Senlan Hope800 Series User manual

Manual for Hope800 Series High-performance Vector Control Inverter

I

Contents

Preface...................................................................................................................................1

1 Precautions.........................................................................................................................4

1.1 Safety precautions...................................................................................................................................4

1.2 Other precautions....................................................................................................................................5

2 Specifications......................................................................................................................7

2.1 Common specifications for Hope800 series .........................................................................................7

2.2 Product series specifications.................................................................................................................8

3 Installation and wiring ....................................................................................................12

3.1 Installation .........................................................................................................................................12

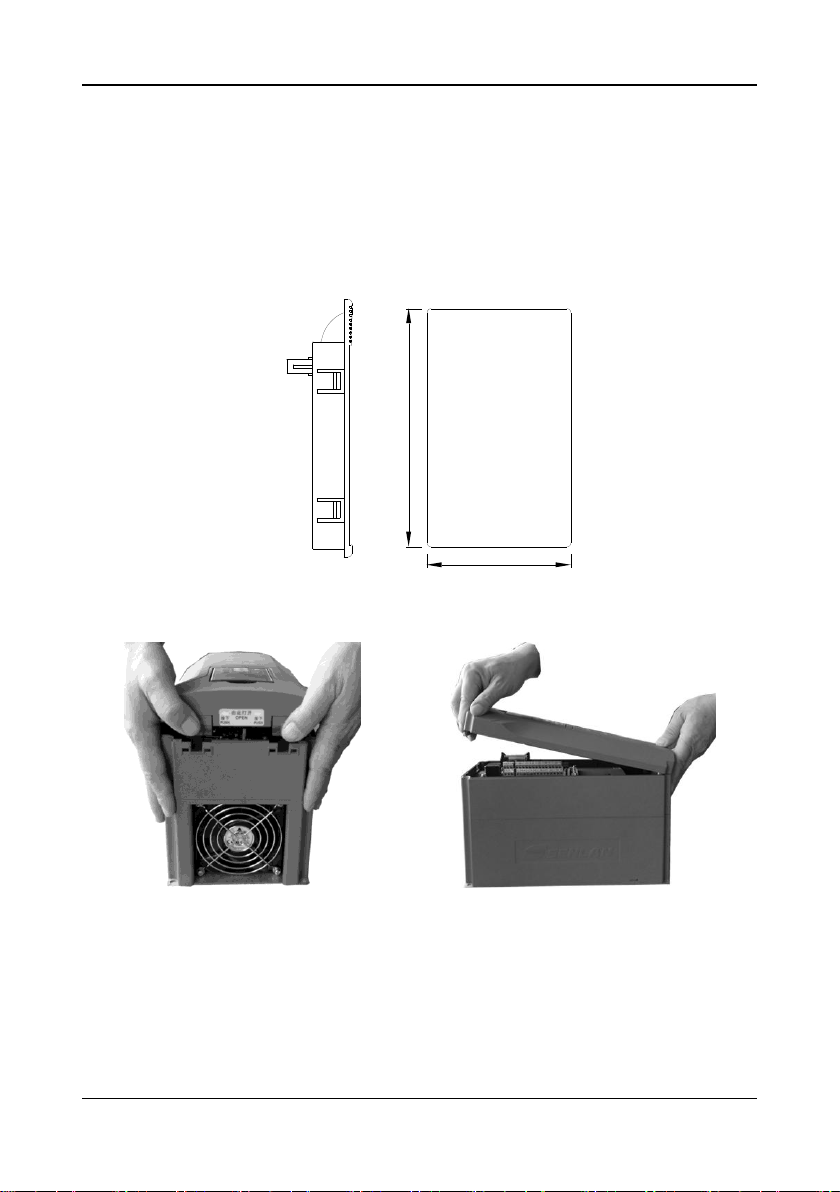

3.2 Removal and installation of parts.......................................................................................................13

3.2.1 Removal and installation of keypad...........................................................................................13

3.2.2 Installation of keypad on cabinet front cover .............................................................................13

3.2.3 Uninstallation/Installation of Cover and Control Panel..............................................................14

3.3 Wiring................................................................................................................................................15

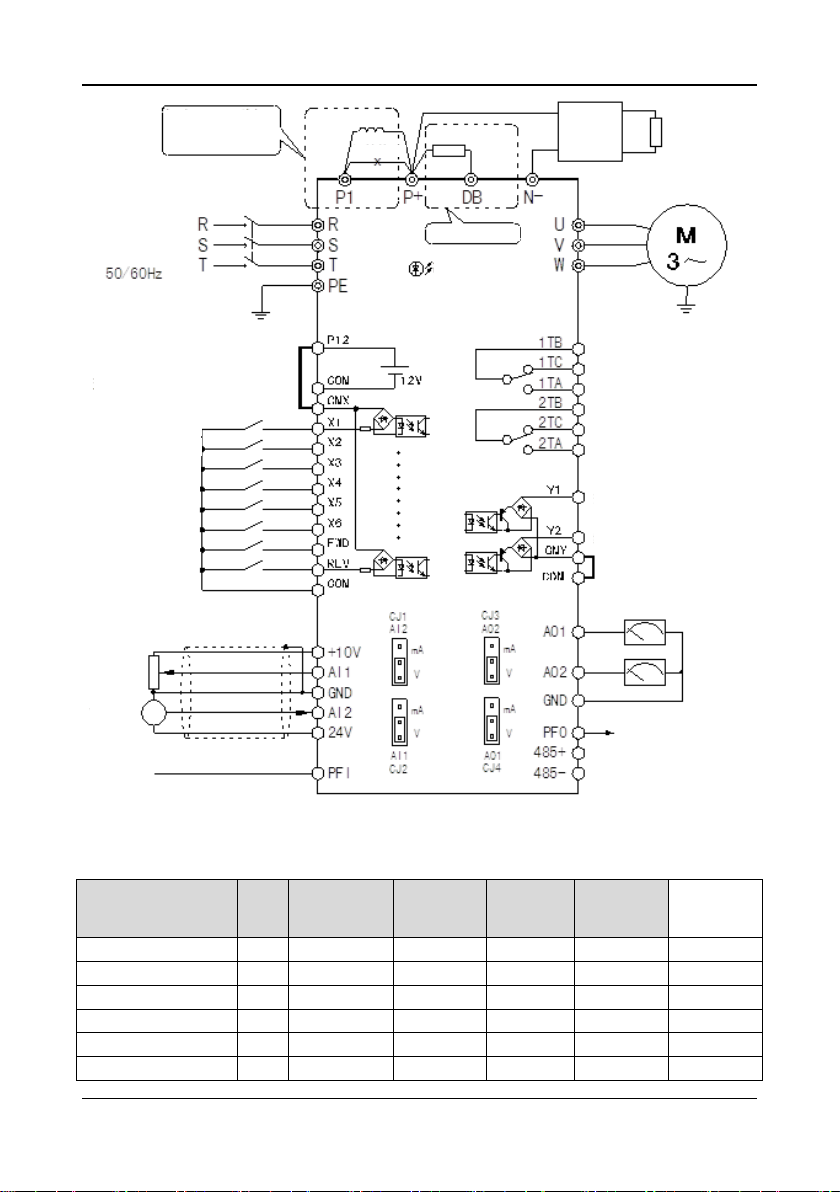

3.3.1 Wiring and configuration of main circuit terminals....................................................................15

