Selleys S39E User manual

OPERATING MANUAL

SELLEYS S39E AIRLESS SPRAYPACK

OPERATING MANUAL – SELLEYS S39E

CONTENTS

1. SAFETY INFORMATION

1.1 General Safety Precautions

1.2 Specific Safety Hazards and Precautions

1.3 Earthing Instructions

2. COATINGS

2.1 Suitable Coatings

2.2 Preparation of Coating Materials

2.3 Viscosity

2.4 2-component Coating Materials

2.5 Coatings Containing Abrasive Materials

3. EQUIPMENT

3.1 Technical Data

3.2 Main Components

4. OPERATING INSTRUCTIONS

4.1 Setup

4.2 Startup

4.3 Pressure Relief Procedure

4.4 Installation of Spray Tip

4.5 Clearing Spray Tip Clogs

4.6 Before Spraying the Coating Material

4.7 Method of Spraying

4.8 Handling the High-Pressure Hose

4.9 In Case of Interrupted Operation

5. CLEANING AND MAINTENANCE

5.1 Cleaning and Shutting Down

5.2 Cleaning the Airless Spray Gun

5.3 Disassembly of the Gun Filter

5.4 Assembly of the Gun Filter

6. MALFUNCTIONS

6.1 Corrective Measures for Common Malfunctions

6.2 Error Codes

7. PARTS AND ASSEMBLY

OPERATING MANUAL – SELLEYS S39E

3

WARNING

This unit is capable of extremely high spraying pressures that can cause serious and/or minor

injury by injection and extensive damage to property.

IMPORTANT

All replacement parts and accessories should ONLY be purchased from SELLEYS or an

authorised distributor of SELLEYS equipment. Servicing should ONLY be carried out by SELLEYS

or an authorised distributor of SELLEYS equipment. If these conditions are not met, the operator

assumes all liability for injury and property damage arising from the use of this unit.

1. SAFETY INFORMATION

Please read the following important information carefully.

The following symbols indicate specific types of safety hazards.

Indicates a potential hazard that may cause serious injury to the operator or

loss of life.

Indicates a potential hazard that may cause minor injury to the operator or

to the equipment.

Indicates important information.

OPERATING MANUAL – SELLEYS S39E

4

1.1 GENERAL SAFETY PRECAUTIONS

NEVER

• use the spray gun without the safety guard in place

• operate faulty units or use faulty accessories

• attempt to repair a damaged hose

• leave this equipment unattended

• move the unit when it is running

• spray outside on windy days

ALWAYS

• ensure that this unit is properly earthed

• ensure that the power cord, air hose and spray hoses are optimally routed to minimise slip, trip and fall hazards

• immediately and thoroughly clean up all material and solvent spills to prevent slip hazards

• follow the material manufacturer’s instructions for safe handling of coating materials

• unplug the cord from the outlet before cleaning, maintaining or repairing this unit

• keep the power cord plug in sight during use to prevent accidental shutdowns and startups

• wear ear protection to protect against possible hearing loss from the noise produced by this unit, which can exceed 85 dB(A)

• keep this unit out of reach of children, unqualified adults and animals

• comply with local codes regarding ventilation, fire prevention, and operation

1.2 SPECIFIC SAFETY HAZARDS AND PRECAUTIONS

SAFETY PRECAUTIONS TO PREVENT INJECTION INJURY

WARNING

Serious risk of injection injury. This equipment produces a high-pressure stream that can pierce the skin and subcutaneous

tissues, resulting in severe injury and even possible amputation.

IMPORTANT

The maximum operating range of the unit is 21 bar (22.1 MPa, 3200 PSI) fluid pressure.

NEVER

• put your fingers, hands or any other parts of your body into the spray jet

• point the spray gun at yourself or anyone else (including animals)

• allow the fluid stream to come into contact with any part of your body

• allow any leak in the fluid hose to come into contact with any part of your body

• put your hand in front of the gun

NOTE: Gloves do not provide full protection against injection injury.

• use a spray gun without both a working trigger lock and trigger guard in place

ALWAYS

• ensure that the gun trigger is locked, the fluid pump is shut o, and all pressure is released before servicing, cleaning the tip

guard, changing tips, or leaving the unit unattended

NOTE: Turning o the engine will not release the pressure. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• ensure that the tip guard remains in place during spraying

• remove the spray tip before flushing or cleaning the system

• carefully check the paint hose for leaks before each use, as even small leaks can cause injection injury

• ensure that all accessories, including but not limited to spray tips, guns, extensions and hose, are rated at or above the

maximum operating pressure range of the sprayer

IMPORTANT MEDICAL INFORMATION

Injection injury is a traumatic injury that requires immediate medical attention. Any laceration of the skin, no matter how minor

it seems, should not be treated as a simple cut. Fully inform the medical team about the coatings or solvents involved, as some

coatings are toxic when injected directly into the bloodstream. For serious injuries, a plastic surgeon or reconstructive hand

surgeon should be consulted.

OPERATING MANUAL – SELLEYS S39E

5

SAFETY PRECAUTIONS TO PREVENT EXPLOSIONS AND FIRE

WARNING

This equipment produces a high-pressure stream that can pierce the skin and subcutaneous tissues, resulting in severe injury

and even possible amputation.

NEVER

• use plastic drop cloths or enclose the spray area with plastic sheets, as plastic can cause static sparks

• smoke in the spray area

• use any materials with a flashpoint lower than 21°C (70°F)

NOTE: Flashpoint is the temperature at which a fluid can produce sucient vapours to ignite.

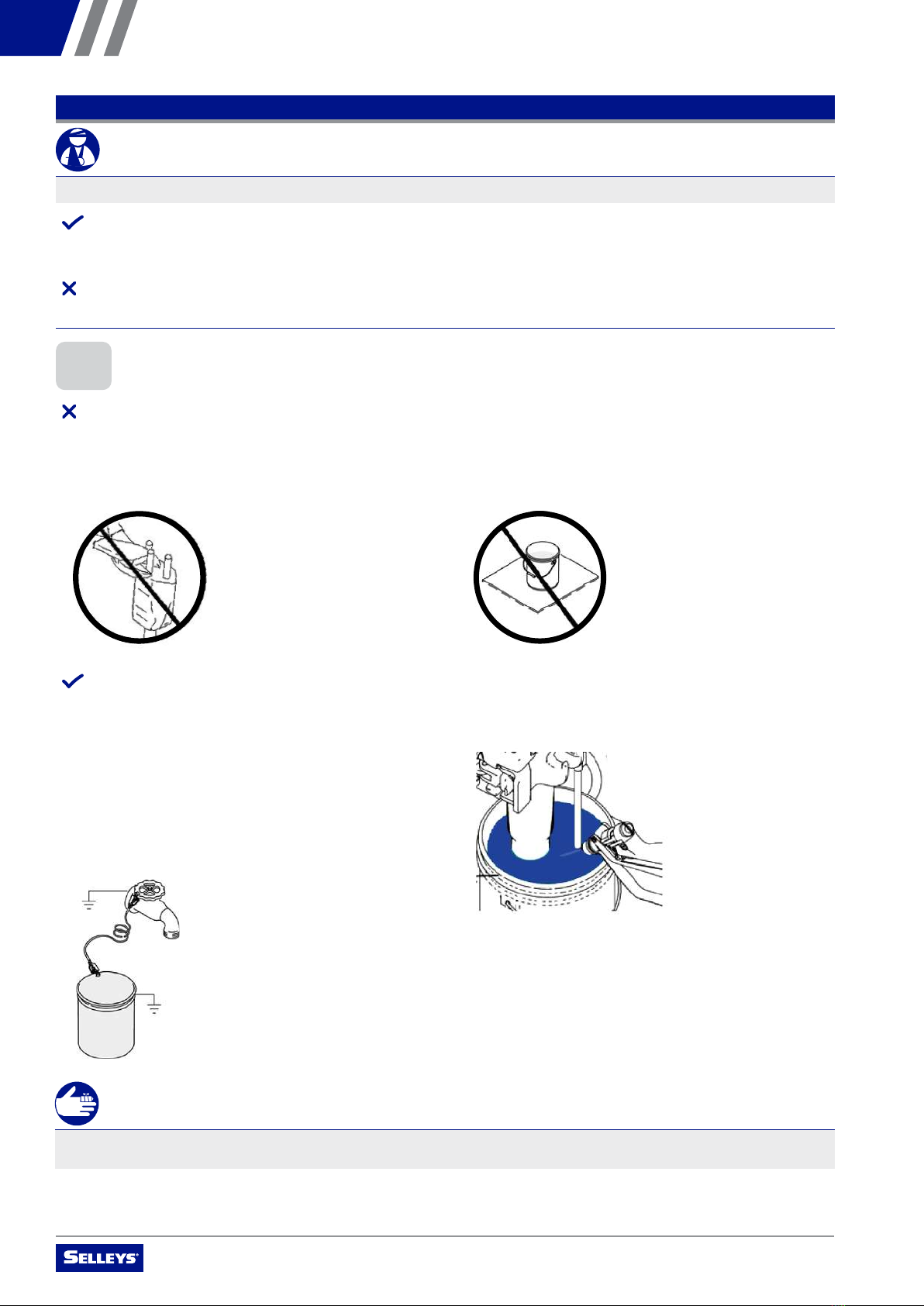

ALWAYS

• ensure that the spray area is well-ventilated to prevent the build-up of flammable vapours

