright fires and fire each load hot. It is important to

load your appliance properly and to avoid smoldering fires. Fast,

effective start-ups are important, as is the moisture content of the

wood being burned. If your wood is not completely seasoned, split

your wood in smaller pieces instead of larger ones. Ideally, the

moisture content of your firewood should be between 18 to 22%.

A good investment in assisting you in monitoring your system is

a surface thermometer for single wall stove pipe or a probe

thermometer for double wall stove pipe. Ensure only low sulphur

content coal (1% or less) such as anthracite is burned.

When wood is burned slowly, it produces tar and other organic

vapors, which combine with expelled moisture to form creosote.

The creosote vapors condense in the relatively cool chimney flue

of a slow-burning fire. As a result, creosote residue accumulates

on the flue lining. When ignited, this creosote creates a chimney

fire with extremely high temperatures.

With a new installation, the chimney should be inspected

frequently(every2wks)todeterminetherateofcreosoteformation.

When familiar with the appliance and chimney characteristics, the

chimney should be inspected at least once every 2 months during

the heating season to determine if a creosote or soot build-up has

occurred. Check spark arrestor screens at least every 2 to 4

weeks. If the spark arrestor becomes clogged with creosote, it

should be cleaned or replaced.

If creosote or soot has accumulated, it should be removed to

reduce the risk of chimney fire. Depending on the rate of buildup

(aslittleas1/16")andasyoulearnwhatisgoingonin the chimney,

you can adjust your cleaning schedule accordingly. Every

chimneyflueandflue pipe shallbeinspectedannuallyandcleaned

as often as may be necessary to keep the chimney and flue pipe

free from dangerous accumulation of combustibles.

Chimney and flue pipe are particularly susceptible to off-seasn

condensation. The incomplete combustion of wood produces

acids which, when combined with moisture, are corrosive. During

the heating season, corrosion tends not to occur because the heat

in the system evaporates the condensation of any water vapour

that may be formed.

Warm, moist air during the summer months passes slowly

through the heating system. It makes any remaining ash or

creosote moist and soggy. Corrosion of steel occurs where these

deposits remain.

Off-season corrosion can be reduced considerably if the system

is thoroughly cleaned after the last fire of the heating season.

Where coal is burned, the system must be thorougly cleaned

within 48 hours of shutting down the system for the season and all

soot be removed from the chimney system. this should be the

Contact a professional certified chimney sweep for chimney

cleaning services and advice if you have any doubts about your

ability to clean your chimney system or if the task is too large.

If chemical cleaner is used to assist in cleaning your chimney,

make sure it is a product which is non corrosive. Selkirk will

assume no liability for damage resulting from the use of chemical

cleaners. It does not replace the need for a mechanical cleaning.

The optimal method for cleaning a chimney is by a mechanical

brushing of the chimney in conjunction with a complete evaluation

by a certified chimney sweep.

CHIMNEY FIRES AND WHAT TO DO ABOUT THEM

Your CF Sentinel chimney is not intended or designed for use as

a combustion or fire chamber. It is very easy to over fire your

woodburning appliance with kindling, scrap lumber, brush or any

fast burning fuel. This can produce flames and high temperatures

all the way up the chimney,and may cause chimney damage. If

you see your appliance or the stove pipeglowing red, you are

risking chimneydamage, or a fire. The creosote may be burning

inside the chimney.

If you see flames coming out the top, you are either overfiring or

there is a chimney fire. The following materials should not be

burned in your woodburning appliance: pressure treated lumber,

rail road ties, salt water driftwood or plastic. Burning such

materials may lead to severe corrosion of the appliance and the

chimney system.

If the fire in your appliance has gotten out of control, or if you

suspect a chimney fire for any reason, follow these steps:

1. Immediately close all dampers and/or air entrance openings to

your appliance.This includes doors on Franklin type stoves. Block

off fireplace openings.

