Selleys PLASTCOAT PC7X User manual

OPERATING MANUAL

SELLEYS PLASTCOAT PC7X

WITH AIR COMPRESSOR

CONTENTS

1. SAFETY INFORMATION

1.1 General Safety Precautions

1.2 Specific Safety Hazards and Precautions

1.3 Earthing Instructions

2. MATERIALS

2.1 Materials Suitable for Use

2.2 Materials Not Suitable for Use

2.3 Spray Real Stone Paint with Caution

3. EQUIPMENT

3.1 Technical Data

3.2 Main Components

4. OPERATING INSTRUCTIONS

4.1 Checking for Air Leakage

4.2 Prior to Starting Up

4.3 Starting Up

4.4 Material Feeding Process

5. SHUTTING DOWN AND CLEANING

5.1 Shutting Down

5.2 Cleaning

6. MALFUNCTIONS

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

WARNING

This unit is capable of extremely high spraying pressures that can cause serious and/or minor

injury by injection and extensive damage to property.

IMPORTANT

All replacement parts and accessories should ONLY be purchased from SELLEYS or an

authorised distributor of SELLEYS equipment. Servicing should ONLY be carried out by SELLEYS

or an authorised distributor of SELLEYS equipment. If these conditions are not met, the operator

assumes all liability for injury and property damage arising from the use of this unit.

1. SAFETY INFORMATION

Please read the following important information carefully.

The following symbols indicate specific types of safety hazards.

Indicates a potential hazard that may cause serious injury to the operator or

loss of life.

Indicates a potential hazard that may cause minor injury to the operator or

to the equipment.

Indicates important information.

3

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

1.1 GENERAL SAFETY PRECAUTIONS

NEVER

• use the spray gun without the safety guard in place

• operate faulty units or use faulty accessories

• attempt to repair a damaged hose

• leave this equipment unattended

• move the unit when it is running

• spray outside on windy days

ALWAYS

• ensure that this unit is properly earthed

• ensure that the power cord, air hose and spray hoses are optimally routed to minimise slip, trip and fall hazards

• immediately and thoroughly clean up all material and solvent spills to prevent slip hazards

• follow the material manufacturer’s instructions for safe handling of coating materials

• unplug the cord from the outlet before cleaning, maintaining or repairing this unit

• keep the power cord plug in sight during use to prevent accidental shutdowns and startups

• wear ear protection to protect against possible hearing loss from the noise produced by this unit, which can exceed 85 dB(A)

• keep this unit out of reach of children, unqualified adults and animals

• comply with local codes regarding ventilation, fire prevention, and operation

1.2 SPECIFIC SAFETY HAZARDS AND PRECAUTIONS

SAFETY PRECAUTIONS TO PREVENT INJECTION INJURY

WARNING

Serious risk of injection injury. This equipment produces a high-pressure stream that can pierce the skin and subcutaneous

tissues, resulting in severe injury and even possible amputation.

IMPORTANT

The maximum operating range of the unit is 21 bar (22.1 MPa, 3200 PSI) fluid pressure.

NEVER

• put your fingers, hands or any other parts of your body into the spray jet

• point the spray gun at yourself or anyone else (including animals)

• allow the fluid stream to come into contact with any part of your body

• allow any leak in the fluid hose to come into contact with any part of your body

• put your hand in front of the gun

NOTE: Gloves do not provide full protection against injection injury.

• use a spray gun without both a working trigger lock and trigger guard in place

ALWAYS

• ensure that the gun trigger is locked, the fluid pump is shut o, and all pressure is released before servicing, cleaning the tip

guard, changing tips, or leaving the unit unattended

NOTE: Turning o the engine will not release the pressure. The PRIME/SPRAY valve or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• ensure that the tip guard remains in place during spraying

• remove the spray tip before flushing or cleaning the system

• carefully check the paint hose for leaks before each use, as even small leaks can cause injection injury

• ensure that all accessories, including but not limited to spray tips, guns, extensions and hose, are rated at or above the

maximum operating pressure range of the sprayer

IMPORTANT MEDICAL INFORMATION

Injection injury is a traumatic injury that requires immediate medical attention. Any laceration of the skin, no matter how minor

it seems, should not be treated as a simple cut. Fully inform the medical team about the coatings or solvents involved, as some

coatings are toxic when injected directly into the bloodstream. For serious injuries, a plastic surgeon or reconstructive hand

surgeon should be consulted.