3.3.2 Wiring method...........................................................................................................................20

3.3.3 Control board terminals, jumpers and wirings............................................................................20

3.4 Methods of suppressing electromagnetic interference........................................................................24

4 Operation and commissioning ........................................................................................26

4.1 Operation and display.........................................................................................................................26

4.1.1 Keypad functions .....................................................................................................................26

4.1.2 Display status and operation of keypad......................................................................................27

4.2 Power on for the first time..................................................................................................................29

4.3 Quick commissioning............................................................................................................................29

4.3.1 Setting of common parameters......................................................................................................29

4.3.2 Quick commissioning for V/F control...........................................................................................30

4.3.3 Quick commissioning for vector control.......................................................................................30

5 Parameter table................................................................................................................31

F0: Basic Parameters................................................................................................................................31

F1: Accel/decel, start, stop and jog parameters ........................................................................................32

Manual for Hope800 Series High-performance Vector Control Inverter

II

F2: V/F control parameters ......................................................................................................................33

F3: Speed, torque and flux control parameters.........................................................................................35

F4: Digital input terminals and multistep speed.......................................................................................36

F5: Digital and relay outputs....................................................................................................................38

F6: Analog and pulse frequency terminals...............................................................................................40

F7: Process PID parameters .....................................................................................................................42

F8: Simple PLC........................................................................................................................................44

F9: Wobble frequency, counter, meter-counter and zero-servo.................................................................45

FA: Motor parameters ..............................................................................................................................46

Fb: Protection functions and advanced settings........................................................................................47

FC: Keypad operation and display settings ..............................................................................................50

Fd: Expansion options and functions........................................................................................................51

FE: Programmable unit............................................................................................................................52

FF: Communication parameters...............................................................................................................56

Fn: Factory parameter..............................................................................................................................56

FP: Fault history.......................................................................................................................................57

FU: Data monitoring................................................................................................................................58

6 Parameter description.....................................................................................................60

6.1 F0: Basic Parameters.....................................................................................................................60

6.2 F1: Accel/decel, start, stop and jog parameters..............................................................................63

6.3 F2: V/F control parameters............................................................................................................68

6.4 F3: Speed, torque and flux control parameters ..............................................................................72

6.5 F4: Digital input terminals and multistep speed.............................................................................76

6.6 F5: Digital output and relay outputs ..............................................................................................83

6.7 F6: Analog and pulse frequency terminals.....................................................................................87

6.8 F7: Process PID parameters...........................................................................................................91

6.9 F8: Simple PLC.............................................................................................................................95

6.10 F9: Wobble frequency, counter, meter-counter and zero-servo....................................................100

6.11 FA: Motor parameters..................................................................................................................105

6.12 Fb: Protection functions and advanced settings...........................................................................109

6.13 FC: Keypad operation and display settings..................................................................................115

6.14 Fd: Expansion options and functions...........................................................................................117

6.15 FE: Programmable unit ...............................................................................................................121

Manual for Hope800 Series High-performance Vector Control Inverter

III

6.16 FF: Communication parameters ..................................................................................................127

6.17 FP: Fault history..........................................................................................................................133

6.18 FU: Data monitoring ...................................................................................................................134

7 Troubleshooting .............................................................................................................137

7.1 Faults and remedies..........................................................................................................................137

7.2 Alarms and remedies........................................................................................................................140

7.3 Operation faults and remedies..........................................................................................................143

8 Maintenance and after-sale services.............................................................................145

8.1 Daily maintenance............................................................................................................................145

8.2 Periodical maintenance.....................................................................................................................145

8.3 Replacement of parts........................................................................................................................146

8.4 Storage of the inverter......................................................................................................................146

8.5 After-sale services............................................................................................................................146

9 Options ...........................................................................................................................147

9.1 Braking unit .....................................................................................................................................147

9.2 Communication component..............................................................................................................147

9.3 AC reactor........................................................................................................................................148

9.4 EMI filter and ferrite chip common-mode filter...............................................................................148

9.5 Digital I/O expansion board .............................................................................................................148

9.6 Encoder interface board(SL-PG0)....................................................................................................149

9.7 Keypad options ................................................................................................................................151

9.8 keypad mounting box.......................................................................................................................152

9.9 Analog input expansion board..........................................................................................................152

PREFACE

1

Preface

Thank you for purchasing our SenLan Hope800 series high-performance vector control inverters.

Hope800 is a new-generation inverter developed independently by the SenLan Science & Technology

Holding Corp., Ltd., featuring low noise, high performance and multiple functions. It adopts the rotor

field-oriented vector control strategy to realize high-accuracy, wide-range speed and torque control of the

motor with high reliability, powerful functions. It can be widely applied in metallurgy, petroleum, chemical

engineering, spinning, electric power, building materials, coal, medicine, food, papermaking, plastic, printing

and dyeing, hoisting, cable, washing, water supply, heating and ventilation, sewage treatment and other

industries, such as drawbenches, mixers, extruders, winding machines, compressors, fans, pumps, grinding

machines, belt conveyors, hoists and centrifuges.

Hope800’s wide application attributes to its modular design and various options, which offer the

customers integrated solutions, lower the system cost and improve the system reliability remarkably.

Furthermore, users can carry out secondary development according to their own needs.

Please carefully read and understand this manual before installing, setting, running and maintaining the

product and keep it in safety. The technical specifications for the product may alter and the contents of this

manual are subject to change without notice.

Check after unpacking

Please check the following items after unpacking the inverter. If there is anything missing, contact us or

our distributors.

Check items

Check method

If the product is exactly what

you have ordered?

Check to see if the data on the nameplate of the inverter is consistent with

those in your order form

If there is any damage of the

product?

Observe the external appearance of the product. Check to see if it has got

any damage during transportation.

