sematic SDS DC-PVM Rel. 3.0 User manual

808-000-000

February 2004

Handbooks

Handbücher

Manuali distruzione

401-000-000

Spare Parts

Ersatzteile

Ricambi

732-000-000

Instaneous Safety Gear - Sematic SR1

Rollensperrfangvorrichtung - Sematic SR1

Paracadute Istantaneo - Sematic SR1

806-000-000

Sematic Encoder System© drive

Sematic Encoder System© abinentürantrieb

Motorizzazione Sematic Encoder System©

807-000-000

Sematic Brushless System© drive

Sematic Brushless System© abinentürantieb

Motorizzazione Sematic Brushless System©

808-000-000

Sematic Drive System© drive

Sematic Drive System© abinentürantrieb

Motorizzazione Sematic Drive System©

301-010-000

Car door locking device

Fahrkorbtür- Verriegelungsvorrichtung

Dispositivo di blocco porta di cabina

301-000-000

Specific instructions, notes and suggestions

Sonder-Anwendungen, Hinweise und Vorschläge

Istruzioni particolari, note e suggerimenti

701-000-000

Installation and maintenance of Sematic 2000 doors

Installation und Wartung für Sematic 2000 Türen

Installazione e manutenzione porte Sematic 2000

Technical catalogues

Technische Kataloge

Cataloghi tecnici

901-000-000

Sematic 2000 B (Basis)

910-000-000

Sematic 2000 SC (Super Compact)

920-000-000

Sematic 2000 C (Compact)

901-930-000

Sematic 2000 G (Goods)

901-940-000

Sematic 2000 HD (Heavy Duty)

906-000-000

Sematic 2000 R (Round)

Sales Catalogue

Verkaufs-Katalog

Catalogo commerciale

201-000-000

SALES CATALOGUE

Doors, entrances and car door operators for lifts

VER AUFS- ATALOG

Türen und abinentürantriebe für Aufzüge

CATALOGO COMMERCIALE

Porte e operatori di cabina per ascensori

SEMATIC DRIVE SYSTEM©

DRIVE

SEMATIC DRIVE SYSTEM©

KABINENTÜRANTRIEB

MOTORIZZAZIONE

SEMATIC DRIVE SYSTEM©

Sematic

Group

Rel. 3.0

Rel. 3.0

Sematic

Group

www.sematic.com

sematic italia spa

Via Zappa Comm.Francesco, 5

ITA Y - 24046 Osio Sotto (BG)

Tel. +39 0354815100

Fax +39 0354815199

www.sematic.com

sematic uk Ltd

Meadow Gate, Valley Park

Wombwell, Barnsley

South Yorkshire S73 0UN

GREAT BRITAIN

Tel. +44 (0) 1226 344800

Fax +44 (0) 1226 344811

www.sematic.com

sematic hungária kft

Debreceni út 236

Nyíregyháza 4400 - HUNGARY

Tel. +36-42-596738/39

Fax +36-42-490454

www.sematic.com

sematic singapore Pte Ltd

www.sematic.com

UNI EN ISO 9001

APPROVED BY IMQ 0051

LIFT DIRECTIVE 95 16 EC

ANNEX IX (Module H)

ISO 14001

qDC-PWM

qBrushless

qBrushless Plus

ITALIANO DEUTSCH ENGLISH

808-000-000 Sematic Drive System©

1

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

© sematic italia spa. All rights reserved.

Sematic regards all the information contained in this instruction manual to be correct at the time of printing. This information does not consti-

tute any obligation to Sematic and can be modified without prior notification. Sematic cannot be held responsible for any possible damages or

claims caused to items or persons due to errors or misunderstandings within the contents of this instruction manual.

© sematic Italia spa. Alle Rechte sind geschützt

Die in diesem Handbuch angegebenen Informationen sind zum Zeitpunkt der Veröffentlichung korrekt. Die Informationen wirken sich nicht

bindend für Sematic aus und können ohne Vorankündigung geändert werden. Sematic ist nicht verantwortlich für eventuelle Personen- oder

Sachschäden, die als Folge von Ungenauigkeiten oder falscher Auslegung entstehen und sich auf den Inhalt dieses Handbuchs beziehen.

© sematic italia spa. Tutti i diritti sono riservati.

Sematic ritiene che le informazioni contenute in questo documento alla data della pubblicazione siano corrette. Tali informazioni non costitui-

scono impegno per la Sematic e possono essere modificate senza preavviso. Sematic non si ritiene responsabile per eventuali danni causati a

persone o cose a seguito di inesattezze o errate interpretazioni relative al contenuto del presente manuale.

Confidentiality agreement Disclaimer

The software/hardware "Sematic Drive System©" and all the relevant information, ideas,

concepts and know-how are confidential and the exclusive property of Sematic.

All information relevant to this instruction manual and any other support supplied by

Sematic must be kept confidential and proprietary to Sematic and shall not to be copied or

reproduced in any form whatsoever.

Any information contained in the "Sematic Drive System©" shall not be disclosed to anyone,

without Sematic's written consent apart from authorized representatives employed by the

user which commits itself to the confidentiality clause.

The Company that makes use of the Sematic Drive System©, binds itself not to use confi-

dential informations owned by Sematic and not to compile or reingineer the Sematic Drive

System©and any information in it contained.

