SEMROC MX Orbital Transport KMX-01 User manual

Copyright © 2018 Semroc

www.semroc.com

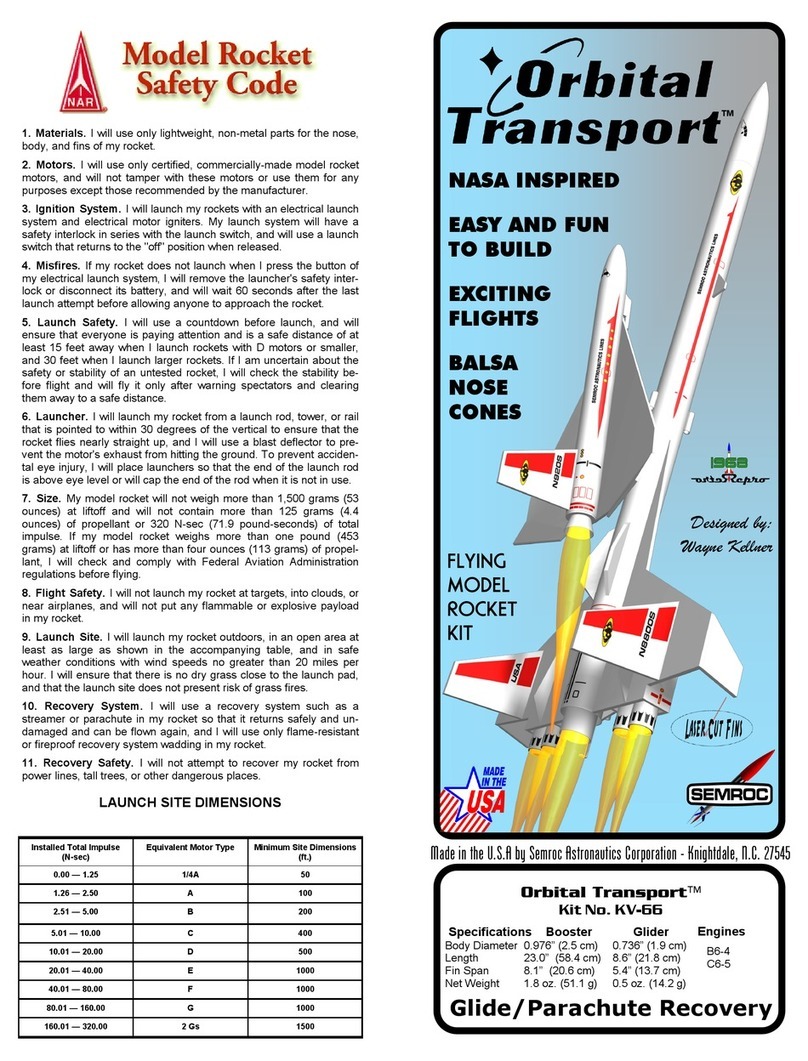

MX Orbital Transport™

Kit No. KMX-01

Engine Approx. Altitude

Micro Maxx 130

’

Skill Level 3

About

Semroc

Semroc Astronautics Corporation was started by

Carl McLawhorn in his college dorm at North Caroli-

na State University in November, 1967. Convincing

a small group of investors in his home town of Ay-

den, North Carolina to invest in a small corporation,

the company was re-incorporated as Semroc Astro-

nautics Corporation on December 31, 1969.

Semroc produced a full line of model rocket kits and

motors. At its peak, Semroc had twenty-five full

time employees working at two facilities. One was

for research and development, printing, shipping,

and administration. The other was outside of town

and handled all production and model rocket motor

manufacturing. For several years, Semroc success-

fully sold model rocket kits, supplies, and motors by

mail-order and in hobby shops. In early 1971, Sem-

roc became insolvent and had to close its doors.

After 31 years of dreams and preparations, Semroc

Astronautics Corporation was reincorporated on

April 2, 2002 with a strong commitment to putting

the fun back into model rocketry. Many years of

excellent service to the rocketry community passed

by until sadly, on August 11 2013, Carl passed away

and left a great void in the hearts of many rocket-

eers. He is forever in our hearts and minds.

