Spellman XRB011 User manual

XRB011 User’s Manual 118148-001 Rev A

R

Instruction Manual

SPELLMAN

HIGH VOLTAGE ELECTRONICS

CORPORATION

One Commerce Park

Valhalla, New York, 10595

+1(914) 686-3600* FAX: +1(914) 686-5424*

E-mail: [email protected]

Website: www.spellmanhv.com

XRB011

118091-001 REV. B

IMPORTANT SAFETY PRECAUTIONS

SAFETY

THIS POWER SUPPLY GENERATES VOLTAGES THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING WITH THIS EQUIPMENT.

High voltage power supplies must always be grounded.

Do not touch connections unless the equipment is off and the

Capacitance of both the load and power supply is discharged.

Allow five minutes for discharge of internal capacitance of the power supply.

Do not ground yourself or work under wet or damp conditions.

SERVICING SAFETY

.

Maintenance may require removing the instrument cover with the power on.

Servicing should be done by qualified personnel aware of the electrical hazards.

WARNING note in the text call attention to hazards in operation of these units

that could lead to possible injury or death.

CAUTION notes in the text indicate procedures to be followed to avoid possible

damage to equipment.

Copyright 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118091-001 REV. B

WICHTIGE SICHERHEITSHINWEISE

SICHERHEIT

DIESES HOCHSPANNUNGSNETZTEIL ERZEUGT LEBENSGEFÄHRLICHE HOCHSPANNUNG.

SEIN SIE SEHR VORSICHTIG BEI DER ARBEIT MIT DIESEM GERÄT.

Das Hochspannungsnetzteil muß immer geerdet sein.

Berühren Sie die Stecker des Netzteiles nur, wenn das Gerät ausgeschaltet ist und die elektrischen

Kapazitäten des Netzteiles und der angeschlossenen Last entladen sind.

Die internen Kapazitäten des Hochspannungsnetzteiles benötigen ca. 5 Minuten, um sich zu entladen.

Erden Sie sich nicht, und arbeiten Sie nicht in feuchter oder nasser Umgebung.

SERVICESICHERHEIT

Notwendige Reparaturen können es erforderlich machen, den Gehäusedeckel während des Betriebes zu

entfernen.

Reparaturen dürfen nur von qualifiziertem, eingewiesenem Personal ausgeführt werden.

“WARNING” im folgenden Text weist auf gefährliche Operationen hin, die zu Verletzungen oder zum Tod

führen können.

“CAUTION” im folgenden Text weist auf Prozeduren hin, die genauestens befolgt werden müssen, um

eventuelle Beschädigungen des Gerätes zu vermeiden.

118091-001 REV. B

PRECAUTIONS IMPORTANTES POUR VOTRE SECURITE

CONSIGNES DE SÉCURITÉ

CETTE ALIMENTATION GÉNÈRE DES TENSIONS QUI SONT DANGEUREUSES ET PEUVENT ÊTRE FATALES.

SOYEZ EXTRÊMENT VIGILANTS LORSQUE VOUS UTILISEZ CET ÉQUIPEMENT.

Les alimentations haute tension doivent toujours être mises à la masse.

Ne touchez pas les connectiques sans que l’équipement soit éteint et que la capacité à la fois de la charge et de

l’alimentation soient déchargées.

Prévoyez 5 minutes pour la décharge de la capacité interne de l’alimentation.

Ne vous mettez pas à la masse, ou ne travaillez pas sous conditions mouillées ou humides.

CONSIGNES DE SÉCURITÉ EN CAS DE REPARATION

La maintenance peut nécessiter l’enlèvement du couvercle lorsque l’alimentation est encore allumée.

Les réparations doivent être effectuées par une personne qualifiée et connaissant les risques électriques.

Dans le manuel, les notes marquées « WARNING » attire l’attention sur les risques lors de la manipulation de ces

équipements, qui peuvent entrainer de possibles blessures voire la mort.