2. Alert your family to the possible danger.

3. Inspect your appliance and chimney surroundings for possible

fire. If in doubt, alert your Fire Department.

4. Do not continue to use your appliance until it and your chimney

have been thorougly inspected. Overheating can cause metal

parts to expand, buckle and crack. If you are not certain, have a

certified wood technician or certified chimney sweep disassemble

all parts so they can be inspected and replaced.

5. Do not use salt or water on the fire in your appliance. Salt is

corrosive and water will cause a dangerous steam explosion. You

might be able to control the fire by using ashes, sand or baking

soda, since baking soda is an ingredient used for dry chemical fire

extinguishers.

6. After a chimney fire, when it is safe to do so, check internal

locations such as the attic and under the roof and keep watching

for two or three hours. There may be delayed smoldering and

subsequent ignition, even if the fire inside the chimney has been

controlled.

To visually inspect the chimney, remove the Round Top by

loosening the the nut and bolt from the securing band. This will

permit the insertion of a flashlight for inspection and a properly

sized plastic chimney cleaning brush. A metal brush may scratch

the liner and lead to premature corrosion.

The Tee Plug can be removed by turning the lugs to the side. Be

sure to replace the Round Top and the Tee Plug when you are

finished inspecting and cleaning the chimney.

WARNING:

DO NOT USE FUEL MATERIALS CORROSIVE TO

THE CHIMNEY LINER SUCH AS DRIFTWOOD,

PLASTICS, CHEMICALLY TREATED WOOD, ETC.

most careful cleaning the system receives all year. Air inlets

should be closed and sealed if necessary to prevent the constant

flow of air through the system.

18

*CF-36

*CF-24

*CF-18

*CF-12

*CF-9

*CR-IT

*CF-EL15K

*CF-EL30K

*CF-CBSP

*CF-WSP

*CF-WB

*CF-CCB

URSP

*CF-FRA-A

*CF-FRA-P

URBK

*CF-AIS

*CF-JS

*CF-IWT

*CF-RTS

*CF-SPA

*CF-AP

SUSI

REPLACEMENT PARTS LIST

DESCRIPTION PART No.

36" Chimney Length

24" Chimney Length

18" Chimney Length

12" Chimney Length

9" Chimney Length

Insulated Tee/Tee Plug

15oInsulated Elbow Kit

30oInsulated Elbow Kit

Ceiling Support Package

Wall Support Package

Wall Band

Cathedral Ceiling Support

Roof Support Package

Flashing Assembly 0/12-6/12

Flashing Assembly 7/12-12/12

Universal Roof Brace

Attic Insulation Shield

Joist Shield

Insulated Wall Thimble

Round Top

Smoke Pipe Adapter

Anchor Plate

Universal Shielding Insulation

SENTINEL CF

An * asterisk denotes the diameter of chimney (6", 7" or 8").

BURN ONLY SEASONEDFIREWOOD!

Wood burns completely only at very high temperatures with

enoughoxygenpresent. Thefuel,heat, andoxygenhavetomix

together in the same place at the same time. Although all

stages of burning wood actually occur at the same time, it will

burn in 3 stages: boiling off the water, vaporizing wood gases

and burning the charcoal.

Wood burning appliances will burn best with clean, well sea-

soned dry firewood with an ideal moisture content of 18% to

22%. The denser or heavier the wood when dry, the greater its

heat value. Seasoned firewood is essential for an optimum

performance. Seasoned wood will burn hot, emit less smoke

and create less creosote.

Un-seasoned wood when burned, must release water stored

within the wood.This cools the fire, creates creosote and

hampers a complete burn. Be careful of wood advertised as

seasoned. You may want to invest in a moisture meter.

Signs of seasoned firewood are:

- Dark colored; wood darkens with age;

- Cracks in the end grain; radiating from the center of the log like

bicycle spokes;

- Light in weight; which indicates low moisture content - but

hardwood will weigh more than softwood;

- Sound; hit 2 pieces together, wet will have a dull "thud" sound

where as dry will ring like a bat hitting a baseball;

- Easily peeled or broken bark; no green should show under the

bark;

- Burn some; if it hisses, then it is to wet.