In February of 2015, Semroc was sold to eRockets

and moved to Dayton, Ohio where it resides today.

It is our goal to continue the level of service and

dedication to the hobby Carl and his family were so

well known for. We strive to serve you, our custom-

ers, to the best of our abilities as we carry the vision

of Carl McLawhorn boldly into the future.

About the MX Orbital

Transport™

The MX Orbital Transport is a Downscale of the

Estes Orbital Transport that was introduced in Cata-

log #683 in late 1968. It was designed by Wayne

Kellner. The Orbital Transport was based on an ear-

ly NASA scramjet design for the Space Shuttle. The

Orbital Transport was released as Cat. No. K-42 and

had an introductory price of $2.50.

Jay Berry was inspired to engineer the MX Orbital

Transport™ to utilize the Micro Maxx brand of en-

gines. These engines allow MX rockets to be flown

in a smaller flying field for greater recoverability.

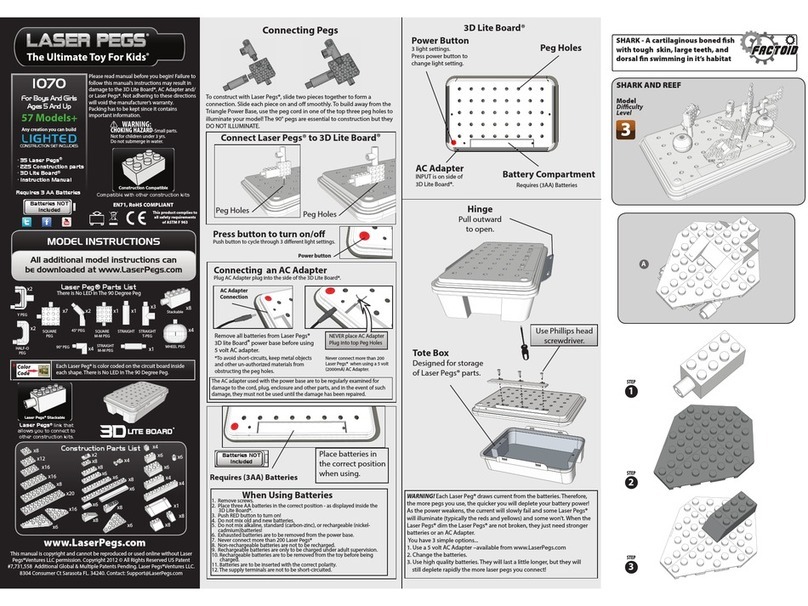

EXPLODED VIEW

Specifications

Body Diameter .488” (1.24 cm)

Length 8.625” (21.907 cm)

Fin Span 3.125” (7.9375cm)

Net Weigh 0.189 oz. (5.37 g)

Made in the U.S.A by Semroc - Dayton, Ohio

Downscale of the

Classic Orbital

Transport

Precision Turned

Balsa Nose Cones

Laser Cut

Basswood Fins

Streamer/Glider

Recovery

Water Slide

Decals

™

Engineered by

Jay Berry

MX

A

B

C

D

J

F

G

H

I I

K

L

M

N

O

2

3

4

5

6

7

8

9

10

11

12

13

14

L G

G 1

PARTS LIST

A 1 Balsa Nose Cone ................................BNC-3SC

B 1 Body Tube..........................................BT-3-6.75

C 1 Balsa Nose Cone………………….BNC-2G

D 1 Body Tube……………………….BT-2-2.5

E 1 Laser-cut Fin Set ...............................FMX-01

F 1 Glider Hook Set (2pcs)……………..FMX-01B

G 1 Glider Hook Cover Set……………...LSKMX-01

H 2 Centering Rings..................................RA-2-3

I 4 Launch Lugs……………………..LL-2AM

J 1 Wood Dowel 1/12”x2.5” .......................WD-13

K 1 Motor Tube ........................................BT-2-1.25

L 2 Thrust Block ......................................TB-2

M 1 Kevlar Cord........................................SCK-24

N 1 Streamer Pack ...................................SP-118

O 1 Launch Lug ........................................LL-MX-1

P 1 Decal (Not Shown)..............................DKMX-05

Q 1 Weight Clay (Not Shown)…………...WC-1

R 1 Fin Alignment Tools (5 Pcs)…………TKMX-01

(Not Shown)

❑1. Find the motor tube

and place a mark 1/4’” from

one end of the tube and

1/8” from the opposite end.

