Senlan SB150 Series User manual

SENLAN INVERTER

USER’S MANUAL

SB150 Variable Speed Drive

Hope Senlan Science & Technology Holding Corp., Ltd.

Table of Contents

Preface ............................................................................................................................1

1. Notes on Safety...........................................................................................................3

1.1 Notes on Safety............................................................................................................................... 3

2 Specifications...............................................................................................................7

2.1 Common specifications for SB150 series ....................................................................................... 7

2.2 Product series................................................................................................................................... 8

4 Operation and commissioning .................................................................................20

4.1 Operation and display....................................................................................................................20

4.3 Quick and optimize commissioning.............................................................................................. 23

5 Parameter table.........................................................................................................25

7 Troubleshooting.........................................................................................................69

7.1 Faults and remedies ....................................................................................................................... 69

7.2 Alarms and remedies ..................................................................................................................... 71

7.3 Operation faults and remedies.......................................................................................................72

8 Maintenance andAfter-sale Service ........................................................................73

8.1 Daily maintenance.........................................................................................................................73

8.2 Replacement of parts .....................................................................................................................74

8.3 Storage of the inverter ................................................................................................................... 74

8.4 After-sale service........................................................................................................................... 74

Preface

1

Preface

Thank you for selecting Senlan SB150frequency inverter series.。SB150 is a compact inverter adopting the

optimized high-performance space vector control VVVF arithmetic and featuring elegant appearance, delicate

circuit design, ingenious circuit design, simple and practical functions, and reasonable menu arrangements, which

supports numerous advanced functions, e.g. auto torque boost, slip compensation, oscillation suppression, tracking

startup, stall prevention, precise deadband compensation, auto voltage stabilization, process identification and

auto carrier frequency adjustment.,the series are suitable for most industrial control applications.

This manual provides the user with a guide on installation & wiring, parameter setting, daily maintenance, fault

diagnosis and troubleshooting. The user is required to peruse the whole content of the manual carefully and be

familiarized with the relevant know-how and notes on inverter safety before any attempts of installation, setting,

operation and maintenance.

The technical specifications applied to this product or the content of this manual may be subject to any change

without prior notifying.

This manual is required to be kept properly until the inverter is out of its service life.

Items to Be Checked on Opening the Packing Case

The user is required to carefully check and confirm the following items on opening the packing case. If you have

any problem, don’t hesitate to contact us or your supplier for a solution.

What to Confirm How to Confirm

Is the inverter identical with the

product you’ve ordered?

Check if the nameplate inscriptions on the side of the inverter comply

with the requirements in your order

If there is any damages on the

product?

Check the overall appearance of the product to see if there are any

damages arising from transportation

Inverter Model Description

Senlan Inverter

SB150 Serie

1.5KW

T:3phase S:1phase

4:400Class 2:200VClass

A: Digital IO+Analog Interface Board

C:Digital IO+Communication Module

D:Digital Interface Board

F:Analog Interface+Digital Interface+Communication

Interface

None:Interface Board WithoutTerminal

E:Built-in EMC Filter

None:Without EMC Filter

Inverter Nameplate Inscriptions(Instance:SB150-1.5T4E-F)

Preface

2

SENLAN INVERTER

Hope Senlan Science and Technology Holding Co.,ltd

SLANVERT

Definition of Safety ID Markings

Any safety-specific content of this manual may use the following markings for identification. The user is required

to follow the instructions of the content identified with safety markings.

CAUTION: Any wrong operation or against the instructions may cause inverter damage or personal

injury/fatality.

CAUTION: Any noncompliant operation may cause abnormal system operation which, in serious

cases, may induce inverter damage or mechanical damage.

1 Notes on Safety

3

1. Notes on Safety

1.1. Notes on Safety

(1) Installation

The inverter must not be installed at places with combustibles or in the vicinity of combustibles;

otherwise there may cause fire.

The inverter must not be installed in an environment exposed to flammable gases; otherwise There

may cause explosion.

(2) Wiring

Confirm that the positive/negative busbar voltage is below 36V; otherwise there may be a risk of

electric shock.