Dans le manuel, les notes marquées « CAUTION » indiquent les procédures qui doivent être suivies afin d’éviter

d’éventuels dommages sur l’équipement.

118091-001 REV. B

IMPORTANTI PRECAUZIONI DI SICUREZZA

SICUREZZA

QUESTO ALIMENTATORE GENERA TENSIONI CHE SONO PERICOLOSE E

POTREBBERO ESSERE MORTALI.

PONI ESTREMA CAUTELA QUANDO OPERI CON QUESO APPARECCHIO.

Gli alimentatori ad alta tensione devono sempre essere collegati ad un impianto di terra.

Non toccare le connessioni a meno che l’apparecchio sia stato spento e la capacità interna

del carico e dell’alimentatore stesso siano scariche.

Attendere cinque minuti per permettere la scarica della capacità interna dell’alimentatore

ad alta tensione.

Non mettere a terra il proprio corpo oppure operare in ambienti bagnati o saturi d’umidità.

SICUREZZA NELLA MANUTENZIONE.

Manutenzione potrebbe essere richiesta, rimuovendo la copertura con apparecchio

acceso.

La manutenzione deve essere svolta da personale qualificato, coscio dei rischi elettrici.

Attenzione alle AVVERTENZE contenute nel manuale, che richiamano all’attenzione ai

rischi quando si opera con tali unità e che potrebbero causare possibili ferite o morte.

Le note di CAUTELA contenute nel manuale, indicano le procedure da seguire per evitare

possibili danni all’apparecchio.

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-1 118149-001 REV F

XRB011 INTRODUCTION

1

XRB011

SERVICE

AND

INSTALLATION

MANUAL

INSTALLATION

2

INTERFACING

3

TROUBLESHOOTING

4

SCHEMATICS (Simplified Diagram)

5

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-2 118149-001 REV F

CHAPTER 1

XRB011 INTRODUCTION

CONTENTS:

Section

1.1 XRB011 DESCRIPTION............................................................................................................................................... 3

1.2 TECHNICAL SPECIFICATIONS ...........................................................................................................................................3

1.2.1 Generator Hardware Specifications .......................................................................................................................... 3

1.2.2 Generator Control Modes / Application Features ..................................................................................................... 3

1.2.3 Power Supply Requirements ...................................................................................................................................... 3

1.2.4 Environment Requirements........................................................................................................................................ 4

1.2.5 Mechanical................................................................................................................................................................. 5

1.3THEORY OF OPERATION .......................................................................................................................................... 7

1.3.1 Function Overview..................................................................................................................................................... 7

1.3.2 Input Line Power........................................................................................................................................................7

1.3.3 HV Inverter ................................................................................................................................................................ 7

1.3.4 High Voltage Transformer......................................................................................................................................... 7

1.3.5 High Voltage Assembly.............................................................................................................................................. 7

1.3.6 System Control PWB..................................................................................................................................................7

1.3.7 Filament Power.......................................................................................................................................................... 8

1.3.8 High Voltage Interlock...............................................................................................................................................8

1.4SAFETY.........................................................................................................................................................................9

1.4.1 Safety and Warning Symbols...................................................................................................................................... 9

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-3 118149-001 REV F

1.1 XRB011 DESCRIPTION

The XRB011 MONOBLOCKis a complete integrated system consisting of a high voltage power supply

(HVPS), filament supply, X-ray tube and oil encapsulant which provide the required high voltage insulation in

one compact enclosure. The combination of proprietary control system and protection circuitry enables the

supplies to operate under arcing and extreme transient conditions without damage or interruptions. Additional

advantages are the elimination of high voltage cables and extremely low leakage X-ray radiation.