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

4

SAFETY PRECAUTIONS TO PREVENT EXPLOSIONS AND FIRE

WARNING

This equipment produces a high-pressure stream that can pierce the skin and subcutaneous tissues, resulting in severe injury

and even possible amputation.

NEVER

• use plastic drop cloths or enclose the spray area with plastic sheets, as plastic can cause static sparks

• smoke in the spray area

• use any materials with a flashpoint lower than 21°C (70°F)

NOTE: Flashpoint is the temperature at which a fluid can produce sucient vapours to ignite.

ALWAYS

• ensure that the spray area is well-ventilated to prevent the build-up of flammable vapours

• avoid all ignition sources such as static electricity sparks, electrical appliances, flames, pilot lights, hot objects, and sparks from

connecting and disconnecting power cords and/or working light switches

• flush the unit into a separate metal container, at the lowest possible pump pressure and with the spray tip removed

• hold the gun firmly against the side of the container to prevent static sparks

• have a fire extinguisher nearby

• place the sprayer at a minimum of 6.1 metres (20 feet) from the surface to be sprayed, extending the hose if necessary. Since

flammable vapours are often heavier than air, the floor area must be well ventilated. The pump contains arcing parts that emit

sparks, which can ignite vapours.

• ensure that the equipment and objects in and around the spray area are properly grounded to prevent static sparks

• ensure that you are using a conductive or earthed high pressure hose

• ensure that the gun is earthed through the hose connection

• ensure that the power cord is connected to a grounded circuit

• ensure that the unit is connected to an earthed object such as a water pipe, steel beam, or other electrically earthed surface, via

the green earthing wire

• strictly follow the material and solvent manufacturer’s warnings and instructions, and read the coating material’s MSDS

(Material Safety Data Sheet) and technical information before use

SAFETY PRECAUTIONS TO PREVENT EXPLOSIONS DUE TO INCOMPATIBLE MATERIALS

WARNING

Serious risk of explosions due to incompatible materials. Accidental explosions due to incompatible materials can cause serious

injury and/or extensive damage to property.

NEVER

• use materials that contain bleach or chlorine

• use halogenated hydrocarbon solvents such as methylene chloride and 1,1,1-trichloroethane

NOTE: These substances are not compatible with aluminium and may cause an explosion. If you are in any doubt over a material’s compatibility

with aluminium, check with your coating supplier.

SAFETY PRECAUTIONS TO PREVENT HARM FROM TOXIC VAPOURS

WARNING

Vapours from paints, solvents, insecticides, and other materials can be harmful in the event of inhalation or contact with any part

of the body. Symptoms include severe nausea, fainting and poisoning.

ALWAYS

• use a respirator or mask

• wear protective eyewear

• wear protective clothing

5

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

WARNING

Incorrect installation of the earthing plug can result in electric shock. If you need to repair or replace the cord or plug, do not

connect the green earthing wire to either blade terminal.

IMPORTANT

The wire with insulation, which has a green outer surface with or without yellow stripes, is the earthing wire. It must be

connected to the earthing pin.

Use of an undersized cord causes a drop in line voltage, loss of power and overheating.

A list of the materials used in the construction of this unit is available upon request for the purpose of determining compatibility

with coating materials.

SAFETY PRECAUTIONS TO PREVENT HARM FROM MOVING PARTS

WARNING

Moving parts can pinch, cut or amputate fingers and other body parts. Furthermore, equipment can start without warning.

