Sencon SIP-6 User manual

1

TECHNICAL

DATA SHEET

SIP-6

SENSOR INTERFACE BOX

DESCRIPTION

The SIP-6 Sensor Interface Box works with Sencon Series 9 Sensors. The purpose of the SIP-6 is threefold;

1.) to provide a convenient means of terminating and wiring up to six sensors;

2.) to provide a visual indication of the output status of each sensor via an LED;

3.) and to provide a local adjustment feature for the operating threshold of each sensor (if so

equipped).

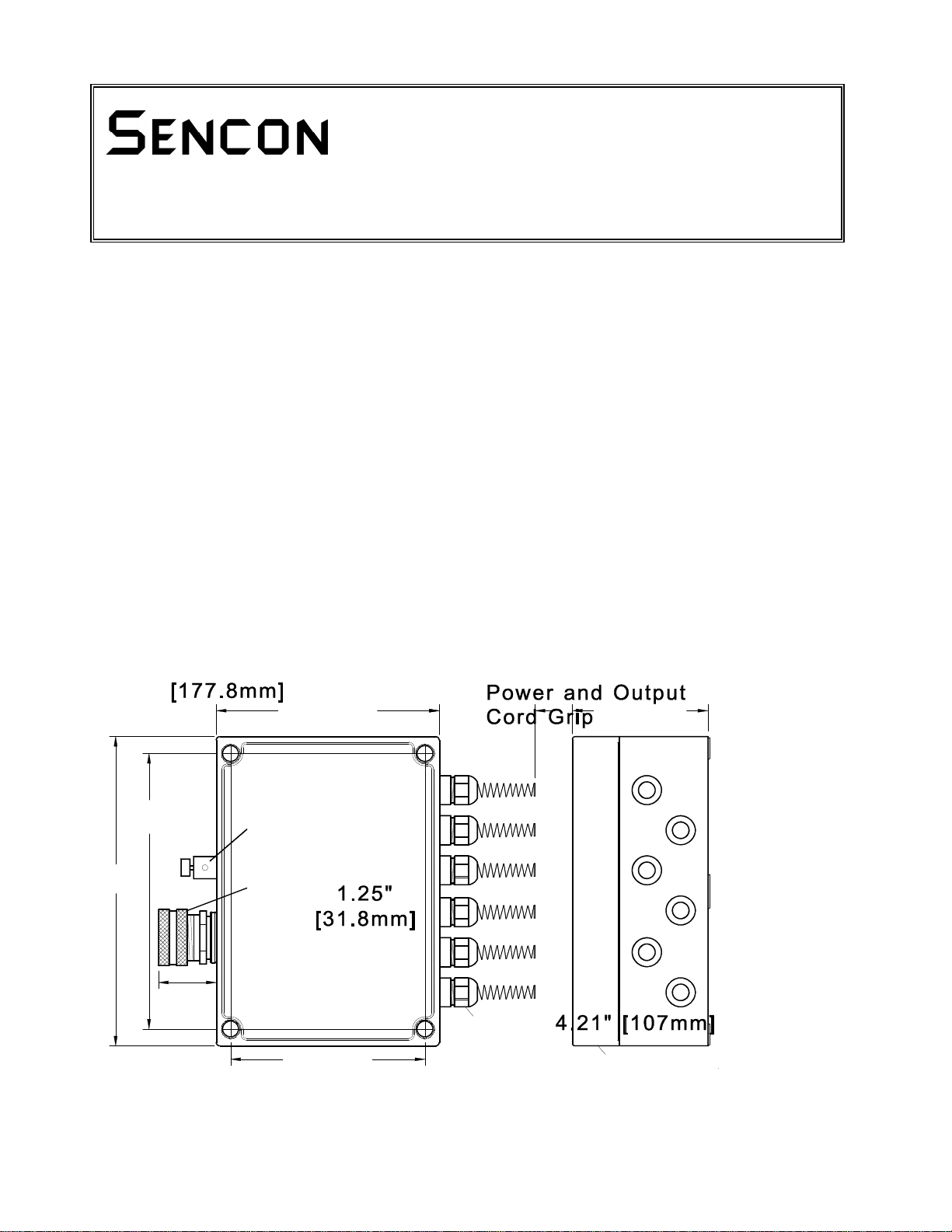

The SIP-6 housing is a tough polycarbonate NEMA 4X enclosure with a clear cover for viewing the LEDs and

adjustment potentiometers located inside. The basic box measures 7 inches [178 mm] high by 5 inches [127

mm] wide by 3 inches [76 mm] deep. Six cord grips with watertight gland fittings and integral strain relief are

located on the right-hand side of the box. Sensor cables enterthe box through these fittings. Thewires terminate

on individualplug-in connectors as shown in the drawings. Power and output signal wiring enter the box through

a larger cord grip and connector on the left-hand side of the box. The cord grip for the output cable works with

cable diameters of 0.375 inches [9.5 mm] to 0.500 inches [12.7 mm]. When using a jacketed cable in thisrange,

the SIP-6 is drip-proof. Change the cord grip when using a larger or smaller diameter cable to maintainthewater

tight seal (cord grips in any desired size range are readily available at an electrical supply house).

