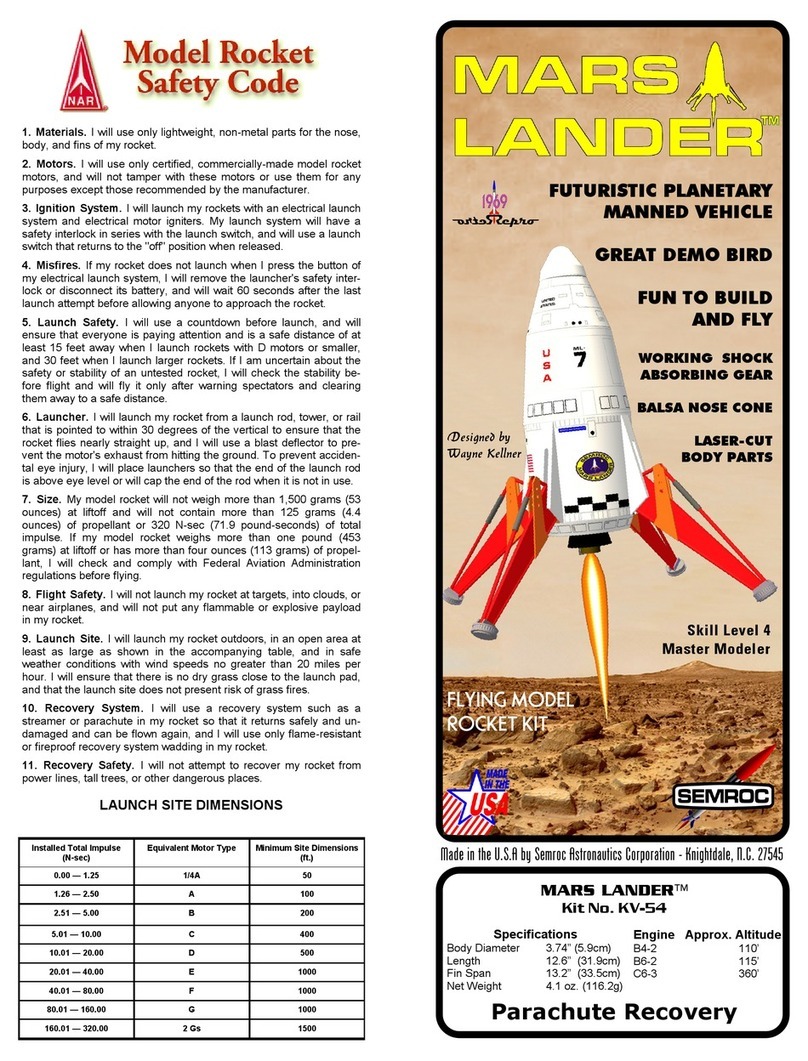

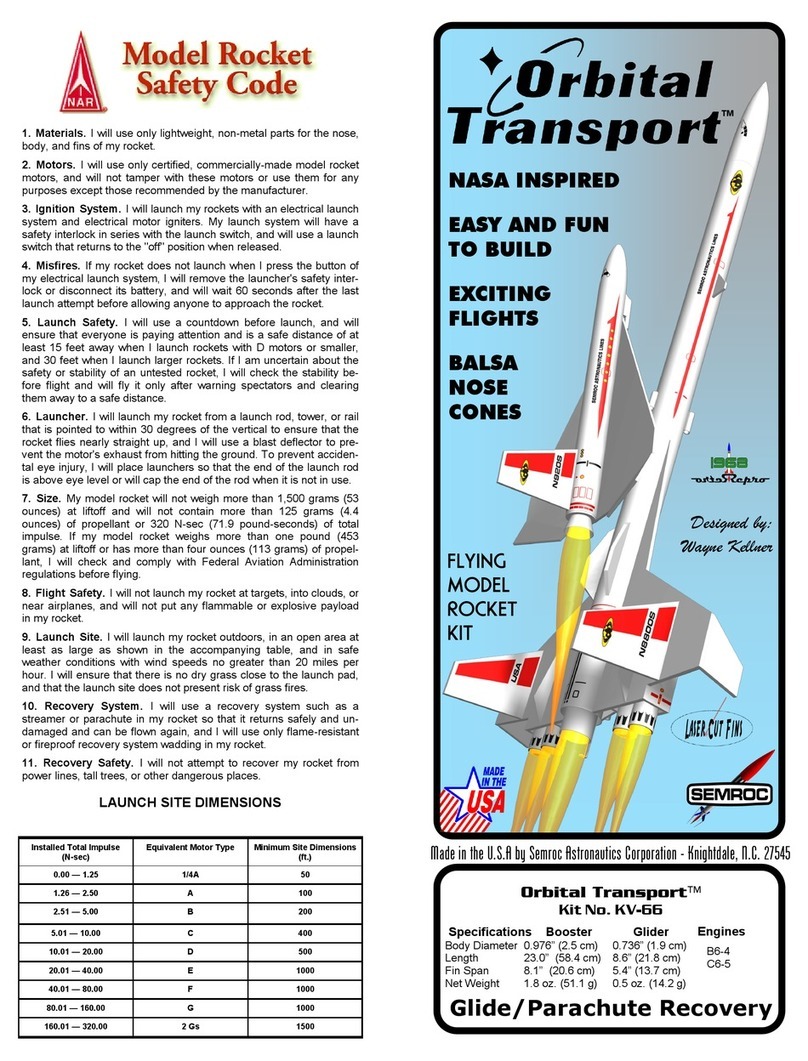

SEMROC Saturn 1B User manual

Saturn 1B

Kit No. KS-1

Specifications

Body Diameter 3.938” (10.0cm)

Length 37.7” (95.8cm)

Fin Span 8.2” (20.8cm)

Net Weight 9.9 oz. (280.9g)

Engine Approx. Altitude

C6-3 (four) 600’

D12-3 220’

D15-4 325’

Skill Level 4

Made in the U.S.A by Semroc - Dayton, Ohio

1967 Retro

Reproduction

1/70 Scale Model

Flies on a single

24mm motor or a

Cluster of four

18mm motors

Laser Cut Parts

Embossed

Wraps

Dual 18”

Parachute

Recovery

FLYING

MODEL

ROCKETKIT

2

What is a Retro-Repro?

A Retro-Repro is a retro reproduction of an out-of-

production model rocket kit. It is a close approxima-

tion of a full scale model of an early historically sig-

nificant model rocket kit from one of the many com-

panies that pioneered the hobby over the past half

century. A Retro-Repro is not a true clone or identi-

cal copy of the original. It incorporates improve-

ments using modern technology, while keeping the

flavor and build appeal of the early kits.

Copyright © 2006 Semroc

www.semroc.com

October 15,2006, January 20, 2018

About

Estes Industries

In July 1958, G. Harry Stine of Model Missiles, Inc.

in Denver, Colorado approached Vern Estes about

making model rocket engines for them. On January

15, 1959, Vern’s automated model rocket engine

fabricating machine, “Mabel”, produced the first of

many millions of Estes model rocket engines. In