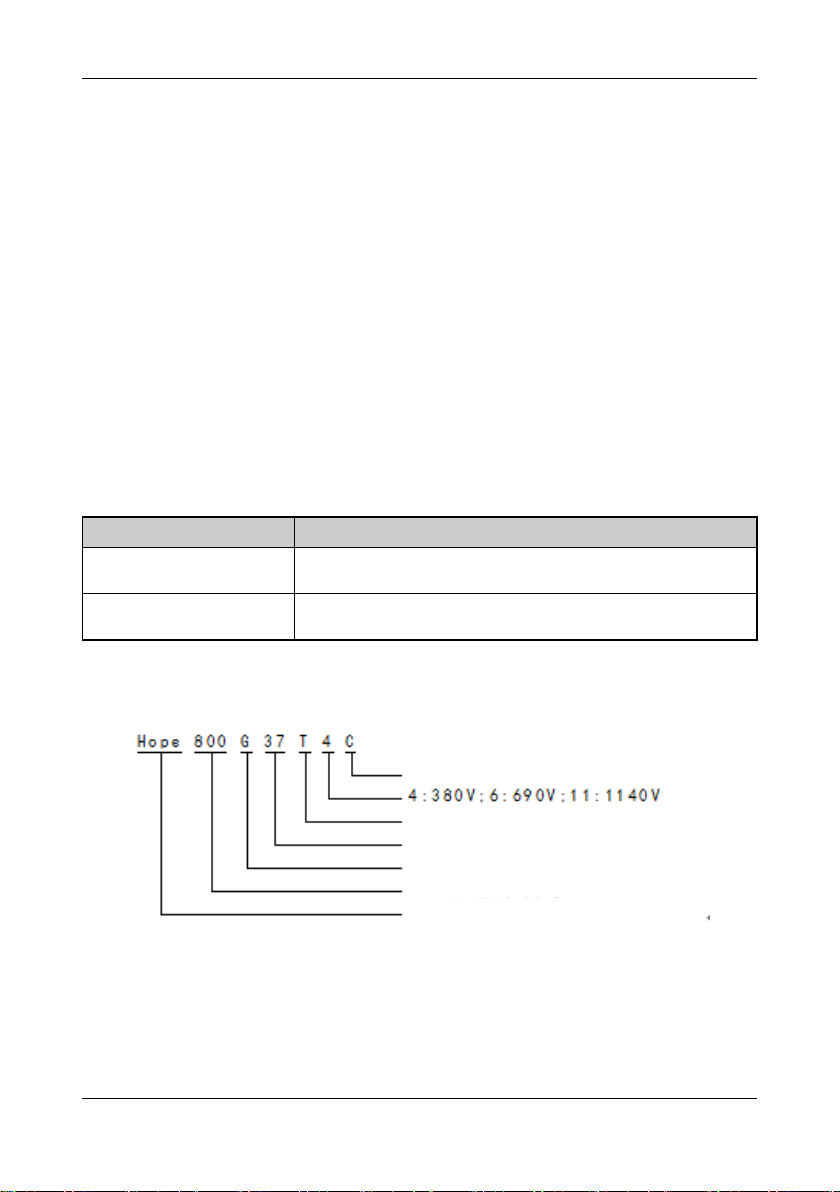

Description of inverter type

C: cabinet; default: on-hook

T: three phases; S: single phase

Rated power: 37kW

G: general type; Q: quadrant 4; H: 12 pulse waves

800: product series number

Hope: English of Chinese word "希望"

Description of Inverter Nameplate: (based on Hope800G132T4)

PREFACE

2

Safety signs

The safety signs in this manual fall into two categories:

DANGER

: indicates that errors in operation may destroy the inverter or lead to death or

heavy injury to people.

!CAUTION

: indicates that errors in operation may lead to damage to the inverter or other

devices.

Terms and abbreviations:

Name

Description

AI

Analog Input, see page 79

AO

Analog Output, see page 81

ASR

Automatic Speed Regulator, see page 60

AVR

Automatic Voltage Regulation, see page 64

EMC

Electric Magnetic Compatibility

EMI

Electric Magnetic Interference

LED

Light Emitting Diode

PFI

Pulse Frequency Input, see page 82

PFO

Pulse Frequency Output, see page 82

PID

Proportion-integration –differentiation, see page 83

PG

Pulse Generator, see page 105

PWM

Pulse Width Modulate

UP/DOWN value

A percentage value that can be adjusted by terminals and keypad / keys. It can

be used as the frequency reference (max. frequency=100%) or PID reference. See page

74

Programmable unit

A software module inside the inverter that implements the arithmetic operation, logic

operation, comparison and the like. See page 109

n(digital input)

The nth digital signal listed in the “Table of digital input functions”in page 70.

It can be used as the input of X, FWD and REV terminals, as well as the output of the

logic unit, timer and comparator.

n (digital output)

The nth digital signal listed in the “Table of digital output functions”on page 76.

It can be used as the output of the Y terminals and relays, as well as the input of the

logic unit, timer, analog multi-switch, counter and meter-counter.

n (analog output)

The nth analog signal listed in the “Table of analog output functions”on page 81

1 Precautions

3

It can be used as the output of the AO1, AO2 and PFO terminals, as well as the input of

the comparator, analog multi-switch and low-pass filter.

1 Precautions

4

1 Precautions

1.1 Safety precautions

I. Installation

Do not install the inverter at a place with or near inflammable objects, otherwise there may be a

risk of fire.

Install the inverter on flat, smooth and solid surface and keep it away from moist, heat and

condensation environment.

II. Wiring

Make sure the high-voltage indicator is off and the DC link voltage is lower than 36V, otherwise

there may be a risk of electric shock.

Make sure that the input power is completely cut off before the wiring is conducted, otherwise

there may be a risk of electric shock.

Do not connect a braking resistor between the DC+ terminals DC- to avoid fire.

The voltage of the input power terminals should not be out of the rated voltage range to avoid

damages to the inverter.

The grounding terminal(PE) of the inverter must be securely connected to earth (resistance to

earth≤10), otherwise there may be a risk of electric fire.

III. Check before switching on the power

Close the door of the inverter before turning on the power, otherwise there may be a risk of

electric shock or explosion.

Before trying to run the motor at a frequency over the rated motor frequency, make sure that the

motor and the mechanical devices can endure such a high speed.

IV. Precautions on power and operation

Check if parameters are appropriately set before commissioning.

Do not open the front cover while the input power is switched on, for the high voltage inside

may cause electric shock.

Do not handle the inverter with wet hands. That may lead to electric shock.

“Power-on auto start”is enabled before shipment from the factory. When the terminal control

and the run signal are valid, the inverter will start automatically once the power is on.

Do not control the run and stop of the inverter by switching on and off the input power.

Related parameters should be reset after parameter initialization.

If the function of restart has been set (such as auto-reset or restart after momentary power failure),

do not approach the motor or mechanical load while the inverter is waiting to restart.

V. Precautions on transport and package

Do not place more inverters than specified in the packaging box.

Do not put any heavy object on the inverter.

Do not open the cover board during transportation.

Do not apply any force on the keypad and the cover board while handling the inverter, otherwise

there may be a risk of injury to people or damage to equipment.

1 Precautions

5

VI. Disposal

Dispose the inverter as industrial waste.

The electrolytic capacitors inside the inverter may explode while burned.

Plastic components of the inverter will generate poisonous gases while burned.

1.2 Other precautions

I. About motor and mechanical load

Comparison with commercial power operation

Hope800 inverter is a voltage-type PWM motor drive. Its output voltage contains some harmonics.

Compared with the commercial power, it creates more loss and noise and leads to largrer temperature rise of

the motor.

The insulation withstands voltage of the cables and motor should be taken into account when the input

voltage is high or the motor cables are long.