ALWAYS

• keep clear of moving parts

• follow the Pressure Relief Procedure and disconnect all power sources before checking, moving or servicing the equipment

NEVER

• operate equipment with protective guards or covers removed

1.3 EARTHING INSTRUCTIONS

NEVER

• operate this unit unless you are sure that it has been properly earthed

• modify the earthing plug

• use a 3-to-2 adapter with this equipment

ALWAYS

• ensure that the earthing plug is plugged into an outlet that has been properly installed and earthed in accordance with local

codes

• seek the advice of a qualified electrician if you need a new outlet installed to fit the earthing plug, do not fully understand these

earthing instructions, or are unsure as to whether this unit is properly earthed

• if required, use only a 3-wire extension cord with a grounding plug and a grounding receptacle that accepts the plug on this

equipment, and a minimum AWG (2.5mm2) to carry the current that this equipment draws

Conductor Size Length

AWG (American Wire Gauge) Metric Maximum

122.5mm215m (50 ft)

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

6

2.2 MATERIALS NOT SUITABLE FOR USE

IMPORTANT

Never use this unit for spraying oily materials. If you need to spray oily materials, please contact an authorised SELLEYS

distributor for further advice.

2.3 SPRAY REAL STONE PAINT WITH CAUTION

WARNING

For the avoidance of serious and minor injuries to bystanders, please familiarise yourself with the operating instructions and

switching steps for real stone paint.

3. EQUIPMENT

Please read the following important information carefully.

2. MATERIALS

Read the following important information carefully.

2.1 MATERIALS SUITABLE FOR USE

This unit is suitable for use with the following coatings: real paint, sand in water, caulking plaster, latex paint, levelling wine slurry,

bonding mortar, silicon mud coating, waterproofing and other materials.

IMPORTANT

The use of materials other than those stated above may lead to damage of parts and a shortened service life of the machine. If in

doubt as to a material’s suitability for use, please consult an authorised SELLEYS dealer.

3.1 TECHNICAL DATA

Dimensions (L x W x H) 1140 x 520 x 790mm

Weight 76kg

Motor output 2.2kW

Flow rate (with water) 18L/min

Max. operating pressure 30 bar

Max. spray height 30m

7

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

25 24

28

23 21 14 13

12

8

29

10

19 22 16

17

18

11

15 9

96

5

432

1

30

7

26 20

31

NO. NAME QUANTITY

1 Motor 1

2 Motor key pin 1

3 Reducer 1

4 Gearbox key pin 1

5 Gearbox connecting flange 1

6 Output bushing 1

7 M10 spring pad 8

8 Gearbox connecting flange screw 8

9 Plane bearing 1

10 Output shaft 1

11 Cage screw 1

12 Output shaft screw 1

13 Oil seal 2

14 Oil seal cartridge 1

15 Auger 1

16 Flat head pin 1

17 R cotter pin 1

18 Hopper inlet 1

19 Screw 1

20 Rubber sleeve 1

NO. NAME QUANTITY

21 Flange nut 2

22 Rubber sleeve rear flange 1

23 Screw nut 3

24 Rubber sleeve nut 3

25 Rubber sleeve front fixing flange 1

26 Pressure gauge assembly 1

27 Drain 1

28 Screw 1

29 Trolley frame 2

30 Rear wheel 2

31 Front wheel 1

32 Control panel 1

33 Three-position switch 1

34 Potentiometer 1

35 ON/OFF switch 1

36 Power indicator 1

37 Speed indicator 1

38 Water separator 1

39 Remote controller 1

40 Hopper 1

3.2 MAIN COMPONENTS

36

35

33

34

37

38

40

27

39

32

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

8

4.1 CHECKING FOR AIR LEAKAGE

IMPORTANT

Connect the air pressure regulating valve (Figure 1) to check for air leakage at the connection part of the air hose.

NOTE: Since this machine is controlled by pneumatic induction, air leakage will aect the sensitivity of the switch.

4. OPERATING INSTRUCTIONS

Please read the following important information carefully.

4.2 PRIOR TO STARTING UP

1. Pour the mixed material into the hopper (Figure 2)

2. Start the machine and wait for the material to flow out from the other end of the high-pressure pipe

NOTE: Remove the nozzle before commencing these steps to prevent the nozzle from being blocked by remaining old material in the material

tube.

Figure 1 Figure 2

9

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

1. Turn on the power switch (ON/OFF switch) (Figure 3) and ensure that the three-position switch is set to AUTOMATIC (Figure 4)

2. Slowly adjust the potentiometer switch clockwise (Figure 5)

3. Confirm the material pipe and connection parts are in good condition and ensure that there is no leakage

4. Pour in material (mixed in strict accordance with the manufacturer’s instructions)

IMPORTANT

When in use, the speed should not be too fast, and the corresponding nozzle output should be sucient for normal use. Failure to

follow these instructions may reduce the service life of the rubber sleeve screw.

