Sencon SI9000 plus User manual

SI9000

plus

Enamel Rater

User Manual

REF

OPERATION

MANUAL No.

092-00900-10

LANGUAGE

ENGLISH

REVISION

10

2ENAMEL RATER MANUAL: V.10

ENAMEL RATER MANUAL: V.10 3

1. INTRODUCTION 5

1.1 THE ENAMEL RATING TEST 5

1.2 THE SI9000+ 5

1.2.1 BODY CONTACT AND LEVEL CHECKING 6

1.2.2 SEMI-AUTOMATIC OPERATION 6

1.2.3 BATCH OPERATION 6

1.2.4 CONSTRUCTION 6

1.3 THE SI9005 CAN STAND 7

2. GETTING STARTED WITH YOUR SI9000+ 8

2.1 SAFETY 8

2.2 SETTING THE MAINS VOLTAGE 8

2.3 ADJUSTING AND CONNECTING THE CAN STAND 10

2.4 CONNECTING ANON-SENCON PROBE 12

2.5 SWITCHING ON AND THE SELF TEST 13

3. OPERATION 14

3.1 GENERAL DESCRIPTION 14

3.2 CONFIGURATION CHECK 14

3.3 FREE RUN AND REVERSE POLARITY15

3.4 BATCH MODE 16

3.4.1 RATING CANS 16

3.5 MASTER RESET 17

3.6 ERROR MESSAGES 18

4. CONFIGURING YOUR SI9000 19

4.1 SETTING THE MAINS VOLTAGE 20

4.2 SETTING UP THE STATISTICAL OUTPUT 21

4.3 THE LEVEL INTERLOCK 21

4.4 THE CONTACT INTERLOCK 22

4.5 CHANGING THE RATING VOLTAGE 22

4.6 CHANGING THE RATING DURATION 22

4.7 AUTORANGING OPERATION 23

4.8 LINE NUMBER ENABLE 23

4.9 AUTOSTART 24

4.10 AUTOSAVE 24

5. MAINTENANCE AND SERVICING 25

5.1 CARE OF YOUR SI9000+ 25

5.2 ROUTINE MAINTENANCE 25

5.3 ROUTINE TESTING 25

5.5 FAULT FINDING 27

5.6 REPLACING THE FUSE 28

5.7 OBTAINING HELP FROM SENCON 28

6. USING THE SI9000+ WITH A PRINTER 29

6.1 OVERVIEW 29

6.2 CHOOSING APRINTER 29

6.3 CONNECTING THE PRINTER 30

6.3.1 THE EPSON FX OR EX PRINTER 30

6.3.2 THE TANDY DMP132 PRINTER 31

6.3.3 USING OTHER PRINTERS 31

6.4 SETTING UP THE RS232 DATA FORMAT 32

6.4.1 SETTING UP THE EPSON PRINTER 32

6.4.2 SETTING UP THE TANDY PRINTER 33

4ENAMEL RATER MANUAL: V.10

6.4.3 SETTING UP OTHER PRINTERS 33

6.5 ENABLING THE PRINTOUT 33

6.6 SELECTING THE PRINTOUT FORMAT 34

6.7 PRINTER PROBLEMS 35

7. USING THE SI9000+ WITH A COMPUTER 36

7.1 GENERAL 36

7.2 COMPUTER PORT CONNECTIONS 36

7.3 SETTING DATA FORMAT AND SPEED 37

7.4 UNI-DIRECTIONAL PROTOCOL 38

7.5 BI-DIRECTIONAL PROTOCOL 38

7.6 FORMAT OF MESSAGE TRANSMITTED 39

7.7 ERROR MESSAGES 39

ENAMEL RATER MANUAL: V.10 5

1. INTRODUCTION

1.1 THE ENAMEL RATING TEST

The can industry has established a standard test for lacquer

integrity of food and beverage cans. The test involves applying a

voltage between a conductive liquid (electrolyte) within the can and

the metallic can body. As the internal lacquer coating is an

insulator, any current which flows is an indication of imperfections

in the lacquer . The larger the current the greater the area of the

imperfections and the poorer the quality of the can.