1960, Estes was producing more engines than Mod-

el Missiles could sell. Vern and his wife Gleda

opened a mail order rocket company and intro-

duced the Astron Scout and Astron Mark.

In 1961, a catalog was mimeographed and hand

stitched on Gleda’s sewing machine. Later that

year, Estes Industries had outgrown the confined

space in Denver. In December 1961, the entire oper-

ation was moved to an old farm in Penrose, Colora-

do and quickly established the small town as the

“Model Rocket Capital of the World.”

Estes Industries was sold to Damon in September

1969. The name Estes is synonymous with model

rocketry. Almost everyone remembers growing up

launching Estes rockets or knowing someone who

did. Estes Industries has introduced millions of peo-

ple of all ages to model rocketry for almost half a

century.

3

About the Saturn 1B

The Estes Saturn 1B was released in 1967. The cul-

mination of over a year of development driven by

Chief Illustrator Gene Street, the Saturn 1B was a

major work of model rocketry art. Not quite an actu-

al scale model, but a close interpretation that has

withstood the test of time as one of the giant leaps

in the hobby. It was followed by much more faithful

scale models over the years, but the Gene Street

paper and balsa interpretation transcends the more

perfect plastic versions. A true modeler’s kit requir-

ing master modeling skills, the Saturn 1B reflects

the builder rather than the kit manufacturer.

