SENDOT FluoMini Pro User manual

User manual

System information

FluoMini Pro type: 300

Firmware: version 200501

Software: version 2.21

Baudrate: 19200

www.sendot.nl

FluoMini Pro Optical O

2

|T Sensor

2

Contents

1. General.......................................................................................................................... 4

1.1. Product....................................................................................................................... 4

1.1.1. Scope of delivery .................................................................................................... 4

1.1.2. Technical specifications .......................................................................................... 4

1.2. Important user instructions ......................................................................................... 6

1.3. Warranty..................................................................................................................... 6

1.4. Transport, storage and disposal ................................................................................. 6

2. Installation...................................................................................................................... 7

2.1. Unpacking and setup.................................................................................................. 7

2.2. Type probe ................................................................................................................. 7

2.3. Connections ............................................................................................................... 7

2.3.1. Handheld sensor..................................................................................................... 7

2.3.2. Digital sensor .......................................................................................................... 7

2.3.3. Analog sensor......................................................................................................... 8

2.4. Display and buttons.................................................................................................... 8

3. Measuring with the FluoMini Pro Optical O2|T Sensor.................................................. 10

3.1. Measurement principle ............................................................................................. 10

3.2. Ending the standby mode......................................................................................... 10

3.2.1. Handheld sensor................................................................................................... 10

3.2.2. Digital sensor ........................................................................................................ 11

3.2.3. Analog sensor....................................................................................................... 11

3.3. Measurements.......................................................................................................... 11

3.3.1. Single measurement ............................................................................................. 11

3.3.2. Continuous measurements ................................................................................... 11

3.4. Logger and transmitter function ................................................................................ 12

4. Settings........................................................................................................................ 13

4.1. Main menu ............................................................................................................... 13

4.2. General settings ....................................................................................................... 13

4.2.1. Date/Time ............................................................................................................. 13

4.2.2. Power management.............................................................................................. 14

4.2.3. Save data ............................................................................................................. 14

4.2.4. Decimal separator................................................................................................. 14

4.3. Logger settings (handheld/digital)............................................................................. 15

4.3.1. Logger On/Off ....................................................................................................... 15

4.3.2. Interval time .......................................................................................................... 16

4.3.3. Memory................................................................................................................. 16

3

4.4. Transmitter settings (analog) .................................................................................... 17

4.4.1. Transmitter On/Off ................................................................................................ 17

4.4.2. Interval time .......................................................................................................... 17

4.4.3. A-out Test ............................................................................................................. 18

4.4.4. Memory................................................................................................................. 18

4.5. Sensor settings......................................................................................................... 19

4.5.1. Calibrate ............................................................................................................... 19

4.5.2. Enter Cal. data...................................................................................................... 21

4.5.3. Measurement settings........................................................................................... 21

4.6. System info .............................................................................................................. 22

5. Troubleshooting ........................................................................................................... 23

4

1. General

1.1. Product

Product FluoMini Pro Optical O2|T Sensor

Version 1

Software 2.21

Firmware 200501

1.1.1. Scope of delivery

•FluoMini Pro Optical O2|T Sensor (handheld, analog or digital)

•Optical Fiber with O2|T Probe (1.0 m)

•USB cable (1.0 m)

•Analog cable (2.0 m; for analog sensor only)

•TTL cable (2.0 m, for digital sensor only)

•Substrate Pre-drill

•Probe support

1.1.2. Technical specifications

Specifications Values

Measuring range O2in gas 0 to 45 %Vol (@STP)

Measuring range dissolved O20 to 18 mg/L (@STP)

Measuring range O2saturation in water 0 to 200 % (@STP)