• avoid all ignition sources such as static electricity sparks, electrical appliances, flames, pilot lights, hot objects, and sparks from

connecting and disconnecting power cords and/or working light switches

• flush the unit into a separate metal container, at the lowest possible pump pressure and with the spray tip removed

• hold the gun firmly against the side of the container to prevent static sparks

• have a fire extinguisher nearby

• place the sprayer at a minimum of 6.1 metres (20 feet) from the surface to be sprayed, extending the hose if necessary. Since

flammable vapours are often heavier than air, the floor area must be well ventilated. The pump contains arcing parts that emit

sparks, which can ignite vapours.

• ensure that the equipment and objects in and around the spray area are properly grounded to prevent static sparks

• ensure that you are using a conductive or earthed high pressure hose

• ensure that the gun is earthed through the hose connection

• ensure that the power cord is connected to a grounded circuit

• ensure that the unit is connected to an earthed object such as a water pipe, steel beam, or other electrically earthed surface, via

the green earthing wire

• strictly follow the material and solvent manufacturer’s warnings and instructions, and read the coating material’s MSDS

(Material Safety Data Sheet) and technical information before use

SAFETY PRECAUTIONS TO PREVENT EXPLOSIONS DUE TO INCOMPATIBLE MATERIALS

WARNING

Serious risk of explosions due to incompatible materials. Accidental explosions due to incompatible materials can cause serious

injury and/or extensive damage to property.

NEVER

• use materials that contain bleach or chlorine

• use halogenated hydrocarbon solvents such as methylene chloride and 1,1,1-trichloroethane

NOTE: These substances are not compatible with aluminium and may cause an explosion. If you are in any doubt over a material’s compatibility

with aluminium, check with your coating supplier.

SAFETY PRECAUTIONS TO PREVENT HARM FROM TOXIC VAPOURS

WARNING

Vapours from paints, solvents, insecticides, and other materials can be harmful in the event of inhalation or contact with any part

of the body. Symptoms include severe nausea, fainting and poisoning.

ALWAYS

• use a respirator or mask

• wear protective eyewear

• wear protective clothing

OPERATING MANUAL – SELLEYS S39E

6

• operate this unit unless you are sure that it has been

properly earthed

• modify the earthing plug

• use an adapter with this equipment

ALWAYS

• ensure that the earthing plug is plugged into an outlet that

has been properly installed and earthed in accordance with

local codes

• seek the advice of a qualified electrician if you need a

new outlet installed to fit the earthing plug, do not fully

understand these earthing instructions, or are unsure as to

whether this unit is properly earthed

• use grounded metal pails for solvent- and oil-based fluids

• connect the ground wire from the metal pail to a true earth

ground such as a water pipe

SAFETY PRECAUTIONS TO PREVENT HARM FROM MOVING PARTS

WARNING

Moving parts can pinch, cut or amputate fingers and other body parts. Furthermore, equipment can start without warning.

ALWAYS

• keep clear of moving parts

• follow the Pressure Relief Procedure and disconnect all power sources before checking, moving or servicing the equipment

NEVER

• operate equipment with protective guards or covers removed

1.3 EARTHING INSTRUCTIONS

NEVER

WARNING

Incorrect installation of the earthing plug can result in electric shock. If you need to repair or replace the cord or plug, do not

connect the green earthing wire to either blade terminal.

• if required, use 1,5 mm2grounded extension cords,

measuring a maximum of 30m in length

• use 3/8 x 50 ft (minimum), non-wire braid hose

• place pail on grounded surface such as concrete

• hold spray gun against grounded metal pail when flushing or

relieving pressure to maintain ground

• place pail on non-conductive materials, which will isolate

pail from ground

OPERATING MANUAL – SELLEYS S39E

7

IMPORTANT

The wire with insulation, which has a green outer surface with or without yellow stripes, is the earthing wire. It must be

connected to the earthing pin.

Use of an undersized cord causes a drop in line voltage, loss of power and overheating.

A list of the materials used in the construction of this unit is available upon request for the purpose of determining compatibility

with coating materials.

NOTE: All sprayer cords include a ground wire to reduce the risk of static and electric shock.

2. COATINGS

Please read the following important information carefully.

2.1 SUITABLE COATINGS

This unit is suitable for the application of:

• dilutable lacquers and paints

• coatings containing solvents

Do not spray coatings other than those listed above without the prior approval of SELLEYS or the authorised distributor of this unit.

• 2-component coating materials

• dispersions

• latex paints

2.3 VISCOSITY

This unit is able to process highly viscous coating materials of up to around 20,000 mPa-s.

Highly viscous coating materials can be diluted according to the manufacturer’s instructions.

When preparing two-component coating materials for spraying, follow the manufacturer’s instructions and do not skimp on the

mixing/processing time. While the components are processing, thoroughly rinse and clean the unit with suitable cleaning agents.

Coatings that contain sharp-edged aggregates and additional materials cause intense wear and tear on this unit’s parts, including

its valves, high-pressure hose, spray gun and tip.

Use of abrasive coatings may shorten the working life of this unit.

2.4 2-COMPONENT COATING MATERIALS

2.5 COATINGS CONTAINING ABRASIVE MATERIALS

Always filter and stir the coating material before application. To prevent downtime, make sure that no air bubbles are introduced,

especially when stirring the coating material with motor-driven agitators.

2.2 PREPARATION OF COATING MATERIALS

OPERATING MANUAL – SELLEYS S39E

8

3. EQUIPMENT

Please read the following important information carefully.

3.1 TECHNICAL DATA

Motor Output 4.0KW

Flow Rate (LPM) 8.3L

Min./Max. Nozzle Size 0.045”