The original Estes Saturn 1B was #K-29 and was

introduced at a price of $9.95. The Semroc Retro-

Repro Saturn 1B is a faithful reproduction of the

original. It uses laser-cut balsa fin ribs and smooth

finished balsa parts for ease of construction. Heavy

embossed wraps are included like the original with

a paint-ready glossy surface. Dual 18 inch para-

chutes are supplied.

TOOLS: In addition to the parts supplied, you will

need the following tools to assemble and finish

this kit. You will also need masking tape and a few

wooden toothpicks.

BEFORE YOU START!

Make sure you have all the parts included in this kit

that are listed in the Parts List in the center of these

instructions. In addition to the parts included in this

kit, you will also need the tools and materials listed

below. Read the entire instructions before begin-

ning to assemble your rocket. When you are thor-

oughly familiar with these instructions, begin con-

struction. Read each step and study the accompa-

nying drawings. Check off each step as it is com-

pleted. In each step, test-fit the parts together be-

fore applying any glue. It is sometimes necessary

to sand lightly or build-up some parts to obtain a

precision fit. If you are uncertain of the location of

some parts, refer to the exploded view in the cen-

ter of these instructions. It is important that you

always ensure that you have adequate glue joints.

4

❑1. These instructions are presented in a logical order

to help you put your Semroc Saturn 1B together quickly

and efficiently. Check off each step as you complete it

and enjoy putting this kit together.

NOTE: The Semroc Saturn 1B is not for inexperienced

modelers. If you have not developed sufficient skills to

build this kit, wait until you have built a few more mod-

els. It will wait for you. Patience is required as well as a

careful review of each instruction before continuing. If

you are ready for this challenge, “Let’s get started!”

There are so many critical measurements required that a

ruler is supplied with this kit. Cut it out next and keep it

handy!

ASSEMBLY

❑2. There are many different balsa and fiber parts in-

cluded in this kit. Use the guide below to identify the

parts that are called out in these instructions. Some of the

parts are similar, but will not work if exchanged. Some of

the parts have a top and a bottom and must be installed

correctly or other parts will not fit later. If you “goof,”

contact us and we can possibly help you out. The laser-

cut rings and parts are messy. Use paper towels to wipe

all the edges as you punch them out.

PARTS IDENTIFICATION

5

ENGINE MOUNT

First Major Decision!

There are parts for two different motor mounts, a four

engine cluster for standard 18mm engines or a single

24mm engine. There are pros and cons for both mounts.

The original used a four engine cluster with lots of

smoke, fire, and sound. Cluster ignition is left for the

most experienced rocketeers. Faulty ignition, improper

launch equipment, or simply bad hookup techniques can

have disastrous consequences. Done properly, a four

engine cluster of C engines in a Saturn 1B is impressive.

A single 24mm engine like the D12-3 will not reach the

altitudes of the cluster, but is generally much more relia-

ble. Some of the newer 24mm reloads can be just as im-

pressive. It is not in the scope of these instructions to

make an interchangeable mount, but an experienced

modeler should be able to accomplish the task. Continue

with the next step if you want to build the four engine

cluster or skip to step 7 to build the single engine version.

Option A - Four Engine Cluster

❑3. Insert one of the short engine hooks (EH-28) in the

slot at one end of an engine mount tube (ST-730E). Start-

ing at the slot, apply a bead of glue along the engine

hook for about 1”. Cover the glue with a piece of masking

tape or paper. Repeat for the other three engine mount

tubes. Allow them all to dry.

❑4. Glue two of the engine mount assemblies together

as shown below. Keep glue off the engine hooks. Glue a

second set together identical to the first. Make sure the

engine hooks are at right angles. When both assemblies

are almost dry, stack them as shown and glue them to-

gether. Apply a ball of tissue in the top central channel

formed by the four tubes. Add a glue fillet over the tissue

and along each joint formed by the tubes. Keep turning it

to prevent runs and allow the assembly to dry complete-

ly.