Diskretions-Klausel

Das software/hardware "Sematic Drive System©" und die darin enthaltenen

Informationen, Ideen, Konzepte und das know how sind vertraulich anzusehen, da

Sematic Eigentum.

Die Informationen dieses Handbuchs und alle von Sematic ausgegebenen Hilfsmittel sind

Sematic Eigentum und dürfen weder kopiert noch vervielfältigt werden.

Die über das "Sematic Drive System©" erhaltenen Informationen dürfen ohne ausdrücklich

erteilte schriftliche Genehmigung nicht an dritte Personen weitergeben werden; ausge-

nommen sind autorisierte Personen der Gesellschaften, die über die Diskretionsklausel

informiert sind.

Die Gesellschaft, die das "Sematic Drive System©" anwendet, verpflichtet sich, vertraulich

erhaltene Informationen weder zu missbrauchen, noch Informationen des "Sematic Drive

Systems©" anderweitig auszuschöpfen.

Clausola di riservatezza

Il sistema software/hardware “Sematic Drive System©” e le informazioni ivi contenute, le

idee, i concetti e il know-how, sono confidenziali e di proprietà della Sematic.

Le informazioni contenute in questo manuale ed ogni altro supporto fornito dalla Sematic

devono essere mantenuti confidenziali e di proprietà della Sematic e non possono essere

copiati o riprodotti in alcuna forma.

Ogni informazione contenuta nel sistema “Sematic Drive System©” non potrà essere

rilasciata ad alcuno, senza l’assenso scritto della Sematic, al di fuori del personale auto-

rizzato dipendente della società che si fa carico dell’impegno di riservatezza.

La società che utilizza il sistema “Sematic Drive System©”, si impegna a non tenta-

re di utilizzare informazioni confidenziali della Sematic ed a non ricompilare o rein-

generizzare il sistema “Sematic Drive System©” e qualsiasi informazione ivi conte-

nuta.

ITALIANO DEUTSCH ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

ITALIANO DEUTSCH ENGLISH

808-000-000 Sematic Drive System©

3

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

Sematic Doors...

Steel execution

Stainless steel execution

Full glass execution

Framed glass execution

Special finishes with logos

Doors for marine applications

Fire rated doors

Vandal resistant doors

Sematic 2000 IP54

Sematic 2000 EEx

Sematic Türen...

Stahlausführung

Edelstahlausführung

Vollglasausführung

Gerahmte Glasausführung

Spezialausführung mit Logos

Schiffstüren

Feuerschutztüren

Antivandalismustüren

Sematic 2000 IP54

Sematic 2000 EEx

Porte Sematic...

Esecuzioni in ferro

Esecuzioni in acciaio inossidabile

Esecuzioni in vetro totale

Esecuzioni in vetro intelaiato

Personalizzazioni speciali con logo

Porte per navi

Porte tagliafuoco

Porte antivandalo

Sematic 2000 IP54

Sematic 2000 EEx

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

ENGLISH

808-000-000 Sematic Drive System©

5

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

Index

1 PREFACE pag. 7

2 WHAT IS THE SEMATIC DRIVE SYSTEM©pag. 9

2.1 Speed profiles

3 GENERAL FEATURES pag. 11

3.1 Technical information

3.2 Door Controller Sematic Drive System©

4 SIGNALS TO/FROM THE DOOR CONTROLLER pag. 12

4.1 Connections

4.1.1 Detector/Photocell/Barriers: Signal-Only Connection to the Door

Controller (Direct Connection)

4.1.2 Detector/Photocell/Barriers: Complete Connection to the Door Controller

5 INSTRUCTIONS WITHOUT HANDSET pag. 16

Display in Automatic and Manual Mode

5.1 Automatic Mode “AUTO”

5.2 Manual Mode “MAN”

5.3 Programming Mode “PROG”

6 FUNCTIONS AVAILABLE pag. 19

6.1 Reversing System Force Setting

6.2 Reversing System choice: INTERNAL or EXTERNAL

6.3 Limited Door Reversal

6.4 Main Lift Controller Test

6.4.1 Main Lift Controller Test (when moving) [default setting]

6.4.2 Main Lift Controller Test (when moving + parking)

6.4.3 No MLC Signal

6.4.3.1 Instant Stop

6.4.3.2 Low Speed to Stop

6.4.3.3 Low Speed Cycle

6.4.4 Main Lift Controller Input Alarm

6.5 Car Door Locking Device

6.6 Full or Framed Glazed Paneled Doors

6.7 Aux Output Relay

6.7.1 Space Percentage

6.7.2 Gong While Opening

6.8 Forced Closing [Nudging]

6.9 Fire Fighting

6.10 Double TB

6.11 EOD (Emergency Opening Device) and timeout

6.12 Protective Device Logic Kn

6.13 Motor Rotation During Closing

6.14 Alarms

7 TRIAL OPERATIONS BEFORE SETTING AT WORK pag. 25

7.1 Self-learning cycle

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

7.2 Self-learning cycle with the door controller only

(without using the handset)