The time it takes to season wood varies from 6 to 18 months.

Hardwood dries slower than softwood and some may take well

over a year to dry. To speed-updrying:

- Cut to length;

- Split in a variety of sizes no larger than 6" exposing the wet

interior and increasing the surface area of each piece;

- Stack loosely in a criss cross pattern to get good air circulation;

- Store above ground at least a foot and away from buildings in

a sunny, well ventilated area;

- Cover the top to keep rain and dew off the wood;

- Leave sides open to breezes; for air circulation.

AVOID BURNING "green", "unseasoned" "wet" wood. Heat is

wasted as it must first dry and evaporate the moisture content in

the firewood. As the water evaporates it will form into creosote

which will then condense in the relatively cool firebox and

chimney and will not permit a clean hotburn.

19

H

W

NOTE: It is of utmost importance that this chimney be

installed in accordance with these instructions. Certifica-

tion of the chimney is void if the installation instructions

are not followed. The CF Sentinel chimney requires 2"

(50mm) clearance (air space) to combustible material.

Refer to the following sections in these instructions to

complete your installation to a masonry fireplace:

- Pre-Installation Guidelines

- CF Sentinel Joint Security

- Framing Details

- Attic Insulation Shield

- Firestop Joist Shield

- Elbow Installation

- Roof Support

- Roof Flashing

- Roof Brace Kit

- Round Top

- Smoke Pipe Adaptor

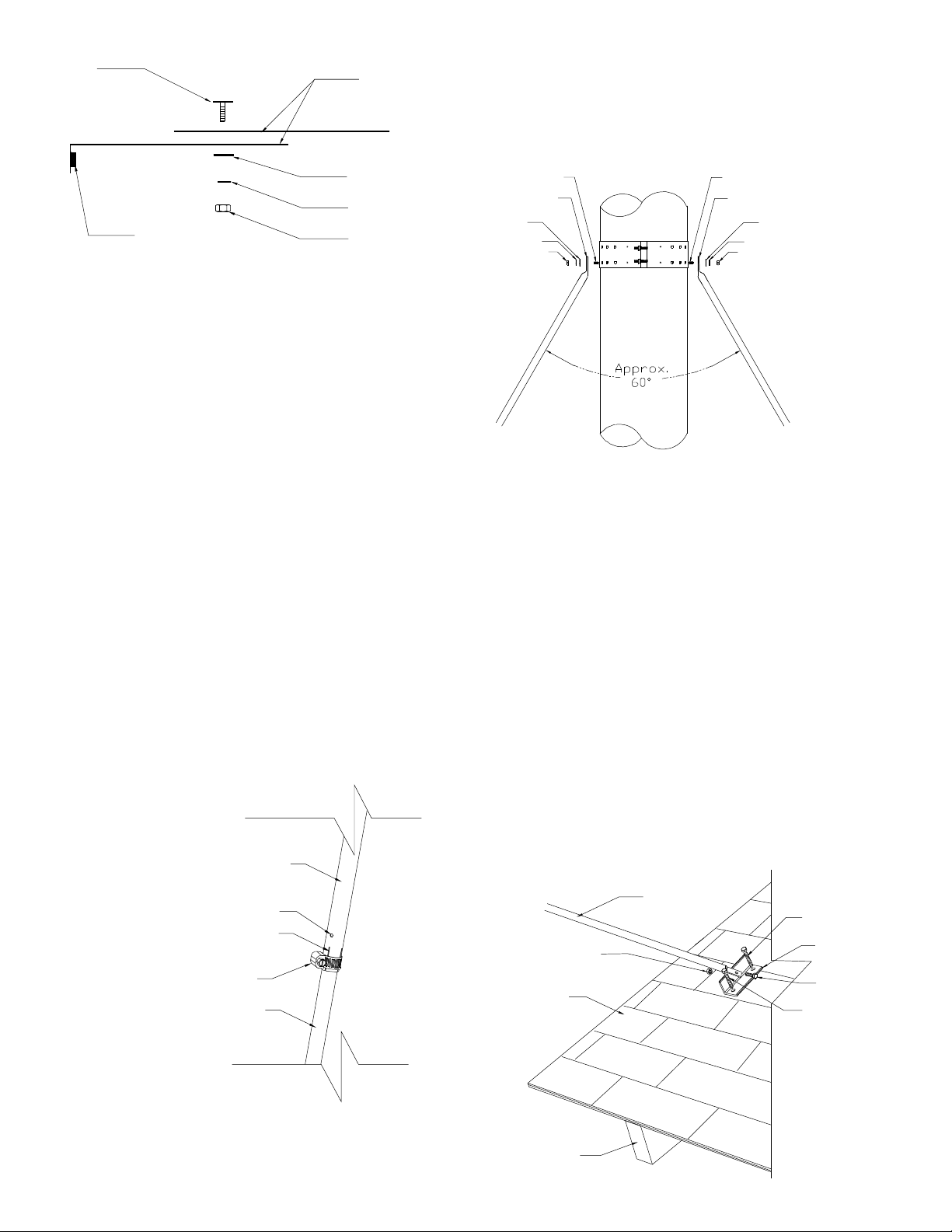

Model CF Sentinel Anchor Plate provides a connection from a

masonry fireplace to a Selkirk Model CF Sentinel chimney. The

following steps describe the installation of this part (component)

and the above mentioned sections of these instructions are to be

followed.

1. Mount four (4) 1/4" diameter bolts, 3" long securely into the