Constant-torque, low-speed operation

When a common motor runs at low speed for a long time, the motor temperature will rise due to the

weakened cooling effect. So if a motor is required to operate at low speed and constant torque for a long period

of time, an inverter or the forced air cooling method must be applied.

Overload protection

If the rated capacity of the motor does not match that of the inverter, regulate the overload protection level

or adopt other protective measures so that the motor can operate safely.

Running above 50Hz

If you plan to run the motor over 50Hz, be aware that the vibration and noise will increase and make sure

that the motor bearings and mechanical devices can withstand such a high speed.

Lubrication of mechanical devices

While running at low speed for a long time, such mechanical devices as gearbox and gears may be

damaged due to weakened lubricating effect. Before you run them, check the lubrication conditions.

Load of regulative torque

Regulative torque often occurs while a load is hoisted, and the inverter often stops due to overvoltage

protection. In this case, an appropriate braking unit should be installed.

Mechanical resonant point

Certain output frequencies of the inverter may be the mechanical resonant points. To avoid these points,

place anti-vibration rubber under the base of the motor or setting the jump frequencies.

Motor insulation check before connected to the inverter

When the motor is used for the first time or reused after it has not been used for a long time, the motor

insulation must be inspected to prevent the damage to the inverter caused by the failed insulation of the motor

windings. Use a 500V voltage-type megaohm meter to measure the insulation resistance, which should be no

less than 5MΩ.

II. About inverter

Capacitor or voltage-dependent resistor for power factor improvement

1 Precautions

6

As the inverter output is of PWM voltage type, the capacitor or voltage-dependent resistor (for improving

the power factor) installed on the output side of the inverter will lead to inverter trip or damage to

components. Do remove the capacitor or the voltage-dependent resistor before using the inverter.

Installation of switching devices (e.g. contactor) on inverter output side

If a switching device like contactor is required to be installed between the inverter and the motor, make

sure the on/off operation is performed while the inverter has no output, otherwise the inverter may be

destroyed.

Frequent start and stop

For applications where frequent start and stop are needed, terminals are recommended for the control of

the start/stop of the inverter. Using the switching device (such as contactor) on the inverter input side to start or

stop the inverter frequently is prohibited. That may destroy the inverter.

Using the inverter beyond the rated value

It is not recommended to operate the inverter beyond the range of the allowable input voltage. If the

inverter has to be used beyond the range, raise or reduce the voltage via a voltage regulator.

Lightning protection

With the built-in protection of overvoltage from lightning, the inverter has certain self-protection ability

against lightning strike.

Leakage protector

The high-speed switching operation during the running of the inverter will generate high-frequency

current which sometimes causes the mis-operation of the leakage protection circuit. To address this issue,

moderately lower the carrier frequency, shorten the wires or install a leakage protector.

Observe the following points while installing the leakage protector.

1) The leakage protector should be installed on the inverter input side, preferably behind the air switch

(non-fuse circuit breaker).

2) The leakage protector should be one that is insensitive to higher harmonics or specially designed for

the inverter (sensitivity above 30mA). If a common leakage protector is selected, its sensitivity and action time

should be greater than 200mA and 0.2s respectively.

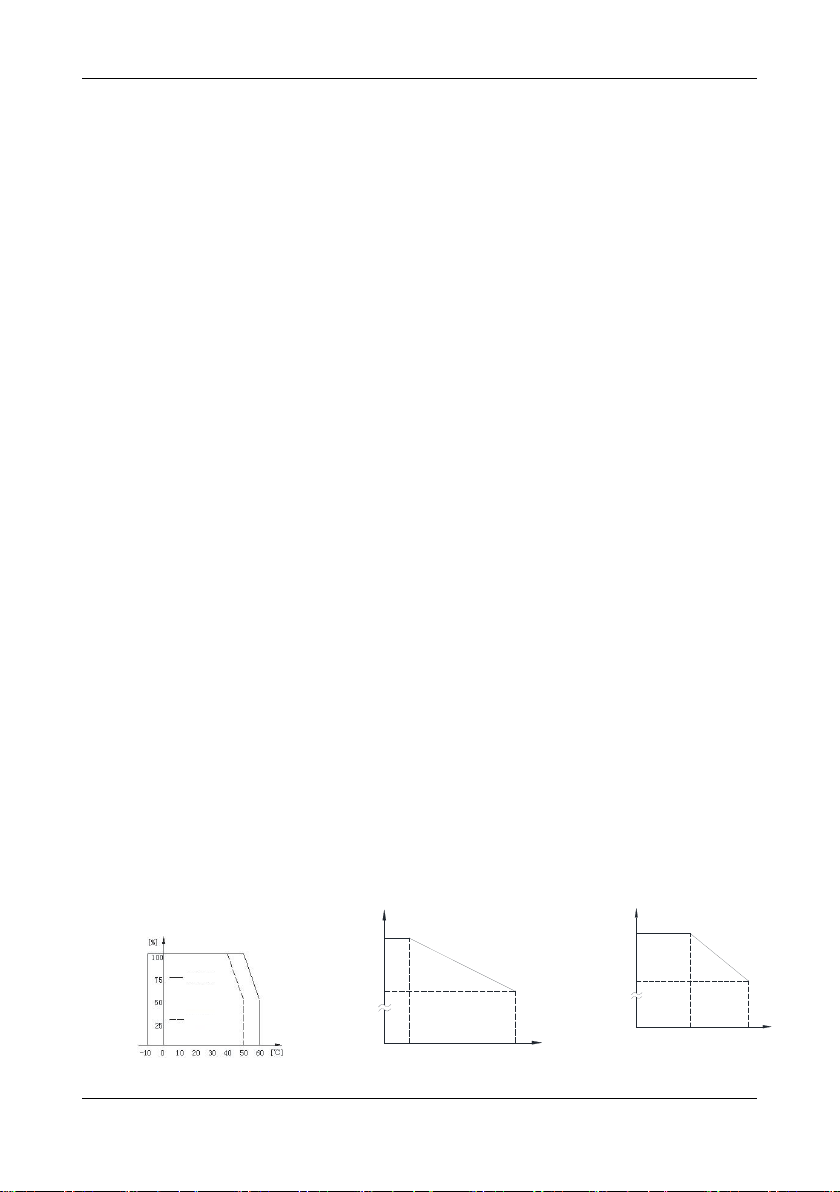

Derating of inverter

1) If the ambient temperature exceeds 40℃, the inverter should be derated as per figure 1 and external

forced cooling should be provided.

2) If the altitude is above 1000 meters, heat dissipation effect of the inverter will be poor due to thin air

thus it should be derated, with derated output and input current value shown in figure B and C;

3) If the carrier frequency is greater than the factory setting, the inverter should be derated by 5% for

every 1kHz increase.