Temperature range + 5 to + 45 °C

Accuracy O2at > 0% O2< 1% O2± 0.1 %

Accuracy O2at > 1% O₂< 25% O₂± 0.2 %

Accuracy O2at > 25% O2± 1 % of measured value

Accuracy temperature ± 1 °C

Accuracy pressure ± 5 mBar

Accuracy dissolved O2at 0 to 1 mg/L ± 0.05 mg/L

Accuracy dissolved O2at 1 to 10 mg/L ± 0.1 mg/L

5

Accuracy dissolved O2at >10 mg/L ± 1 % of measured value

Accuracy O2saturation in water at 0 to 10 % ± 0.5 %

Accuracy O2saturation in water at > 10 % ± 1 % of measured value

Resolution O20.01 %

Resolution O2saturation in water 0.01 % (0-10 %) 0,1 % (10-100 %)

Resolution temperature 0.1 °C

Resolution pressure 1 mBar

Response time gas (T90) ≤ 5 sec

Response time water (T90) ≤ 60 sec (depending on flow rate)

Temperature compensation Yes

Drift / Stability O2at < 1 %O2≤ 0.1 % per month

(operating frequency 0.1Hz)

Drift / Stability O2at > 1 %O2< 25 %O2≤ 0.2 % per month

(operating frequency 0.1Hz)

Drift / Stability O2at > 25 %O2≤ 2 % per month

(operating frequency 0.1Hz)

Drift / Stability dissolved O2≤ 0.2 mg/L per month

Sample time > 2 sec (freq. > 1.25 Hz)

Calibration 1 or 2 point for O2

1 point for temperature

Coating lifetime 6 months year or 50000 measurements

(excluding effects of chemical

incompatibility)

Connectivity Handheld: USB serial interface

Digital: USB serial interface

digital output / TTL serial port

Analog: USB serial interface

4 – 20 mA output (4 wires)

12 – 24 V AC/DC

Dimensions (l x w x h in mm) 169 x 62 x 25

Weight (g) 235

Housing material Aluminium, with ABS covers

Electrical connections Handheld: 1 x M5 4 pole male

Digital: 2 x M5 4 pole male

Analog: 1 x M5 4 pole male

1 x M5 4 pole female

Probe material Stainless steel (6mm OD, l = 100) with optical

fiber

Protection level IP53

6

Power supply Handheld/digital: USB port (5V, < 200 mA)

Analog:12-24 V

Battery lifetime (handheld/digital) 48 h at 5 sec intervals

2 weeks at 60 sec intervals

1.2. Important user instructions

This sensor is suitable for measurements in water/fluids and air/gas. The sensor is not suitable

for measurements in strongly oxidizing, strongly acidic (pH < 1) and strongly caustic (pH > 12)

media. In general, it is advised to test the sensor for the required application. Some strong

(fluorescing) dyes might disturb the measurement; for those applications, the sensor should

be tested first. We are constantly improving our sensors. Please keep following our website

(www.sendot.nl) to check for new developments.

1.3. Warranty

This product has a warranty of two years on the mechanics and electronics (excl. battery).

The sensitive coating can be used for a period depending on the measurement frequency and

environment where the sensor must operate in, like temperature, pressure and average

oxygen partial pressure.

1.4. Transport, storage and disposal

This product is subject to the “GENERAL RESEARCH, ADVICE, SALES, DELIVERY AND

PAYMENT CONDITIONS OF SENDOT RESEARCH BV (deposited with no. 62488295 bij KvK

Haaglanden)”. It can be downloaded from www.sendot.nl.

CAUTION!

Always use the included substrate pre-drill & probe support for measurements in substrate to protect

the coating from any damage and guarantee an adequate measurement.

7

2. Installation

2.1. Unpacking and setup

The sensor will be delivered with the separate probe. It has been calibrated, ready to be used.

Before first use, the sensor might need to be charged using the included USB cable. The

display is protected with a plastic film that can be removed. The protection cap must be

removed from the fiber and the fiber needs to be screwed on the SMA port on the top of the

sensor.

For the installation of a digital or analog sensor, please read the corresponding manual.

2.2. Type probe

The FluoMini Pro Optical O2|T Sensor is provided with a stainless-steel probe with an outer

diameter of 6 mm.

2.3. Connections

2.3.1. Handheld sensor

The sensor can be connected to a Windows or Android system by means of a USB cable.