The XRB011 incorporates local and remote programming, monitoring, and fault indicators including safety

interlock. The X-ray source is a sealed unit containing a HVPS and an X-ray tube. The insulating oil provides

electrical insulation for the high voltage sections of the power supply and the X-ray tube in a sealed tank. The

oil also functions as a coolant to carry heat away from the tube. Convection cooling augmented by customer

provided minimum 50cfm external fan is required for the 50W option. A rubber bellows in the tank of the X-ray

source compensates for the expansion of the oil as the oil temperature varies with operating conditions thereby

eliminating the need for bulky overflow tank.

.

1.2 TECHNICAL SPECIFICATIONS

1.2.1 Generator Hardware Specifications

kVp range:

35 to 80 kVp output capability

kVp steps:

Continuous with 12 bits resolution

kVp accuracy:

<=1% (measured after kVp rises to the

peak level)

Ripple (kV):

<= 1% Peak to Peak

Settling time:

< 10ms to within 95% of the

programmed voltage

Reproducibility:

<0.5%

Stability:

<=0.01% per 8 hours after a ½ hour

warm up

Temperature Coefficient:

<=100ppm/ ℃

Time range:

XRB011 is specified as a Continuous

operation.

mA :

250µA maximum for 20W option

700µA maximum for 50W option

mA accuracy:

<2.5% (measured after mA rises to

stable DC level)

mA range

0 to 250 µA for 20W option

0 to 700 µA for 50W option

Reproducibility:

<0.5%

1.2.2 Generator Control Modes / Application Features

Manual Operating Mode –2 Parameters Mode (kV, mA)

System Communication Protocol / Fault & Error Management

See details in the Serial Communication Protocol Specifications

1.2.3 Power Supply Requirements

Single Phase

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-4 118149-001 REV F

Line Voltage

24VDC±1VDC, 2.5A (20W option). 4A (50W option)

The following table defines the power line requirements for the generators.

NOTE: THE FOLLOWING TABLE CONTAINS RECOMMENDED VALUES FOR THE 24V INPUT POWER.

A POOR QUALITY INPUT LINE MAY RESULT IN THE INSTALLER HAVING TO

DERATE THE GENERATOR'S MAXIMUM POWER

Mains

Voltage

Minimum

Recommended

Minimum

Recommended

Ground Wire Size

Apparent

Mains

Resistance

24VDC

J1-1

J1-2

J1-3

#20 AWG (0.52 mm2)

#20 AWG (0.52 mm2)

#20 AWG (0.52 mm2)

0.033

0.033

0.033

24V RETURN

J1-5

J1-6

J1-7

#20 AWG (0.52 mm2)

#20 AWG (0.52 mm2)

#20 AWG (0.52 mm2)

0.033

0.033

0.033

1.2.4 Environment Requirements

Operating Environment

Operating Temperature

0 to 40 C (32 to 104 F).

Relative Humidity

10 to 95%, non-condensing.

Atmospheric pressure range

500 to 1060 hPa (375 to 795 mm Hg).

TRANSPORT AND STORAGE

Ambient temperature range

-20 to 70 C (-4 to 158 F).

Relative humidity

5 to 95%, non-condensing.

Atmospheric pressure range

500 to 1060 hPa (375 to 795 mm Hg).

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-5 118149-001 REV F

1.2.5 Mechanical

20W OPTION

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-6 118149-001 REV F

50W OPTION

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-7 118149-001 REV F

1.3 THEORY OF OPERATION

1.3.1 Function Overview

The XRB011 MONOBLOCK Series is a complete integrated system consisting of a high voltage power

supply (HVPS), filament supply, X-ray tube and oil encapsulant which provide the required high voltage

insulation in one compact enclosure. The combination of proprietary control system and protection circuitry

enables the supplies to operate under arcing and extreme transient conditions without damage or interruptions.

Additional advantages are the elimination of high voltage cables and extremely low leakage X-ray radiation.

The XRB011 MONOBLOCK Series incorporates local and remote programming, monitoring, and fault

indicators including safety interlock. The X-ray source is a sealed unit containing a HVPS and an X-ray tube.