6

❑5. Using a drawer or door facing, draw a line on the

TR-9115 ring. Remove the cluster bulkhead (1) from the

ring set. As with all the fiber parts, sand the hold-in tabs

slightly and use a toothpick to soak each edge with cy-

anoacrylate glue to keep them from de-laminating. Glue

the ring in the cluster bulkhead (1), aligning the notch

with the line. Apply a fillet around the outside joint.

❑6. Apply a bead of glue around the tops of the engine

mount tubes. Align the cluster bulkhead assembly over

the engine mount tube assembly as shown. Apply a bead

of glue on the joint between the two assemblies. Set the

assembly aside to dry. Skip to step 9.

Option B - Single 24mm Engine

❑7. Insert the long engine hook (EH-38) in the slot at

one end of the large engine mount tube (ST-940E). Apply

a piece of masking tape 1-1/2” from the bottom of the

tube. Apply a bead of glue along the engine hook from

the slot to the tape.

❑8. Mark the engine mount tube 1/2” from the top.

Apply a film of glue to this area and slide the ring (TR-

115) over the tube until it is even with the mark. Apply a

bead of glue around the joint and allow to dry.

7

❑9. Apply a bead of glue inside one end of one of the

stuffer tubes (ST-990). These tubes are 9” long and

should not be confused with the BT-51N tank tubes! In-

sert the tube coupler (HTC-9) into one end of a tube to

about 1/2”. When it sets sufficiently, add a bead of glue

inside the other stuffer tube and join the two tubes. Roll

on a flat surface to make sure the resulting tube is

straight.

MAIN ASSEMBLY

❑10. When the stuffer

tube is dry, hold it against

a door facing, drawer

edge, or another channel

and make a long continu-

ous line down the length

of the tube.

❑11. Mark one end of

the stuffer tube 1/2” from

the end of the tube over

the long line just drawn.

Add a bead of glue inside

the stuffer tube and insert

a tube coupler (HTC-9)

until it has about 1/4”

exposed. This will help

protect the stuffer tube

from hot gases.

❑12. Apply a film of glue around the end of the stuffer

tube between the mark and the end of the tube. Insert the

top of your engine mount (cluster or single) over the

stuffer tube until the top of the ring (TR-115) is even with

the 1/2” mark. Do not fillet the joint between the thrust

ring and the stuffer tube. If you are using the cluster

mount, make sure the line drawn on the thrust ring is

aligned with the long mark drawn on the stuffer tube.

This is very important! The tank tubes will not fit if this is

not correct. If you are using the single engine mount, it is

not important how the mount is aligned as long as it is

even with the 1/2” mark. Allow this assembly to dry com-

pletely.

8

❑13. This step can be skipped if you have the single

24mm engine mount. Locate four of the fuel tubes (BT-

51N.) Mark a rectangle on the end of each tube 3/8” wide

by 2-7/8” long. Carefully cut out a slot from all four of the

tubes. Leave the remaining tubes alone for now.

❑14. Place one of the stars (2) over the stuffer tube

and slide it into place against the thrust ring on the en-

gine mount. Align the small notch on the star with the

long line on the stuffer tube. Place a fillet of glue on each

side of the star.

❑15. Place the other star (2) over the stuffer tube and

slide it into place even with the top of the mid joint and

with the small notch aligned with the long line on the

stuffer tube. Place a fillet of glue on each side of the star.

9

❑16. Mark the end of each stuffer tube 1/8” from the

end. The four slotted tubes should be marked at the op-

posite end from the slot. (If the tubes were not slotted for

the 24mm option, use any four tubes.) Glue the first slot-

ted tank tube to the two stars as shown, with the slot over

one of the engine mount tubes and the 1/8” mark even

with the top of the star. Since the walls are thin on the

tank tubes, be careful as you handle this section.

❑17. Repeat for the other three slotted tank tubes,

keeping them 1/8” from the top of the star. It gets harder

to glue as more tubes are added. Make sure you have

good joints on the stars. Also watch for drips since there

are many joints and lots of glue used in these steps.

❑18. Glue the remaining four tubes between the first

four, also keeping them aligned at the top 1/8” from the

star. Run a fillet of glue around all the joints at the top of

the assembly.