DIMENSIONS AND MOUNTING

2

SPECIFICATIONS

Input Voltage

12 to 30 Volts DC

Input Current

60 mA Maximum with All LEDs On (Plus Sensor and Load Current)

Short Circuit

Protected

Protected

Reverse

Polarity

Protected

Isolation

250 Volts

EMI

Protected

Storage

Temperature

- 40EF to +176EF [- 40EC to +80EC]

Operating

Temperature

+32EF to +140EF [0EC to +60EC]

Environment

The box is gasketed and sealed similar to NEMA 4X or IP65. The

watertight integrity of the box depends on the proper selection and

use of the power and output cable and its cord grip.

GENERAL CHARACTERISTICS

Weight

30 oz. [850 grams]

Material

Polycarbonate

Termination

5 and 12 position "Touch Safe" terminal blocks, suitable for

22 AWG [0.32 mm

2

] to 12 AWG [3.3 mm

2

] wire sizes.

3

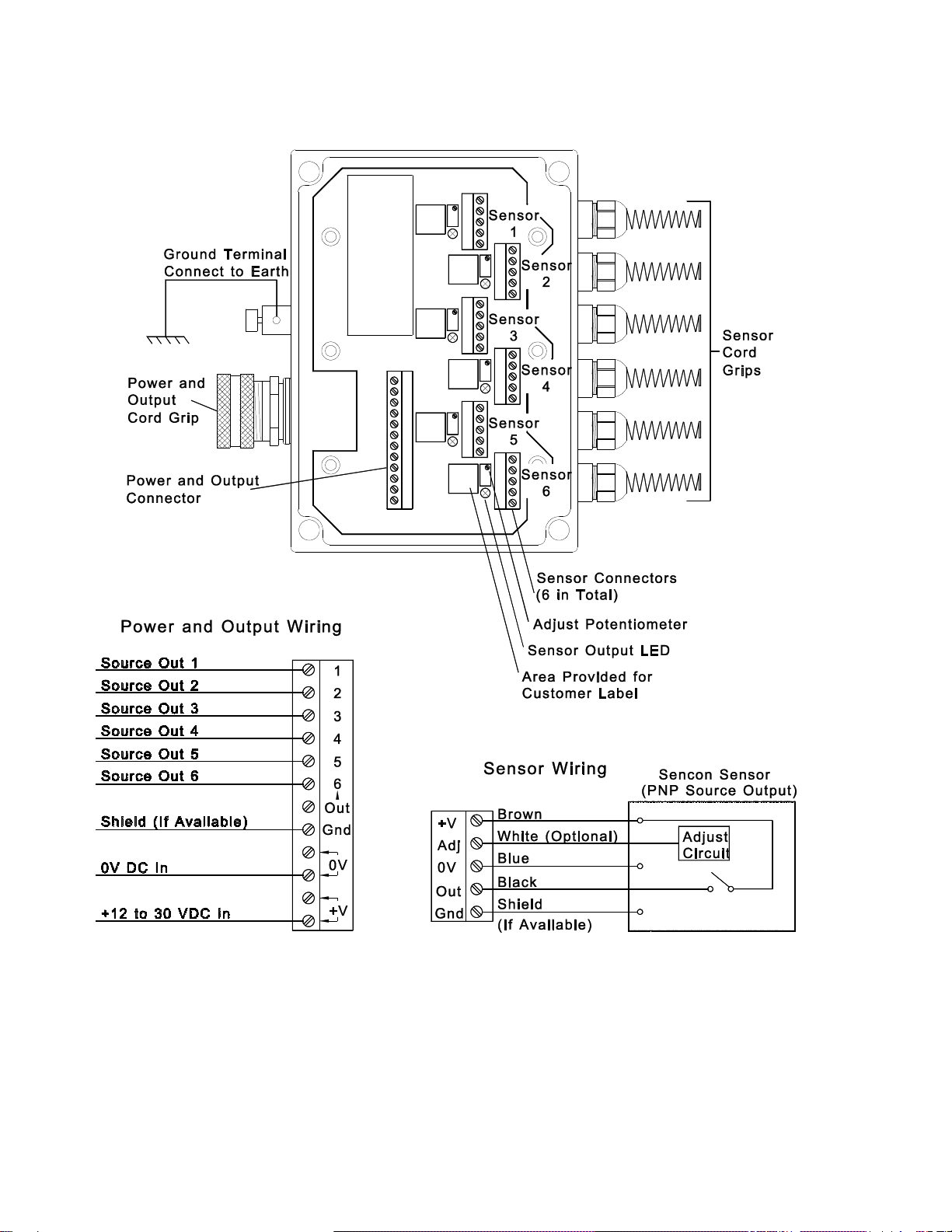

INTERCONNECTION

4

SETUP AND USE

Install the SIP-6 in a convenient location within reach of the sensors. With the cover removed, pass the endof the

sensor cable through the spiral cord grip and into the SIP-6. Do not tighten the cord grip down yet. Pull enough

cable through to simplify working on the wires. Strip back the outer jacket for a distance of about 1 inch [25 mm]

and separate the wires. Strip one-quarter inch [6 mm] of insulation off the end of each wire. Lift the five pin

connector out of its socket on the board and wire the cable to the connector as shown in the interconnection

drawing. Now grasp the cable outside the box and pull it back out of the SIP-6 until the five pin connector can plug

into its socket and the wires are dressed neatly over to the fitting. Tighten the cord grip now, but do not go

overboard with the amount of force applied. Tighten the cord gripusingonlymoderateforce. Repeatthis procedure

with the other five sensors. There is a 0.5" [13 mm] square blank area on the circuit board next to each connector

for the user to attach a sensor ID label.

Now bring the power and output cable into the SIP-6 through the cord grip on the opposite side of the box. Strip

back the outer jacket and insulation on the wires as described above. Lift the 12pin connector out of its socket on

the board and wire the cable to the connector as shown in the interconnection drawing. Dress the cable back out

through the cord grip and plug the connector into the board. Tighten the cord grip just enoughtograbthe cableand

act as a seal.

Bring a wire from the machine frame to the ground terminal on the outside the SIP-6 just above the power cable.