The insulating oil provides electrical insulation for the high voltage sections of the power supply and the X-ray

tube in a sealed tank. The oil also functions as a coolant to carry heat away from the tube. Convection cooling

augmented by customer provided minimum 50cfm external fan is required for the 50W option. A rubber

bellows in the tank of the X-ray source compensates for the expansion of the oil as the oil temperature varies

with operating conditions thereby eliminating the need for bulky overflow tank.

The XRB011 MONOBLOCK is basically a DC to DC power converter. Within the generator, conversions of DC

to DC, then to high frequency AC, then to high voltage DC take place. By reviewing further the sub-

assemblies, a basic understanding of the process can be gained.

1.3.2 Input Line Power

The Input DC voltage provides the voltage for the high voltage inverter and the filament supply.

The line input voltage can vary from 23V up to 25V within the series.

1.3.3 HV Inverter

The inverter is a “Push-Pull” topology. Voltage mode control is used for driving the inverter. Two MOSFET

transistors are used as switches in the HV inverter. These MOSFET provide high frequency switching to

control the primary current flow in the high voltage transformer.

Circuits on the Control board provide the gate control of the switches. The PWM IC generates gate drive

control signals.

1.3.4 High Voltage Transformer

The output of the High Frequency Quasi-resonant Inverter is connected to the primary of the High Voltage

Transformer. The High Voltage Transformer is a step up type. Typical secondary voltage is in the range of

5.7kV depending upon output voltage ratings.

1.3.5 High Voltage Assembly

The High Voltage Assembly circuitry typically consists of two high voltage multipliers to generate ±40kV. The

high voltage section is a bipolar ground-referenced supply. The multiplier is a standard diode-capacitor

multiplier with seven stages of voltage multiplication and the divider is a precision resistance divider string.

Each supply is capable of generating 40 kV.

A high bandwidth resistive/capacitive divider provides voltage feedback for regulation and monitoring. A sense

resistor connected at the low voltage end of the High Voltage Rectifier provides current feedback for regulation

and monitoring.

1.3.6 System Control PWB

Control of the generator utilizes sophisticated analog and digital circuitry resulting in fast and accurate control,

protection and signaling to the user.

This generator is based on advanced PWM control utilizing the specific integrated circuit. Analog signals are

digitized in A/D converter and processed within DSP circuits to provide maximum accuracy and reliability.

All feedback signals are sent to the user interface through digital and D/A circuits where switching is possible

between feedback and program signals. This allows the user to preset the desired output before energizing

high voltage.

All program voltages are typically ramped up to set level by the digital ramp generator.

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-8 118149-001 REV F

A-D and D-A converters and drivers provide system Fault Control and Indication. User interface is processed

on this PWB as well, providing isolated relay coils, opt couplers and open collectors contact.

1.3.7 Filament Power

The filament inverter provides the filament power for the X-ray tube. The filament inverter is a high frequency,

series resonant inverter. The inverter provides ac current to the primary of the filament isolation transformer.

The filament isolation transformer secondary is connected to the filament tube. The filament power is

2.25Vac/1.7Aac.

See Figure 1.2 for a simplified diagram of the X-RAY tube connection and current sensing circuits. The

filament circuitry also provides a variety of control, diagnostic and protection functions.

If any abnormal condition appears, monitoring circuitry will shut down the unit.

Figure 1.2 Simplified schematic of X-RAY tube connection

1.3.8 High Voltage Interlock

The XRB011 is equipped with safety interlocks for user personnel and equipment protection. An open interlock

circuit inhibits operation of the XRB011 MONOBLOCK.

POS HV MULT

NEG HV MULT

GND

+

-kV

+kV

FILAMENT

XFMR

X-RAY TUBE

ARC DETECT

mA Monitor

-

GND

GND

HV XFMR

HV XFMR

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-9 118149-001 REV F

1.4 SAFETY

1.4.1 Safety and Warning Symbols

WARNING: THIS X-RAY UNIT MAY BE DANGEROUS TO OPERATOR UNLESS SAFE EXPOSURE

FACTORS AND OPERATING INSTRUCTIONS ARE OBSERVED.