Fig.A Fig. B Fig. C

01000

80

85

100

M

%

2000 3000 4000

0 1000

77

80

100

M

%

2000 3000 4000

Variable torque

Constant torque

2 Specifications

7

2 Specifications

2.1 Common specifications for Hope800 series

Item

Description

Input

Rated voltage and

frequency

3 phases: 380v; 50/60Hz

Allowable range

Voltage fluctuation range: ±15%; voltage unbalance: <3%;

frequency: 47~63 Hz

Output

Output voltage

3-phase, 0V~input voltage, with the error less than 5%.

Output frequency

range

V/F control: 0.00~650.00Hz

Vector control: 0.00~200.00Hz

Basic

specifications

Motor control

mode

V/F control without PG, V/F control with PG, vector control without

PG, vector control with PG, V/F separate control

Steady-state speed

precision

Vector control without PG: ≤1%

Vector control with PG: ≤0.02%

Starting torque

Not less than 150% of rated torque at 0.50Hz

Overload capacity

150%of rated current for 1 minute

Frequency

resolution

Digital reference: 0.01Hz Analog reference: 0.1%of max.

frequency

Output frequency

precision

Analog reference: : ±0.2%of max. frequency(25±10℃)

Digital reference: 0.01Hz(-10~+40℃)

Command source

Keypad, terminal and communication. They can be switched over by

terminals

Frequency

reference source

Keypad, communication, UP/DOWN value, AI1, AI2, PFI and

arithmetic unit

Auxiliary

frequency

reference

Achieves flexible frequency setting

Torque boost

Auto or manual torque boost

V/F curve

User defined V/F, linear V/F and 5 reduced-torque curves

Accel/decel

Linear or S-curve acceleration/deceleration

Jog

Jog frequency: 0.10~50.00Hz

Jog accel/decel time: 0.1~60.0s

Auto energy saving

V/F curve is optimized automatically based on the load condition,

achieving auto energy-saving run

AVR

Keeps the output voltage constant automatically when the voltage of

power grid fluctuates

Auto carrier

regulation

Carrier frequency is regulated automatically based on the load

characteristic and ambient temperature

Random PWM

Regulates the tone of the motor noise

Droop control

Applicable to cases where multiple inverters drive the same load

Momentary power

failure

Ensures uninterrupted operation by controlling the DC link voltage

DC braking

Braking time: 0.0~60.0s

Braking current: 0.0~100.0%of rated current

PFI

Highest input frequency: 50kHz

PFO

Open-collector pulse(square wave) output of 0~50kHz,

programmable

Analog input

2 channels of analog input, voltage or current type, positive or

negative

Analog output

2 channels of analog output, 0/4~20mAor 0/2~10V, programmable

Digital input

8 channels of optional multi-function digital input(leakage/source

2 Specifications

8

Item

Description

type)

Digital output

2 channels of optional multi-function digital output(leakage/source

type); 2 channels of multi-function relay output

Communication

Built-in RS485 port, supporting Modbus protocol and USS

commands

Characteristic

functions

Process PID

Two sets of PID parameters; multiple correction modes; free PID

function

Multiple PLC

modes

User can set 8 PLC run modes, with each having up to 48 stages. The

mode can be selected by terminals. PLC status can be saved at power

failure.

Multi-speed select

mode

4 selection modes. Refer to F4-17

User defined menu

30 user parameters can be defined

Parameter display

change

Can display parameters different from the default ones

Torque control

Torque/speed control can be switched by terminals. Multiple torque

setting modes.

Zero-servo

Zero-speed position can be locked

Characteristic

functions

High-speed

UP/DOWN

counter

Synchronous control, counting in production, stop contol by count

and precise position control can be realized

High-speed meter

counter

Stop control by length and length indication can be achieved

Wobble

Ensures even winding of textiles

Programmable unit

Comparator, logic unit, trigger, arithmetic unit, filter, multiple-way

switch, timer

kWh meter timer

For adjustment of optimal energy saving strategy

Protection functions

Overcurrent, overvoltage, undervoltage, input/output phase loss,

output short-circuit, overheating, motor overload, external fault,

analog input disconnection, stall prevention, etc.

Options

Braking unit, remote control box, digital I/O expansion board,

encoder interface board, analog input expansion board, keypad with

copying function or potentiometer, keypad mounting box, keypad

extension line, I/O reactor, EMI filter, Profibus-DP module, etc.

Ambient

Service site

Altitude less than 1000 meters; indoor; no direct sunlight; free of

dust, corrosive gases, inflammable gases, oil mist, water vapor,

water drops, salt mist, etc.

Temperature/humid

-10~+40℃/20~90%RH, no condensation

Storage

temperature

-20~+60℃

Vibration

Less than 5.9m/s2(0.6g)

Structure

Protection degree

IP30

Cooling method

Forced air cooling, with fan control

2.2 Product series specifications

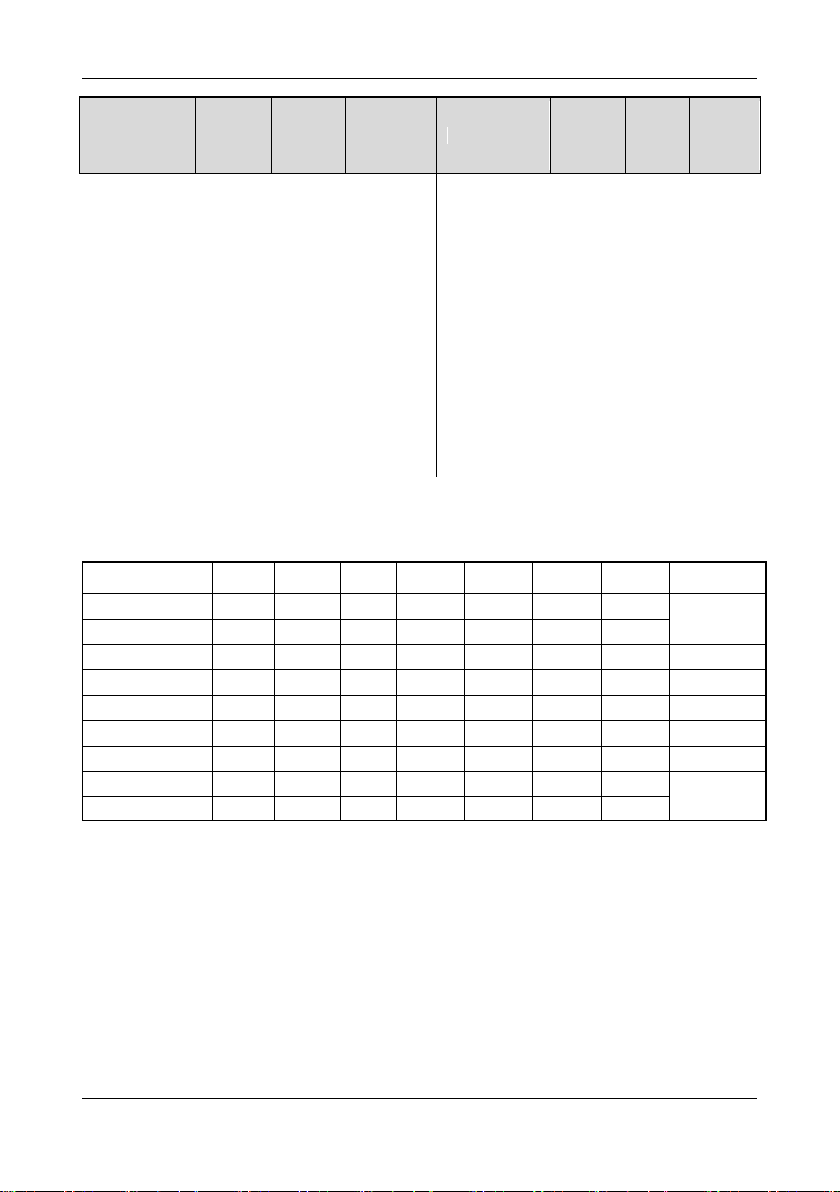

Table of rated value of inverter: Table of

Model

Rated

capacity

(kVA)