top of the masonry fireplace around the outlet opening. Use the

4 holes on the anchor plate as a template to locate the placement

of these bolts.

2. Apply a bed of mortar approximately 3/4" in depth and 3" in

width completely around the fireplace opening. Make sure the

threadedendsoftheboltsprotrudeaminimumof1"abovethebed

of mortar.

3. While the mortar is still damp, place and level the Anchor Plate

overthe extended studs. Secure using a washer andnut for each

bolt.

4. Check the Anchor Plate for level and allow mortar to set.

5. Place the flue extension (crimped end down) into the opening

of the Anchor Plate. Place a section of chimney onto the Anchor

Plate and secure to the Anchor Plate with a Locking Band and

stainless steel sheet metal screws (see CF Sentinel Joint

Security section of these instructions and Figure 4). Up to 85 feet

of chimney may be stacked on the Anchor Plate.

ANCHOR PLATE - MASONRYFIREPLACE

AllMasonryorSteelShell

ModelSentinelCF

ChimneyLenght-Requires

2"(50mm)clearanceto

Combustibles

AtticInsulationShield

Flashing

Stormcollar

RoundTop

"LISTED" FACTORY-BUILT FIREPLACES

When Selkirk chimney Model CF Sentinel is approved with a

"Listed" factory-built fireplace, the chimney and fireplace are

tested in combination as a complete system and the fireplace

instructions must be followed.

Where required in the "Listed" factory-built fireplace installation

instructions, an Anchor Plate can be used to provide a connection

from a "Listed" factory-built fireplace to the insulated chimney

Model CF Sentinel.

AnchorPlateAssembly

Ensure that you obtain any necessary building permits and that your installation will conform with all federal, provincial,

municipal installations and fire codes for all requirements affecting your installation. Check with your local Building Code

for masonry fireplace requirements.