The following advisory symbols are used on the safety warning labels, and/or on circuit boards.

“CAUTION” symbol used to indicate a potential

hazard to operators, service personnel or to the

equipment.

“CAUTION” symbol used to indicate an X-RAY

RADIATION EXPOSURE, is hazard to operators,

service personnel or to the equipment.

Protective Earth

IEC 60417-5017

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual –XRB011 Page 2-10 118149-001 REV F

CHAPTER 2

INSTALLATION

CONTENTS:

2.1 INTRODUCTION........................................................................................................................................................11

2.2 UNPACKING ..............................................................................................................................................................11

2.3OVERALL CONNECTIONS................................................................................................................................................12

2.4INPUT POWER VOLTAGE........................................................................................................................................13

2.5CABLE CONNECTION ILLUSTRATION..............................................................................................................................13

2.5.1 MULTI INTERFACE CABLE CONNECTIONS.......................................................................................................13

2.5.1 Pin Layout of the Multi interface .............................................................................................................................14

2.5.2 GROUND CONNECTION ..........................................................................................................................................14

2.5.3 CHASSIS GROUND .........................................................................................................................................................15

2.5.4 X-RAY PORT............................................................................................................................................................15

2.6FINAL CHECKS..........................................................................................................................................................15

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual –XRB011 Page 2-11 118149-001 REV F

2.1 INTRODUCTION

This Chapter contains instructions for unpacking the XRB011 MONOBLOCK, allowing for initial power-up

and exposures.

2.2 UNPACKING

WARNING: THE XRB011MONOBLOK WEIGHS APPROXIMATELY 20 POUNDS (9.07 KG) IN ITS

SHIPPING CONTAINER.

1. Inspect the package exterior for evidence of damage due to handling in transit. Notify the carrier

and Spellman immediately if damage is evident. Do not destroy or remove any of the packing

material used in a damaged shipment.

2. Remove the cardboard outer pack. See the cautionary note below before removing the pack.

CAUTION: OPEN THE CARDBOARD PACK CAREFULLY. SHARP TOOLS MAY DAMAGE THE

CONTENTS.

3. Set aside the cardboard pack(s).

4. After unpacking, inspect the panel and chassis for visible damage.

5. Keep the shipping containers. In case of shipping damage, place the unit(s) back in its shipping

pack and notify the carrier and the Customer Support Department as shown on the inside cover

page of this manual.

6. Fill out and mail the Warranty Registration card accompanying the unit. Spellman XRB011

MONOBLOCK is covered by warranty.

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual –XRB011 Page 2-12 118149-001 REV F

2.3 OVERALL CONNECTIONS

NOTE: THIS IS BASIC CONNECTION ILLUSTRATION FOR TESTING. MORE COMPLEX AND

DEDICATED CIRCUITRY IS NEEDED IN ULTIMATE APPLICATION.

All cables should be routed away from the X-Ray port, and dressed and secured neatly in place. Cables

should be cut to the correct length if possible as excess cabling may contribute to EMI/RFI problems. For

those cables that cannot be cut to the correct length, try to minimize the area inside any loops of excess

cable, as these loops are in effect an antenna.

Figure 2-1: XRB011 I/O location

GND

RJ45

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual –XRB011 Page 2-13 118149-001 REV F

Figure 2-2: Overall connection

2.4 INPUT POWER VOLTAGE

1. Check the input voltage rating on the nameplate of the supply and make certain that this is the

rating of the power source to be connected.

2. Units operate on 24VDC, 2.5A (20W option), 4A (50W option).

3. DO NOT SWITCH ON MAINS POWER AT THIS TIME.

2.5 CABLE CONNECTION ILLUSTRATION

2.5.1 MULTI INTERFACE CABLE CONNECTIONS

Multi Interface connections include digital I/O, serial communication, and interlock. Operator must verify

and connect every signal properly though some of them are optional, before initiating power-up and basic

test.