Rated

output

current

(A)

Applicable

motor

(kW)

Model

Rated

capacity

(kVA)

Rated

output

current

(A)

Applicable

motor

(kW)

Hope800G0.4T4

1.1

1.5

0.4

Hope800

G45T4

60

91

45

Hope800G0.75T4

1.6

2.5

0.75

Hope800G55T4

74

112

55

2 Specifications

9

Model

Rated

capacity

(kVA)

Rated

output

current

(A)

Applicable

motor

(kW)

Model

Rated

capacity

(kVA)

Rated

output

current

(A)

Applicable

motor

(kW)

Hope800G1.5T4

2.4

3.7

1.5

Hope800G75T4

99

150

75

Hope800G2.2T4

3.6

5.5

2.2

Hope800G90T4

116

176

90

Hope800G4T4

6.4

9.7

4

Hope800G110T

4

138

210

110

Hope800G5.5T4

8.5

13

5.5

Hope800G132

T4

167

253

132

Hope800G7.5T4

12

18

7.5

Hope800G160

T4

200

304

160

Hope800G11T4

16

24

11

Hope800G200

T4

248

377

200

Hope800G15T4

20

30

15

Hope800G220T

4

273

415

220

Hope800G18.5T4

25

38

18.5

Hope800G250T

4

310

475

250

Hope800G22T4

30

45

22

Hope800G280T

4

342

520

280

Hope800G30T4

40

60

30

Hope800G315T

4

389

590

315

Hope800G37T4

49

75

37

Hope800G375T

4

460

705

375

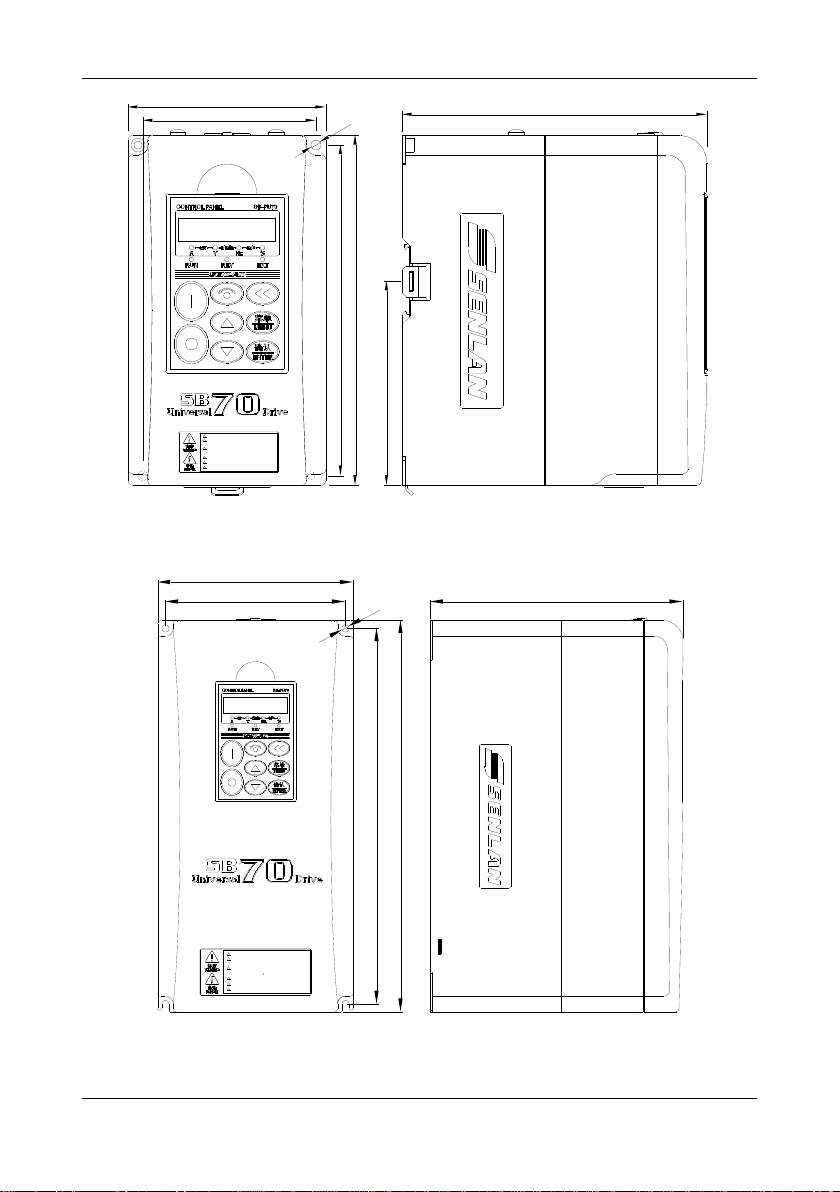

Outline and installation dimensions of HOPE800G0.4~15T4 are as follow:

Model

W(mm)

W1(mm)

H(mm)

H1(mm)

H2(mm)

d(mm)

Φ(mm)

Weight (kg)

Hope 800G0.4T4

100

87.5

180

170

5

157

4.5

2

Hope800G0.75T4

Hope800G1.5T4

Hope800G2.2T4

135

125

240

230

5

170

4.5

3

Hope800G4T4

Hope800G5.5T4

150

138

300

288

6

195

5.5

7

Hope800G7.5T4

Hope800G11T4

200

185

380

367

6

225

7

10

Hope800G15T4

2 Specifications

10

W

A

B

H

D

d

H1

Must connect the PE terminal to the ground

Do not touch any components when the high

voltage LED is lighting

Do not connect input power to the output

terminals (U,V,W)

必须将变频器PE端子可靠接地

高压指示灯熄灭之前禁止接触机内任何部件

禁止将输入电源线接到输出端子(U,V,W)上

Boundary dimension of Hope800G18.5~375T4:

A

W

D

d

B

H

Must connect the PE terminal to the ground

Do not touch any components when the high

voltage LED is lighting

Do not connect input power to the output

terminals (U,V,W)

必须将变频器PE端子可靠接地

高压指示灯熄灭之前禁止接触机内任何部件

禁止将输入电源线接到输出端子(U,V,W)上

2 Specifications

11

Model

W

(mm)