8 INSTRUCTIONS WITH THE HANDSET pag. 26

8.1 Handset (optional)

8.2 User Handset menus and submenus

8.3 Self-learning cycle activation by means of the handset

8.4 Reversing System Force setting by means of the handset

8.5 Speed Profile and High Speed adjustments by means of the Handset

8.5.1 Option "Fast settings"

8.6 Option "Set Factory Default"

8.7 Option "Manufacturer Menu"

8.8 Option "Advanced Settings"

8.8.1 Option "Opening Parameters"

8.8.2 Option "Closing Parameters"

8.8.3 Option "Change Password"

9 GENERAL OPTIONS CON L'UTILIZZO DEL TASTIERINO pag. 32

9.1 Reversing System Setting by means of the Handset

9.2 Limited Door Reversal Activation by means of the Handset

9.3 Activation of the Main Lift Controller Test by means of the Handset

9.4 Activation of the Main Lift Failure by means of the Handset

9.5 Main Lift Controller Alarm - (MLC Input Alarm)

9.6 Activation of the Car Door Locking Device setting by means of the Handset

9.7 Activation of the Glazed Paneled Doors setting by means of the Handset

9.8 AUX Output Relay setting by means of the Handset

9.9 Fire Fighting Option setting by means of the Handset

9.10 EOD Timeout setting by means of the Handset

9.11 Protective Device Logic Kn setting by means of the Handset

9.12 Closing Rotation

10 MAINTENANCE MENU - DIAGNOSTICS AND ALARM MANAGEMENT pag. 36

10.1 Consulting the Maintenance Menu with the Handset

11 CONTROLLER SOFTWARE UPGRADE pag. 38

12 DOOR OPERATOR MAINTENANCE pag. 38

13 SPARE PARTS pag. 38

ENGLISH

808-000-000 Sematic Drive System©

7

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

1 PREFACE

This manual has been drafted taking into account that the Company installing genuine

Sematic products will comply with the following necessary requirements:

• personnel responsible for the installation and/or maintenance of the doors must be fami-

liar with the General and Specific regulations in force on the subjects of work safety and

hygiene (89/391/CEE - 89/654/CEE - 89/656/CEE);

• personnel responsible for the installation and/or maintenance must be familiar with the

Sematic product and must have been trained by Sematic or by an authorized Sematic

agent;

• installation equipment used must be in good working order with all measuring instruments

calibrated (89/655/CEE).

Sematic:

• undertakes to update the present manual and send the customer copies of all new

updates together with material;

• within its continuous product improvement policy, reserves the right to make

changes to the designs and materials of its products. Sematic will give an agreed

reasonable time to all its customers to allow them to adapt to the new changes

their complementary current constructions;

• guarantees a good performance only of the original parts sold directly and cor-

rectly installed.

Therefore:

parts manufactured and/or added to the Sematic product without his direct control, or non-

original parts based upon a Sematic design (even if supplied by authorised agents) cannot

be considered under guarantee since the following conditions have not been ensured:

1 Quality control of raw material supply

2 Process control

3 Product control

4 Conformity tests according to Sematic specifications

Furthermore, Sematic:

• guarantees the performance life of its products only if correctly stored (indoors storage at

temperatures ranging between -10 and +60 °C out of direct sunlight) and correctly instal-

led;

• guarantees the perfect performance of the products installed in environments with

temperatures between -10 and +60 °C and with a non-condensing, relative humi-

dity level included between 20% and 80%.

(Special note: for temperatures and humidity rates outside these ranges, please

consult our Technical Dept.)

The present document has been drafted in accordance with the following EU Directives:

• 98/37/CE Machinery Directive and subsequent modifications (when applicable)

• 95/16/CEE Lifts Directive

• 93/68/CEE Markings

• 90/269/CEE Heavy loads handling

• Noise (Acoustic emission) 86/188/CEE modified according to Directive 98/24/CEE

• Electromagnetic compatibility 89/336/CEE

and with the following particular standards:

• EN81; (+)

• AS1735; (+)

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

• EN12015/EN12016; (+)

• EN13015; (+)

• ASME A17.1 :2000; (*)

• UL508C; (*)

(+)ofor motors:

• B105 AAAX 01 - IP20 (IP54 on request)

• B105 AAAX 02 - IP20 (IP54 on request)

• B105AAKX - IP50

• B105AAHX - IP40 (IP65 on request)

• B105AAIX - IP40 (IP65 on request)

• B105AAJX - IP40 (IP65 on request)

(*) oonly for motors:

• B105AAKX - IP50

• B105AAIX - IP40 (IP65 on request)

• B105AAJX - IP40 (IP65 on request)

• B105AAHX - IP40 (IP65 on request)

Taking into account, during all project planning, the Risk Assessments relating to:

A. RISKS OF MECHANICAL HAZARDS

• Squeezing during operations

• Squeezing after Trapping caused by friction (glass panels)

• Cuts caused by sharp edges, or static sharp pieces

B. RISKS OF ELECTRICAL HAZARDS

• Persons in contact with energized parts (direct contact)

• Persons in contact with parts that become energized due to a fault (indirect contact)

C. RISKS OF OVERHEATING

D. RISKS GENERATED BY NOISE

E. RISKS GENERATED BY VIBRATION

F. RISKS GENERATED BY MATERIALS AND SUBSTANCES

ENGLISH

808-000-000 Sematic Drive System©

9

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

2 WHAT IS THE SEMATIC DRIVE SYSTEM©

The System consists of:

• a Car Door Operator (1)

• a microprocessor-based Door Controller (2)

• DC (brushed or brushless type) Motor (3)

with feedback signals (4).