Max. Pressure 20 mPa

Weight 68kg

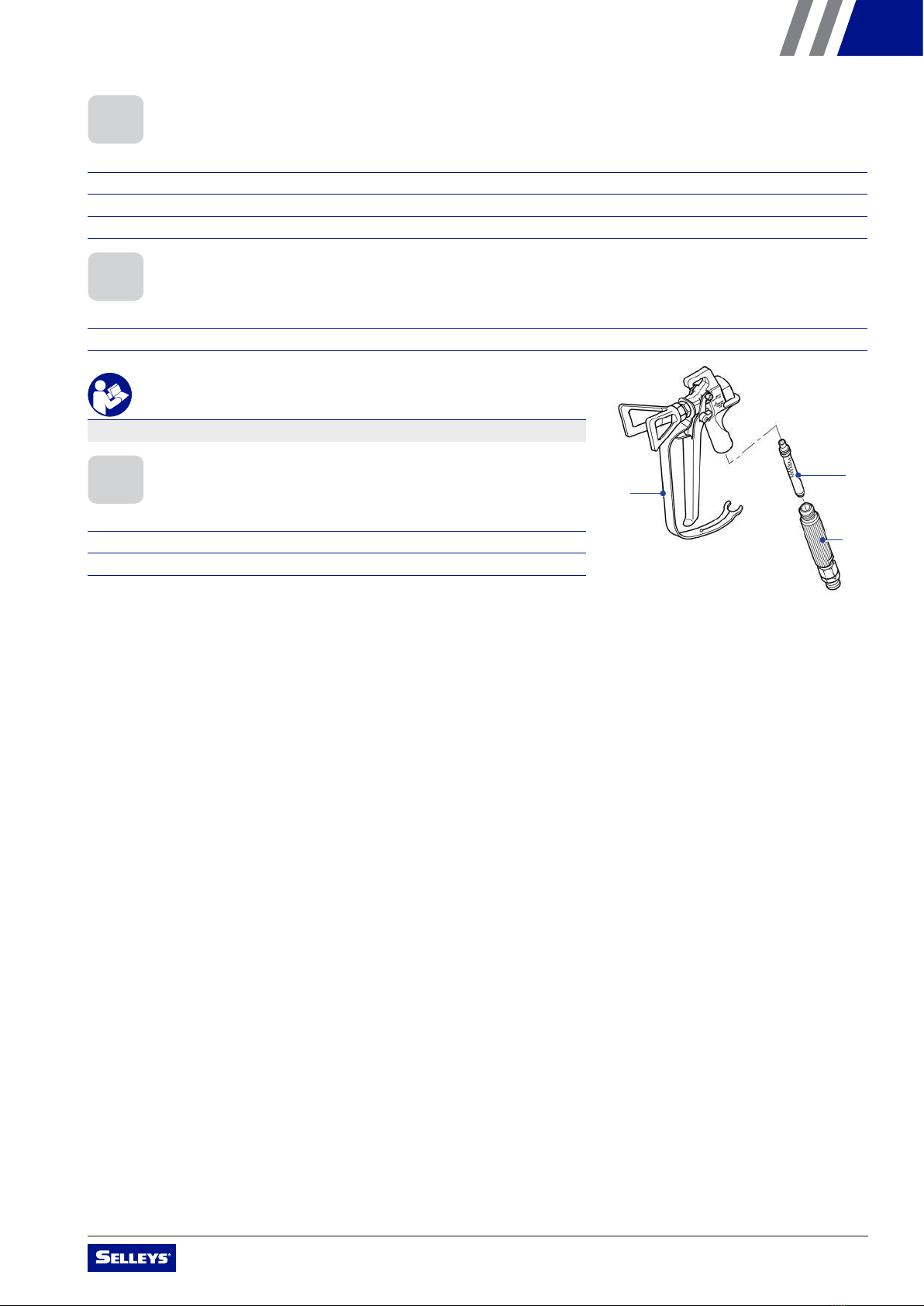

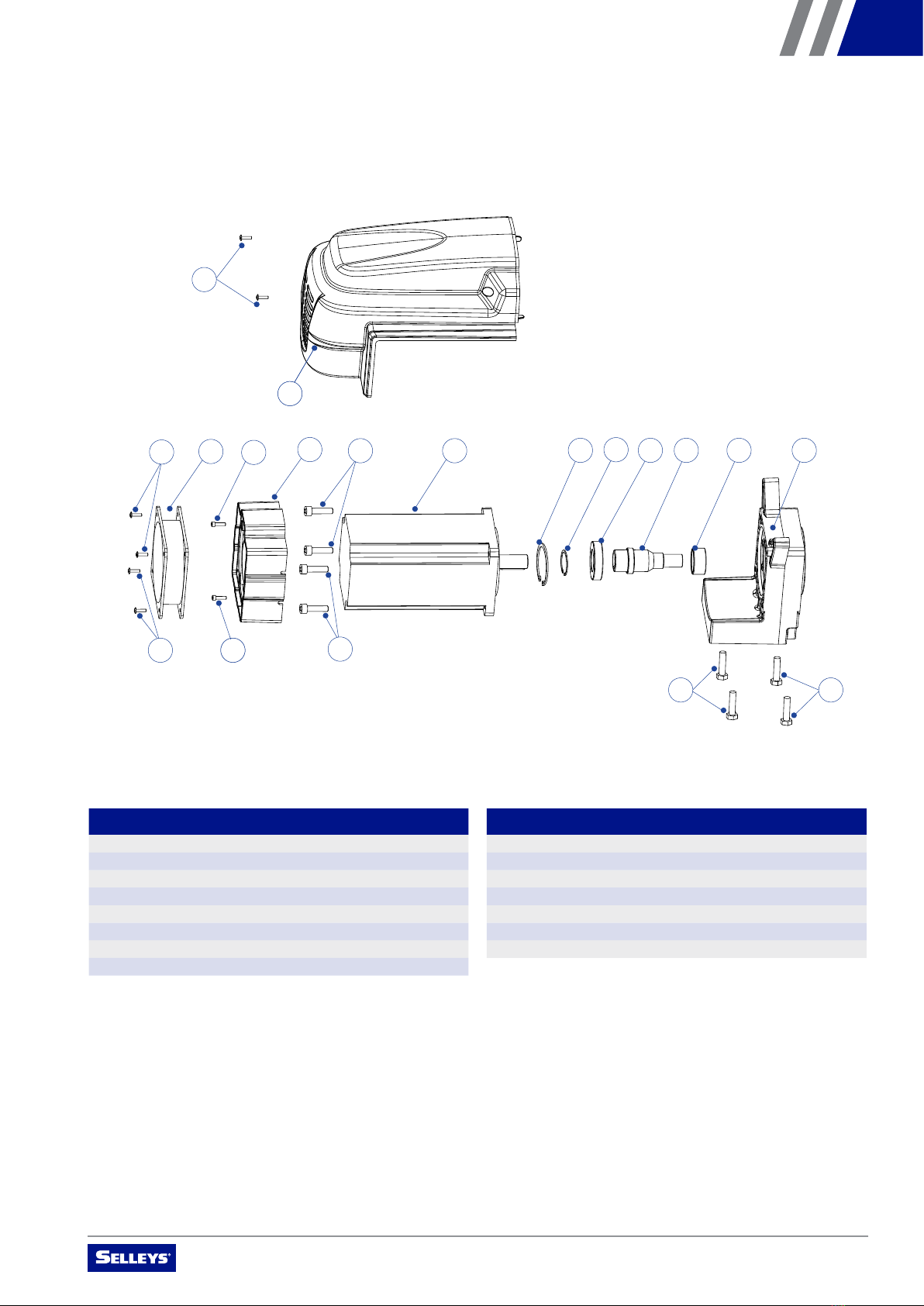

3.2 MAIN COMPONENTS

A

DD

E

B

C

DF

NO. PRODUCT NAME

A ON/OFF switch

B Pressure control knob

C Relief valve

NO. PRODUCT NAME

D Fluid outlet

E Return hose

FSuction Tube

OPERATING MANUAL – SELLEYS S39E

9

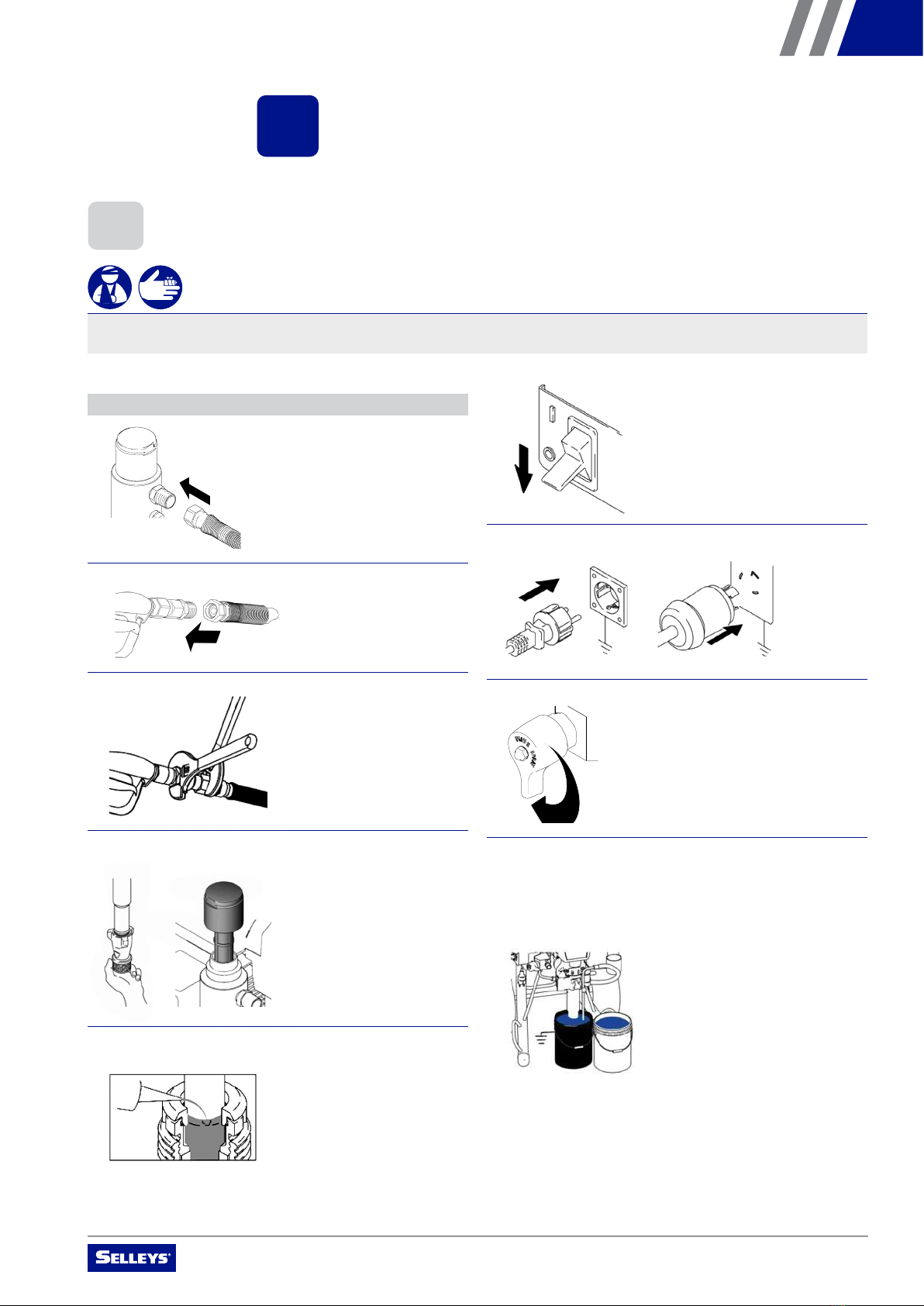

4.1 SETUP

WARNING

Serious risk of explosions due to incompatible materials. Accidental explosions due to incompatible materials can cause serious

injury and/or extensive damage to property.

