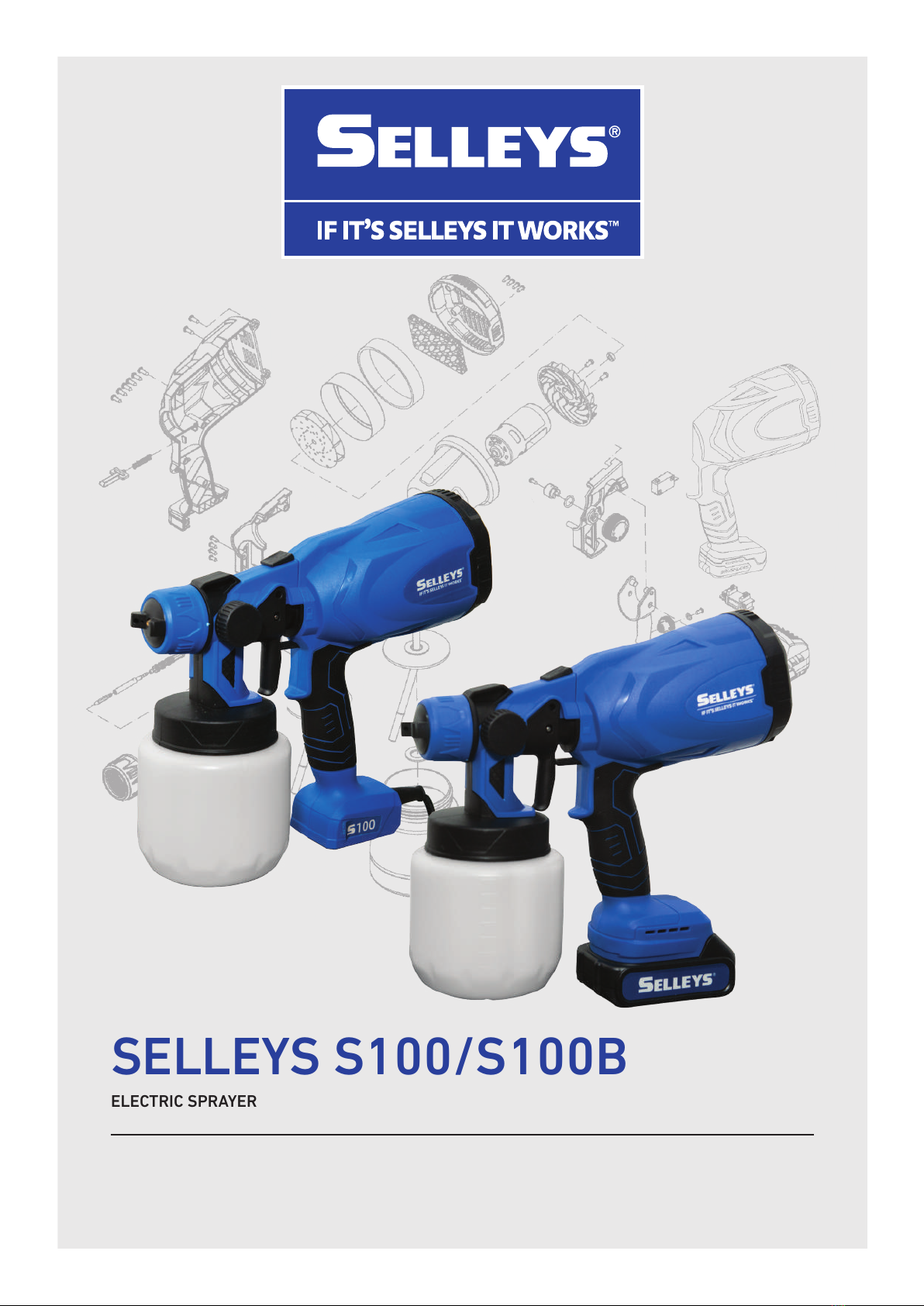

OPERATING MANUAL – SELLEYS S100/S100B

3

1.2 SPECIFIC SAFETY HAZARDS AND PRECAUTIONS

SAFETY PRECAUTIONS TO PREVENT INJECTION INJURY

WARNING

Serious risk of injection injury. This equipment produces a high-pressure stream that can pierce the skin and subcutaneous

tissues, resulting in severe injury and even possible amputation.

IMPORTANT

The maximum operating range of the unit is 21 bar (22.1 MPa, 3200 PSI) fluid pressure.

NEVER

• put your fingers, hands or any other parts of your body into the spray jet

• point the spray gun at yourself or anyone else (including animals)

• allow the fluid stream to come into contact with any part of your body

• allow any leak in the fluid hose to come into contact with any part of your body

• put your hand in front of the gun

NOTE: Gloves do not provide full protection against injection injury.

ALWAYS

• ensure that the gun trigger is locked, the fluid pump is shut o, and all pressure is released before servicing, cleaning the tip

guard, changing tips, or leaving the unit unattended

NOTE: Turning o the engine will not release the pressure. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• ensure that the tip guard remains in place during spraying

• remove the spray tip before flushing or cleaning the system

• carefully check the paint hose for leaks before each use, as even small leaks can cause injection injury

• ensure that all accessories, including but not limited to spray tips, guns, extensions and hose, are rated at or above the

maximum operating pressure range of the sprayer

IMPORTANT MEDICAL INFORMATION

Injection injury is a traumatic injury that requires immediate medical attention. Any laceration of the skin, no matter how minor

it seems, should not be treated as a simple cut. Fully inform the medical team about the coatings or solvents involved, as some

coatings are toxic when injected directly into the bloodstream. For serious injuries, a plastic surgeon or reconstructive hand

surgeon should be consulted.

1.1 GENERAL SAFETY PRECAUTIONS

NEVER

• use the spray gun without the safety guard in place

• operate faulty units or use faulty accessories

• attempt to repair a damaged hose

• leave this equipment unattended

• move the unit when it is running

• spray outside on windy days

ALWAYS

• ensure that this unit is properly earthed

• ensure that the power cord, air hose and spray hoses are optimally routed to minimise slip, trip and fall hazards

• immediately and thoroughly clean up all material and solvent spills to prevent slip hazards

• follow the material manufacturer’s instructions for safe handling of coating materials

• unplug the cord from the outlet before cleaning, maintaining or repairing this unit

• keep the power cord plug in sight during use to prevent accidental shutdowns and startups

• wear ear protection to protect against possible hearing loss from the noise produced by this unit, which can exceed 85 dB(A)

• keep this unit out of reach of children, unqualified adults and animals

• comply with local codes regarding ventilation, fire prevention, and operation