Tie a double overhand knot

in the Kevlar shock cord

near one end. See picture at

right to see how to tie the

knot. Trim excess cord off

close to the knot. Put some

glue in the end of the motor

tube marked at 1/8” to hold

the motor thrust block. In-

sert the end of the Kevlar

shock cord with the knot

into the motor tube. Trap

the shock cord between the

thrust block and motor

tube. Push the thrust block

in until it is flush with the

motor tube. Pull Shock cord

until the knot is seated

against the motor block.

Install the two centering

rings onto the motor tube

and glue them at the marks

that were made on the tube.

Set aside to dry.

ASSEMBLY

❑5. Cut the piece of supplied

Streamer material in half

lengthwise. Attach one of these

pieces to the shock cord near

the nose cone with a piece of

Masking Tape as shown. Put

the shock cord, and streamer

into the body tube and put the nose cone in the end of

the body tube to make it easier to handle the complet-

ed body tube before proceeding to the next step.

1/4” 1/8”

You will need the following for your assembly:

Pencil Ruler Knife Wax Paper Wood/Modelers Putty

White or Wood Glue 220 Grit Sandpaper

Medium Viscosity Super Glue Brush or Spray Paint

TOOLS

❑6. Set up all 3 Fin Alignment Jigs so that they will

stand up by themselves. Lay the body tube assembly in

the cradle with 2 of the jigs near the end with the motor

mount tube. Attach the Wing and Wing Fairings to both

sides of the body tube by resting them on the alignment

jigs, keeping them even with the end of the body tube.

The forward Canard Fins (5) can be installed the same

way with the front point of the Canard being 1 3/4” back

from the front end of the body tube. Set aside to dry.

❑2. Using the Fin Sheet

diagram, locate the Wing (1)

and the Wing Fairing (2).

Carefully remove them from

the sheet and glue them

together on a piece of wax

paper. Keep them flat while

they dry. Do this for both

wings.

❑4. Take the toothpick and

push it approximately 1/4 of

the way into the rear end of

the Nose Cone. Make a mark

on the toothpick and then

remove it. Fill the hole with

glue and insert the free end

of the shock cord. Cut the

toothpick at the mark you

made and insert it back into

the hole to hold the shock

cord in place before the glue

dries.

B

A

❑3. Glue the Motor Mount

Tube into the Main Body

Tube (A). Be sure to put the

shock cord through the body

tube before inserting the

motor mount tube. Use the

notch in the Fin Alignment

Tool to set the correct depth

of the motor tube as shown.

INSTALL MOTOR MOUNT

ATTACH NOSE CONE

INSTALL STREAMER

INSTALL FINS

1 3/4” 1 3/4”

❑7. After the wings have dried, find the launch Lug

(O), and put it in two of the Fin Alignment Jigs. Keep

the Jigs at the ends of the Launch Lug. Mark the Main

Body Tube (A) 1 3/4” from the rear end of the tube, (end

with the wings/motor tube). Using Medium Viscosity

Super Glue, attach the lug to the body tube, keeping the

rear of the launch lug even with the mark on the tube

and the jigs flat on the wings/wing fairings . Once dry,

remove jigs and apply glue fillets to wings/wing fair-

ings, and launch lug. Set aside to dry.

Fin Sheet Diagram

1

1 22

3

3

4

4

5

5

6

6

7

7

8 8

9 9

10

10

10

10

11

11

12

12

13

14

14

Stabilizer and Wing

Fence Guide

Fin Alignment Tool

Feet

Launch Lug Position Guide

Motor Tube Position

Slots for Feet

Slots for Feet

Glider Hook

Position Guide

Glider

Elevon

Guide

❑8. Attach the Wing Tips (3)

to the ends of the wings. You

can make sure that these are

perpendicular to the wings by

using one of the square cor-

ners of the fin alignment

guides to check for square-

ness. Make sure the wing tips

are glued on the same side as

the launch lug.