Charging is possible via the USB port. A battery is included, so the sensor does not necessarily

need to be attached to a power source for use.

2.3.2. Digital sensor

The sensor can be connected to a Windows or Android system by means of a USB cable.

Charging is possible via the USB port. A battery is included, so the sensor does not necessarily

need to be attached to a power source for use. Additionally, a digital input/output can be used

to attach the sensor to an external control device, e.g. a wireless transmitter.

Stainless steel probe

8

2.3.3. Analog sensor

The sensor can be connected to a Windows or Android system by means of a USB cable. A

battery is not included, so the sensor must be attached to a power source via the USB port for

use. Additionally, an analog output can be used to attach the sensor to an external control

device (e.g. a climate computer). The sensor will also be powered through this port.

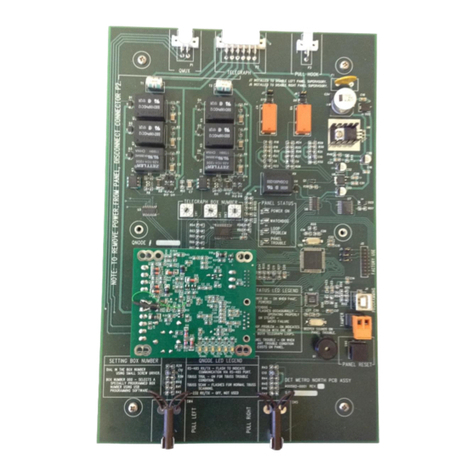

2.4. Display and buttons

In the picture below the basic sensor screen is shown, as well as the buttons with their names

as being used in this manual.

1 Battery

2 Measurement indicator

3 Measurement unit for O2

4 Measured temperature

5 Measured O2

6 Pressure

2

8

10

7

9

4

6

1

3

5

11

9

7

Menu/Exit button

With this button the main menu can be entered, and every menu can be quit.

The feature of this button is always visible on the display (bottom left).

8

Measure/Enter button

This button is used to end the standby mode.

This and additional features of this button are always visible on the display (bottom right).

This button has several

features, but for simplicity, it is named Measure/Enter button

throughout this manual.

9 Down button

10 Up button

11

Reset button

This button is located on the back of the sensor and resets the sensor to factory settings.

It is protected by a white plastic screw which needs to be unscrewed to reach the reset

button with a thin device.

10

3. Measuring with the FluoMini Pro Optical O2|T Sensor

3.1. Measurement principle

The FluoMini Optical O2|T Sensor has two active components embedded in a polymer host.

One component measures the temperature of the coating necessary for the compensation of

the oxygen measurement. The other component measures the oxygen partial pressure.

The total pressure of a gas is the sum of the so-called partial pressures of the components in

the gas. A standard atmosphere is composed of oxygen, nitrogen, CO2, water and trace

gasses. (formula 1)

Ptotal = pO2 + pN2 + pCO2 + pH2O + …

The O2|T sensitive coating can be considered as a small gas compartment, in gas as well as

in water. Basically, it makes no difference for the coating to measure in gas or in water.

Though, in water the partial pressure of water is well defined because the humidity is always

100 %. The response time of the sensor depends on the speed with which the gas

compartment in the coating will come into equilibrium with its surroundings. The gas diffusion

being 10000 times faster in gas than in water causes a different response time for the two

applications.

Measuring in air is relatively simple. A percentage O2is directly given. The measurement is

pressure dependent, so the pressure is measured and can be optionally corrected for.

Customers can also choose to correct for it later, if necessary. A second unknown factor, if

one measures in air, is the humidity. The higher the temperature the more water can be

contained by the air and the larger the influence.

If the sensor is used to measure in water, saturation% as well as mg/L measurement units are

available.