W1

(mm)

W2

(mm)

H

(mm)

H1

(mm)

H2

(mm)

H3

(mm)

D(mm)

Φ(mm)

Weight (kg)

Hope800G18.5T4

275

160

200

530

515

7

490

285

7

22

Hope800G22T4

Hope800G30T4

Hope800G37T4

280

160

210

625

605

10

575

300

9

35

Hope800G45T4

Hope800G55T4

305

200

240

800

780

10

750

350

9

47

Hope800G75T4

50

Hope800G90T4

340

240

280

930

910

10

875

370

9

80

Hope800G110T4

82

Hope800G132T4

360

260

300

960

935

10

905

375

11

90

Hope800G160T4

460

300

400

1260

1235

10

1199

385

11

148

Hope800G200T4

150

Hope800G220T4

500

300

400

1260

1235

10

1205

385

11

175

Hope800G250T4

180

Hope800G280T4

650

400

500

1350

1320

13

1280

385

13

200

Hope800G315T4

Hope800G375T4

220

3 Installation and wiring

12

3 Installation and wiring

3.1 Installation

DANGER

1. The installation of the inverter can be performed only by qualified

professionals.

2. Do not install and run the inverter if there is any damage on the

inverter or any part is missing, otherwise there may be a risk of fire

and injury.

3. Install the inverter on a firm support that can bear its weight,

otherwise the inverter may fall and cause damage or injury.

4. Do not apply force on the keypad or cover board while handling the

inverter, otherwise the falling of keypad or cover board may cause

damage or injury.

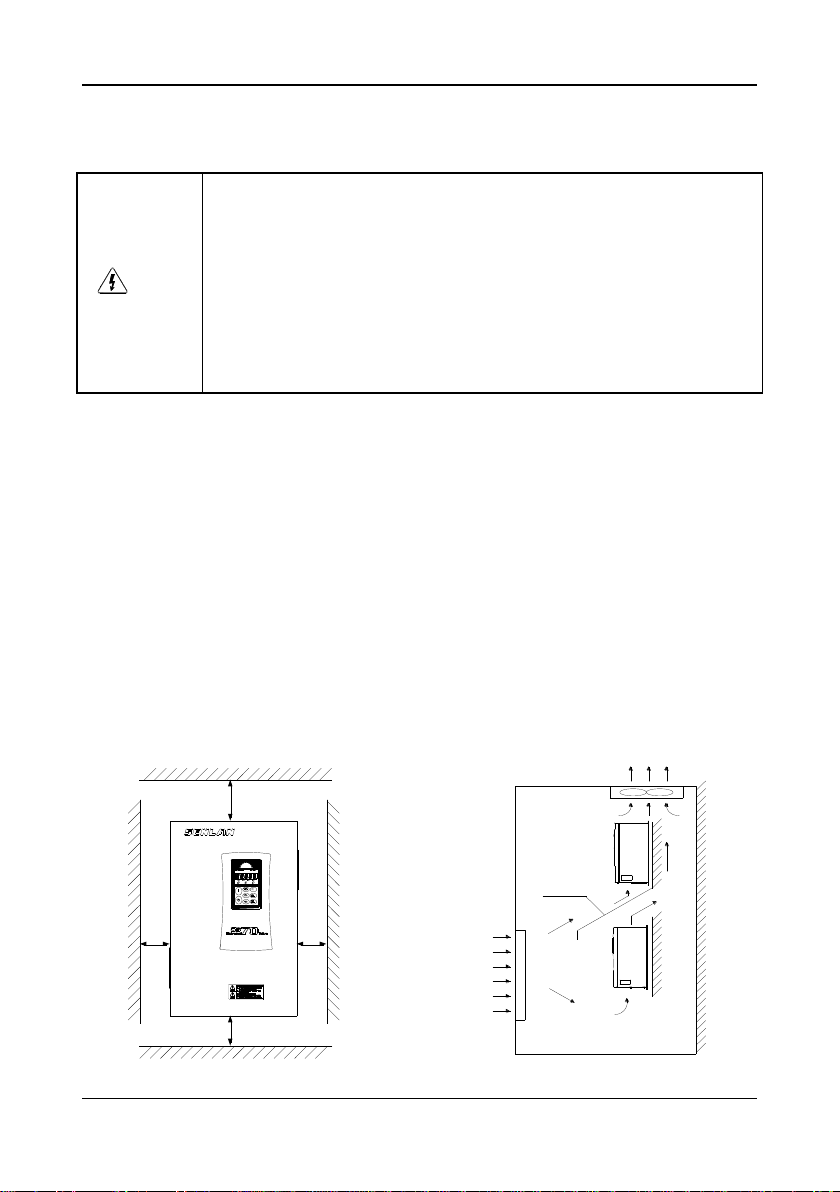

The inverter should be installed in a room with good ventilation. The installing environment should meet

the following requirements:

1. Ambient temperature: -10~40℃. If the temperature exceeds 40℃, derate the inverter by 5% for every

one-degree increase in temperature and apply external forced cooling.

2. Altitude: not greater than 1000m. If the altitude exceeds 1000m, derate the inverter by 1% for every

100-meter increase in altitude.

3. Humidity: less than 90% RH, no condensation.

4. Vibration: less than 5.9m/s2 (0.6g)

5. Avoid installing it at a place with direct sunlight

6. Avoid installing it at a place with much dust and metal powder

7. Never install it at a place with corrosive and inflammable gases

8. The inverter should be installed vertically instead of upside down, slantways or horizontally, and fixed to a

firm structure with screws. Installation, installation space and distance requirements are shown in the figure

below:

5cm or

more

5cm or

more

15cm or

more

10cm or

more

Air out

Air in

Partition

board

Inverter

Inverter

3 Installation and wiring

13

3.2 Removal and installation of parts

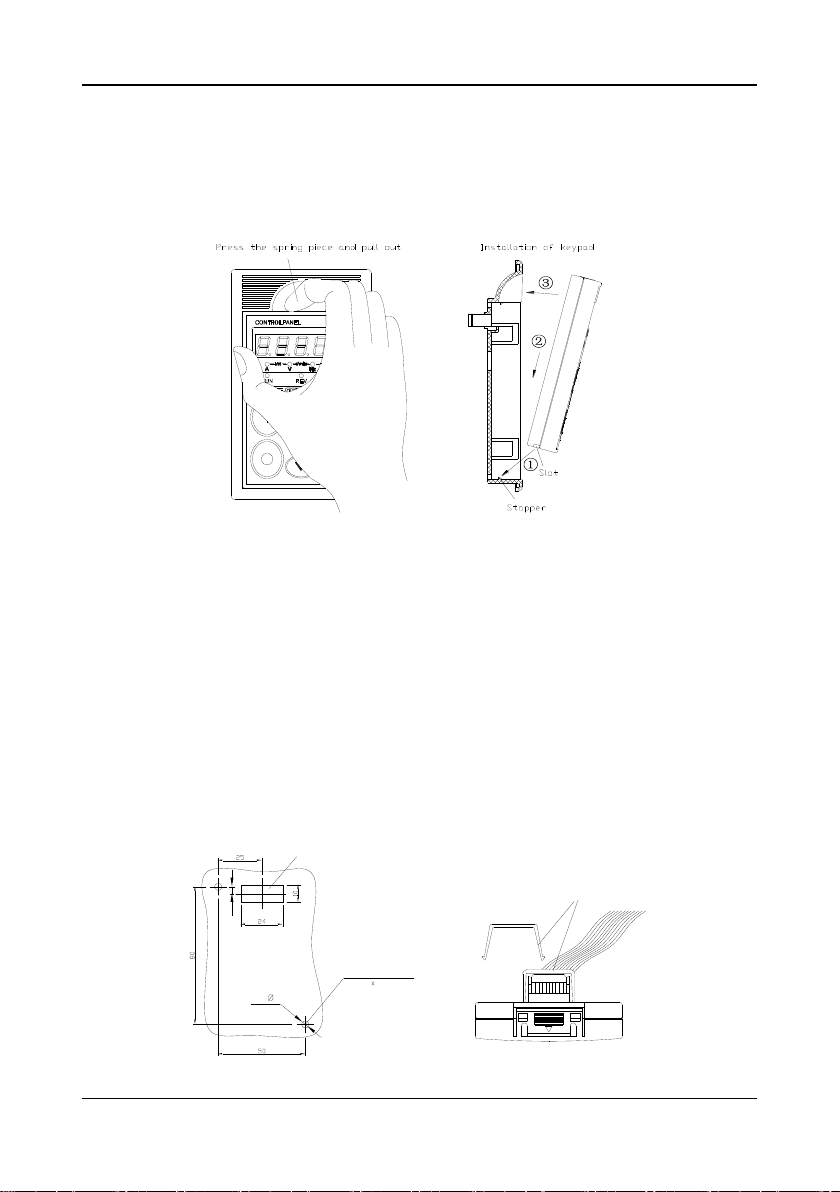

3.2.1 Removal and installation of keypad

Removal: press the spring piece on top of the keypad and pull out.

Installation: push the keypad in with the slot on its bottom aligning with the stopper on the mounting box.

3.2.2 Installation of keypad on cabinet front cover

The keypad of a Hope800 inverter can be taken off from the inverter and installed on the front cover of

the cabinet, with the keypad and inverter connected by the extension line. You can choose any one of the

following two installing methods.

Method 1: direct installation

①Make an opening on the front cover of the cabinet according to the following drawing.

②Take off the keypad and the two screws on the diagonal of the keypad. Fix the keypad to the front

cover with the two M3×14 screws shipped with the product.

③Insert one end of the extension line into the keypad and fix it with the fastener shipped with the

product. Insert the other end of the extension line into the corresponding slot on the inverter circuit

board and lock it. Close the cover board of the cabinet.

2× 4

4

Rectangle hole

for wires

Material thickness

less than 3mm

Screw hole

Two M3 14 screws

Holes for installing keypad

Holder T/SL-23(accessory) prevents the extension

line connector coming off from the keypad

3 Installation and wiring

14

Method 2: installation via the mounting box

①Make an opening on the front cover of the cabinet according to the following drawing.

②Install the mounting box (option) onto the front cover.

③Install the keypad into the mounting box.

④Insert one end of the extension line into the keypad and the other end into the corresponding slot

on the inverter circuit board, and lock the line. Close the cover board of the cabinet.

110

67

Keypad mounting box Sizes of cabinet holes

Material thickness: 1~1.5mm

3.2.3. Uninstallation/Installation of Cover and Control Panel

During uninstallation, disassemble keypad and press the two buckles on the top of cabinet simultaneously

with two hands as shown in the left figure to take cover board down with slight upward force.

During installation, align hook at the bottom of cover board to cabinet slot and press cover board top

downward by taking bottom as pivot till hook on top enters slot; finally, install keypad as per the figure above.

The bottom, rather than shell of the product, can be held when transporting;

3 Installation and wiring

15

3.3 Wiring

DANGER

1. Wiring of the inverter can be performed only by qualified professionals.

2. Before opening the cover board of the inverter, cut the power supply and wait

for at least five minutes after all indicators on the keypad go out.

3. The wiring inside the inverter can only begin after the internal high-voltage

indicator of the inverter goes out or the voltage between terminals DC+and

DC- (measured with voltmeter) is less than 36V.

4. The inverter must be earthed reliably, otherwise there may be a risk of electric

shock or fire.

5.Shorting DC+and DC- is prohibited. That may cause fire or damage to

properties.

6.Connecting the power line with U, V or W is prohibited.

7.The inverter has passed the voltage resistance test before it is shipped from the

factory; the users need not do this test again.

8. Major loop terminals and conductor cold-pressed terminal shall be firmly

connected. Attachment DC electric reactor shall be installed if power is over

90kW.

9. All terminals must be securely connected.

10. Connecting surge absorbing capacitors or voltage-dependent resistors on the

output side of the inverter is prohibited.

3.3.1 Wiring and configuration of main circuit terminals

The inverter and its peripherals are connected as follows:

3 Installation and wiring

16

Only for 18.5kw or more.

Remove shorting bar

between P1 and P+ before

installing DC reactor.

DC reactor

Shorting bar

Braking resistor Braking unit

3-phase input

380V power supply

Circuit breaker

Only for 15kw or less

High-voltage indicator

SB70G series inverter

Multi-function digital

input terminal and factory

configurations

Multi-function relay output

and factory configurations

Malfunction output

Multistage frequency selection 1

Shorting bar

Multistage frequency selection 2

Multistage frequency selection 3

Multistage frequency selection 4

External fault input

Fault resetting

Forward starting terminal

Reverse starting terminal

Alarm output

Multi-function digital output

and factory configurations

Inverter in operation

Frequency reached

Shorting bar

Shielding layer

Potentiometer

Sensor

Impulse frequency input

Multi-function analogy output

Operation frequency

Output current

Impulse frequency output

Frequency modulation output “operation

frequency”

RS485 port

We recommend you to choose the following air switches and main circuit wirings (copper-core

insulation wires):

Inverter model

Aire

switch

(A)

Main circuit

wiring (mm2)

AWG

Bolt

dimension

Torque

value

Wiring lug

Hope800G0.4~1.5T4

16

2.5

12

M3

2N.m

IT2.5-2

Hope800G2.2~4T4

20

4

10

M3

2N.m

IT4-3

Hope800G5.5~7.5T4

40

6

8

M4

3N.m

UT6-5

Hope800G11~15T4

63

8

6

M5

5N.m

UT10-6

Hope800G18.5~22T4

100

10

4

M8

10N.m

DT-16

Hope800G30T4

125

16

3

M8

10N.m

DT-25

This manual suits for next models

11

Table of contents

Other Senlan Inverter manuals