There is no definitive standard for the enamel rating test. Different

users have their own standards specifying the test voltage and test

duration, however a common standard requires a voltage of 6.3V to

be supplied for 4 seconds. In its factory supplied configuration the

SI9000+ uses this voltage and duration.

When a faulty can is detected the normal procedure is to reverse

the polarity of the applied voltage, which causes bubbles of gas to

be released from the area of the fault. This gives a visual indication

of the location of the fault and enables corrective action to be

taken.

1.2 THE SI9000+

The following description of operation assumes that the SI9000+ is

operated in its factory set configuration (see Appendix A Fig 1 for

settings).

6ENAMEL RATER MANUAL: V.10

1.2.1 BODY CONTACT AND LEVEL CHECKING

One of the problems the enamel rating test has suffered in the past

is that if any part of the circuit has a poor, high resistance contact

only a small current will flow and the instrument will show a bad can

as good. This is a particular problem where electrical contact is

made with the can body.

In order to overcome this problem the SI9000+ has special circuitry

which checks the contact with the can body and will not allow the

test to proceed until a good contact has been detected. In addition

to this, a similar circuit checks that the electrolyte level within the

can is adequate and so avoids the problem of the upper zone of

the can not being fully tested due to insufficient electrolyte. These

two circuits together will also detect a fault anywhere in the

connector or wiring to the probe, making the SI9000+ fail-safe in its

operation.

1.2.2 SEMI-AUTOMATIC OPERATION

Another spin-off of these check-circuits is that the SI9000+ can be

configured to detect a change of can and will automatically start the

test once a new can is correctly inserted. An internal timer will

freeze the reading when a preset time (e.g. 4 seconds) has elapsed

and one key press then prepares the instrument for the next can.

1.2.3 BATCH OPERATION

As the operator rates cans the SI9000+ will store the readings (up

to 99) in its memory as a batch. At any time during the batch

statistical information about the batch can be displayed and at the

end of the batch the readings in tabular format together with the

statistical information can be output to a printer or computer if

required.

1.2.4 CONSTRUCTION

The acrylic coated steel case and waterproof polyester facia panel

are designed to ensure that the SI9000+ will withstand the rigours

of a factory environment. Further to this the case, mains-switch

and connectors are all sealed to I.P.65 rating, thus preventing any

ingress of corrosive electrolytes and allowing operation of the

SI9000+ in "hose-down" areas.

ENAMEL RATER MANUAL: V.10 7

1.3 THE SI9005 CAN STAND

Due to the corrosive nature of the electrolytes used in enamel

rating the life of probe attachments can be very poor. With this in

mind, the SI9005 has been designed using nylon parts wherever

possible, whilst all metal parts are made from specially selected

stainless steels, heat treated where appropriate. The wiring of the

can stand is completely sealed against corrosion from electrolytes

which not only improves the life but ensures accuracy and reliability

of the readings taken.

Electrical contact is made with the can by three hardened knife

edges, one of which is wired separately to allow electrical contact

checking, and the two probes (one for rating and a shorter probe

for level checking) are supported on an adjustable arm and

telescopic column. This arrangement allows the probes to be lifted

and rotated to one side while the can is being inserted.

8ENAMEL RATER MANUAL: V.10

2. GETTING STARTED WITH YOUR SI9000+

2.1 SAFETY

The test voltages used by the SI9000+ are sufficiently low so as to

present no hazard whatsoever under all circumstances. Although

potentially dangerous mains voltages are present inside the unit,

the construction of the case to I.P.65 rating will prevent any hazard

from this whilst the case remains intact. Should the facia become

perforated or the case become damaged in such a way as to

destroy the seal then the unit must be removed from service

immediately and returned to Sencon for repair. Operators should

be warned to keep electrolytes away from electrical socket outlets

and never handle plugs with wet hands.

2.2 SETTING THE MAINS VOLTAGE

The mains voltage of the SI9000+ is factory set as appropriate for

the particular country to which it is supplied and the setting will be

clearly marked on the back panel. Should you need to change the

voltage proceed as follows:-

i. Remove the six button head screws in the base of the

case using the 2.5mm hex wrench supplied.

ii. Remove the base panel taking care not to damage the

earthing cable.

iii. Referring to Appendix A Fig 1 move the mains voltage

switch to the required position.

iv. Check that the foam seal on the bottom of the case is

intact and replace the base panel and six screws.

v. Change or remove the voltage label.