❑19. Slide the tank tube cover (3) over the stuffer tube

and glue into place flat against the tops of the tank tubes..

10

❑20. Apply fillets around each joint between the tank

tubes and the tank cover.

❑21. Remove the 8 spacer strips (A) from the balsa

sheets. Sand slightly to remove tabs. These will be cov-

ered so finishing is not necessary. The strips are not

square so glue the laser-cut edge to the tank tubes for

best fit. Glue one to the outermost part of each tank tube

and even with the bottom edge.

❑22. Place a mark .65” (21/32”) inside the edge of the

tail ring tube (BT-101T).

❑23. Slide the tail ring over the tank tube assembly

until the balsa spacer strips line up with the line drawn on

the inside of the tail ring. Apply a fillet of glue along each

joint.

11

❑24. Insert the lower cap ring (4) over the end of the

motor mount and flush against the tank tubes. If you

have the 24mm single mount, align the engine hook in

the center of one of the holes. Apply a fillet of glue

around all the joints.

❑25. If you have the 24mm single mount, glue the

hole cover (5) over the engine tube with the hook cen-

tered in the slot. Apply a fillet of glue around the cover.

❑26. Remove the 8 fairing supports (B) from the two

balsa sheets. Sand them lightly to remove the tabs. Bevel

the longest edge slightly and fit them into the joint be-

tween the tank tubes and the tail ring. Glue them into

place with the short edge even with the top of the tail

ring. These will provide support for the tank fairing in the

next step. Use a scrap piece of balsa to get glue on the

joints with the tail ring. Allow to dry.

12

❑27. Carefully cut out the fairing shroud and glue the

ends together with the glossy side out. Slide the fairing

over the tank tubes and against the fairing supports and

the tail ring. Check it for fit and trim slightly if necessary.

Pull it back and apply a small bead of glue on each fairing

rib and around the tail ring. Reseat the fairing and apply

glue fillets at all joints.

❑28. Measure 7.6’ (7-19/32”) from the tube cover on

the exposed end of the stuffer tube. Glue one of the

adapter rings (6) even with the mark. Apply a fillet around

both sides of the joint.

❑29. Glue the other adapter ring (6) to the end of the

stuffer tube. Apply a fillet around both sides of the joint.

❑30. Place a mark at 2.7” (2-11/16”) from the end of

the parachute tube (BT-70V.) Slot it with your hobby knife

and insert the shock cord (EC-236.) Tie a knot in the end

and pull the opposite end until the knot is against the

tube. Apply a bead of glue to the knot and tube joint.

13

❑31. Pull the shock cord out of the top of the para-

chute tube so it is out of the way. Apply a bead of glue

inside the end closest to the knot. Slide the main tube

assembly into the parachute tube until the bottom ring is

recessed 1/16”. Let the glue dry in an upright position,

then turn it upside down and add a fillet against the re-

cessed ring.

❑32. Locate the parachute tube adapter ring (7). This

is the ring with the smooth outer edge. Do not confuse

this with the shroud adapter (8) which is the same size

but has a beveled edge. Glue it to the parachute tube

3.2” (3-13/64”) from the bottom edge. Apply a fillet of

glue to each side, heavy to the bottom and thinner to the

top. Allow to dry.

❑33. Fit the upper body tube (BT-100Z) over the para-

chute tube ring and over the tank cover ring. It should be

even with the top ring and have a slight overlap over the

bottom ring. Remove the tube and apply a bead of glue

around the top edge of both rings. Quickly slide the tube

back into place, wiping any glue that may drip. Allow the

tube to dry, then apply a fillet at the bottom end. Wipe

the top ring so it is smooth and the ring is flush with the

tube.

❑34. Carefully cut out the LEM shroud from its sheet.

Roll it into a conical section with the glossy side out. Ap-

ply a thin film of glue on the overlap area. Press the other

end into place making sure it is even with the marked

area. Hold it in place while the glue sets. Use your finger

to remove the beveled edge from the shroud adapter ring

(8) Run a thin bead of glue just inside the LEM shroud

and glue the ring in place with the bevel facing inside.