The Sematic Drive System©automatically con-

trols the opening and closing of the lift doors,

monitoring the timing, current variations,

speeds (high, low, acceleration and decelera-

tion curves), various safety systems (reversing

system, Limited Door Reversal etc.) and faults

(high voltage, signal failure, ...).

There are two independent speed curve profiles

for the opening and closing cycles (as better

shown later on) which can be modified by

means of the door controller push buttons or

by means of the Sematic handset (an optional

8 digit keypad and display accessory which can

be connected to the card by an RJ45 plug).

The handset (5) is a key pad that allows

viewing and modification of the function para-

meters stored in the controller.

It is important to use the Sematic handset for

installation or maintenance, as it enables

viewing and/or variation of the Encoder para-

meters, systems, and operation errors.

Furthermore, it is possible to use the Sematic

handset directly from the inside of the car (5).

Making it possible to monitor and modify the

door operating parameters from a completely

safe position, and also to control the movement

of the coupled car and landing doors during

their effective operating cycle.

1

23

4

5

Note: the pictures on this document are

examples only; real components appearan-

ces may differ according to supplied configu-

ration of door operator and motor.

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

2.1 Speed profiles

OPENING CYCLE

01 Opening acceleration

02 Opening high speed

03 Opening deceleration

CLOSING CYCLE

C1 Closing acceleration

C2 Closing high speed

C3 Closing deceleration

MAX.

1.1 m/s

O2

C2

O1

O3

C1 C3

V (m/s)

t (s)

Ka

La

Lc

Kc

KEY

Ka Door opening

Kc Door closing

La Open limit

Lc Close limit

Closing cycle

Active reversing system

Opening cycle

DOOR CLOSED

DOOR CLOSED

DOOR OPENED

ENGLISH

808-000-000 Sematic Drive System©

11

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

3. GENERAL FEATURES

3.1 Technical information

MAIN SUPPLY VOLTAGE 90-290 Vac (115 V-20%, 230V+26%), 50-60 Hz

TYPICAL POWER CONSUMPTION 200 VA

PEAK POWER COMSUMPTION 300 VA

MOTOR OVERLOAD PROTECTION @In<15 minutes

@2In<3 minutes

OPERATIONAL TEMPERATURE RANGE from -10°C to +60°C

HUMIDITY non-condensing between 20% and 80%

PROTECTION rapid cartridge fuse [5x20, 4 A], battery fuse

[5x20, 8 A]

PERFORMANCE SPEED separately adjustable for opening and closing

REVERSAL SENSITIVITY Variable, only operational on door close cycle

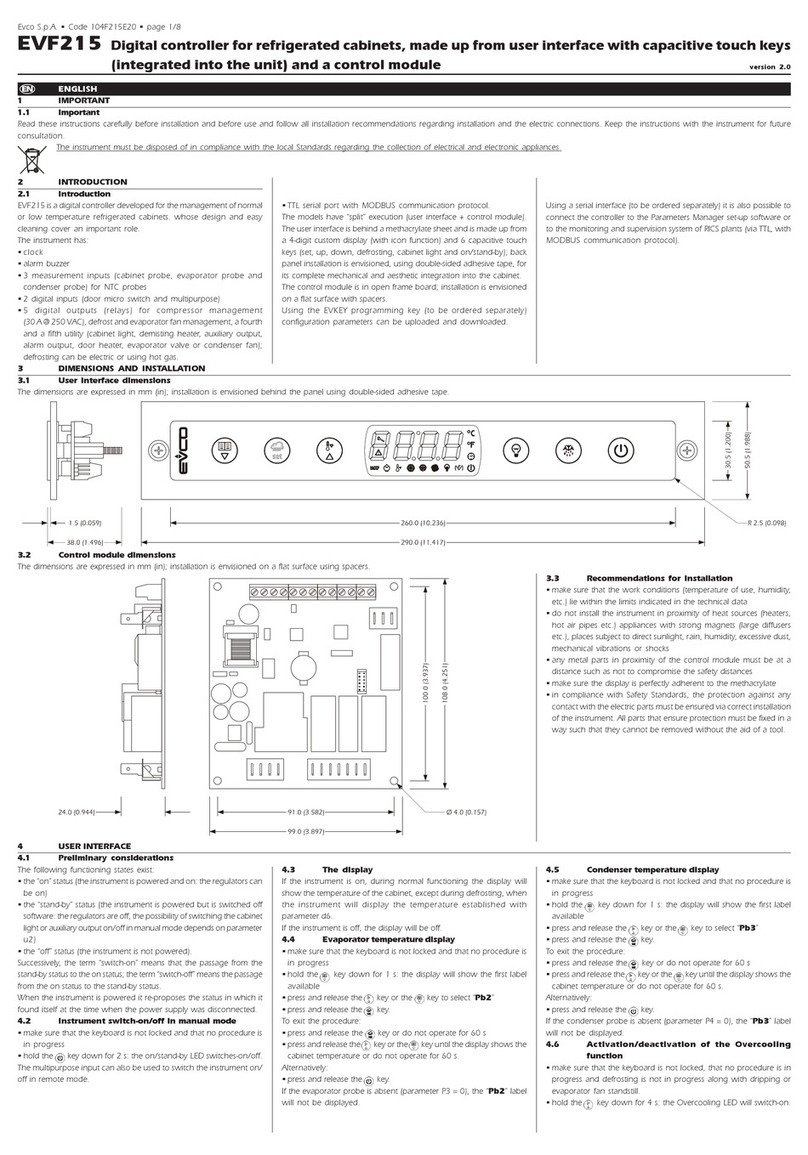

3.2 Door Controller Sematic Drive System©

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

4 SIGNALS TO/FROM THE DOOR CONTROLLER

4.1 Connections

Tk - Tk

Safety chains

Main Lift Controller

Photocells

or

Detectors

Motor

ENGLISH

808-000-000 Sematic Drive System©

13

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

Signal Connector

Pins Contact Type &

Normal State Notes

INCOMING SIGNALS FROM THE DOOR CONTROLLER

Opening control Ka

(coming from the Main

Lift Controller)