ENAMEL RATER MANUAL: V.10 9

Key to Enamel Rater Probe

1 -

Bushing

7 -

Body Contact

2 -

Foot

8 -

Locating Ring

3 -

Clamp Screw

9 -

Probe Arm

4 -

Locking Screw

10 -

Inner Column

-

Level Probe

11 -

Outer Column

6 -

Main Probe

12 -

Stand Base

FIGURE 2: ENAMEL RATER PROBE

10 ENAMEL RATER MANUAL: V.10

2.3 ADJUSTING AND CONNECTING THE CAN STAND

In order to make use of the electrolyte level checking facilities of

the SI9000+, it is important that the can stand is adjusted correctly

for the height of can to be tested. Referring to Fig.2 proceed as

follows:-

i. Raise outer column (item 11) and place can through the

can locating ring (item 8) onto the body contacts (item 7).

ii. Lower the outer column.

Note If at any time the outer column will not return to

its normal position resting on the stand base

(item 12) due to the cable fouling inside, then

raise the outer column and rotate clockwise for

several turns until the column moves freely

again.

iii. Slacken clamp screw (item 3) using the 3mm hex wrench

supplied, and slide the probe arm (item 9) so that the

bottom of the level probe (item 5) is at the minimum

permissible electrolyte level and the outer column is firmly

against the stand base.

iv. Tighten the clamp screw making sure the main probe

(item 6) is central in the can. Take care not to overtighten

the clamp screw as this will cause the outer column to

bind on the inner column.

