For the very latest specifications visit www.aeroflex.com

also need to enable each channel.

When you press the [return] key, the display will show you which

channels are enabled. Check this is correct before you continue.

Pressing the [data rate] key toggles between 9600 and 4800

baud data. If you aren’t sure what speed data is used on your sys-

tem, try 9600, and if this doesn’t work, try 4800.

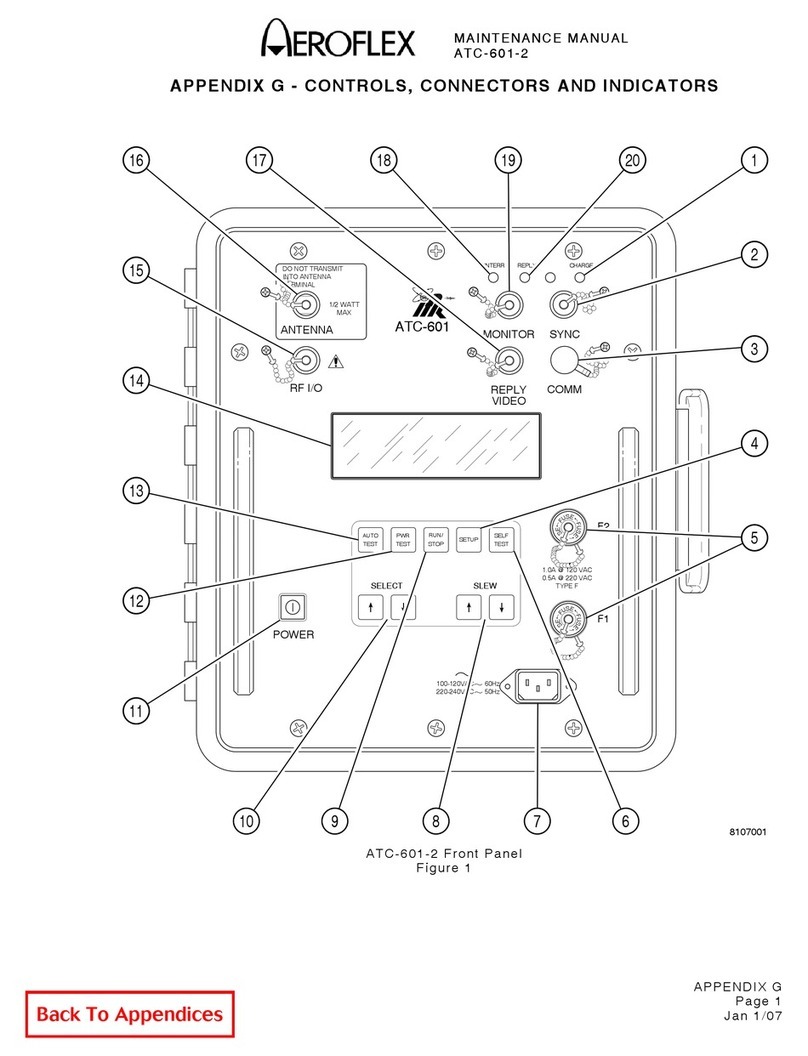

The [RF port select] key allows you to change which of the ports

on the front panel of the test set will be used for RF input and out-

put. For simplicity, we’ll start with off-air tests, so this should be

set to [BNC out ANT in]. If the RF signal is very strong, such as the

area immediately around a repeater, then you should select [BNC

out N in] which greatly reduces the test set sensitivity. You should

also connect an antenna to both the input and output ports since

using two antennas avoid problems where the test set signal gen-

erator swamps reception of channels that have small duplex off-

sets.

Finally, you can set what data deviations are to be used by the test

set. Altering these values is not really necessary at this stage - the

values of 3 kHz for high speed deviation and 750 Hz for low speed

deviation will work for all EDACS systems.

When you press the [return] key the system is set up, and your fre-

quency plan is loaded into the instrument.

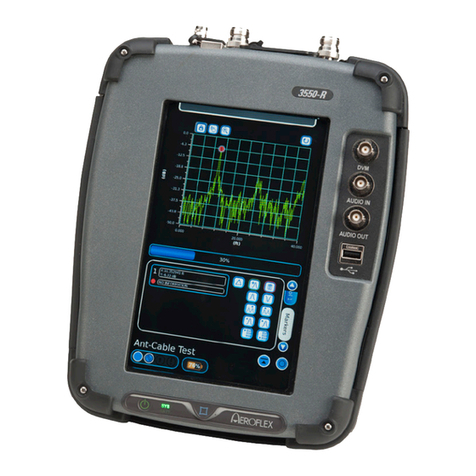

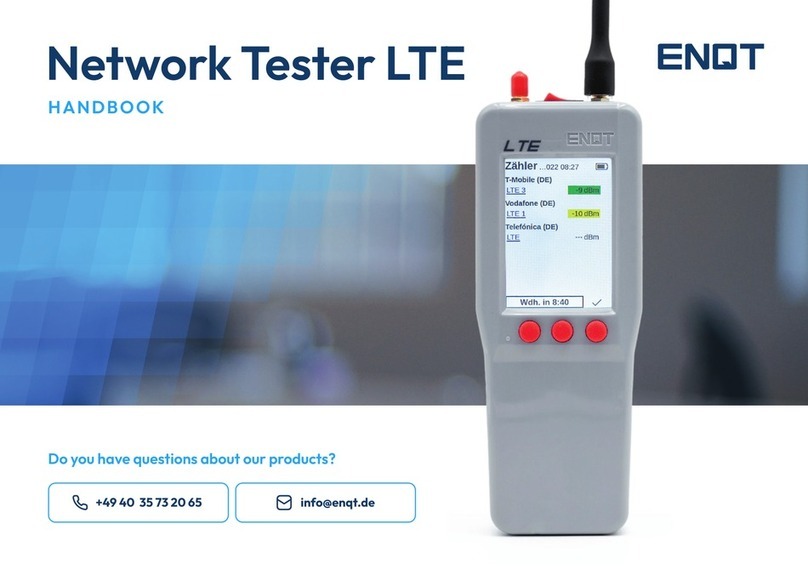

The manual test screen with a valid control channel.