Connector

pins 5 - 15 These connections require

dry (voltage free) contacts

(contact open when inac-

tive)

When the Door Controller is

installed on a Front & Rear

entrance car, it is important

that the opening and closing

controls have no common con-

tacts between the two doors.

Shielded, Grounded Wire

Highly Recommended

Closing control Kc

(coming from the Main

Lift Controller)

Connector

pins 3 - 15 These connections require

dry (voltage free) con-

tacts. (contact open when

inactive)

Forced closing

control at

low speed Kb

Connector

pins 15 - 22 These connections require

dry (voltage free) contacts

(contact open when inac-

tive)

The main lift controller may

signal the forced closing when

the photocell (or similar device)

shall be made inoperative due

to a failure, or after several

door closing failures.

Re-Opening control Kn Connector

pins 15 - 23 These connections require

dry (voltage free) con-

tacts. (both logics availa-

ble)

See sections 4.1.1 & 4.1.2. for

the connection to the door

controller

Fire-Fighting Contact

Kff Connector

pins 15 - 39 These connections require

dry (voltage free) con-

tacts. (contact open when

inactive)

See section 6.9

Contact K2TB Connector

pins 15 - 41 These connections require

dry (voltage free) con-

tacts.

(contact open when inac-

tive)

This signal allows the door

controller to recognize diffe-

rent door opening widths in

the same lift installation.

Given this signal, the opening

and closing operations are car-

ried out referring to an alter-

native TB (door width recorded

by an additional self-learning

cycle).

Encoder

Signals Connector

RJ45 (A) Factory prewired

connector

Handset (Optional) RJ45 connec-

tor (B)

Auxiliary Contact Kaux Connector

pins 15 - 42 These connections require

dry (voltage free) con-

tacts. (contact open when

inactive)

Not yet implemented

Contact KEOD Connector

pins 15 - 40 These connections require

dry (voltage free) con-

tacts. (contact open when

inactive)

This connection is to signal the

use of the Sematic E.O.D.

Emergency Opening Device to

the Door controller

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

Opening limit switch

contact La Connector

pins 16 - 17 These connections provide

dry (voltage free) contact. The contact is open when the

door is fully open.

Contact rating: 3A 250Vac

30Vdc

Closing limit switch

contact Lc Connector

pins 18 - 19 These connections provide

dry (voltage free) contact. The contact is open when the

door is fully closed.

Contact rating: 3A 250Vac

30Vdc

Reversing system

signal IM

Connector

pins 1 - 4

Connector

pins 2 - 4

These connections provide

dry (voltage free) contact.

(contact normally closed)

(contact normally open)

This signal is generated by dry

(voltage free) Form C contacts

(relay within the Door

Controller) and is activated only

when either a mechanical obsta-

cle (excessive force)

prevents the doors

from closing, or a

signal is received from

an external safety devi-

ce that is connected to

the door controller.

It is used to signal the main lift

controller to interrupt the door

close command and give a door

open signal. Contact rating: 3A

250Vac 30Vdc

Auxiliary Output

Signal AUX

Connector

pins 35 - 34

Connector

pins 35 - 36

These connections provide

dry (voltage free) contact.

(contact normally open)

(contact normally closed)

These contacts can be used to

signal that a particular (pre-set)

door opening distance has been

achieved, or as a Gong or Buzzer

while the door is opening.

Contact rating: 3A 250Vac

30Vdc.

Motor Connector

pins 43 - 44 -

45

Factory-prewired connec-

tor

Acoustic alarm

(BUZZER)

-optional-

Connector

pins 15 - 21 These connections provide

a 24Vdc, 100ma contact.

Contact is open when not

active.

• For the Door Operator mechanical installation refer to the "Installation and

maintenance of Sematic doors" manual.

• The door controller is supplied already mounted on the operator. All the con-

nections between the door controller and the motor are pre-wired at Sematic.

In order to prevent possible damage to the wiring cables by coming into contact

with the drive belt, they are fixed to the header as shown in the following image

(only for B105AAIX, B105AAJX, B105AAKX, B105AAHX motors):

Signal Connector

Pins Contact Type &

Normal State Notes

OUTGOING SIGNALS FROM THE DOOR CONTROLLER

RIFERIRSIALMANUALE UTENTERIFERIRSIALMANUALE UTENTE

.PERMAGGIORI INFORMAZIONI.PERMAGGIORI INFORMAZIONI

(PREMEREALLAINSTALLAZIONE)(PREMEREALLAINSTALLAZIONE)

TASTOPERCICLO DI AUTOAPPRENDIMENTOTASTOPERCICLO DI AUTOAPPRENDIMENTO

RELE'DIINVERSIONE DI MOTO

RELE'

DIINVERSIONEDI MOTO

RELE'DICHIUSURA IN BASSA VELOCITA'

RELE'DICHIUSURA IN BASSA VELOCITA'

RELE'DICHIUSURA

RELE'DICHIUSURA

RELE'DIAPERTURA

RELE'DIAPERTURA

LIMITECHIUSURA

LIMITECHIUSURA

LIMITEAPERTURA

LIMITEAPERTURA

IM

M

E

EMCPROTECTIONEMCPROTECTION

KEEPCLOSED!KEEPCLOSED!