Confirm that no wiring operation is permitted unless the power supply is thoroughly disconnected;

otherwise there may be an electric shock hazard.

Do not try to connect the DC terminals (DC+、DC-) directly with a dynamic braking resistor;

otherwise there may be a fire hazard.

The terminal voltage of the power supply must not exceed the rated voltage; otherwise there may be

inverter damage.

The grounding terminal (PE) of the inverter must be securely connected to earth (resistance to

earth≤10Ω); otherwise there may be a risk of electric fire.

(3)Check before switching on the power

Close the cover board of the inverter before turning on the power; otherwise there may be a risk of

electric shock or explosion.

Before trying to run the motor at a frequency over the rated motor frequency, conform that the

motor and the mechanical devices can endure such a high speed.

(4)Precautions on power and operation

Check to see if parameters are set appropriately before commissioning.

Do not open the front cover while the input power is switched on, for the high voltage inside may

cause electric shock.

Do not handle the inverter with wet hands. That may lead to electric shock.

“Power-on auto start” is enabled before shipment from the factory. When the terminal control and

the run signal are valid, the inverter will start automatically once the power is turned on.

Do not control the run and stop of the inverter by switching on and off the input power.

Related parameters should be reset after parameter initialization.

If the function of restart has been set (such as auto-reset or restart after momentary power failure),

do not approach the motor or mechanical load while the inverter is waiting to restart.

1 Notes on Safety

4

(5)Precautions on transport and package

Do not place more inverters than specified in the packaging box.

Do not put any heavy object on the inverter.

Do not open the cover board during transport.

Do not apply any force on the keypad and the cover board while handling the inverter, otherwise

there may be a risk of injury to people or damage to equipment.

(6)Disposal

Dispose the inverter as industrial waste.

The electrolytic capacitors inside the inverter may explode while burned.

Plastic components of the inverter will generate toxic gases while burned.

1.2 Other precautions

(1)About motor and mechanical load

Comparison with commercial power operation

SB150 inverter is a voltage-type PWM motor drive. Its output voltage contains some harmonics. Compared

with the commercial power, it creates more loss and noise and leads to higher temperature rise of the motor.

The insulation withstands voltage of the cables and motor should be taken into account when the input

voltage is high or the motor cables are long.

Constant-torque, low-speed operation

When a common motor runs at low speed for a long time, the motor temperature will rise due to the

weakening cooling effect. So if a motor is required to operate at low speed and constant torque for a long term, an

inverter or the forced air cooling method must be used.

Running above 50Hz

If you plan to run the motor over 50Hz, be aware that the vibration and noise will increase and make sure that

the motor bearings and mechanical devices can withstand such a high speed.

Lubrication of mechanical devices

While running at low speed for a long period, such mechanical devices as gearbox and gears may be

damaged due to worsening lubricating effect. Before you run them, check the lubrication conditions.

Load of regerative torque

Regerative torque often occurs while a load is hoisted, and the inverter often stops due to overvoltage

protection. In this case, an appropriate braking unit should be selected and installed.

Mechanical resonant point

Certain output frequencies of the inverter may be the mechanical resonant points. To avoid these points,

place anti-vibration rubber under the base of the motor or setting the jump frequencies.

Motor insulation check before connected to the inverter

1 Notes on Safety

5

When the motor is used for the first time or reused after it has not been used for a long period, the motor

insulation must be inspected to prevent the damage to the inverter cause by the failed insulation of the motor

windings. Use a 500V voltage-type megaohm meter to measure the insulation resistance, which should not be

less than 5MΩ.

DANGER:While performing the insulation test on the motor, be sure to disconnect the motor with the

inverter, otherwise the inverter will be damaged.

DANGER:Do not perform the voltage resistance test and insulation test on the control circuit,

otherwise the circuit elements will be damaged.

(2) About inverter

Capacitor or voltage-dependent resistor for improving power factor

As the inverter output is of PWM voltage type, the capacitor or voltage-dependent resistor(for improving

the power factor) installed on the output side of the inverter will lead to inverter trip or damage to

components. Do remove the capacitor or the voltage-dependent resistor before using the inverter.