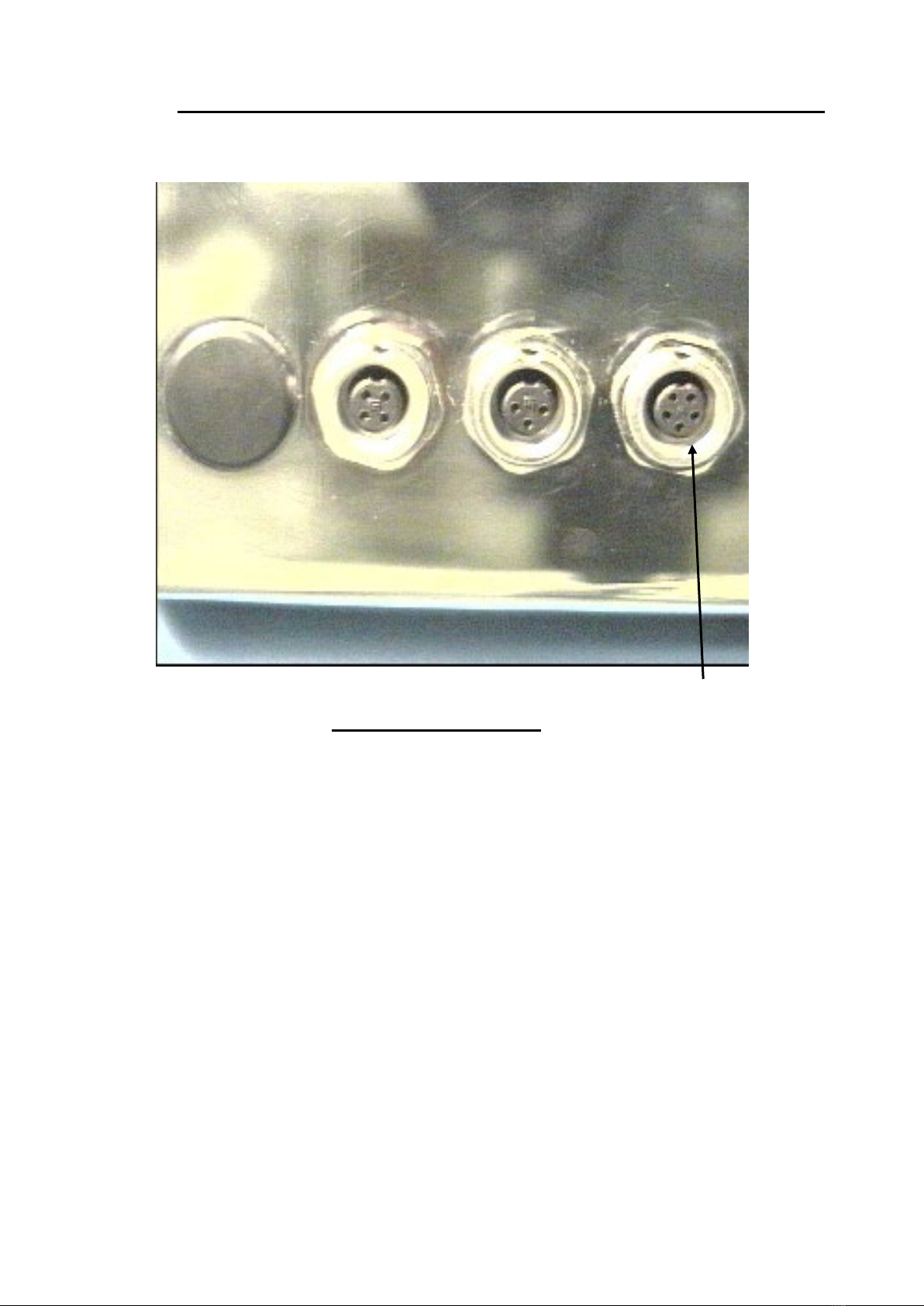

The can stand is now ready for use and should be connected to the

SI9000+ via the probe socket (refer to Fig.3). This connector is

polarised so it must be aligned before insertion. Always screw in

the locking ring and tighten finger-tight to ensure it is sealed against

electrolyte.

ENAMEL RATER MANUAL: V.10 11

FIGURE 3: SIDE PANEL

CAN PROBE

CONNECTOR

12 ENAMEL RATER MANUAL: V.10

2.4 CONNECTING A NON-SENCON PROBE

If you want to connect another probe to your SI9000+ for

specialised tests such as end, or side-seam enamel rating this is

always possible using the 5 pin plug supplied, but the following

points should be noted:-

i. The cable diameter must be in the range 3mm to 5mm to

ensure correct sealing.

ii. Other probes are unlikely to support body contact and

level checking and so these functions will be disabled.

iii. If (ii) above applies, then the automatic restart facility after

each can will be disabled.

Soldering of the cable should be carried out by an electrician as

follows:-

Pin Function

1 Main probe (electrolyte connection).

2 Level probe (if not used, connect to 1).

3 Body contact check (if not used connect to

4).

4 End or can body contacts.

5 Not connected.

The probe can now be connected to the SI9000+ via the probe

socket (refer to Fig.3). Ensure the connector is aligned before

insertion and screw in the locking ring finger-tight to ensure a good

seal.

ENAMEL RATER MANUAL: V.10 13

2.5 SWITCHING ON AND THE SELF TEST

Having satisfied yourself that the mains voltage setting is correct,

connect the mains plug to a suitable socket outlet or if you prefer

wire the mains cable directly into a fused outlet. Switch on the

SI9000+ by depressing the mains on/off switch on the back panel.

On power up, the system will perform a self-test. The numeric

displays will cycle through each digit from 0 through to 9 allowing

the operator to see that all the segments illuminate correctly. The

LED indicators will be illuminated in sequence.

Finally the SI9000+ will go to standby mode with the can number

and timer set to zero and the milliamp display set to dashes.

Enamel rating can then begin by pressing.

i. The start key. Enamel rating will start when the level and

contact check requirements are satisfied (indicators off)

and continue for 4 seconds.

ii. The Free Run key. The SI9000+ will enamel rate for up

to 99 seconds in free run.

iii. The Reverse Polarity key. As ii) but with reversed

polarity (can body negative)

14 ENAMEL RATER MANUAL: V.10

3. OPERATION

3.1 GENERAL DESCRIPTION

The SI9000+ will operate in two basic modes, "free run" and

"batch".

The free run mode includes reverse polarity operation, and is a

totally manual operation not using any of the automatic features or

interlocks of the SI9000+. Although it can be used as an operating

mode on its own it is also available from within batch mode.