4. OPERATING INSTRUCTIONS

Please read the following important information carefully.

1. Connect 15m (50 ft) airless hose to sprayer and tighten

securely

NOTE: Remove adapter fitting for 13mm (1/2 in.) hose.

5. Fill throat packing nuts with separating oil to prevent

premature packing wear. Do this each time you spray.

2. Install airless hose to the fluid inlet of the spray gun

3. Tighten securely

6. Turn power OFF

8. Turn the relief valve to "PRIME" position

7. Plug power supply cord into a properly grounded electrical

outlet

9. Place suction tube into a metal pail partially filled with

residual water. Attach ground wire to pail and to true earth

ground (see Earthing Instructions). Perform steps 1 – 5

of Startup to flush out storage oil shipped in sprayer. Use

water to flush water-based paint and appropriate solvent to

flush oil-based paint and storage oil.

4. Remove inlet strainer and suction filter when spraying

plaster materials

OPERATING MANUAL – SELLEYS S39E

10

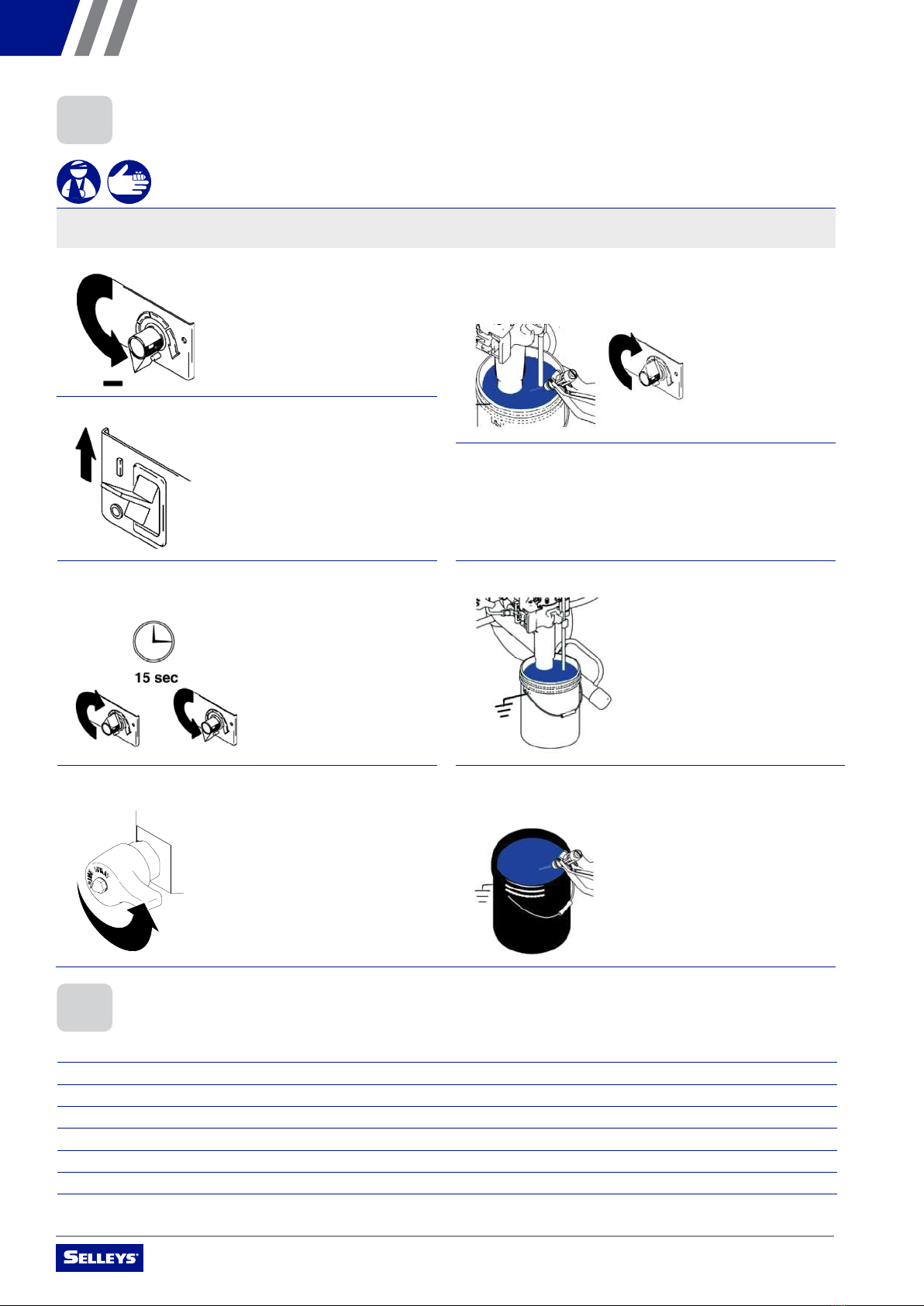

4.3 PRESSURE RELIEF PROCEDURE

4.2 STARTUP

WARNING

Serious risk of explosions due to incompatible materials. Accidental explosions due to incompatible materials can cause serious

injury and/or extensive damage to property.

1. Turn pressure control knob to "minimum" 5. Trigger the spray gun, whilst increasing the pressure

control knob, if neccessary

6. Inspect for leaks. If leaks occur, perform Pressure Relief

Procedure. Tighten fittings. Perform Startup steps 1 - 5.

If no leaks, proceed to step 6.

7. Place suction tube into the container of material

8. Trigger gun again into flushing pail until paint appears.

Move gun to paint pail and trigger for 20 seconds. Set gun

safety ON. Assemble tip and guard.

2. Turn power ON

3. Increase pressure to start motor and allow fluid to

circulate through return hose for 15 seconds. Decrease

pressure control knob to "minimum".

4. Turn relief valve to "SPRAY" position

Follow these steps carefully.