GESCHLOSSENHALTEN!GESCHLOSSENHALTEN!

MANTENERECHIUSO!MANTENERECHIUSO!

AUX

RELE'DIFIREFIGHTTINGRELE'DI FIREFIGHTTING

RELE'AUSILIARIORELE'AUSILIARIO

RELE'DIATTIVAZIONE E.O.D.RELE'DIATTIVAZIONE E.O.D.

RELE'DIDOPPIO TB

RELE'

DIDOPPIOTB

FUSE

250V4A250V4A

cyl.5x20cyl.5x20

BENUTZENSIE BITTE DAS HANDBUCHBENUTZENSIE BITTE DAS HANDBUCH

.FUR WEITERE INFORMATIONEN.FUR WEITERE INFORMATIONEN

(BEIINSTALLATION DRUCKEN)(BEIINSTALLATION DRUCKEN)

TASTEFUR SELBSTLERNZYKLUSTASTE FUR SELBSTLERNZYKLUS

REVERSIERUNGS-RELAIS

REVERSIERUNGS-RELAIS

SCHLIESS-RELAISKLEINE GESCHWINDIGKEIT

SCHLIESS-RELAISKLEINE GESCHWINDIGKEIT

SCHLIESS-RELAIS

SCHLIESS-RELAIS

OFFNUNGS-RELAIS

OFFNUNGS-RELAIS

TUREZU-ENDKONTAKT

TUREZU-ENDKONTAKT

TUREAUF-ENDKONTAKT

TUREAUF-ENDKONTAKT

.

.

..

.

..

.

.

.

COD.H147AASXCOD.H147AASX

..

..

Kn

Kff

Kff

Kaux

Kaux

K2TB

K2TB

Kb

Kb

KEOD

KEOD

Kc

Kc

Ka

Ka

Sematic Drive SystemSematic Drive System c

FEUERSHUTZ-RELAISFEUERSHUTZ-RELAIS

ZUSATS-RELAIS

E.O.D.ACTIVIERUNG-RELAISE.O.D.ACTIVIERUNG-RELAIS

DOPPELTETB-RELAISDOPPELTETB-RELAIS

REFERTO THE USER'S GUIDE

REFERTO THE USER'S GUIDE

.FOR FURTHER INFORMATIONS

.FORFURTHER INFORMATIONS

(PUSHAT INSTALLATION)

(PUSHAT INSTALLATION)

SELF- SELF LEARNING CYCLE BUTTON

SELF- SELF LEARNING CYCLE BUTTON

IM - REVERSE MOTION RELAYIM -REVERSE MOTION RELAY

Kn - PHOTOCELL / NUDGINGKn -PHOTOCELL / NUDGING

Kb - DOOR CLOSING RELAY IN SLOW SPEEDKb -DOOR CLOSING RELAY IN SLOW SPEED

Kc - DOOR CLOSING RELAYKc - DOOR CLOSING RELAY

Ka - DOOR OPENING RELAYKa - DOOR OPENING RELAY

Lc - CLOSING LIMITLc -CLOSING LIMIT

La - OPENING LIMITLa -OPENING LIMIT

LEGENDA

ENCODER

OUTPUT

OUTPUT

NC

La

Lc

MOTOR

DETECTOR/

(OPTIONAL)

Gnd

IN

+24V

PHOTOCELLPHOTOCELL

PNPN/OPNPN/O

NC

Battery

24V24 V

RJ45

(B)

RJ45

(A)

38

37

21

19

18

17

16

2

4

1

33

32

31

30

43

44

45

-

+

28

NO

Gnd

42

41

40

3

5

15

39

23

22

0

110V-230V

34

35

36

COMMON

+24V+24V

NC

NO

F

GND

N

Kff - FIREFIGHTING RELAYKff - FIREFIGHTING RELAY

Kaux- AUXILIARY RELAYKaux-AUXILIARY RELAY

KEOD- E.O.D. ACTIVATION RELAYKEOD- E.O.D. ACTIVATION RELAY

K2TB- DOUBLE TB RELAYK2TB - DOUBLE TB RELAY

(OPTIONAL)(OPTIONAL)

FUSE

250V8A250V8A

cyl.5x20cyl.5x20

ENGLISH

808-000-000 Sematic Drive System©

15

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

Note: In case of motor replacement be sure to bind the excess cable lenght as above

pictured, to avoid any contact of the motor cable with the driving belt.

• Warning: to avoid possible induced currents within field wiring, it is recommended to

shield the Ka and Kc signals (connector pins 3, 5 and 15) with grounded, shielded cables.

• Changes made to the factory wiring length or position can damage the EMC system cha-

racteristics and is not recommended.