The normal operating mode is batch mode and this should be used

for rating cans even if a batch is not being tested.

All instructions assume the SI9000+ is initially in standby mode, i.e.

the milliamp display shows dashes and set to the factory

configuration given in Appendix A Fig 1.

3.2 CONFIGURATION CHECK

The Rating voltage and rating duration can be inspected whilst the

SI9000+ is in standby mode (i.e. the milliamp display shows

dashes) and before or after rating. To examine the rating voltage

and rating duration:

i. Press the set key. The rating voltage is displayed on the

milliamp display. The ↑and ↓key are ignored.

ii. Press the set key again. The rating duration is displayed

on the timer display. The ↑and ↓keys are ignored.

iii. Press the End key. The SI9000+ drops back to the

condition it was in before the configuration check was

made.

ENAMEL RATER MANUAL: V.10 15

3.3 FREE RUN AND REVERSE POLARITY

i. Place a can in the can stand, fill with electrolyte and lower

the probe.

ii. Press FREE RUN.

The rating indicator will light, the timer display will

increment and the current will be displayed in milliamps.

The check circuits will be active but will not prevent

operation. If either of the red warning indicators is lit then

more electrolyte should be added or the can should be

rotated against the body contacts as necessary.

iii. To freeze the reading at any point press FREE RUN.

Rating will stop and the timer will be halted. Rating can

be resumed by pressing FREE RUN once more.

iv. To reverse the polarity press REVERSE POLARITY.

Note that the contact and level check circuits are disabled

when reverse polarity is selected.

v. To return to normal polarity, press FREE RUN.

vi. To return to standby mode, press END.

Reverse polarity operation is similar, but press REVERSE

POLARITY instead of FREE RUN.

If the timer should reach 100 seconds, the mode will be cleared

automatically and the SI9000+ will revert to standby mode.

Free run and reverse polarity are available from within batch mode

and operate as described above except that pressing END or the

timer reaching 100 seconds will return the SI9000+ to the stage

from where free run or reverse polarity had been selected.

16 ENAMEL RATER MANUAL: V.10

3.4 BATCH MODE

3.4.1 RATING CANS

i. Place a can in the can stand, fill with electrolyte and lower

the probe.

If the body contact and level checks are clear, the can number will

change to 1 and rating will commence. If either of the red warning

indicators are lit then more electrolyte must be added or the can

should be rotated against the body contacts as necessary.

After the preset time has elapsed (usually four seconds), rating will

stop and the reading will be frozen. The operator has the following

options:-

i. Save the reading in the internal memory by pressing

SAVE.

ii. Abandon the reading by pressing CLEAR.

iii. Enter free run mode by pressing FREE RUN.

iv. Enter reverse polarity mode by pressing REVERSE

POLARITY.

v. View the set rating time and rating voltage by pressing

SET.

If options iii or iv are chosen, operation will be as described in

section 3.3. Remember that if END is pressed, or timeout occurs,

the original timed reading will be redisplayed and the operator must

press SAVE or CLEAR to continue.

Having pressed SAVE or CLEAR the SI9000+ will be waiting for a

new can and it will use its check circuits to detect the can being

changed. Free run and reverse polarity are available at this point.

To test the next can proceed as follows:-

i. Remove the can just tested.

ii. Insert a new can, fill with electrolyte, and lower the probe.

If the SI9005 can stand is being used, the SI9000+ will detect the

new can and as soon as both checks are clear will start rating the

new can. If another probe that does not support body contact and

level checks is being used, then press START to tell the SI9000+ it

has a new can.

By repeating the above operations up to 99 cans can be tested and

their results stored. When 99 readings have been stored a "batch

end" is automatically invoked.

ENAMEL RATER MANUAL: V.10 17

3.5 MASTER RESET

In the event of a major change, error or fault it may become

necessary to completely reset the instrument. This is always

required when the operating mode is changed.

A reset will erase all stored settings and reading from the units

memory.

To perform a master reset proceed as follows;

A) Switch off power to the unit.

B) Simultaneously hold down the SET, ↑and ↓

keys.

C) Switch on the power.

D) After 2 seconds release the keys and the

system will be reset.