1. Immerse the suction tube and return hose in a container, filled with a suitable cleaning agent

2. Turn the pressure control knob counter-clockwise to minimum pressure

3. Turn the relief valve and set to "PRIME" position

4. Wait until the cleaning agent discharges from the return hose

5. Turn the relief valve and set to "SPRAY" position

6. Pull the trigger of the spray gun

7. Spray the cleaning agent from the unit into a container

OPERATING MANUAL – SELLEYS S39E

11

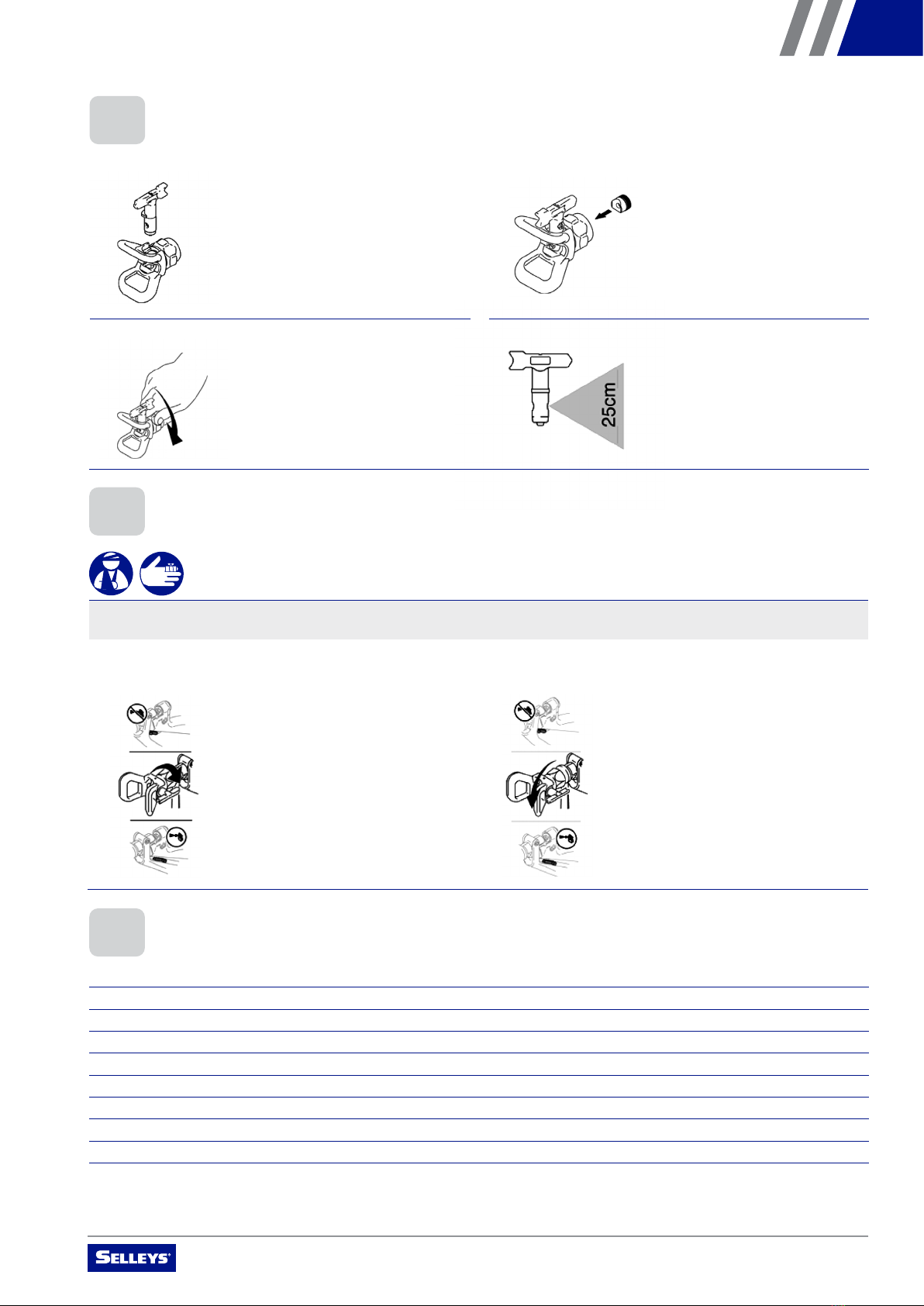

3. Install assembled spray tip and nozzle holder in spray gun 4. Install appropriate spray tip for your material

1. Release trigger, put safety ON. Rotate Spray Tip. Take

safety OFF. Trigger gun to clear clog. Never point gun at

your hand or into a rag!

2. Put safety ON. Return Spray Tip to original position. Take

safety OFF and continue spraying.

11

4.3

1. Insert tip cylinder into guard (arrow points forward).

2. Install Nozzle Seal (curved side in) into housing.

3. Install assembled tip and guard onto spray gun.

4. Install appropriate tip for your material.

4.4 Clear pray Tip Clogs

1. Release trigger, put safety ON. Rotate Spray Tip.

Take safety OFF. Trigger gun to clear clog. Never

point gun at your hand

or into a rag!

2. Put safety ON. Return Spray Tip to original position.

Take safety OFF and continue spraying.

4.6 BEFORE SPRAYING THE COATING MATERIAL

Follow these steps carefully.

1. Turn the pressure control knob counter-clockwise to minimum pressure

2. Turn the relief valve and set to "PRIME" position

3. Switch the unit ON

4. Wait until the coating material discharges from the return hose

5. Turn the relief valve and set to "SPRAY" position

6. Trigger the spray gun and spray into a container until the coating material exits the spray gun continuously

7. Increase the pressure by slowly turning the pressure control knob clockwise

8. Check the spray pattern and increase the pressure until the desired atomisation is attained

9. The unit is ready to spray

1. Insert spray tip into nozzle holder (arrow points forward) 2. Insert nozzle seal (curved side in) into housing

4.5 CLEARING SPRAY TIP CLOGS

WARNING

Serious risk of explosions due to incompatible materials. Accidental explosions due to incompatible materials can cause serious

injury and/or extensive damage to property.

4.4 INSTALLATION OF SPRAY TIP

OPERATING MANUAL – SELLEYS S39E

12

2. Trigger the gun AFTER starting the stroke

3. To ensure even application:

• keep your arm moving

at a constant speed

• keep the spray gun

perpendicular to the

surface

• keep the spray gun at

a constant distance

of 25 to 30cm from

the surface

• overlap each stroke

by about 30%

4. Release the gun BEFORE ending the stroke

NOTE: Gloves do not provide full protection against injection injury.

IMPORTANT

If very sharp edges or streaks appear on the coated surface, increase the operating pressure or dilute the

coating material.

4.8 HANDLING THE HIGH-PRESSURE HOSE

Avoid sharp bending or kinking of the high-pressure hose. The smallest bending radius amounts to about 20cm.

Do not drive over the high-pressure hose, and avoid contact with sharp objects and edges.

WARNING

Defective high-pressure hoses can leak and cause serious injection injury. Replace defective high-pressure hoses immediately.

Never attempt to repair a defective high-pressure hose.

4.9 IN CASE OF INTERRUPTED OPERATION

Follow these steps carefully.

1. Turn the relief valve and set to "PRIME" position

2. Switch the unit OFF

3. Turn the pressure control knob counter-clockwise to minimum pressure

4. Pull the trigger of the spray gun in order to release the pressure from the high-pressure hose and spray gun

5. Secure the spray gun

6. Leave the suction tube (or the suction hose and return hose) immersed in the coating material, or in a cleaning agent

IMPORTANT

If a fast-drying or two-component coating material is used, ensure that the unit is rinsed with a suitable cleaning agent within the

processing time.

25 – 30cm 25 – 30cm

4.7 METHOD OF SPRAYING

WARNING

Never trigger the gun unless the tip is completely turned to either the spray or the unclog position. Always engage the gun trigger

lock before removing, replacing or cleaning the spray tip.

Follow these steps carefully.

1. Ensure that the nozzle holder guard is in place

25 – 30cm 25 – 30cm

OPERATING MANUAL – SELLEYS S39E

13

5. CLEANING AND MAINTENANCE

Please read the following important information carefully.

A. Turn power OFF. Wait 30 seconds for power to dissipate. 1. Do Steps A - D first. Remove suction tube from paint and

place in flushing fluid.

C. Turn the pressure control knob to "minimum", and trigger

the gun to release pressure

B. Lock gun trigger safety. Remove nozzle holder and spray tip. 2. Unscrew the filter cap, and clean the strainer filter

D. Put the return hose in a container and turn the relief valve

to "PRIME" position

3. Switch power ON, and turn the relief valve to "SPRAY" position

NOTE: Use water for water-based material and appropriate solvent

for oil-based material.

4. Increase pressure slowly. Hold gun against the paint

container. Unlock the trigger, and flush the gun until the

flushing fluid appears.

5.1 CLEANING AND SHUTTING DOWN

WARNING

Serious risk of explosions due to incompatible materials. Accidental explosions due to incompatible materials can cause serious

injury and/or extensive damage to property.

OPERATING MANUAL – SELLEYS S39E

14

5. Move gun to waste pail, hold gun against pail, trigger gun

to thoroughly flush system. Release trigger and put trigger

safety ON.

9. Turn the relief valve to "PRIME" position, and ensure the

pressure control knob is set to "minimum". Unplug the unit

from the power source.

6. Turn the relief valve to "PRIME" position and allow the

flushing fluid to circulate and clean the return hose 10. Remove filters from gun and sprayer, if installed. Clean

and inspect. Install filters.

7. Remove the suction tube and allow the unit to run and

drain the flushing fluid

11. If flushing with water, flush again with mineral spirits, or

a suitable product, to leave a protective coating to prevent

freezing or corrosion

8. Turn the relief valve to "SPRAY" position. Trigger the gun

into the flushing pail. Switch OFF power. 12. Wipe sprayer, hose and gun with a rag soaked in water or

mineral spirits

IMPORTANT

The container must be earthed in case of coating materials that contain solvents.

13

5. Move gun to waste pail, hold gun against pail,

trigger gun to thoroughly flush system. Release

trigger and put trigger safety ON.

6. Turn prime valve down and allow flushing fluid to cir-

culate for 15 seconds to clean drain tube.