LockingBand

FlueExtension

Anchorplate(base)

20

2-7/8"

7-3/4"

8-1/4"

11-1/2"

14-3/8"

18-5/8"

20-1/4"

25-1/8"

26-1/8"

28-5/8"

32-3/8"

38-7/8"

AABBAB

13"

20-1/4"

21-1/2"

27"

31-7/8"

39-3/4"

42-1/2"

49-7/8"

50-3/4"

56-1/4"

61"

69-1/4"

3-3/4"

8-3/8"

9-3/8"

11-5/8"

15-1/4"

20-1/4"

22"

26"

26-3/4"

29-3/4"

34-3/8"

39-1/4"

14"

21-1/4"

22-3/4"

27-1/2"

33"

40-3/8"

42-1/2"

50-3/8"

52"

56-1/2"

61-5/8"

70-7/8"

3-3/4"

7-3/4"

7-5/8"

11-3/8"

14-1/2"

18"

21"

24-1/4"

24-3/4"

28-3/8"

32-1/4"

37-1/4"

14-1/4"

22-1/8"

23-1/2"

28-3/4"

34-1/4"

42-1/4"

44-1/4"

52-3/8"

53-7/8"

58-7/8"

64"

72-1/2"

1"

3-1/4"

4"

5-1/2"

7-1/8"

9-5/8"

10-3/8"

12-1/2"

13-1/4"

15-7/8"

22-1/4"

23-1/2"

AA

BBAB

11"

19-1/2"

20-7/8"

26-1/2"

32"

40-5/8"

43-7/8"

52-1/4"

54"

59"

64-7/8"

75-1/8"

1-1/4"

4"

4-1/4"

5-5/8"

7-1/8"

10-1/4"

10-3/4"

13"

13-1/2"

15-5/8"

17-7/8"

20-1/2"

11"

19-1/2"

21-1/8"

26-3/4"

32-5/8"

40-7/8"

43-7/8"

52-1/8"

53-5/8"

59"

65-1/8"

75-3/8"

1-3/4"

4-1/8"

4-3/8"

6"

8"

10"

11-1/8"

13-1/8"

14-1/2"

15-1/8"

17-3/8"

21-1/4"

10-3/4"

19-1/4"

20-7/8"

26-3/4"

32-3/4"

41-1/8"

44"

52-1/8"

53-3/4"

59-3/4"

65-5/8"

75-1/2"