Strip back the insulation and insert the wire into the hole in the terminal. Tighten the black thumb-nut to hold the

wire.

Apply power to the SIP-6 and verify that all of the sensors are working by observing the red LED located next to

each sensor connector. Also, check for the proper signals on the power/output connector. If the on-off operating

point for a sensor is not satisfactory, and it has the optional remote adjustment feature, then turn the adjustment

potentiometer for that sensor to obtain the desired setup. An adjustment tool is supplied with each SIP-6 to help

installation. Turning the potentiometer clockwise increases the range of the sensor. Turning it counterclockwise

decreases the sensor range. Note that the SIP-6 only slightly adjusts the operating point of the sensor. It cannot

compensate for improper installation of your sensors. Follow the setup instructions that accompany the sensors

before trying to adjust their operation via the SIP-6. Failure to follow these guidelines mayresult in marginal sensor

operation.

Note: To return the SIP-6 to the factory settings follow these steps.

1. Place a DC voltmeter between the "ADJUST" terminal (positive meter lead) and "0V" terminal

(negative meter lead) on the five pin sensor connector.

2. Turn the potentiometer until the adjust voltage equals +3 VDC. This is the neutral setting.

3. Adjust the sensor location as needed to obtain proper operation.

Replace the cover on the SIP-6. The installation is now complete.

5

ORDERING INFORMATION

For more detailed specifications, price quotes, or applications information, contact your SENCON sales office listed below:

NORTH, CENTRAL & SOUTH AMERICA

Sencon Incorporated

6385 W.74th Street

Bedford Park, IL 60638

USA

Tel: +1 708 496 3100

Fax: +1 708 496 3105

EUROPE - MIDDLE EAST - ASIA

Sencon (UK) Ltd

Stonebridge Cross Business Park

Droitwich WR9 0LW

UK

Tel: +44 1905 827800

Fax: +44 1905 795876

www.sencon.com

PUBLISHED 11 July 1994 TECHNICAL DATA SHEET# 096-41371-00

Please Note: Due to product improvement, specifications are subject to change without notice.

Table of contents

Popular Recording Equipment manuals by other brands

Ramix

Ramix PMC551 Hardware Reference and Installation Manual

DEVA Broadcast

DEVA Broadcast DEVA DB8000 Maintenance and operation instruction manual

Digitimer

Digitimer D400 Operator's manual

KEYBOARDPARTNER

KEYBOARDPARTNER HX3.5 WiFi Module Update manual

L-Acoustics

L-Acoustics LA4X owner's manual

Future light

Future light ICL-6 user manual