Senlan SB40S0.75-1.5 User manual

This manual suits for next models

12

Table of contents

Other Senlan Inverter manuals

Popular Inverter manuals by other brands

Chicago Electric

Chicago Electric 92464 Assembly and operating instructions

SolarEdge

SolarEdge SE66.6KUS installation guide

HSS Hire

HSS Hire HW038 Operating & safety guide

SolaX Power

SolaX Power X1 Series user manual

SALUPO

SALUPO SOFT START PLUS 1 Instruction and installation manual

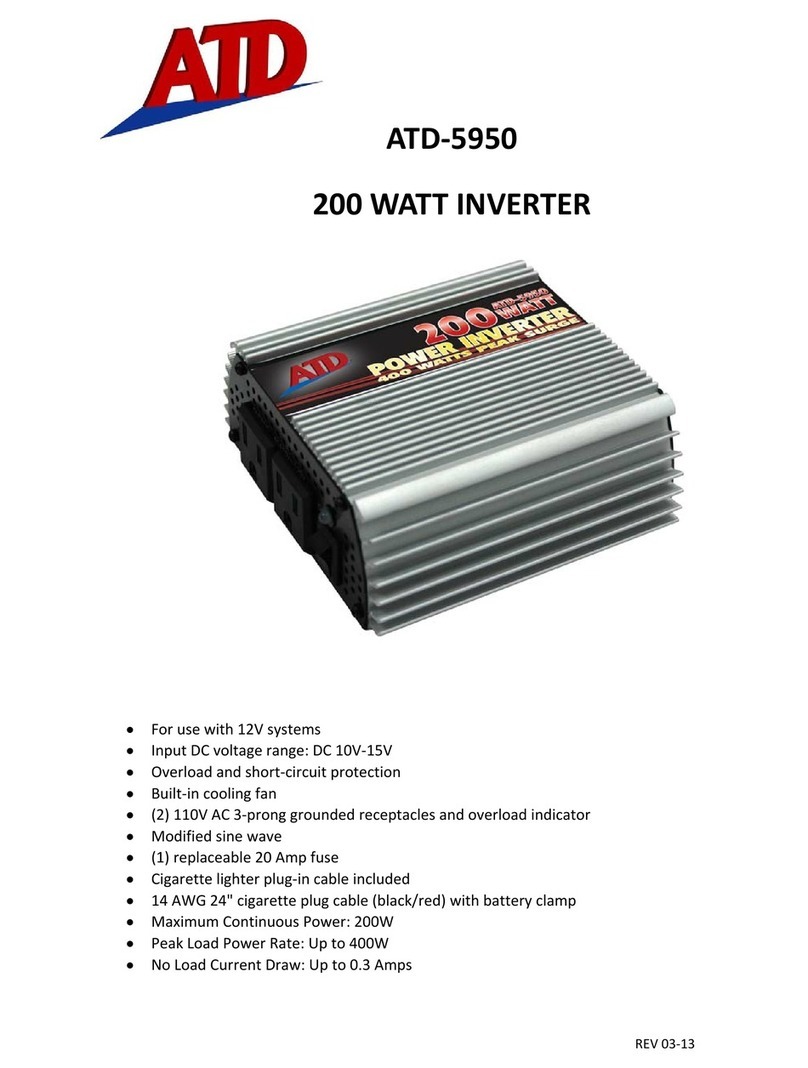

ATD Tools

ATD Tools ATD?5950 user guide

DORNA TECHNOLOGY

DORNA TECHNOLOGY DLM1-0D40S2G user manual

Samlexpower

Samlexpower Pure Sine PST-60S-12E owner's manual

Kaco

Kaco Powador 30.0 TL3 M/X operating instructions

IRONRIDGE

IRONRIDGE BX SYSTEM installation manual

Vector

Vector MAXX SST VEC049C owner's manual

Mitsubishi Electric

Mitsubishi Electric F700 instruction manual

Daikin

Daikin RKC09NV2S Service Manual Removal Procedure

Mid-Continent Instrument

Mid-Continent Instrument TRUE BLUE POWER TI1200 Series Installation manual and operating instructions

Hyundai power products

Hyundai power products 1500 quick start guide

ZUCCHETTI

ZUCCHETTI 50000TL user manual

PROLiNK

PROLiNK IPS Series user manual

INVT

INVT SPC Series Operation manual