Frequent start and stop

For applications where frequent start and stop are needed, terminals are recommended for the control of the

start/stop of the inverter. Using the switching device(such as contactor) on the inverter input side to start or

stop the inverter frequently is prohibited. That may destroy the inverter.

Using the inverter beyond the rated value

It is not recommended to operate the inverter beyond the range of the allowable input voltage. If the inverter

has to be used beyond the range, increase or decrease the voltage via a voltage regulator.

Lightning protection

With the built-in protection of overvoltage from lightning, the inverter has certain self-protection ability

against the lightning strike.

Leakage protector

The high-speed switching operation during the running of the inverter will generate high-frequency current

that sometimes causes the mis-operation of the leakage protection circuit. To address this issue, moderately

lower the carrier frequency, shorten the wires or install a leakage protector.

Observe the following points while installing the leakage protector.

1) The leakage protector should be installed on the inverter input side, preferably behind the air

switch(non-fuse circuit breaker).

2) The leakage protector should be one that is insensitive to higher harmonics or specially designed for the

inverter(sensitivity above 30mA). If a common leakage protector is selected, its sensitivity and action time should

be greater than 200mA and 0.2s, respectively.

Derate of inverter

a) If the ambient temperature exceeds 40℃, the inverter should be derated by 5% for every 1℃

increase, and external forced cooling should be provided.

1 Notes on Safety

6

b) If the altitude is above 1000 meters, the inverter should be derated by 1% for every 100m rise

c) .If the carrier frequency is greater than the factory setting, the inverter should be derated by

5% for every 1 kHz increase.

2Specifications

7

2 Specifications

2.1 Common specifications for SB150 series

Item Description

Rated voltage and

frequency

3-phase: 220v/380V,50/60Hz

Input

Allowable range Voltage: 320~420V; voltage imbalance<3%; frequency:47~63 Hz

Output voltage 3-phase, 0V~input voltage, with the error less than 5%.

output Output frequency

range

V/F control: 0.00~650.00Hz

Vector control: 0.00~200.00Hz

Overload capacity 150%of rated current for 1 minute

Frequency

resolution

Digital reference: 0.01Hz Analog reference: 0.1%of max. frequency

p

erformance

standard

Output frequency

precision

Analog reference: :±0.2%of max. frequency(25±10℃)

Digital reference: 0.01Hz

Communication Built-in RS485 port, supporting Modbus protocol

Analog input AI 2 channels AI(also used as digital input),voltage or current type, positive or

negative, with drop detection

Analog output AO 1 channels AO,voltage or current type independent terminal to choose

Digital input 5 channels of multi-function digital input(two of them are analog inputs),

sampling period 1ms

Control

terminal

Digital output 1 channel of NPN multi-function digital output,1 channels of multi-function

relay output

Motor control

mode

Space vector V/F control, with auto torque boost and slip compensation

Command source Keypad, terminal and communication. They can be switched over by terminals

Frequency

reference source

Keypad(keys and POT), communication, UP/DOWN value, AI1, AI2 and PFI.

Auxiliary frequency reference can be introduced for fine tuning

V/F curve Linear curve and two reduced-torque curves, with manual and auto torque

boost

Dynamic braking Built-in braking unit and external braking resistor

DC braking Braking time: 0.0~60.0s

Braking current: 0.0~100.0%of rated current

Accel/decel Linear or S-curve acceleration/deceleration

Jog Jog frequency: 0.10~50.00Hz

AV R Keeps the output voltage constant automatically when the voltage of power grid

fluctuates

Auto carrier

regulation

Carrier frequency is regulated automatically based on the load characteristic

and ambient temperature

Momentary power

failure

Ensures uninterrupted operation by controlling the DC link voltage

Process PID process PID adjustor, can do 4 references, can disable terminals, and provide

PID revise mode, sleep function (suit for water supply industry)

Wobble Ensures even winding of textiles

Multistep

frequency

7 multistep frequencies.,selected by digital input terminal.

Software

function

others Smooth start, stall prevention, zero-speed delay, oscillation suppression,

deadband compensation

Protection functions Overcurrent, overvoltage, undervoltage, input/output phase loss, output

short-circuit, overheating, motor overload, external fault, analog input

2Specifications

8

Item Description

disconnection, stall prevention, etc.