3.2. Ending the standby mode

3.2.1. Handheld sensor

To save energy the sensor display automatically turns off after 30 seconds. During battery

operation, the sensor will automatically go into standby mode after 1 min. The sensor will wake

up again when the Measure/Enter button is pressed. When the sensor is attached to a

computer or external power source, it will not turn into standby mode, only the display will turn

off. If the sensor is in logging mode, the sensor turns off after each measurement.

11

3.2.2. Digital sensor

When the sensor is connected to an external control device (e.g. a computer) through the USB

port, it will wake up when the Measure/Enter button is pressed. From that moment on, it will

respond like a regular handheld sensor. When the sensor is connected through the serial

digital port it will operate in a special mode. For more information about running the sensor

through the digital port please contact Sendot Research via phone (+31 (0)30-636-8477) or

e-mail ([email protected]).

3.2.3. Analog sensor

This sensor has no battery, why it always must be attached to a power source to operate. The

sensor display automatically turns off after 30 seconds. When the sensor is connected to an

external control device (e.g. a computer) through the USB port, it will operate as a regular

handheld sensor. When it is connected via the analog port it will also never turn into standby

mode. As soon as the sensor is coupled to an external control device it will start measuring

with the interval specified in the sensor and output the analog value through the port.

3.3. Measurements

Apply the probe to the medium to be measured. For measurements in substrates, always use

the probe support and substrate pre-drill to avoid damages on the coating. Therefore, first

apply the probe support at the desired position, make a hole using the substrate pre-drill and

carefully stick in the probe until the bottom of the hole. In liquid media, air bubbles caught up

on the coating can result in false measurements, why they must be avoided.

3.3.1. Single measurement

1. Press the Measure/Enter button to activate the sensor.

2. Press the Measure/Enter button again to start a single measurement.

3.3.2. Continuous measurements

In continuous measurement mode the sensor will perform a measurement every 2 seconds.

To activate this mode:

Tip: The sensor will store single measurements not automatically. This can be changed. For further

information see chapter 4.2.3.

12

1. Press the Measure/Enter button to activate the sensor.

2. Press the Measure/Enter button for 2 seconds to start continuous measurements.

3. Press the Measure/Enter button for 2 seconds to stop continuous measurements.

3.4. Logger and transmitter function

With this sensor it is possible to measure continuously. In case of a handheld and digital

sensor, the data is stored on the internal memory (for further information on this logger function

see chapter 4.3). In case of an analog sensor, the data is sent to an external device, e.g. a

computer (for further information on this logger function see chapter 4.3).

Tip: The sensor will store measurements not automatically. This can be changed. For further

information see chapter 4.2.3 and 4.3.

13

4. Settings

4.1. Main menu

The main menu can be entered by pressing the Menu/Exit button. The screen with the different

setting options will be opened.

The main menu consists of four submenus: <General settings>, <Logger settings>, <Sensor

settings>, and <System info>. To navigate towards any menu, use the Up and Down buttons

and enter a submenu with the Measure/Enter button.

4.2. General settings

The menu <General settings> contains submenus to set date and time, control power

management, save data and change the decimal separator. Use the Up and Down buttons to

navigate to the desired submenu. To enter a submenu, press the Measure/Enter button.

4.2.1. Date/Time

In this menu, date and time can be set manually. Alternatively, date and time can be

synchronized with the current date and time on the computer using the FluoMini Sensor

Software Suite (for further information see manual for FluoMini Sensor Software Suite).

Default, date and time are set to 0:00:00, 01/01/1999 and must be set after a restart due to an

empty battery or a hard reset (pressing Menu/Exit button and Measure/Enter button parallel

for 30 sec).

1. Open the menu <General settings>.

2. Open the menu <Date/Time>.

3. Use the Up and Down buttons to set date and time.

4. Use the Measure/Enter button (Next) to navigate to the next

position in date and time.

5. Confirm settings and close menu with the Measure/Enter button.

14

4.2.2. Power management

In this menu, the standby mode can be turned on and off. Default, this function is turned on,

so the sensor will turn into standby mode after 30 sec.