When a master reset is performed the operator has the opportunity

to change the default times and voltage settings (factory set to 4

seconds and 6.3V) using the SET, ↑and ↓keys. The new default

values are stored in battery backed memory and are retained until

another master reset is performed. The rating voltage and duration

can be checked during operation as described in Section 3.2.

18 ENAMEL RATER MANUAL: V.10

3.6 ERROR MESSAGES

"OL" The SI9000+ has tripped out on current

overload. Remove the cause of the overload

and press CLEAR.

"ERR" The Err message is displayed if the Batch/Stats

key is depressed before any readings have been

taken. Under these conditions it is not possible

to calculate statistical information and there is

no information available to send to a printer.

"FAIL" This message may flash on power up and

indicates that battery back-up of memory has

failed. A master reset should be performed (see

section 3.5). The clear key can be pressed to

continue operation, but the chance that

previously saved readings are corrupted is very

high.

"BUSY" The SI9000+ is waiting for the printer (see

Section 6.7).

"BUFFER Scrolling, computer buffer is 90% full

NEARLY FULL" (see Section 7.7).

"FULL" Flashing, computer buffer is full (see Section

7.7).

"PSU" The power supply generating the rating voltage

has failed. The SI9000+ may reset when

CLEAR or END is pressed, alternatively switch

off the SI9000+ for a few seconds.

"CLR?" If BATCH/STATS is pressed when no printer is

connected and the statistical output is disabled

(see section 4.2) the CLR? message is

displayed. Press CLEAR to clear the memory or

END to return to the condition before

BATCH/STATS was pressed.

"PR ?" BATCH/STATS has been pressed when the

statistical output is off (see section 4.2). The

raw data may be printed by pressing SAVE.

ENAMEL RATER MANUAL: V.10 19

4. CONFIGURING YOUR SI9000+

In order to change the configuration of the SI9000+ it is necessary

to remove the base panel. Instructions for doing this are given in

section 4.1 (i) and (ii). Before changing the configuration of the

SI9000+ it is recommended that users familiarise themselves with

the internal layout shown in Appendix A Figure 1. A list of the

switches and jumpers of interest follows:

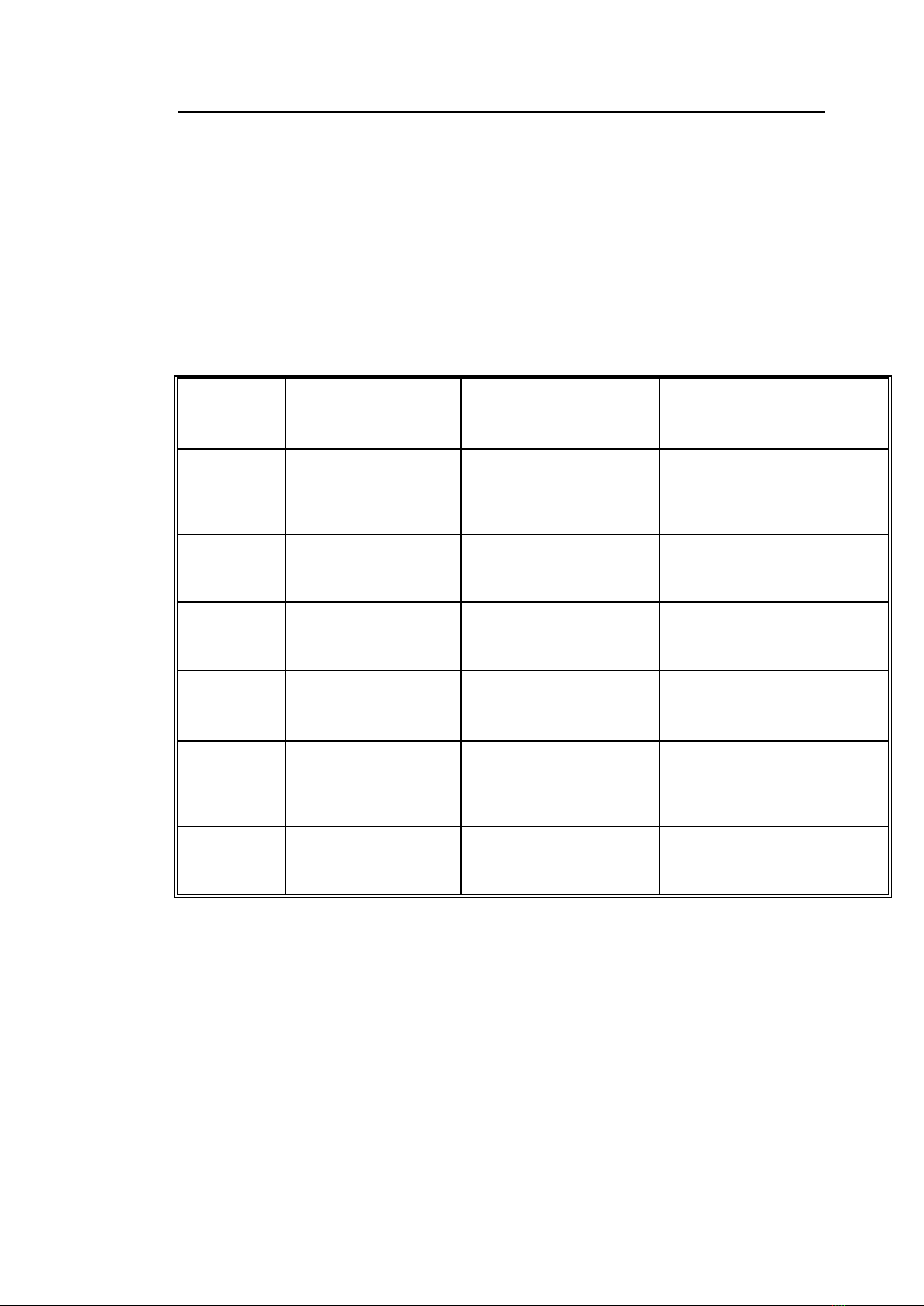

SWITCH/

JUMPER

NAME

LOCATION

TYPE

OPERATION

SW1

Micro board (Top

Board) To right of

SW2

Block of 8 miniature

rocker switches

numbered 1 to 8 on the

device

A switch is off when its rocker

is pressed down adjacent to

the "open" legend.

SW2

Micro board (Top

Board) To left of SW1

Block of miniature rocker

switches numbered 1 to 8

on the device

A switch is off when its rocker

is pressed down adjacent to

the "open" legend.

SW11

Applications board

(Lower Board) Below

Fuses

Block of miniature rocker

switches numbered 1 to 8

on the device

A switch is off when its rocker

is pressed down adjacent to

the "open" legend.

Mains

Selector

Switch

Applications board

(Lower Board) To the

right of the fuses

Slide Switch

Slide to correct position for

supply voltage.

J1

Micro board (Upper

Board) R.H.S.

3 position jumper

Connect the pair of pins

adjacent to the required

legend A,B or C using the

jumper.

J2

Micro board (Upper

Board)

2 position jumper

Connect the upper pair of pins

for A or the lower pair for B,

using the jumper.

20 ENAMEL RATER MANUAL: V.10

SWITCH/

JUMPER

NAME

LOCATION

TYPE

OPERATION

J3

Micro board (Upper

Board)

2 position jumper

Connect the left hand pair

of pins for A or the right

hand pair for B, using the

jumper.

VR1

VR5

Applications board (Lower

board) below the

transformer

Multiturn Pot

Adjust in accordance with

Section 5.4.1.

VR6

VR7

Applications board (Lower

board) to the right of the

transformer

Multiturn Pot

Adjust in accordance with

Section 5.4.2.

The factory settings for the jumpers and switches are shown in Appendix A Fig 1.

4.1 SETTING THE MAINS VOLTAGE

The mains voltage of the SI9000+ is factory set as appropriate for

the particular country to which it is supplied and the setting will be

clearly marked on the back panel. Should you need to change the

voltage proceed as follows:-

i. Remove the six button head screws in the base of the

case using the 2.5mm hex wrench supplied.

ii. Remove the base panel taking care not to damage the

earthing cable.

iii. Referring to Appendix A Fig 1move the mains voltage

switch to the required position.

iv. Check that the foam seal on the bottom of the case is

intact and replace the base panel and six screws.

v. Change or remove the voltage label.

Table of contents