14

❑35. Apply a bead of glue around the top of the para-

chute tube ring and upper body top. Slide the LEM

shroud over the parachute tube and into place over the

parachute tube ring. fit the base of the shroud to the up-

per body tube and smooth any excess glue. Apply a thin

fillet of glue around the top joint and smooth it into place.

There should be 2.56” of the parachute tube left exposed.

WRAPS

❑36. Start with Wrap #1, the longest corrugated piece.

Fit it around the base of the ring tube. Trim if necessary.

Apply a thin film of white glue on the dull side and place

it around the ring tube, even with the bottom and the

edge lined up and parallel with one of the tank tube

joints. Refer to the drawing below. The joint selected will

become the fin position between POS. I and POS. IIII. Re-

peat with Wrap #2, the wrap with no corrugations. It

should be placed glossy side out and almost touching

Wrap #1 and with the edges in line.

❑37. Wrap #3, the widest corrugated piece, is next. It

should be glued with the flat spots toward the rear on the

upper body tube. The edges should be aligned with the

edges of the first two wraps. The bottom edge should

be .385” from the edge of the upper body tube. Refer to

the drawing. Fit it into place and draw a line around it to

make it easier to align while gluing it in place. Make sure

15

it is aligned exactly as shown before continuing. As with

the first wraps, glue it with the glossy side out. Wrap #4,

the smallest remaining wrap, is glued just above Wrap

#3. Make sure it is positioned as shown by the NOTE! If it

is installed upside down, none of the detail pieces will fit

later. Wrap #5 is glued .518” from the top of the upper

body tube. Also refer to the drawing carefully for the cor-

rect position of the corrugations. All the edges should be

in a straight line.

FIN CONSTRUCTION

❑38. Carefully cut out eight of the fin covers. Place a

straight edge along the center fold line. Draw a dull table

knife or a ball-point pen along the line to score the paper

without cutting through. Align the straight edge on the

two crease lines and make a lighter crease on each of

those. Fold the fin cover in half along the fold line. Slight-

ly crease each of the crease lines. Repeat for all eight co-

vers.

Second Major Decision!

The built-up fins are one of the most difficult steps in the

construction of the Saturn 1B. They require lots of pa-

tience, but give the best result. We have provided 1/8”

laser-cut balsa fins as an alternate solution. At a distance,

they are hard to tell they are not the real thing. If you do

decide to use the balsa, still give the built-up fins a try.

They will give you a flavor of building the original model.

❑40. Remove all the rib parts from the laser-cut sheet.

Sand them slightly to remove the hold-in tabs. Separate

them into eight sets of parts. Start with the main root rib

(C) and test it for fit over the dotted line. Add a small

bead of glue to the edge of the root fin and apply it to the

fin cover. Add the trailing edge spar (D) against the main

root rib with a small amount of glue.

❑39. Sand both sides of the 1/16” thick laser-cut sheet

B carefully before breaking the individual pieces out.

They are hard to sand once they are loose since they are

so small. Remove the four small junction boxes (K) and

put them in a safe place. They are easily lost.

16

Parts List

A1Apollo Capsule KS-2

B8Body Tubes BT-51N

C1Body Tube BT-70V

D1Body Tube BT-100Z

E1Body Tube BT-101T

F2Body Tubes ST-990

G4Body Tubes ST-730E

H1Body Tube ST-940E

I2Launch Lugs LL-180

J1Laser-cut Fin Set FS-1

K1Thrust Ring TR-115

L1Launch Lug LL-320

M1 Elastic Cord EC-236

N4Engine Hooks EH-28

O1Engine Hook EH-38

P3Tubing Couplers HTC-9

Q1 Wood Dowel WD-212

R1Centering Ring Set (3) CR-KS-1

S1Body Wrap Set (5) IKS-1W

T1Shroud Sheet Set (3) IKS-1S

U2Chute Pak CP-12-18RW

V1Decal Set DKS-1

W1Saturn 1B RulerIKS-1R

X1Instruction Manual IKS-1

17

EXPLODED

VIEW

18

❑41. Test the tip rib (E) for fit and add it next. It may

be necessary to sand the edge of the trailing edge spar.

Test fit the long brace rib (F) next. The bottom may need

to be beveled to fit. Apply a small amount of glue and set

it into place over the dotted line.