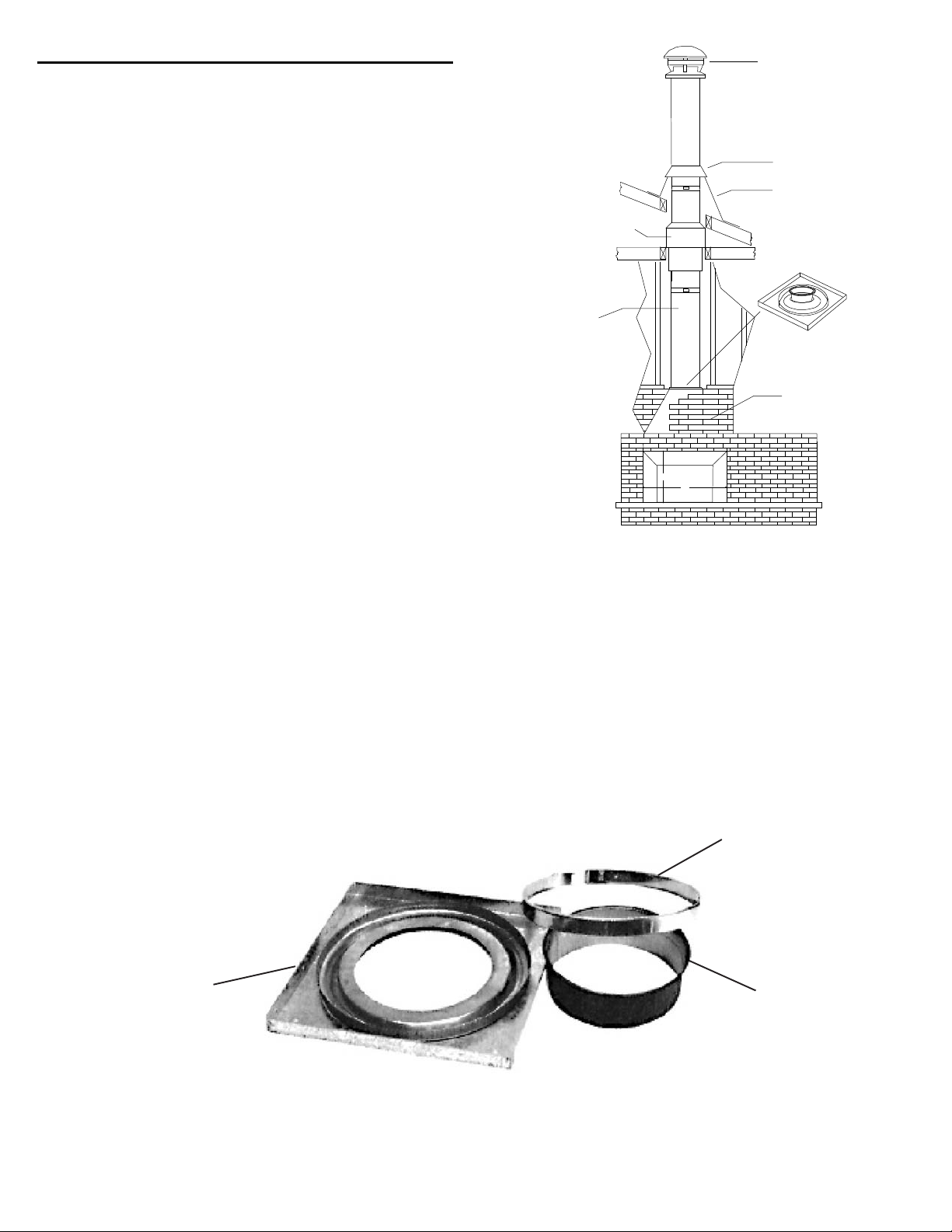

CHART 1 - OFFSET CHIMNEY INSTALLATION

When the chimney path cannot be perfectly straight, the need to install a chimney offset must be used when it becomes necessary

to offset the chimney in order to clear a joist or an obstacle. The two (2) charts below will assist you in selecting the proper combination

of elbow angle and chimney length(s) that will provide the necessary degree of offset within an available height.

1. Select the column with the proper chimney

diameter of your system.

2. Determine the distance of the offset required

by dropping a plumb bob for an accurate mea-

surement. The offset is measured at the chim-

ney centre line as per the "A" measurement in

the diagram.

3. On the chart, find the predetermined distance

(under the "A" column) required for the 15o

elbow. For greater offset, use the 30ooffset

chart.

4. After finding the offset, look under column "B"

to find the specified height and appropiate "chim-

ney lengths" required in the left column.

NOTE:

•Sentinel CF chimney is limited to offsets not exceeding 30 degrees. Combining offsets for greater

angle is not permitted.

•Two pairs of (four) 15oor 30oelbows may be used per interior installation.

•Locking bands must be used at each joints. For added security on multiples lengths forming

an offset, fasten the joints using two (2) #6 x 1/2" stainless steel sheet metal screws through

the pre-punched holes in the locking bands (see diagram on the left).

•Never install an elbow in a joist area. Chimney sections must pass vertically through framed

joist areas.

•Elbow support will support 30 feet of chimney and the maximum length of chimney allowed

between elbows is 6 feet.

StainlessSteel

SheetMetal

Screws

"A"

Offset

"B"

Height

30oOFFSET CHART

Chimney 7" Diameter6"Diameter 8" Diameter

Lengths

none

9"

12"

18"

24"

9" + 24"

36"

9" + 36"

12" + 36"

18" + 36"

24" + 36"

12"+24"+36"

All measurements in these charts are in inches. Construction tolerances + one inch.

15o OFFSET CHART

Lengths

Chimney 7" Diameter6"Diameter 8" Diameter

none

9"

12"

18"

24"

9" + 24"

36"