4.1.1 Detector/Photocell/Barriers: Signal-Only Connection to the Door Controller

(Direct Connection)

This connection requires a dry (voltage free) external relay contact connected to the Door

Controller Connector pins 15 & 23.

If desired, it is possible to connect the single output signal from a photocell (or similar devi-

ce) formed by a voltage free contact, so that the door controller will directly receive the

command to re-open.

The photocell (or similar device) has therefore an independent power supply and

sends only its outgoing signal to the Sematic Drive System©controller.

Reopening is operated according to the REVERSING SYSTEM, LIMITED DOOR

REVERSAL EFFECT and PROTECTIVE DEVICE LOGIC settings (see sections 6.2, 6.3

and 6.12).

NOTE: This connection method does not provide for Door Controller interaction with Fire

Service Operation. The Main Lift Controller must be arranged to either interrupt the signal

from the Detector/Photocell/Barrier, or to interrupt the power supply of the

Detector/Photocell/Barrier as required under Fire Service Operation (Fire Fighting).

4.1.2 Detector/Photocell/Barriers: Complete Connection to the Door Controller

Complete Connection means that the device draws its power supply from and sends the re-

open signal directly and only to the Sematic Drive System©controller.

It is possible to have the complete connection of detectors or photocells with a 24 Vdc max

100 mA supply and a PNP N/O or N/C output, through the connector pins:

Connector pin 30 can be used as a pass-through (dummy) connector pin for connections

between the detector system components.

33 GND ground connector pin

32 IN PNP N/O or N/C signal from

detector/photocell/barrier

31 +24 Vdc Vdc power supply to detector/

photocell/barrier

30 NC dummy free connector pin

(it can be used as a dummy con-

nector for connection between the

detectos system components).

The operating reopening modes depend upon the setting of the REVERSING SYSTEM, LIMI-

TED DOOR REVERSAL EFFECT and PROTECTIVE DEVICE LOGIC settings (see section 6.2, 6.3

and 6.12).

GNDGND

+ Vdc

OUT PNP N/O - N/C

Example of photocells/bar-

riers with transmitter and

receiver connected between

themselves through the

dummy free connector pin

30. RXTX

GND

33

+24 Vdc

31

IN

32

NC

30

5 INSTRUCTIONS WITHOUT HANDSET

Display in Automatic and Manual Mode

5.1 Automatic Mode “AUTO”

• When the Door Controller is working in automatic mode the "AUTO" red led is on,

whereas the other two red leds are off.

• When the Door Controller is switched on, or after a self-resetting, it starts directly in

the automatic mode.

• All the signals sent by the main lift controller and by the external devices (barriers,

photocells, etc.) are active in this mode.

• Keys 2 and 3 are not functional during automatic mode.

• Key 1 selects Self Learning Cycle.

• When Key 4 is kept pressed for a while, the Door Controller (ca. 3 sec.), swit-

ches to the manual mode “MAN”.

5.2 Manual Mode “MAN”

• When the Door Controller is working in manual mode the "MAN" red led is on, whe-

reas the other two red leds are off.

• All signals coming from the main lift controller and from the external devices are igno-

red.

• The IM contact is deactivated, therefore the Door Controller does not recognize any

signal coming from the external devices to reverse door movement, such as photo-

cells or barriers.

• Opening and Closing commands may be manually input by pushing Key 2 (open) or

Key 3 (close).

• Key 1 selects Self Learning Cycle.

• When the key 4 is kept pressed for a while (ca. 3 sec.), the Door Controller switches

to the automatic mode “AUTO”.

• If no keys are pressed for at least 10 minutes, the Door Controller will switch to the

"automatic mode “AUTO”.

Both in automatic and manual mode the Door Controller will show the following

display:

Door opening (Flashing Display)

Door open

Door closing (Flashing Display)

Closed door

Self Learning

Forced Closing

It signals an alarm and flashes giving the code of the recognised alarm. See

chapter 10

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

o P

C L

C L

o P

F C

S L

A L

ENGLISH

808-000-000 Sematic Drive System©

17

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

5.3 Programming Mode “PROG”

• When the Door Controller is working in "programming mode" the "PROG" red led is

on whereas the other two red leds are off.

• Press contemporaneously Key 1 and Key 4 for few seconds to enter the programming

mode. The display on the Door Controller will show “P” and “00” flashing alternately.

• When the Door Controller is in programming mode, all signals coming from the main

lift controller and from the external devices (barriers, photocells,…) are ignored.

• The parameter to be modified is selected by means of the increasing and decreasing

KEYs, respectively the buttons 2 and 3; this parameter is then confirmed by pushing

the key 1, ENTER.

• After confirming the parameter to be modified, the display shows the relevant nume-

ric value.

• Modify the chosen parameter using the key 2, increase, and 3, decrease, and confirm

the changes by pressing key 1 ENTER.

• At the end of the necessary configurations, use the key 4 pressing to select the requi-

red operating mode (manual “MAN” or automatic “AUTO”).