Options Braking resistor、input/output reactor、EMI filter、Profibus-DP module、remote

control box、LCD keypad etc.

Service site

Altitude less than 1000 meters; indoor; no direct sunlight; free of dust,

corrosive gases, inflammable gases, oil mist, water vapor, water drops, salt

mist, etc.

Temperature/humid -10~+40 /20℃~90%RH, no condensation

Storage

temperature

-20~+60℃

Ambient

Vibration Less than 5.9m/s2(0.6g)

Protection degree IP20

Structure Cooling method Forced air cooling, with fan control

2.2 Product series

SB150 inverter rated value is as follows:

Model Rated capacity(kVA)Rated output current

(A)

Applicable motor

(kW)

SB150-0.4S2 1.1 3 0.4

SB150-0.75S2 1.7 4.5 0.75

SB150-1.1S2 2.3 6.0 1.1

SB150-0.4T2 1.1 3 0.4

SB150-0.75T2 1.9 5 0.75

SB150-1.5T2 2.8 7.5 1.5

SB150-0.4T4 1.0 1.5 0.4

SB150-0.75T4 1.6 2.5 0.75

SB150-1.5T4 2.4 3.7 1.5

Outline drawings of model type SB150-0.4~SB150-1.5

Inverter Outline Drawing

4 Operation and commissioning

20

4 Operation and commissioning

4.1 Operation and display

4.1.1 Functions of keypad

The keypad is used to set or browse parameters, control operations, display error information and so on. The

appearance of the keypad is as follows.

-+

Status light Unit light

Operation key run Stop key stop fault reset

Description of keys on the keypad:

Key Name Function

Menu/Enter 1、Enter each menu

2、Data storage confirmation

Shift /Exit

1、Select the data digit to be modified; switch

between monitored parameters

2、Under the status of parameter modification

and return to the previous menu.

3、Constantly press 3 seconds and return to the

previous menu.

Decrease number

(-)Key

-+

Increase number

(+)Key

Inc/Dec number or data

Description of keys on the keypad:

Indicators Unit Indicators Unit Indicators Unit

Hz

A

V

4 Operation and commissioning

21

Indicators Unit Indicators Unit Indicators Unit

r/min

m/s

%

Meanings of three indicators status

Indicator Status Inverter state

Off Standby state

On Stable run state

RUN indicator

Blinking Accelerating or decelerating state

Off Both preset and current direction are forward

ON Both preset and current direction are reverse

REV indicator

Blinking Preset direction is inconsistent with current direction

Off Keypad control

ON Terminal control

EXT indicator

Blinking Communication control

4.1.2 Display status and operation of keypad

The keypad of SB150 has the following display status: monitoring status(including in standby state and in run

state), parameter editing status, fault display status, alarm display status, etc.

Monitoring

status 1st-level menu 2nd-level menu

Press 3secs quit

Display monitored

parameters cyclically

Press 3secs quit

Select digit to be

modified

Inc/Dec parameters value

Select digit to be

modified

Monitoring status in standby state

Pressing in this status cyclically displays the standby-state parameters(defined by FC-01~FC-04)

Monitoring status in run state

Pressing in this status cyclically displays the run-state parameters(defined by FC-01~FC-07)

4 Operation and commissioning

22

Parameter editing status

In monitoring status, pressing enters the editing status, which contains second level menus: parameter

group number→serial number in parameter group→parameter value. Pressing enters the next menu and

pressing 3 second, returns to the previous menu(returns to monitoring status if at the first level menu).

Pressing change the parameter group numbers, serial numbers in parameter group or parameter values. .

Under the second level menu, the digit which can be edited blinks. Pressing switches the digit to be

edited to another digit, and pressing saves the modified data and returns to the first level menu, and the

next parameter is displayed.

Password check status

If there is a user password(F0-12 not equal to zero),before you can edit any parameter you enter the password

check status and “――――” is displayed. Input the password with 、 (“――――” is displayed

during input)and press If the password is not correct, “Err” blinks. At this moment, press

returning to the password check status and press again exiting the password check status. If there is no

any keystroke within ten minutes, the password protection will take effect automatically.