4.4 MATERIAL FEEDING PROCESS

Before filling the hopper with the standard consistency of the material to be sprayed, follow these steps.

1. Pour out approx. 20 litres of the mixed material to be sprayed, add approx. 5 litres of clean water, stir, and pour it into the hopper

2. Discharge this diluted material from the other end of the spray gun

NOTE: Remember to remove the nozzle before filling the hopper to prevent residual old material in the material pipe from clogging the nozzle.

IMPORTANT

This material feeding process must be performed to lubricate the pipe wall before the standard material to be sprayed is poured in.

4.3 STARTING UP

Figure 3 Figure 4

Figure 5

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

10

6. MALFUNCTIONS

5.2 CLEANING

FOR USE ON CONSECUTIVE DAYS

After spraying, if you intend to resume spraying tomorrow, the unit does not need to be cleaned. Simply remove the pressure,

immerse the spray gun in water, fill the hopper with water, and cover the remaining mixed material to prevent it from drying out.

BEFORE USE AND/OR WHEN CHANGING MATERIALS

When using, pour clean water into the hopper to flush the residual paint and water pressure in the unit out of the tube. When

clean water is flowing out, fold down the tube connecting the machine, put the special cleaning ball into the tube and re-fasten it

(Figure 7). Then turn it on and wait until the cleaning ball is discharged from the other end of the tube.

Figure 7

5.1 SHUTTING DOWN

1. Turn o the air source from the spray gun

2. Repeatedly pull the trigger to release the pressure in the hose

3. Turn the three-position switch to “REV” (Figure 6), wait for the rotor-stator to reverse for about

1 - 5 minutes, and confirm that there is no air in the machine before removing the spray gun

5. SHUTTING DOWN AND CLEANING

Please read the following important information carefully.

Figure 6

11

OPERATING MANUAL – SELLEYS PLASTCOAT PC7X WITH AIR COMPRESSOR

6. MALFUNCTIONS

Refer to the chart below for instructions on how to correct common malfunctions.

TYPE OF MALFUNCTION POSSIBLE CAUSES CORRECTIVE MEASURES

A. The red working light is on and

the machine is not running

1. The automatic switch is not turned on

2. The speed control knob stops at the

0-3 position

3. The pneumatic sensor is blocked and

the magnetic core is not returned

4. The circuit board connection is loose

or damaged

5. The motor is damaged, the motor and

the gear are stuck

1. Turn the switch to AUTOMATIC

2. Adjust the knob to the corresponding

position

3. Clean the inside of the sensor

4. Check the circuit board for damage and

replace if necessary

5. Replace the motor or gear and add

lubricant

B. The motor works but barely

spins

1. The connection between the motor and

the gearbox has fallen o or is stuck

2. The output wire of the control box may

not be in good contact with the motor

wire

3. The rubber sleeve is stuck after it has not

been used for a long time or is dried out

1. Check whether the motor pin is falling o

and/or whether the gearbox is stuck

2. Check to see if the wire card is loose

3. Remove and clean the rubber sleeve,

add detergent or petroleum jelly, then

reinstall it; or replace the rubber sleeve

C. Paint suddenly stops flowing

while sprayer is in use

1. The nozzle is clogged due to impurities

in the paint, or excessive particle size

of the paint, i.e. nozzle is too small

2. Paint is clogged inside the mortar hose,

which may not have been pre-lubricated

1. Stop the mortar sprayer, turn o the

material switch on the gun, remove the

texture nozzle, clean the air duct of the

nozzle and change the air volume setting

2. Clean the mortar and the bottom of the

coater, refill the hopper and use the pump

to circulate the paint until the bubbles in

the paint subside

NOTE: Always top up the hopper with

sucient material. Running the pump dry

may cause overheating and clogging.