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual –XRB011 Page 2-14 118149-001 REV F

The interlock, serial communication and exposure buttons interface shall be made available via a multi

signal cable. Refer to *-* for a schematic of isolation and signal direction.

2.5.1 Pin Layout of the Multi interface

The multi signal interface shall have a female 25 pin D-Sub (J1). Twisted pairs shall be used where

applicable. The pin layout is given in Table 2-3.

PIN

SIGNAL

PARAMETERS

1

+24V

+24Vdc±1Vdc @ 4A

2

+24V

+24Vdc±1Vdc @ 4A

3

+24V

+24Vdc±1Vdc @ 4A

4

NC

No connection

5

+24V RETURN

+24V RETURN

6

+24V RETURN

+24V RETURN

7

+24V RETURN

+24V RETURN

8

Signal Ground

Signal Ground

9

Interlock Input

Input, Active low, Interlock is low safe to enable high

voltage. Connect to +24V Return

10

kV Monitor

Output, 0 to 8V = 0 to rated output voltage. Zout=100Ω

11

µA Monitor

Output, 0 to 10V = 0 to rated output current. Zout=100Ω

12

X-Ray Ready status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

13

X-Ray ON status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

14

Filament Standby status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

15

Over Voltage Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

16

Over Current Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

17

ARC Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

18

Filament Current Limit

Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

19

Signal Ground

Signal Ground

20

Interlock Output

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

21

µA Program

Input, 0 to 10V = 0 to rated output current. Zin=10kΩ

22

kV Program

Input, 0 to 8V = 0 to rated output voltage. Zin=10kΩ

23

X-Ray ON Command

Input, Active low,

Low (short)=X-Ray ON

High (open)=X-Ray OFF

Internal pull up resistor to +15V

24

Signal Ground

Signal Ground

25

Over Temp.

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

Table 2-3 Pin layout of multi signal connector

Refer to chapter 3 for detailed requirements and function descriptions.

2.5.2 GROUND CONNECTION

NOTE: THE INSTALLER SHOULD ENSURE THAT ALL CABLE CONNECTIONS TO THE

GENERATOR ARE SECURE, AND ALL CABLES EXTERNAL TO THE GENERATOR

ARE ADEQUATELY PROTECTED AGAINST ACCIDENTAL DISCONNECTION.

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual –XRB011 Page 2-15 118149-001 REV F

2.5.3 CHASSIS GROUND

The chassis of the XRB011 MONOBLOCK must be grounded to the local earth ground and also to the

tube housing ground.

2.5.4 X-RAY PORT

ENSURE THAT THE EXIT PORT IS PROPERLY MATED TO COLLIMATOR OR SATISFACTORILY

SHIELDED WITH LEAD PLUG TO LIMIT EXPOSURE TO LEAKAGE RADIATION.

X-ray Safety Procedures must be followed when testing this unit. The XRB011 is capable of producing

Lethal Voltages and X-ray Radiation. Only proceed with operation of the HVPS after

Consulting with the Manufacturer and verification of X-Ray setup for the proper precautions.

Reading this entire document.

NEVER OPERATE THIS UNIT WITH AN OPEN X-RAY EXIT PORT.

It is recommended not to allow leakage radiation exceeding 0.5mR/hr at 5cm from any surface of the

MONOBLOCK.

2.6 FINAL CHECKS

The room interface connections may now be completed. Before power on, user needs to check the items

as below finally.

When finished all wiring, check that all connections are tight and secure.

Check that all cables are dressed neatly outside the cabinet, and secured as necessary.

Check the ground connection again.

THIS EQUIPMENT GENERATES DANGEROUS VOLTAGES THAT MAY BE FATAL.

PROPER GROUNDING OF ALL HIGH VOLTAGE EQUIPMENT IS ESSENTIAL.