Fault display status

Once the inverter detects a fault signal, the keypad enters the fault display status, and the error code blinks. The

fault can be reset by inputting reset command ( key, control terminal or communication command). If

the fault still exists, the error code continues to blink, during this period you can modify related parameters to

eliminate the fault.

4 Operation and commissioning

23

Alarm display status

When the inverter detects the alarm information, the alarm code blinks. If there are multiple alarm signals, the

alarm codes display alternately. The alarm information can be temporarily hidden by pressing or

. The alarm signal is automatically removed if normal state is recovered. The inverter does not stop in

alarm display status.

4.2 Switching on the power for the first time

Connect the wires in accordance with the technical requirements specified in section 3.4.

After checking the wiring and power supply, close the air switch of the AC power on the inverter input side.

“8.8.8.8.8” will fist be displayed on the keypad of the inverter. When the contactor inside the inverter is closed

normally, the display becomes the reference frequency. This shows the inverter initialization has been completed.

If anything unusual occurs when the power is turned on, disconnect the air switch and check and remove the error.

4.3 Quick and optimize commissioning

SB150series inverter is controlled by keypad, the frequency setting is digital setting, refer to 3.4.1 to check the

terminal function

Below is some common and necessary settings of SB150 inverter besides default setting.

1、Frequency setting channel and reference frequency: refer to page 37;

2、Command source: refer to F0-02, page40;

3、Maximum frequency, upper-limit frequency lower-limit frequency and max. output voltage : refer to F0-06,

F0-07, F0-08 and F2-10, make sure F0-06≥F0-07>F0-08.

4 Motor run direction: refer to F0-05, page38;

5、Accel/decel time: the accel/decel time should be as long as possible. Too short time will cause overcurrent

or overlarge torque which damages the load, refer to page39;

6、Start and stop mode: refer to F1-04 and F1-08, page 42;

7、Motor parameters: rated power, motor pole number, rated current, rated frequency, rated speed and rated

voltage. Refer to page 44。

SB150 optimize commissioning:

1、F2-00“Manual torque uprising amplitude”: If the current at the start is too large, reduce the value, refer

to page 42;

2、It is recommended to boost the torque automatically in order to increase the inverter’s starting torque and

its output torque at low speeds.,refer to page 42

3、Slip compensation can ease the speed drop caused by the load. It is only valid when “auto torque boost” is

valid, refer to page 43;

4 Operation and commissioning

24

4、Vibration damping: If the motor vibrates, increase this parameter gradually until the vibration disappears.

Refer to F2-06.

5 Parameter table

25

5 Parameter table

Note: In the “Change” column of the table below, “O” indicates the parameter can be changed in any state, “×”

indicates the parameter is only changeable in running state, while “△” indicates the parameter is read only.