❑10. Find the 4 Scramjet

Tubes (I) and glue them

together in sets of two with

the ends even and the tubes

parallel. While these are

drying find the parts for the

surrounding boxes, parts

(8), (9) and (10) on the Fin

Sheet. Glue part (9) to part

(8) with the tab located in

the slot in the middle of part

(8) as shown and parts (10)

to the sides of part (8) as

shown. Make sure all parts

are perpendicular as they

dry. Glue Scramjet Tubes (I)

in opening behind part (8)

and then glue the assembly

to the wing locating the

tabs in the appropriate

slots. Make sure all parts

are fully seated against

wing. Repeat for other

wing. Set aside to dry.

❑9. Attach the Ventral Fins (7)

to the rear of the body tube

flush with end of the body tube.

These also attach on the same

side as the Launch Lug. Use the

smaller fin locating guide to

position these fins. Use the out-

er slots on this jig for these fins.

BUILD SCRAMJETS

UPPER WING DETAILS

❑11. Locate the Wing

Fences (14) on the Fin Sheet

and glue them to the upper

side of the wings. They are

positioned in the slots di-

rectly above the Scramjet

boxes, one on each wing.

❑12. Locate the Rudders

(4) on the Fin Sheet and

glue them to the upper side

of the wings. They are posi-

tioned in the slots towards

the end of the wings, again,

one on each wing.

❑13 Locate the Glider

Supports (6) on the Fin

Sheet. Make a mark on the

top of the body tube 1 3/16”

from the rear of the body

tube. This will be the rear of

the Glider Supports. Using

the center two slots on the

smaller Fin Positioning

Guide, glue the Glider Sup-

ports to the top of the Body

Tube.

GLIDER SUPPORTS

❑14. Locate one of the

Glider Hooks (F). Make a

mark on the top of the body

tube 3 5/16” from the front

of the body tube. This will

be the front of the Glider

Hook. Glue the Glider Hook

to the top of the Body Tube.

Make sure the Hook is cen-

tered between the Glider

Supports and that the saw-

tooth edges are facing the

front of the rocket.

GLIDER ASSEMBLY

❑15. Lay the Glider Body

Tube (D) on a flat surface.

Place a sheet of wax paper

over it to prevent glue from

sticking while the wings

dry. Place a bead of glue on

the root edge of one of the

Glider Wings (11) and at-

tach it to the other wing. As

the glue joint starts to set,

drape the assembly over

the body tube and wax pa-

per and let the wing tips

rest on the surface to form

the wing dihedral. Let dry.

❑16. Once the wing as-

sembly has dried, take the

Glider Body Tube (D) and

using the Fin Alignment Jig,

mark the Glider Body Tube

for Wing and Rudder place-

ment. Place the Glider Body

Tube in the hole in the Fin

alignment Jig and make a

mark on the tube at the

hash marks that are across

from each other. Extend

these marks the length of

the tube using a door jamb

or angle.

❑17. Glue the wing as-

sembly to the Glider Body

Tube keeping the rear edge

of the wings even with one

end of the body tube, and

the root edges of the wings

centered over one of the

lines that were drawn on

the body tube. Make sure

the wing tips remain on the

surface to keep the correct

wing angle.

❑18. Glue the Glider

Rudder (13) to the top of the

body tube on the other line

you previously marked on

the body tube. Keep the

Rudder even with the same

end of the body tube as the

wings, and lined up with the

joint of the wings on the

bottom of the body tube.

Add glue fillets to all joints.

❑19. Glue the Glider

Elevons (12) to the outer

rear edges of the wings.

Use the large Fin Alignment

Guide to set the angle of the

Elevons.

Glue

Here

Glue Fillets

1/2”

❑20. Get the remaining

Glider Hook (F) and square

up the bottom side where it

will be glued to the under-

side of the glider. Make a

mark on the under side of

the wing 1/2” back from the

point where the two wing

halves join. File or sand a

flat across the wing joint so

the Hook will sit flat and

glue down the Glider Hook.

