Sens PowerCab 2 User manual

SENS PowerCab2 Technical Manual

1

SENS Part Number: 101343

Document Revision: A

DCN Number: 108523

Date: February 27, 2024

PATENTED US 9,270,140; 9,385,556; 9,413,186; 9,509,164;

9,466,995; 9,948,125; 10,575,433

Installation or service questions?

Call SENS between 8 a.m. and 5 p.m. (Mountain Time),

Monday through Friday, or visit our website.

Copyright © Stored Energy Systems LLC 2024

The SENS name / logo, PowerCab, HELIX, and Dynamic Boost are trademarks of Stored Energy Systems LLC

Installation & Operation Manual

PowerCab®2

Factory-packaged Non-stop DC Power Systems

1840 Industrial Circle

Longmont, CO 80501

Phone: 303.678.7500

800.742.2326

Fax: 303.678.7504

Email: service@sens-usa.com

Web: www.sens-usa.com

SENS PowerCab2 Technical Manual

2

TABLE OF CONTENTS

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR ............................................................ 4

2PERFORMANCE SPECIFICATIONS........................................................................................................................ 6

3MOUNTING INSTRUCTIONS.............................................................................................................................. 10

3.1. Mounting Location...................................................................................................................................10

3.2. Mounting Instructions.............................................................................................................................. 10

4SETUP AND WIRING .......................................................................................................................................... 11

4.1. Wire Ratings and Sizes .............................................................................................................................11

4.2. Grounding Instructions and Connection ..................................................................................................11

4.3. DC Distribution Connection...................................................................................................................... 11

4.4. AC Connection..........................................................................................................................................12

4.5. Standard Alarm Connections ................................................................................................................... 12

4.6. High Current Relay Connections—Optional............................................................................................. 13

4.7. CANbus Connections................................................................................................................................15

4.8. RS-485 Connections .................................................................................................................................15

4.9. Ethernet ................................................................................................................................................... 16

4.10. Service Connection................................................................................................................................... 17

4.11. Verify Connections ................................................................................................................................... 17

4.12. Verify Covers ............................................................................................................................................17

5START-UP PROCEDURE ..................................................................................................................................... 18

5.1. Connect Battery ....................................................................................................................................... 18

5.2. Verify Configuration.................................................................................................................................18

5.3. Apply AC Input Voltage ............................................................................................................................ 18

5.4. Connect DC Distribution Outputs.............................................................................................................18

5.5. Power Off ................................................................................................................................................. 18

6ALARMS, LEDS AND DISPLAY ............................................................................................................................ 19

6.1. LED Indicators...........................................................................................................................................19

6.2. Individual Alarm Relay Contacts...............................................................................................................20

6.3. LCD Panel .................................................................................................................................................20

6.4. Latched Alarms.........................................................................................................................................20

6.5. Alarm Definitions .....................................................................................................................................20

7OPERATION ....................................................................................................................................................... 26

7.1. Charging Algorithms................................................................................................................................. 26

7.2. Float Mode............................................................................................................................................... 26

7.3. Dynamic Boost™Mode ............................................................................................................................ 26

7.4. HELIX Mode..............................................................................................................................................26

7.5. Charging Low or Zero-volt Batteries ........................................................................................................27

7.6. Commissioning Batteries.......................................................................................................................... 27

7.7. Battery Check ........................................................................................................................................... 27

7.8. Shunt Trip AC Breaker—Optional............................................................................................................. 27

7.9. Restore Factory Defaults.......................................................................................................................... 28

7.10. Keypad Operation ....................................................................................................................................28

7.10.3. Menu Options ..........................................................................................................................................29

7.11. Configuration with SENS Setup Utility ..................................................................................................... 35

7.12. Protocol Communications Circuit Board..................................................................................................35

7.13. Temperature Compensation....................................................................................................................36

7.14. Efficiency ..................................................................................................................................................37

8SERVICE AND MAINTENANCE ........................................................................................................................... 38

8.1. Recommended Annual Maintenance....................................................................................................... 38

8.2. Power Module Access ..............................................................................................................................38

8.3. Air Filter.................................................................................................................................................... 38

8.4. Fans ..........................................................................................................................................................38

8.5. Supplemental Surge Protectors ...............................................................................................................38

9MODBUS COMMUNICATIONS .......................................................................................................................... 39

9.1. TCP/IP Modbus.........................................................................................................................................39

SENS PowerCab2 Technical Manual

3

9.2. Modbus RS-485 ........................................................................................................................................ 39

9.3. Modbus Holding Registers ....................................................................................................................... 40

9.4. Basic Charging Alarms Bit Definition........................................................................................................ 41

9.5. Charging Status Bit Definition ..................................................................................................................42

9.6. Charging Alarms Extended Bit Definition.................................................................................................43

9.7. Charging AC Alarms Bit Definition............................................................................................................43

9.8. Accessory Channel Alarms Bit Definition .................................................................................................43