F0 Basic Parameters

No. Name Setting range Default Chan

ge page

F0-00 Digital reference

frequency 0.00~650.00Hz 50.00Hz ○37

F0-01 Main reference

channel

0:F0-00digital setting

2:AI1

4:UP/DOWN value

1:Communication

3:AI2

5:Keypad POT

0 ○37

F0-02 Command source

1:Keypad

2:Terminal,invalid

3:Terminal,valid

4:Communication,invalid

5:Communication,valid

1 ×37

F0-03 Frequency holding

0: Saved upon power loss

1: Restored to F0-00 upon power loss

2: Restored to F0-00 upon power loss or stop

Note: For keypad digital potentiometer, revise by

or communication setting

0 ○38

F0-04 Auxiliary reference

channel

0:None 1:Communication setting

2:AI1 3:AI2

4:UP/DOWN value

0 ○38

F0-05 Direction lock 0: Forward or reverse 1: Forward only

2: Reverse only 0 ○38

F0-06 Max. frequency 0.00~650.00Hz 50.00Hz ×38

F0-07 Upper-limit frequency 0.00~650.00Hz 50.00Hz ×38

F0-08 Lower-limit frequency 0.00~650.00Hz 0.00 Hz ×38

F0-09 Inverter rated capacity Min. unit:0.01kW

Depend

s on

model

△38

F0-10 Software version 0.00~99.99

Depend

s on

version

△38

F0-11 Parameter

initialization 11:initialization 22:clean fault log 00 ×38

F0-12 User password 0000~9999,0000 means no password 0000 ○38

5 Parameter table

26

F1 Accel/decel, start, stop and jog parameters

No. Name Setting range Default Cha

nge Page

F1-00 Accel time 1

F1-01 Decel time 1

F1-02 Accel time 2

F1-03 Decel time 2

0.1~3600.0s

Acceleration time: time period over which the

frequency rises by 50Hz.

Deceleration time: time period over which the

frequency drops by 50Hz.

Inc/Dec time 2 is also be used as jog Inc/Dec

time.

6.0s ○39

F1-04 Starting mode 0:Start from starting frequency 1:Start

from searched speed 0 ×39

F1-05 Starting frequency 0.00~60.00Hz 0.50Hz ○39

F1-06 Starting delay time 0.0~60.0s 0.0s ○39

F1-07 Starting frequency

duration 0.0~60.0s 0.0s ○40

F1-08 Stop mode 0: Slowdown stop 1: Coast stop

2: Slowdown+DC braking 0 ○40

F1-09 DC braking frequency (at

stop) 0.00~60.00Hz 0.50Hz ○40

F1-10 DC braking waiting time 0.0~10.0s 0.0s ○40

F1-11 DC braking / Zero-speed

delay time 0.0~60.0s 0.0s ○40

F1-12 DC braking current 0.0~100.0%,rated current is100% 50.0%○41

F1-13 Jog frequency 0.10 ~50.00Hz ,jog use the second set

Inc/Dec time. 5.00Hz ○41

F1-14 Accel/decel mode 0: Linear 1: S-curve 0 ×41

F1-15 S-curve accel start-stage

time 0.01~10.00s 0.20s ○41

F1-16 S-curve accel end-stage

time 0.01~10.00s 0.20s ○41

F1-17 S-curve decel start-stage

time 0.01~10.00s 0.20s ○41

F1-18 S-curve decel end-stage

time 0.01~10.00s 0.20s ○41

F2 V/F control parameters

No. Name Setting range Default Cha

nge Page

F2-00 Manual torque boost

level

0.0~15.0%Depends on

model ○42

F2-01 Manual torque boost

cut-off point

0.00~650.00Hz 50.00Hz ○42

5 Parameter table

27

No. Name Setting range Default Cha

nge Page

F2-02 Auto torque boost level 0.0~100.0%80.0%×42

F2-03 Slip compensation gain 0.0~300.0%0.0%○43

F2-04 Slip compensation

filtering time

0.1~25.0s 1.0s ×43

F2-05 Torque boost 0: No boost 1: Manual

2:Auto 3:Maunal+auto 1 ×43

F2-06 Vibration damping 0~200 20 ○43

F2-07 AVR function 0: Inactive 1: Active

2: Active except during decel 1 ×44

F2-08 V/F curve

0:Linear 1:Reduced-torque V/F curve 1

(1.5)

2:Reduced-torque V/F curve 2 (2.0)