D. The pressure on the pressure

gauge rises above 40 bar

1. Paint viscosity is too high

2. Mortar hose diameter is too small

3. Mortar hose is too long

4. Paint is jammed in mortar hose, which

may not have been pre-lubricated

1. Dilute paint

2. Use a larger diameter mortar hose

3. Use a shorter mortar hose

4. Decrease mortar hose pressure:

• Set selector switch to 90 pressure

• Repump paint back into release hopper

• Disconnect the mortar hose and rinse

with water

• After the blockage is removed,

reconnect the mortar hose

E. Not enough paint is being

pumped by the post-mortar

coater

1. Delivery volume selected is too low

2. Mortar hose diameter is too small

3. The screw sleeve is worn

4. The nozzle is too small and the gun

hole is blocked

1. Increase the delivery volume

2. Use a larger diameter hose

3. Replace screw sleeve

4. Remove, clean and reattach nozzle,

then increase the orifice size

Selleys is a subsidiary of

Nippon Paint (Singapore) Co. Pte Ltd

1 First Lok Yang Road, Jurong, Singapore 629728

Tel: 6265 5355 (Main Line)

www.selleys.com.sg

Table of contents

Other Selleys Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Greenleaf

Greenleaf PSE Workhorse ATV 2527 Assembly / operation instructions / parts

B&G

B&G BULB DUST-R 1150 user manual

Sumake

Sumake SS-1208B Original instructions

Conrad

Conrad Hobby Airbrush K3 operating instructions

Graco

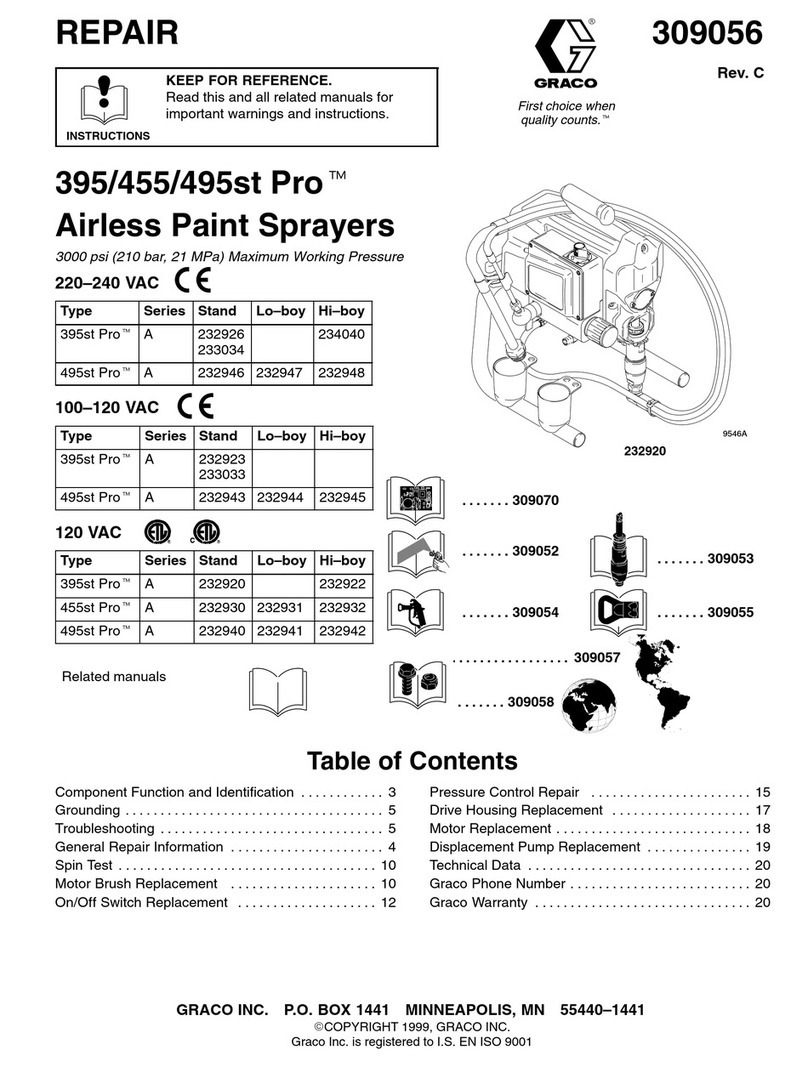

Graco Pro 455 Repair manual

MSW Motor Technics

MSW Motor Technics MSW-PCS-50 user manual