WARNING X-RAY RADIATION EXPOSURE IS HAZARDOUS

Failure to follow these procedures may void the warranty.

Check the input voltage rating on the nameplate of the supply and make certain that this is the rating of the available

power source. Spellman MONOBLOCKXRB011 operates on 24VDC±1VDC

WARNING

WARNING

Table of contents

Other Spellman Inverter manuals

Popular Inverter manuals by other brands

Hoymiles

Hoymiles HMS-800-2T Quick installation guide

Eguana

Eguana Evolve ESS AU 13 Installation & start?up guide

Duracell

Duracell Digital inverter 400 owner's guide

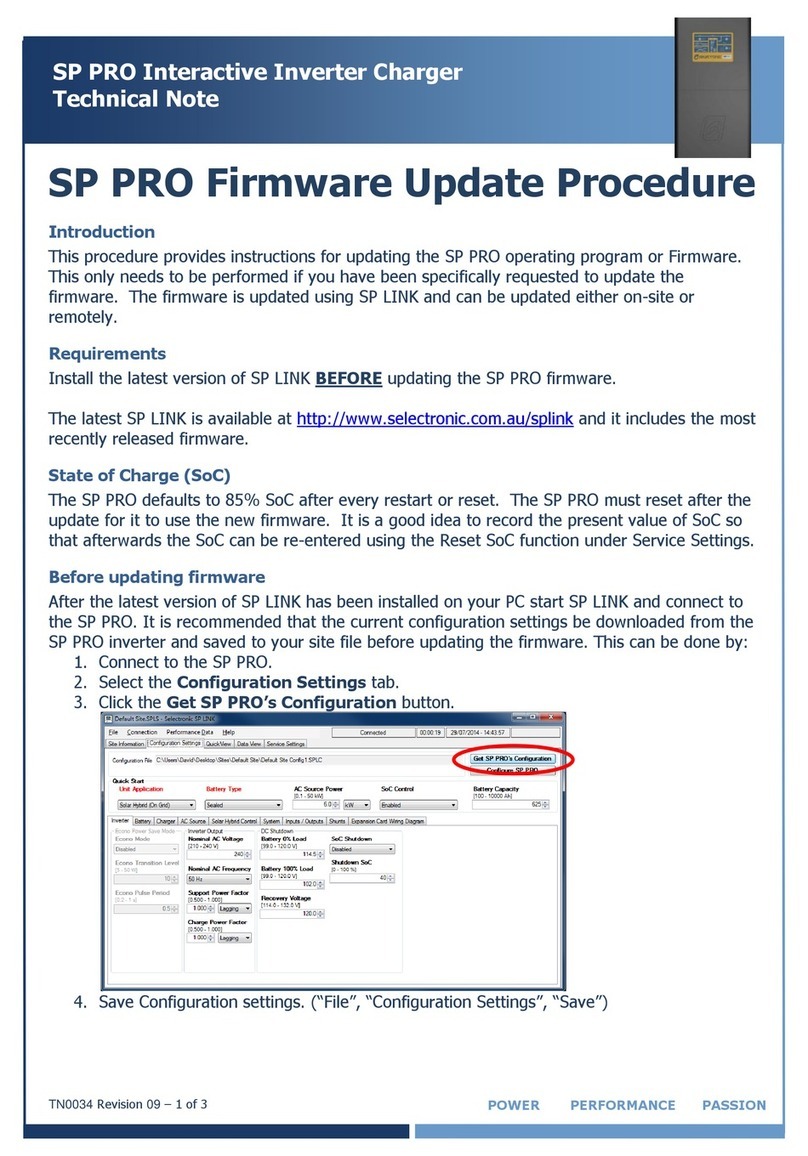

Selectronic

Selectronic SP PRO Series Technical note

SMA

SMA WINDY BOY 3300 installation manual

MLT Inverters

MLT Inverters Oasis 436 user manual