7. Raise pump above flushing fluid and run sprayer for

15 to 30 seconds to drain fluid.

8. Close drain valve. Trigger gun into flushing pail to

purge fluid from hose. Turn power OFF.

9. Open prime valve. Unplug sprayer.

10. Remove filters from gun and sprayer, if installed.

Clean and inspect. Install filters.

11. If flushing with water, flush again with mineral spirits,

or Pump Armor, to leave a protective coating to pre-

vent freezing or corrosion.

12. Wipe sprayer, hose and gun with a rag soaked in

water or mineral spirits.

OPERATING MANUAL – SELLEYS S39E

15

5.4 ASSEMBLY OF THE GUN FILTER

Follow these steps carefully.

1. Place the gun filter (Figure 1.3) with the long cone pointing up into the gun housing

2. Screw the grip (1.2) into the gun housing and tighten

3. Slot in the protective guard (1.1)

1

3

2

IMPORTANT

Replace the gun filter if it is clogged or faulty.

Figure 1

5.2 CLEANING THE AIRLESS SPRAY GUN

Follow these steps carefully.

1. Rinse the airless spray gun with a sucient amount of a suitable cleaning agent

2. Thoroughly clean the tip with a sucient amount of a suitable cleaning agent until all unused coating material has been removed

3. Thoroughly clean the outside of the airless spray gun

5.3 DISASSEMBLY OF THE GUN FILTER

Follow these steps carefully.

1. Pull the protective guard (Figure 1.1) forward with moderate force

2. Unscrew the grip (1.2) from the gun housing and remove the gun filter (1.3)

OPERATING MANUAL – SELLEYS S39E

16

6. MALFUNCTIONS

Refer to the chart below for instructions on how to correct common malfunctions.

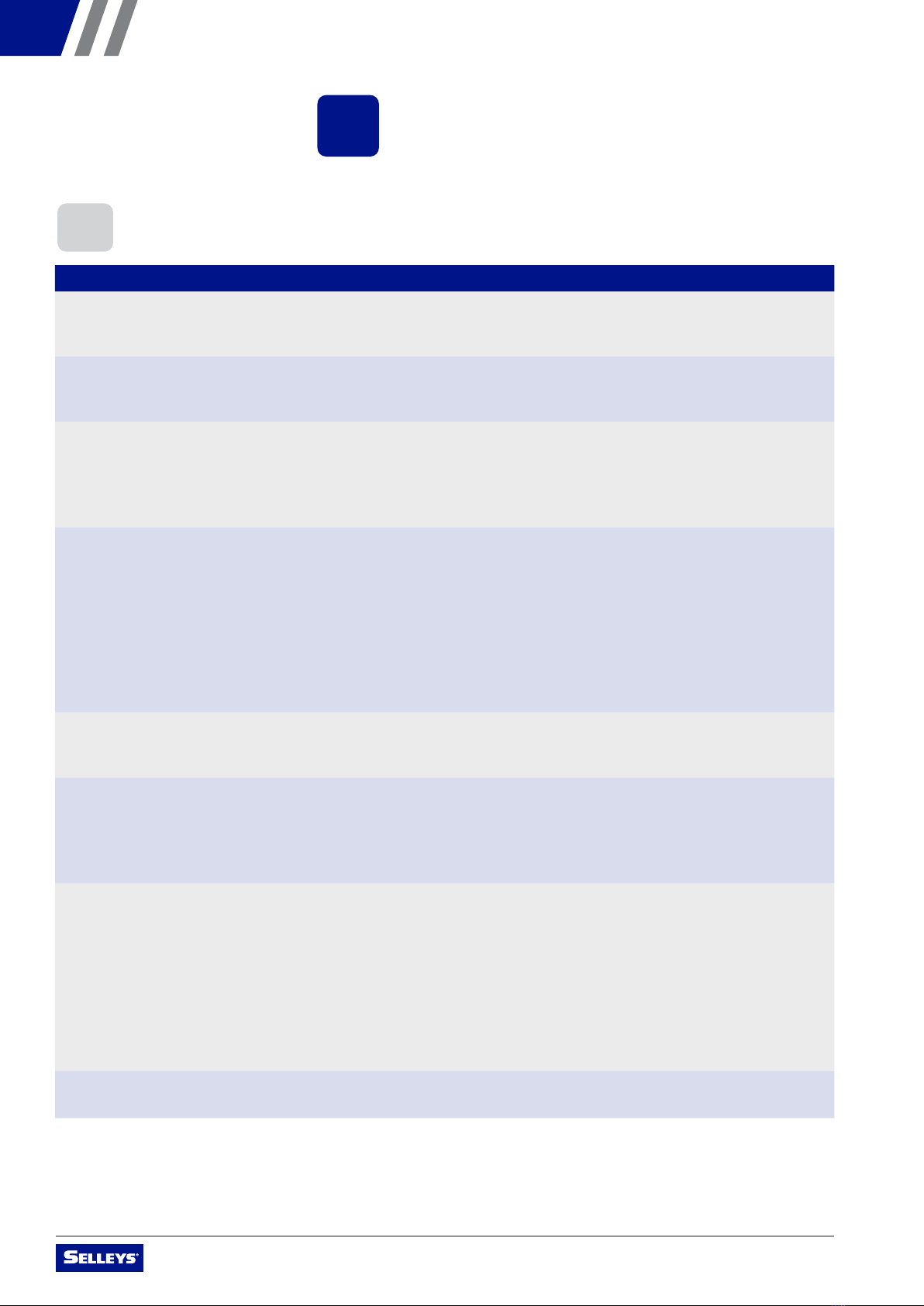

6.1 CORRECTIVE MEASURES FOR COMMON MALFUNCTIONS

TYPE OF MALFUNCTION POSSIBLE CAUSES CORRECTIVE MEASURES

A. Motor works but pump does not

work. There is no error code

displayed.

1. Connecting rod is worn or damaged 1. Replace the connecting rod

B. The motor does not start.

Error code E-XX is displayed.

1. Piston rod is stuck due to dry paint

2. Connecting rod/piston rod is damaged

and/or stuck

1. Replace worn or damaged parts

C. The motor does not start. There

is no error code displayed.

1. Gun/nozzle is clogged

2. Pressure setting is too low

3. Filter is clogged

4. High pressure hose is clogged

1. Clean the gun/nozzle

2. Turn the pressure control knob clockwise

to increase the pressure

3. Clean the filter

4. Clean or replace the high pressure hose

D. Pump output is low 1. Pressure setting is too low

2. Filter is clogged

3. Piston rod/suction valve ball is not

in place

4. Pump packing is worn or damaged

5. Gun/nozzle is clogged

6. High pressure hose is clogged or its

diameter is too small

1. Turn the pressure control knob

clockwise to increase the pressure

2. Clean the filter

3. Clean or replace the ball or seat

4. Replace the packing set

5. Clean the gun/nozzle

6. Clean or replace the high pressure hose

with one of a sucient diameter

E. Paint residue in the pump body

lock nut

1. Lock nut has loosened

2. Upper packing is worn or damaged

3. Piston rod is worn or damaged

1. Remove the nut, clean it and re-install it

2. Replace the upper packing

3. Replace the piston rod

F. Paint is discharged

intermittently

1. Air is present in the pump body,

filter assembly or high pressure hose

2. Nozzle is partially clogged

3. Insucient supply of paint

1. Ensure that the connecting pipe is firmly

connected and continue to trigger the

spray gun until air is discharged

2. Clean the nozzle

3. Add more paint to the paint pail

G. Pump works but paint is not

being discharged

1. Air intake valve is leaking

2. Pump seal(s) are worn

3. Paint is too thick

1. Turn the return valve to the return

position until the return pipe has material

flowing out continuously

2. Check to determine if the sealing ring in

the intake valve is worn or damaged, and

the intake valve is loose. If so, replace the

seal(s) and lock the intake valve.