Press [MANUAL] to access the manual testing screen. Now you

have to establish which channel is the control channel. The eas-

iest way is to step through the enabled channels in the frequency

plan using the [control channel] key. When the correct control

channel is found, the SERVICE indicator will change from NO SER-

VICE to a percentage figure, in inverse text.

If this doesn’t work, first check that the system is available, using

a radio programmed for that system. If it indicates service, and

will make a call, then either the data rate is incorrect, the signal is

too weak to be picked up by the test set, or the frequency plan is

incorrect.

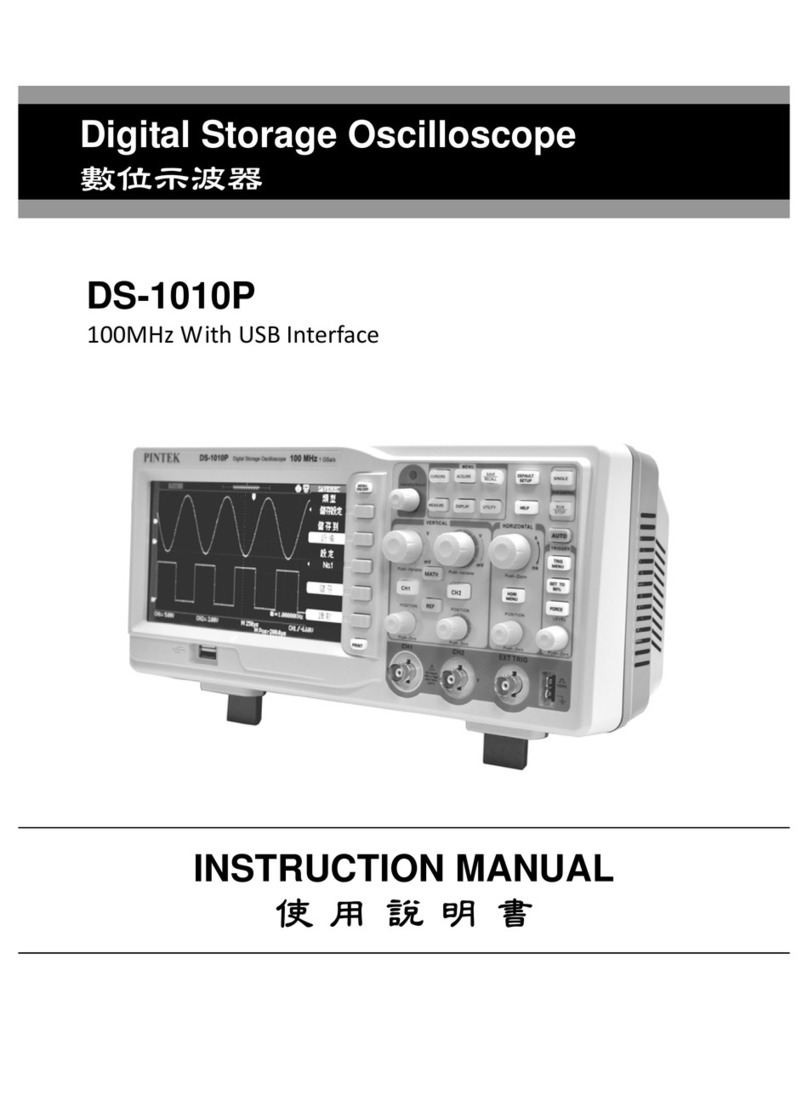

To check the data rate, you should turn the sound volume up on

the front panel, and then step through the channels using the

[control channel] key. When you hear a continuous drone, select

[Tx TEST], and press [Scope /Bar] until the large ‘scope display

appears. Press the [Persistence] key until High is highlighted

when you should see an ‘eye’ diagram of the modulation from the

repeater. This then allows you to calculate the system data rate.

An ‘eye’ diagram produced off-air from an EDACS control

channel.

Press [SYSTEM], and noting the channel, change the data rate

using the [SET-UP], [edit current] and [data rate] keys. Then press

[return] and [MANUAL], and select the channel again (altering the

current system will force the test set to re-initialise the system).

If the test set still doesn’t indicate service, or no channel gives a

droning noise, then you should check the entered frequency plan

again and ensure that there is reasonable signal strength present

- the 2945B service monitor will detect a signal reliably at levels

of around -40 dBm to -50 dBm using the ANT port. EDACS radios

are far more sensitive, however, and if you are working without a

direct connection you should get closer to the repeater and try

again.

Once the service indicator shows that the control channel is 'visi-

ble' to the test set, the next step is to get the test set to commu-

nicate with the repeater. To do this, you need to use the data per-

formance test, in the manual test screen, by pressing [mode],

[data perform].

The MANUAL TEST screen showing a data performance test in

progress.

In data performance mode the test set sends messages to the

repeater on the control channel, and gets acknowledgement

responses back. This allows you to check that you have set the

duplex offset correctly for the channel that is currently the control

channel.

Set the RF generator level to maximum (+5 dBm using the BNC

output port), and when the SUCCEEDED count reads above 0%,

contact is established.

Finally, you should check that the other channels are correct. This

involves making a call on the system, which will then assign the

test set to a working channel