1. Open the menu <General settings>.

2. Open the menu <Power management>.

3. Use the Up and Down buttons to choose the desired setting.

4. Confirm setting and close menu with the Measure/Enter button

(Set).

4.2.3. Save data

In this menu, automatic storage of every measurement can be turned on and off. Default, this

function is turned off.

1. Open the menu <General settings>.

2. Open the menu <Save all data>.

3. Use the Up and Down buttons to choose the desired setting.

4. Close menu with the Measure/Enter button (Set).

4.2.4. Decimal separator

In this menu, the decimal separator for values shown on the screen can be changed.

1. Open the menu <General settings>.

2. Open the menu <Decimal separator>.

3. Use the Up and Down buttons to choose the desired setting.

4. Confirm setting and close menu with the Measure/Enter button

(Set).

15

4.3. Logger settings (handheld/digital)

With the logger function continuous measurements are performed and

stored internally. Within the menu <Logger settings> the logger function

can be turned on and off, the interval time of the measurements can be

set, or the stored data erased. Use the Up and Down buttons to navigate

to the desired submenu. To enter a submenu, press the Measure/Enter

button.

Remark: If the sensor is in logging mode, it is not possible to

communicate with the sensor through an external device, e.g. a

computer. Logging must be stopped first to communicate with the

sensor. Nevertheless, by pressing the Measure/Enter button the last

measured value will be visible on the display.

4.3.1. Logger On/Off

In this menu, the logger function can be turn on and off.

1. Open the menu <Logger settings>.

2. Open the menu <Logger On/Off>.

3. Use the Up and Down buttons to choose the desired setting.

4. Confirm the setting with the Measure/Enter button

(Set).

5. Exit menu with the Menu/Exit button. Logging will start automatically.

If date and time have not been set in advance, the sensor will show an error (Date & Time not

set.). In this case, the logger function can still be started, if wanted. To start the logger function,

press the Measure/Enter button (Ignore) or wait for 5 sec. The start date and time will be set

to 00:00, 01/01/1999. Another option is to cancel the logger function by pressing the Menu/Exit

button (Cancel). Now, date and time can be set before the logging function is started again

(see chapter 4.2.1).

16

4.3.2. Interval time

In this menu, the time interval between the measurements during logging can be changed.

For the most applications, an interval time of 5 min or higher is sufficient. The interval time

should be set before the first use of the sensor.

1. Open the menu <Logger settings>.

2. Open the menu <Interval time>.

3. Use the Up and Down buttons to change value.

4. Use the Measure/Enter button (Next) to navigate to the next

position in time (hh:mm:ss).

5. Confirm the setting and close menu with the Measure/Enter

button.

4.3.3. Memory

In this menu, the storage volume in total as well as used by stored data can be read. The

stored data can be deleted.

1. Open the menu <Logger settings>.

2. Open the menu <Memory>.

3. Use the Up and Down buttons to choose the desired setting.

4. Confirm the setting and close menu with the Measure/Enter

button (Set).

It is advisable to use the FluoMini Sensor Software Suite to store the data on a computer

before the data is deleted from the sensor’s memory.

17

4.4. Transmitter settings (analog)

With the transmitter function continuous measurements are performed and send to an external

device, e.g. computer. Within the menu <Transmitter settings> the transmitter function can be

turned on and off, the interval time of the measurements can be set, stored data erased and

the analog output being tested. Use the Up and Down buttons to navigate to the desired

submenu. To enter a submenu, press the Measure/Enter button.

4.4.1. Transmitter On/Off

In this menu, the transmitter function can be turn on and off.

1. Open the menu <Transmitter settings>.

2. Open the menu <Transmitter On/Off>.

3. Use the Up and Down buttons to choose the desired setting.

4. Confirm the setting with the Measure/Enter button

(Set).

5. Exit menu with the Menu/Exit button. Transmitting will start automatically.

4.4.2. Interval time

In this menu, the time interval between the measurements transmitted can be changed. For

the most applications, an interval time of 5 min or higher is sufficient. The interval time should

be set before the first use of the sensor.