❑42. Test the center rib (G) for fit and place it along

the dotted line. Glue it into place. After the glue has set

on all pieces, run a thin bead of glue around each internal

joint for strength. Fold the fin cover and test for fit. Apply

a thin bead of glue on all the top edges of the ribs and

fold the cover over into its final position. Hold it in place

until the glue sets. If all the pieces fit correctly, little addi-

tional work is required. If there are edges that do not line

up, wait for the glue to completely dry and sand the fin.

Fill ‘n Finish can be used to smooth the tip and trailing

edge. Repeat for the remaining seven fins.

❑43. If you decided to use the balsa fins (H) instead of

the built-up fins, sand a gradual bevel on each so the

leading edge is smaller than the trailing edge. Use Fill ‘n

Finish to fill the balsa and sand it smooth. Repeat for all

eight fins.

❑44. Check each fin for fit using the drawing below.

Each fin should be centered between two tank tubes and

against the Wrap #2 and the fairing shroud. Use enough

glue to get a good joint. a very small fillet can be used on

the root joint, but most of the strength comes from the

glue on the root edge.

19

FINAL DETAILS

❑45. All the remaining small laser-cut fiber parts will

be attached in the following steps. They are small and

look very much alike so keep the parts identification page

handy. As each piece is removed, a very light sanding

should be used to get rid of any tabs. Use cyanoacrylate

glue applied to each edge with a toothpick to seal the

layers of paper so they do not de-laminate. Select the

main tunnel (9) from the fiber sheet. Center it on the two

corresponding flat spots on the two upper wraps.

❑46. Detach the auxiliary tunnel (10) from the fiber

sheet. Align it on the flat area on Wrap #5 beside the

main tunnel extended onto the upper body tube and glue

into place.

❑47. Detach the eight camera targets (11) from the

fiber sheet. Align them as shown below. They should be

centered over each tank tube and 2.13” from the bottom

edge of the base of the upper body tube. It may be neces-

sary to depress the corrugation slightly to get a close fit

on the wrap.

20

❑48. Detach the two telemetry antennae (12) from the

fiber sheet. Align them as shown below and glue into

place on Wrap #5. They should be centered over the two

flat spots on either side of the main channel.

❑49. Detach the thermal sensors (13) from the fiber

sheet. Align them as shown below and glue into place on

the upper body tube. Center them between the top of the

upper body tube and the top of Wrap #5. Align the first

one directly over the long main tunnel and space the sec-

ond one 2.118” towards the auxiliary tunnel. Refer to the

drawing.

❑50. Detach the four latch pads (14) from the fiber

sheet. Align them as shown below and glue into place on

the LEM shroud. They should be in line over each POS.

fin and 1.2” from the base of the shroud.

❑51. Detach the cover (15) from the fiber sheet. Center

it on the final flat spot on Wrap #5 and glue it into place.

This manual suits for next models

1

Table of contents

Other SEMROC Toy manuals

Popular Toy manuals by other brands

marklin

marklin 601 "BST" manual

East Coast Vario

East Coast Vario Starwood SA315B LAMA Assembly manual

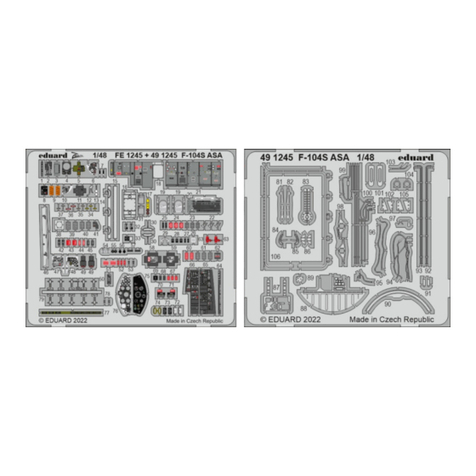

Eduard

Eduard F-104S ASA quick start guide

KidKraft

KidKraft Mosaic Magnetic Play Kitchen with EZ Kraft... manual

roco

roco BB 8100 SNCF operating manual

EDU-TOYS

EDU-TOYS CIRCUIT MAKER Skill Builder 125 instruction manual