Make sure the hook is cen-

tered over the joint and is

parallel with the Body Tube,

and the Saw-tooth edge is

facing rearward.

❑21. Glue the aprons to

the sides of the hook. Use a

toothpick to spread the glue

so that you don’t get glue

into the hook area. Once the

glue has dried, lightly sand

the sides of the hook on the

booster and check that the

glider will release freely

when hooked together.

❑22. Cut the Orbiter Noz-

zle from the carrier sheet

and Pre form it into a nozzle

around the end of a sharp-

ened pencil. Once it is to

shape, glue the ends to-

gether with the ends sliding

together in the slot. Set

aside to dry. Glue the disc

to the end of the TB-1+

Thrust Block (L), centering it

over the end of the tube.

When the nozzle is dry,

attach it to the disc, keeping

it centered. When this as-

sembly is dry it can be in-

serted into the rear of the

Orbiter Body Tube. It is

recommended that this not

be glued into place until

after painting, to make it

❑23. Check the fit of the

nose cone in the Orbiter

Body Tube. Do Not Glue to

Body Tube at this time.

Nose cone will be glued in

after glider has been bal-

anced for gliding.

Stall–Add Nose Weight

Good Glide

Dive–Remove Nose

Weight

TRIMMING YOUR GLIDER

❑24. Before you can fly

your glider, it must be bal-

anced correctly. Remove

the nose cone from the

glider and glue the remain-

ing piece of the toothpick

into the rear of the nose

cone. Add a small amount

of clay around the toothpick

and re-insert the nose cone

into the glider without glue. Gently toss the glider and

check how it glides. If it stalls, add more clay. If it dives,

remove some. When it glides straight, it is balanced

correctly. It is best to wait on gluing in the nose cone

until after you have your model painted so that you can

check the glide characteristics and make any modifica-

tions necessary.

FINISHING YOUR MODEL

❑25. Now that you

have completed assem-

bly of your MX Orbital

Transport it is time for

finishing. For best look-

ing results, some filling

and sanding will be re-

quired. Using Carpenters

wood putty or Modelers

putty, fill the areas where

the tabs and slots came

together on the wings,

and sand smooth once it

has dried. Use sanding

sealer on the nose cones

to fill the pores in the

balsa wood. Several

coats may be needed to

get a smooth surface

sanding between coats.

Prime and paint your

model as you see fit and

add decals as shown in

the attached diagram.

FLIGHT PREPPING

❑26. Mounting the engine: Friction fit the Micro Maxx

motor with masking tape applied around it to keep it

from being kicked out of the motor mount at ejection

time.

❑27. Insert recovery wadding into the top of the Main

Body Tube. Use a sufficient amount to protect the

streamer, about 1 1/2 times the width of the body tube is

enough.

❑28. Roll the Streamer and pack it and the shock cord

on top of the recovery wadding. Slide the nose cone into

place making sure not to pinch the shock cord or stream-

er.

❑29. Place the Booster Portion onto the Launch Rod.

We recommend the Semroc ER-9080 Micro Maxx Launch

Rod and Holder which attaches to a regular 1/8” launch

rod. Make sure the motor seats onto the igniter fully.

Load the Glider onto the Booster.

❑30. Connect your controller leads, conduct your

countdown. Launch your MX Orbital Transport.

❑31. Always check all parts of your rocket before each

flight as part of your pre-flight check list, and make any

repairs as needed before flight. Enjoy.

Other SEMROC Toy manuals

Popular Toy manuals by other brands

Mega Construx

Mega Construx Pokemon Detective Pikachu GJC34 manual

BLOTZ

BLOTZ 10mm Skyscraper Dice Tower manual

Jazwares

Jazwares Pokemon Surprise Attack Game quick guide

HSD

HSD J10 user manual

Learning Resources

Learning Resources GEARS! MOTORIZED Wacky Wigglers Building Set instructions

Faller

Faller 242 manual