0 ×44

F2-09 Base frequency 1.00~650.00Hz 50.00Hz ×44

F2-10 Max. output voltage 200V class:75~250V,default 220V

400V class:150~500V,default 380V

220V

380V ×44

F3 Motor parameters

No. Name Setting range Default Cha

nge Page

F3-00 Motor rated capacity 0.40~1.5kW Depends on

model ×44

F3-01 Pole number 2~16 4 ×45

F3-02 Motor rated current 0.5~7.5A Depends on

model ×45

F3-03 Motor rated frequency 20.00~650.00Hz 50.00Hz ×45

F3-04 Rated rotation speed 12.5~4000(x10)r/min Depends on

model ×45

F3-05 Motor cooling condition 0: Common motor

1: Inverter-controlled motor 0 ○45

F3-06

~

F3-09

Reserved

-

-- -

F4 Digital input terminals and multistep speed

No. Name Setting range Default Cha

nge Page

F4-00 X1/AI1 terminal 0

F4-01 X2/AI2 terminal 5

F4-02 X3 terminal

0:No signal

±1:Multistep frequency

1

±2:Multistep frequency

2

±3:Multistep frequency

3

±4:Accel/decel time

select

±14:3-wire stop

command

±15:Internal virtual FWD

terminal

±16:Internal virtual REV

terminal

±17:Accel/decel disabled

±18:Run command

switched to terminal or 6

×45

5 Parameter table

28

No. Name Setting range Default Cha

nge Page

F4-03 FWD terminal 15

F4-04 REV terminal

±5:External fault input

±6:Fault reset

±7:Jog forward

±8:Jog reverse

±9:Coast stop /

Operation disabled

±10:UP/DOWN

increase

±11:UP/DOWN

decrease

±12:UP/DOWN clear

±13:Process PID

disabled

keypad.

±19:Reference frequency

switched to AI1

±20:Multi-PID select 1

±21:Multi-PID select 2

±22 :Wobble frequency

injection

±23:Wobble state reset

Note :Plus sign

means low level is

valid, while minus

sign means high

level is valid

16

F4-05 Digital input terminal

anti-jittering time 0~2000ms 10ms ○45

F4-06 FWD/REV mode

0: 1-wire mode(start/stop)

1: 2-wire mode 1(FWD, REV)

2: 2-wire mode 2(start/stop, direction)

3: 2-wire mode 3(start, stop)

4: 4-wire mode(pulse type start/stop、direction)

5:3-wire mode 1(FWD, REV, stop)

6:3-wore mode 2(run, direction, stop)

1 ×45

F4-07 UP/DOWN regulation

mode

0: Level type(terminal) 1: Pulse

type(terminal)

2: Level type(keypad) 3: Pulse

type(keypad)

0 ○47

F4-08 UP/DOWN speed/step 0.01~100.00,unit is%/s or %1.00 ○48

F4-09 UP/DOWN memory

select

0: Stored on power loss

1: Cleared on power loss

2: Cleared at stop and on power loss

0 ○48

F4-10 UP/DOWN upper limit 0.0~100.0%100.0%○48

F4-11 UP/DOWN lower limit -100.0~0.0%0.0%○48

F4-12

~

F4-18

Multistep frequency 1~

7

0.00~650.00Hz

Note: The default values of multistep

frequencies 1~ 7are their respective frequency

code numbers, for example, the default value

of the multistep frequency 3 is 3.00Hz.

n.00Hz

(n=1~7) ○49

F5 Digital and relay outputs

No. Name Setting range Default Cha

nge Page

F5-00 Y1 terminal

0: Inverter ready

±1: Inverter running

±2: Frequency reach

±3: Frequency reach

±7: Restart after momentary

power failure

±8: Alarm output

±9: Reverse running

1 ×49

5 Parameter table

29

No. Name Setting range Default Cha

nge Page

F5-01 T1 relay output

detection signal

±4: Fault output

±5: Undervoltage

lockout

±6: Fault auto-reset

±10:Process PID sleep

±11: Wobble frequency

upper/lower limit

±12: Feedback exceed upper

limit alarm

±13:Feedback low lower

limit alarm.

Note: Set minus indicates

output negate

4

F5-02 T1 terminal closing

delay 0.000s

F5-03 T1 terminal opening

delay

0.000~65.000s

0.000s

○49

F5-04 Frequency reach

detection band 0.00~650.00Hz 2.50Hz ○50

F5-05 Frequency reach

detection level 0.00~650.00Hz 50.00Hz ○50

F5-06 Frequency reach

detection hysteresis 0.00~650.00Hz 1.00Hz ○51

F6 Analog and pulse frequency terminals

No. Name Setting range Default Cha

nge Page

F6-00 AI1 Min. input analog

quantity 0 ○51

F6-01 AI1 Max. input analog

quantity

0.00~100.0%

100.0%○51

F6-02

AI1 Min. input analog

quantity corresponding

set value/feedback value

0.00%○51

F6-03

AI1 Max. input analog

quantity corresponding

set value/feedback value

0~100.00%

Note: set frequency use max. frequency as

reference value.