The following table contains the available parameters, the relevant codes,

the description and the allowed modification range:

Param.

codes Default Parameter NoteRange

00 00 Reversing system choice 00 -> Internal

01 -> External

00,01

01 00 Main Lift Controller Test 00 -> When Moving

01 -> Moving + Parking

02 -> Off

00,01,02

02 00 No MLC signal; 00 -> Instant Stop

01 -> Low Speed to Stop

02 -> Low Speed Cycle

00,01,

03 00 MLC Input Alarm 00 -> Off

01 -> On

00,01,

04 00 Limited Door Reversal Effect 00 -> Off

01 -> On

00,01,

05 00 Car door locking device 00 -> Off

01 -> On

00,01,

06 00 Glass doors 00 -> Off

01 -> On

00,01,

07 00 Aux Output Relay 00 -> Off

01 -> Gong While opening

02 -> according to % of space

00,01,02

08 00 Space Percentage

(Percentage of the available

space to operate the AUX relay)

00..99%

(00 = closing limit)

00..99

09 66 Reversing force setting 10-150 N (10-135 N U.S. version)

00..99

10 50 Opening High Speed 01..99

11 50 Opening Low Speed 01..99

12 50 Opening "comfort 01..99

ENGLISH

808-000-000 Sematic Drive System©

www.sematic.com

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

14 50 Closing Low Speed 01..99

15 80 Closing "comfort" 01..99

16 -Not Used -

17 -Not Used -

18 -Not Used -

19 01 Fire Fighting Mode 00 -> Reversing system OFF

01 -> Reversing System redu-

ced sensitivity

00,01

20 01 Timeout EOD Opening time on EOD

contact (minutes)

00 -> 05

minutes

22 00 Closing Rotation 00 -> Clockwise

01 -> Anti-clockwise

00,01

21 00 Protective Device Logic Kn 00 -> N/O, on obstruction clo-

sed

01 -> N/C, on obstruction open

00,01

Closing High Speed13 30 01..99

Param.

codes Default Parameter NoteRange

ENGLISH

808-000-000 Sematic Drive System©

19

© SEMATIC zAll rights reserved

Changes can be made without notice

see www.sematic.com for latest release

www.sematic.com

6 FUNCTIONS AVAILABLE

6.1 Reversing System Force Setting

The reverse motion torque parameter sets the sensitivity degree to detect an obstacle

during the door closure, thus giving the reopening command. The parameter's value can be

manually set.

Please note that a minor sensitivity corresponds to higher values and vice versa. After a

number of operations, such parameter may change due to an automatic adjustment

system.

6.2 Reversing System choice: INTERNAL or EXTERNAL

If the reversing system is INTERNAL, the reopening of the doors due to obstacle detection

is solely controlled by the Door Controller and door reopening is signalled to the main lift

controller through the IM contacts (1, 4 contacts normally closed, 2, 4 contacts normally

open).

If the reversing system is EXTERNAL, the Door Controller signals, through the IM

contacts, the presence of an obstacle to the main lift controller, which in turn must

signal the re-opening command using Ka. IM signal is present up to the complete

reopening of the doors.

If the main lift controller does not give the re-opening signal, the Door Controller

commands a low-speed closure.

6.3 Limited Door Reversal

(Partial door re-opening, controlled by photoelectric barriers with either "Direct" or

"Complete" Connection to the Door Controller; see § 4.1.1 and 4.1.2).

This function allows a partial reopening of the doors when an obstacle has been detected by

means of optoelectronic, traditional or proximity door protection devices.

The doors re-open only for the time during which the obstacle is detected and not necessa-

rily up to the opening limit.

IM signal is sent to the lift controller as long as the obstacle is present.

6.4 Main Lift Controller Test

When set to "OFF" selection (no MAIN LIFT CONTROLLER TEST), a simple impulse of signal

Ka or Kc from the Main Lift Controller is sufficient to produce door movement; the signal is

stored by the Door Controller which will complete the required movement even if the main

lift controller signal fails. The impulse width must be at least 400ms in duration.

When the MAIN LIFT CONTROLLER TEST is set to "WHEN MOVING" (default setting) or set

to "MOVING + PARKING", the operation is as described in the next two sections.

6.4.1 Main Lift Controller Test (when moving) [default setting]

When this parameter is set to “WHEN MOVING”, the Door Controller checks for the

Ka or Kc signal coming from the main lift controller only during the door movement

(Ka signal during the opening cycle, Kc signal during the closing cycle). At the end

of the movement, which can be detected through the La and Lc signals, respectively

Door Open and Door Closed, it is possible to remove the signal that has controlled

the movement, without the Door Controller detecting this as failure.

For this setting, the main lift controller must be equipped with 2 relays: 1 for the

opening command, and 1 for the closing command.

The Door Controller checks for continuous presence of the Ka and Kc signals coming

from the main lift controller.

The Door Controller detects signal drops exceeding 200ms; this is interpreted as

NO MLC SIGNAL alarm if the relevant parameter MAIN LIFT CONTROLLER TEST

is set on “WHEN MOVING”.

In case of signal failure, the Door Controller acts as described in the parameter

setting NO MLC SIGNAL (see § 6.4.3).

This manual suits for next models

2

Table of contents

Languages:

Popular Controllers manuals by other brands

Schaudt

Schaudt EBL 99 L instruction manual

ELGO Electric

ELGO Electric P8822-000-P Series manual

Lake Lite

Lake Lite LL-REG-12v-5A-HD Connection diagram

Precision Digital Corporation

Precision Digital Corporation Helios PD2-6310-7H7 instruction manual

V2

V2 STARK3-230V instruction manual

Powtran

Powtran PR5200 Series user manual