3. Thin the paint according to the

manufacturer’s instructions

H. Sprayer works but display is

blank

1. Display has a loose connection of fault 1. Check and tighten the connections, and

replace the display if necessary

OPERATING MANUAL – SELLEYS S39E

17

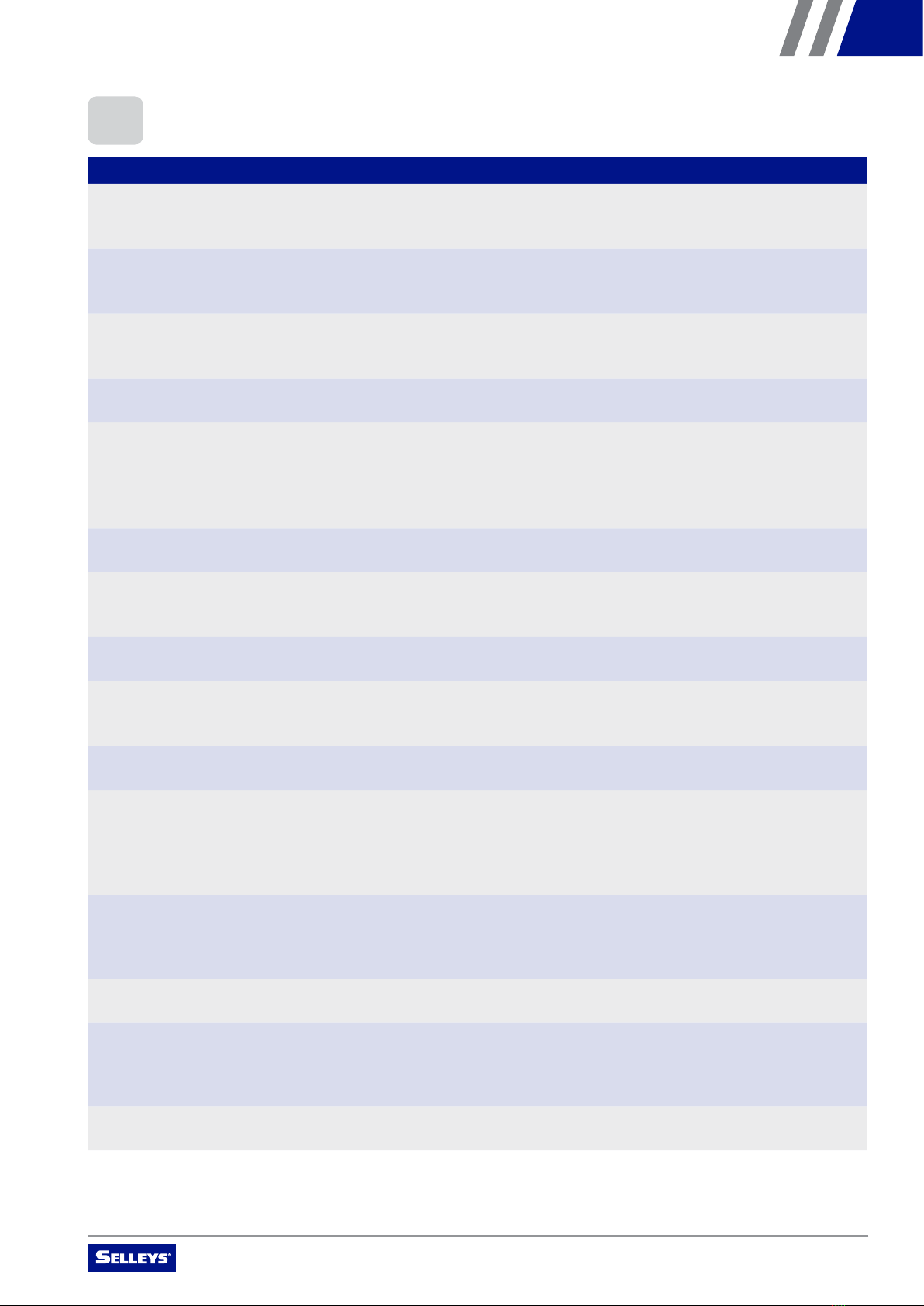

6.2 ERROR CODES

ERROR CODE ERROR DESCRIPTION CONDITIONS MAINTENANCE ADVICE

ERR_1 Hardware overcurrent

protection

Hardware overcurrent circuit

signal is detected

1. Switch power OFF and ON

2. Replace circuit board

3. Replace electric motor

ERR_2 Software detects that the motor

current is high

The software detects the

motor current is high

1. Switch power OFF and ON

2. Replace circuit board

3. Replace electric motor

ERR_3 Bus-bar voltage is high The input voltage is high 1. Check that input voltage is

not more than 260VAC

2. Replace circuit board

ERR_4 Bus-bar voltage is low The input voltage is low 1. This feature is temporarily