1. Open the menu <Transmitter settings>.

2. Open the menu <Interval settings>.

3. Open the menu <Interval time>.

4. Use the Up and Down buttons to change value.

18

5. Use the Measure/Enter button (Next) to navigate to the next position in time

(hh:mm:ss).

6. Confirm the setting and close menu with the Measure/Enter button.

4.4.3. A-out Test

This function only applicable for analog sensors and is to test the analog output signal send

to an external device, e.g. computer.

1. Open the menu <Transmitter settings>.

2. Open the menu <A-out Test>.

3. Use the Up and Down buttons to set a value.

4. Confirm the value with the Measure/Enter button (Set). A

signal will be sent to the external device, which is translating it into % O2.

5. Compare this value with the O2and temperature on the external device. For O2,

4 – 20 mA can be translated to 0 - 30 % O2for air saturation, 0 - 200 % O2for

saturation or 0 - 20 mg/L for dissolved oxygen, depending on the settings. Therefore,

a change of 1 mA relates to a change of 0.53 %, 0.08 % or 0.8 mg/L, respectively. For

the temperature, 4 – 20 mA can be translated to -10 – 100 °C. Therefore, a change of

1 mA relates to a change of 6.875 °C.

4.4.4. Memory

In this menu, the storage volume in total as well as used by stored data can be read. The

stored data can be deleted as followed:

1. Open the menu <Transmitter settings>.

2. Open the menu <Memory>.

3. Use the Up and Down buttons to choose the desired setting.

4. Confirm setting and close menu with the Measure/Enter button

(Set).

Remark: It is advisable to use the FluoMini Sensor Software Suite to store the data on a

computer before the data is deleted from the sensor’s memory.

19

4.5. Sensor settings

Within this menu, the sensor can be calibrated automatically or manually. Additionally, the

measurement units can be changed.

4.5.1. Calibrate

The FluoMini Pro O2|T Sensor has been calibrated prior to delivery. Therefore, no calibration

is necessary. Whenever the probe is exchanged, the sensor must be recalibrated for this new

probe.

Remark: When you have more than one FluoMini Pro O2|T Sensor, you cannot exchange the

probes with each other without a new calibration. Ensure to always use the same probe for a

FluoMini Pro O2|T Sensor to guarantee reproducible measurements.

In this menu, the sensor can be calibrated automatically for a new probe. Calibration can be

performed either as a 1-point calibration (at 20.95 % O2) or a 2-point calibration (at 0 % and

20.95 % O2). To choose the desired calibration mode:

1. Open the menu <Sensor settings>.

2. Open the menu <Calibrate>.

3. Use the Up and Down buttons to navigate to the desired

calibration mode.

4. Confirm the mode with the Measure/Enter button (Select).

The temperature is always the first parameter to be calibrated. A temperature calibration is

advisable for accurate measurements but can be skipped by pressing the Menu/Exit button

(Skip), if wanted. If so, the sensor will automatically ask for the next parameter to be calibrated.

20

For a 1-point calibration (incl. temperature calibration):

1. Expose the probe to 20.95 % O2environment.

2. Use the Up and Down buttons to set the actual temperature.

3. Confirm the setting with the Measure/Enter button (Set).

4. Wait until the measured temperature on the display has stabilized and press the

Measure/Enter button (Apply).

5. Wait until the measured O2value on the display has stabilized and press the

Measure/Enter button (Set).

For 2-point calibration (incl. temperature calibration):

1. Expose the probe to 20.95 % O2environment.

2. Use the Up and Down buttons to set the actual temperature.

3. Confirm the setting with the Measure/Enter button (Set).

4. Wait until the measured temperature on the display has stabilized and press the

Measure/Enter button (Apply).

5. Expose the probe to 0 % O2.

6. Wait until the measured O2value on the display has stabilized and press the

Measure/Enter button (Set).

7. Expose the probe to 20.95 % O2.

Other manuals for FluoMini Pro

2

Table of contents

Other SENDOT Measuring Instrument manuals