PID setting/feedback use percentage of PID

reference scalar. 100.0%○51

F6-04 AI1 filtering time 0.000~10.000s 0.100s ○51

F6-05 AI2 Min. input analog

quantity 0 ○51

F6-06 AI2 Max. input analog

quantity

0.00~100.0%

100.0%○51

F6-07

AI2 Min. input analog

quantity corresponding

set value/feedback value

0.00%○52

F6-08

AI2 Max. input analog

quantity corresponding

set value/feedback value

0.00~100.00%

Note: set frequency use max. frequency as

reference value.

PID setting/feedback use percentage of PID

reference scalar. 100.0%○52

F6-09 AI2 filtering time 0.000~10.000s 0.100s ○52

This manual suits for next models

9

Table of contents

Other Senlan Inverter manuals

Popular Inverter manuals by other brands

Zeus Appollo

Zeus Appollo Z20I4KT user manual

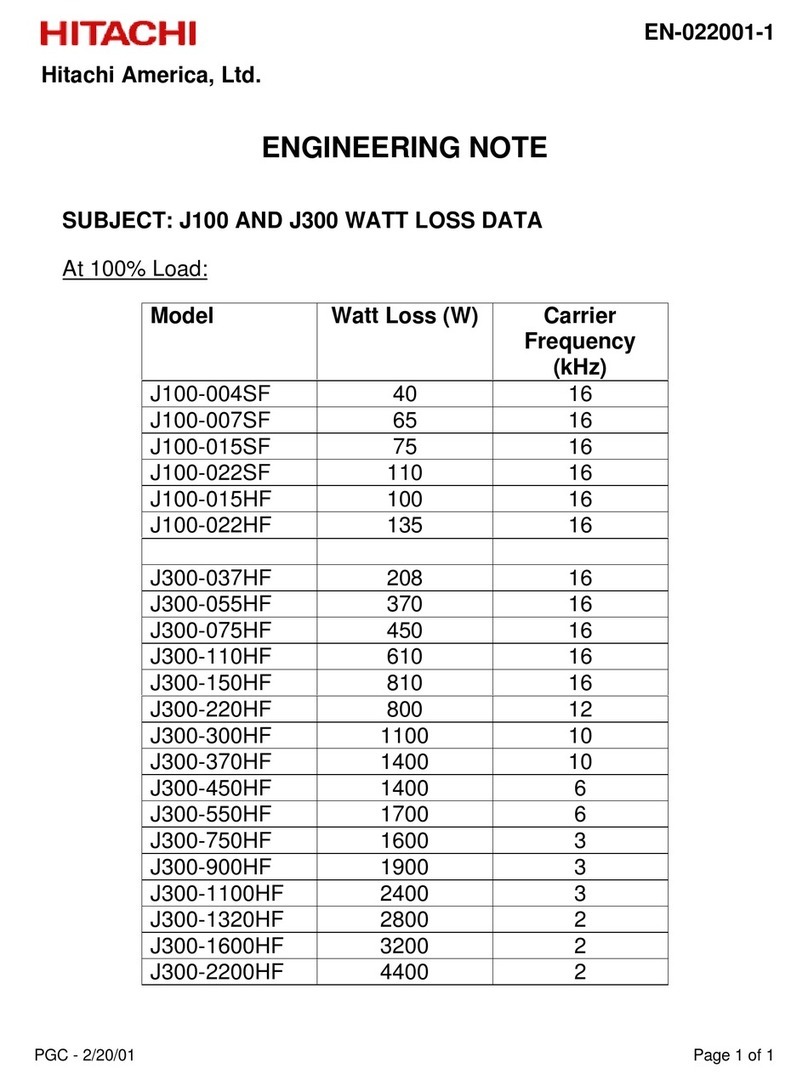

Hitachi

Hitachi J300 Series Engineering note

MIL-Solar

MIL-Solar Eclipse 5000-II Installation and operation manual

Powfuture

Powfuture Venus 3000TL user manual

Generac Power Systems

Generac Power Systems ECOGEN SERIES owner's manual

Samlexpower

Samlexpower 60S-12A instructions