disabled

ERR_5 Abnormal motor hall The three halls of the motor

appear at high level or low level

1. Check that the hall terminal

is tightly fitted into the

circuit board

2. Replace circuit board

3. Replace electric motor

ERR_9 Chip memory error alarm An error occurred while data

is stored in the chip

1. Replace circuit board

ERR_10 Motor current amplifier error The internal operational

amplifier circuit is abnormal when

the motor is not running

1. Replace circuit board

ERR_11 High pressure error The output circuit voltage of

the pressure sensor is high

1. Reduce pressure

ERR_12 The motor is protected when

the equipment has no pressure

A protection mechanism when the

motor is running continuously for

one minute during return phase

1. Switch power OFF and ON

ERR_13 Chip ID error Abnormality was detected

after powering ON

1. Replace circuit board

ERR_14 Starter motor stall protection The motor is blocked or

not running

1. Check that the UVW

connection of the motor

is intact

2. Replace circuit board

3. Replace electric motor

ERR_15 Pressure sensor failure Detected abnormal signal

of pressure sensor

1. Check that the pressure

sensor is well connected

2. Replace pressure sensor

3. Replace circuit board

ERR_16 Communication check

code error

The chip indicated a checksum

error during internal communication

1. Replace circuit board

ERR_17 Abnormal pressure feedback The pressure estimated by

the software diers from the

actual pressure

1. Check that the pressure

sensor is well connected

2. Replace pressure sensor

3. Replace circuit board

ERR_18 Communication failure No communication signal

is received in the chip

1. Replace circuit board

OPERATING MANUAL – SELLEYS S39E

18

1002

1005 1005

1006

1006

1007

1003

1003

1004

1004

1001

1002

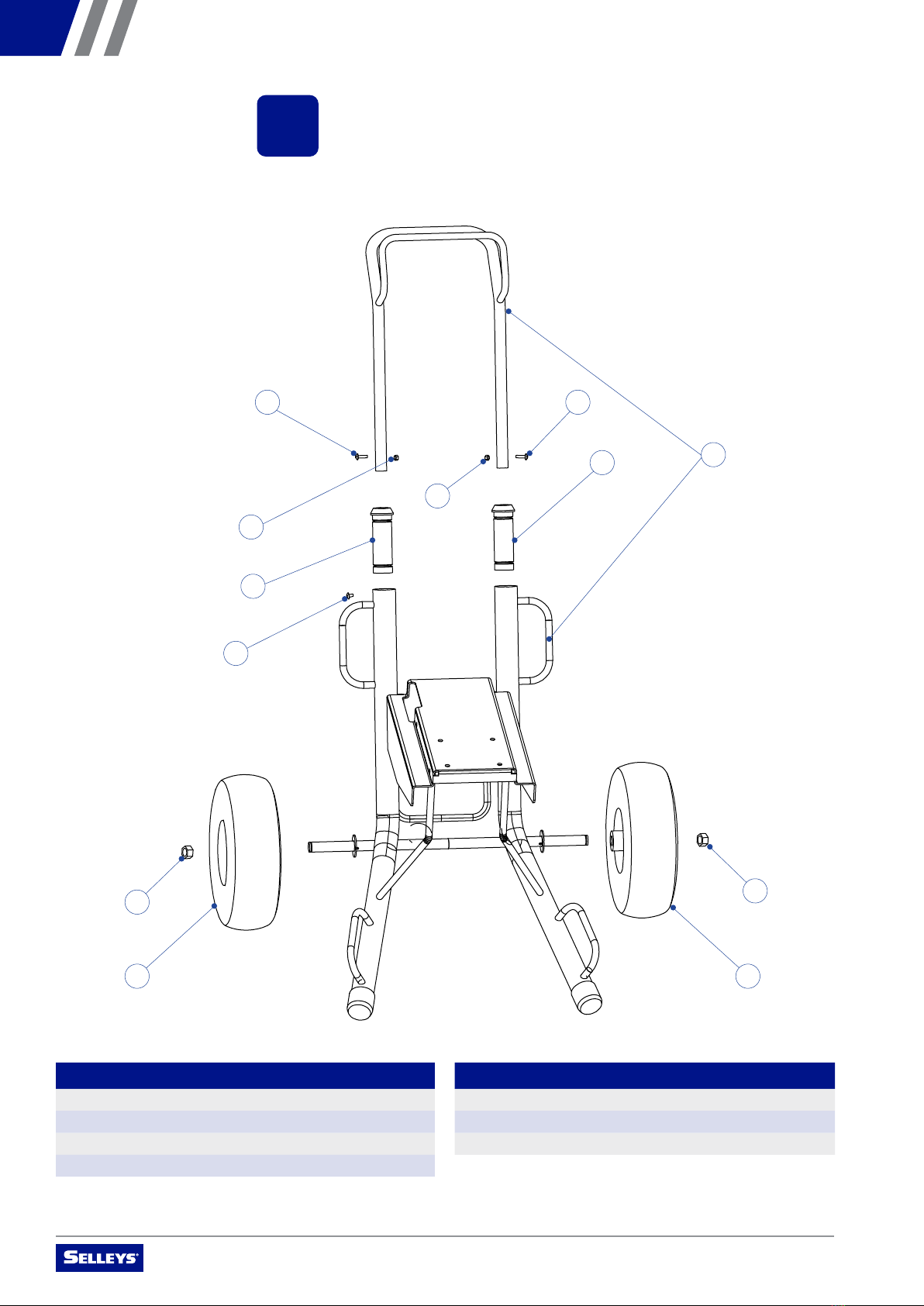

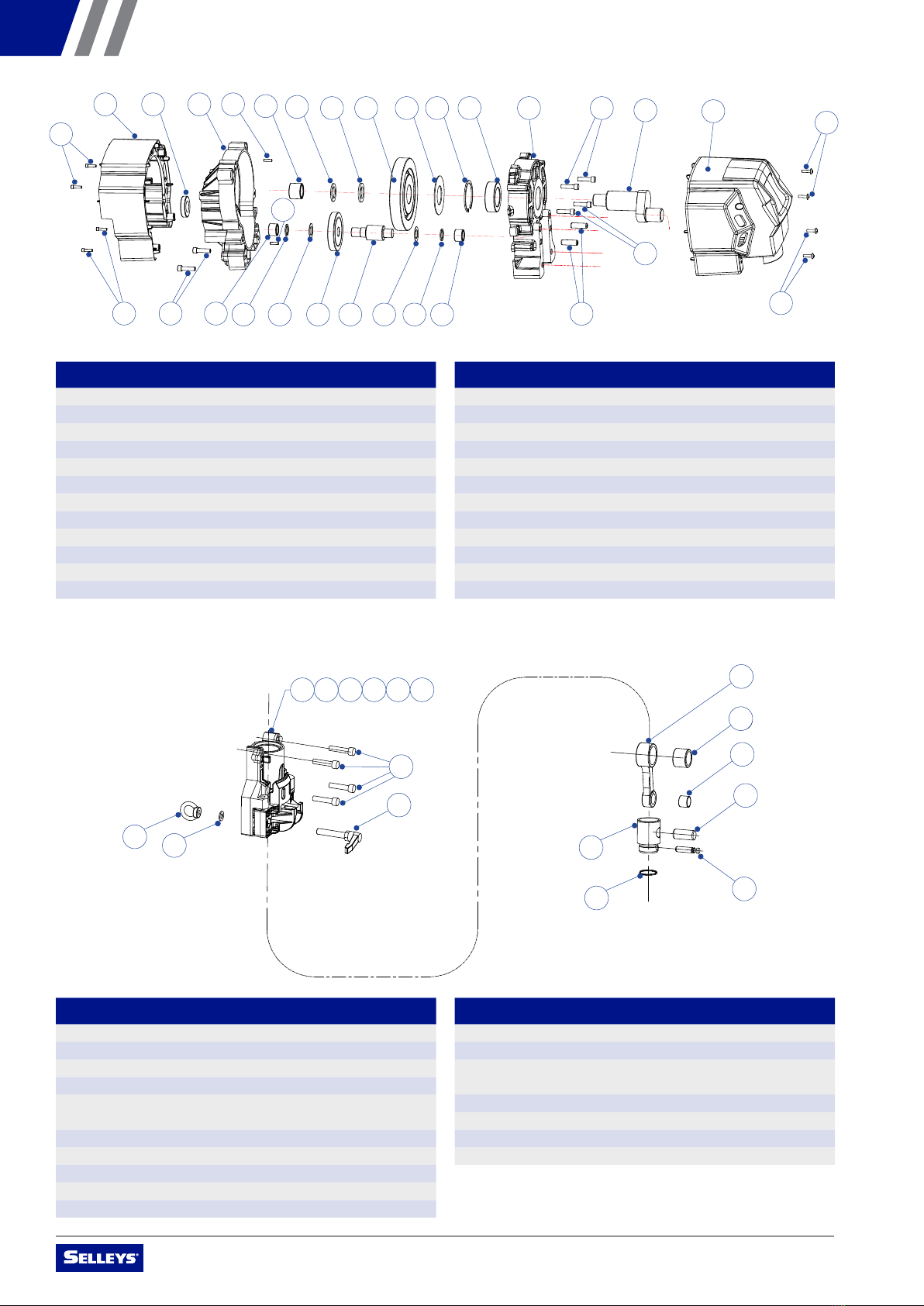

7. PARTS AND ASSEMBLY

Please read the following important information carefully.

NO. NAME QUANTITY

1001 Trolley frame 1

1002 Handle holder 2

1003 Hexagon nut M18 2

1004 Pneumatic tyre 2

NO. NAME QUANTITY

1005 Screw M4 * 25mm 2

1006 Hexagon nut M4 2

1007 Screw M5 * 5mm 1

OPERATING MANUAL – SELLEYS S39E

19

NO. NAME QUANTITY

101 Motor base 1

102 Roller bearing HF3520 1

103 Gear assembly 1

104 Ball bearing 6007 1

105 Circlip for hole ø62 1

105A Circlip for hole ø35 1

106 Electric motor 1

107 Hexagon screw M8 * 20mm 4

NO. NAME QUANTITY

108 Air shield 1

109 Hexagon screw 2

110 Axial fan 1

111 Screw ST4.8 * 16P * 15mm 4

112 Rear cover 1

113 Cross-head screw 2

114 Hexagon machine screw M8 * 20mm 4

113

112

110 109

109

108 106 105 104

105A 103 102 101

114 114

111

111

107

107

OPERATING MANUAL – SELLEYS S39E

20

NO. NAME QUANTITY

201 Middle cover 1

202 Ball bearing 1

203 Gearbox primary cover 1

204 Cylindrical pin 2

205 Ball bearing SCH1616 1

206 Ball bearing SCH1212 1

207 Gasket ø32 * ø19.05 * 1.6T 1

208 Gasket ø32 * ø19 * 0.8T 1

209 Secondary gear disc 1

210 Secondary gear shaft 1

211 Gear washer ø41 * ø25.7 * 3.2T 1

212 Gear washer ø39 * ø25.7 * 2.4T 1

NO. NAME QUANTITY

301 Piston sleeve (OD) ø57.2 *(ID) ø47 *76 (H) 1

302 Piston mount 1

303 Piston screw M10 1

304 Screw 4

305 Piston rotary shaft sleeve

(OD) ø12.7 * (ID) ø9.5

1

306 Piston rotary axis ø9.525 * 76mm 1

307 Piston hexagon screw BM10 * 80 8 60mm 1

308 Shank screw BM10 * 80 8 60mm 1

309 Double-sided washer M10 1

310 Nut M10 x SUS304 1

NO. NAME QUANTITY

401 Link rod 1

402 Needle roller bearing SCH1818 1

403 Self-lubricating bearing

(OD) ø23 * (ID) ø20 * 18.6mm

1

404 Piston valve ø47.6 * 67.5mm 1

405 Piston rod connecting pin ø20 * 38.1mm 1

406 Piston rod pin ø11.1 * 50mm 1

407 Spring wire (OD) ø1.5 * (ID) ø36.4 1

201 202 203 204 205 211 212 213 214 215 216 217 220

218

223 206 207 208 209 210 208 207 206

224

224

204

219

222

222

221

221

NO. NAME QUANTITY

213 Primary gear disc 1

214 Gasket ø84 * ø41.3 * 1.6T 1

215 Circlip for hole ø62 1

216 Roller bearing F-45087-00 1

217 Gearbox secondary cover 1

218 Eccentric gear 1

219 Cylindrical pin ø11.1 * 36mm 2

220 Front cover 1

221 Screw M5 * 10mm 4

222 Hexagon screw M8 * 35mm 4

223 Hexagon screw M8 * 50mm 2

224 Hexagon screw M8 * 1P * 30mm 4

308

310

309 404

407

406

405

403

402

401

301 302 303 305 306 307

304

Table of contents

Other Selleys Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

CAMPAGNOLA

CAMPAGNOLA LIPO 550 Use and maintenance manual

Campbell Hausfeld

Campbell Hausfeld PS240R Assembly instructions and parts list

Longray

Longray MistGen MG-SB16 user manual

Silvan Selecta

Silvan Selecta TR25-S7 instruction manual

Ryobi

Ryobi P2804 Operator's manual

Mesto

Mesto 3237 Instructions for use