9.9. Accessory System Alarms Bit Definition................................................................................................... 44

9.10. Accessory Assigned Channel Alarms Bit Definition..................................................................................44

9.11. Writable Control Flags (Coils) - Single coil writes: 0xFF00 for ON, 0x0000 for OFF .................................44

10 DNP3 COMMUNICATIONS—Optional .............................................................................................................. 45

10.1. TCP/IP DNP3.............................................................................................................................................45

10.2. RS-485 DNP3 ............................................................................................................................................45

10.3. SENS DNP3 Config Tool ............................................................................................................................ 45

10.4. Implementation Table.............................................................................................................................. 46

10.5. Binary Inputs ............................................................................................................................................47

10.6. Binary Outputs .........................................................................................................................................49

10.7. Analog Inputs ...........................................................................................................................................50

10.8. Analog Outputs ........................................................................................................................................51

11 NACL SALT BATTERY OPERATION—Optional ................................................................................................... 52

11.1. LED Indication .......................................................................................................................................... 52

11.2. Modbus TCP/IP......................................................................................................................................... 53

12 TROUBLESHOOTING/ERROR CODES................................................................................................................. 58

12.1. Reset Button............................................................................................................................................. 58

12.2. Configuration Error Codes........................................................................................................................ 58

12.3. Troubleshooting Guide............................................................................................................................. 59

13 GLOSSARY.......................................................................................................................................................... 66

SENS PowerCab2 Technical Manual

4

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR

1.1. SAVE THESE INSTRUCTIONS –This manual contains important safety and operating instructions for

PowerCab2 DC backup systems.

1.2. Before using system, read all instructions and cautionary markings on battery charger, battery, and product

using battery.

1.3. Use of an attachment not recommended or sold by the backup system manufacturer may result in a risk of

fire, electric shock, or injury to persons.

1.4. This backup system is intended for commercial and industrial use. ONLY TRAINED AND QUALIFIED

PERSONNEL MAY INSTALL AND SERVICE THIS UNIT.

1.5. Do not operate system if it has received a sharp blow, been dropped, or otherwise damaged in any way;

shut off power at the branch circuit protectors and have the unit serviced or replaced by qualified

personnel.

1.6. To reduce risk of electric shock, disconnect the branch circuit feeding the system before attempting any

maintenance or cleaning. Turning off controls will not reduce this risk.

1.7. Use appropriate lockout / tagout procedures to ensure safety of all personnel installing and servicing this

equipment. The AC, BATTERY and CHARGER breakers are equipped with provision to lock breakers in the

OFF position.

1.8. WARNING –RISK OF EXPLOSIVE GASES

1.8.1. WORKING IN THE VICINITY OF A BATTERY IS DANGEROUS. STORAGE BATTERIES MAY GENERATE

EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS REASON, IT IS OF UTMOST

IMPORTANCE THAT YOU READ THIS MANUAL AND FOLLOW THE INSTRUCTIONS EACH TIME YOU

USE THE CHARGER.

1.8.2. To reduce the risk of battery explosion, follow these instructions and those published by the battery

manufacturer and the manufacturer of any equipment you intend to use in the vicinity of a battery.

Review cautionary markings on these products and on the engine.

1.9. PERSONAL PRECAUTIONS

1.9.1. Someone should be within range of your voice or close enough to come to your aid when you work

near a storage battery.

1.9.2. Have plenty of fresh water and soap nearby in case battery electrolyte contacts skin, clothing, or

eyes.

1.9.3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near a

storage battery.

1.9.4. If battery electrolyte contacts skin or clothing, wash immediately with soap and water. If electrolyte

enters eye, immediately flood the eye with running cold water for at least 10 minutes and get

medical attention immediately.

1.9.5. NEVER smoke or allow a spark or flame in vicinity of battery or engine.

1.9.6. Be extra cautious to reduce risk of dropping a metal tool onto the battery. It might spark or short

circuit the battery or another electrical part that may cause explosion. Using insulated tools reduces

this risk but will not eliminate it.

1.9.7. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

storage battery. A storage battery can produce a short circuit current high enough to weld a ring or

the like to metal, causing a severe burn.

SENS PowerCab2 Technical Manual

5

1.9.8. When charging batteries, charge LEAD-ACID, LIQUID ELECTROLYTE NICKEL-CADMIUM, NICKEL-

ZINC or SODIUM-CHLORIDE batteries only. Consult SENS before using with any other type of

battery or changing battery type from originally supplied with system - other batteries may burst

and cause injuries to persons and damage to property. NEVER charge a frozen battery.

1.9.9. Consult national and local ordinances to determine if additional battery fault protection is necessary

in your installation.

1.10. Preparing Battery For Charge

1.10.1. Be sure area around battery is well ventilated while battery is being charged.

1.10.2. Ensure battery terminals are clean and properly tightened. Be careful to keep corrosion from

coming in contact with eyes.

SENS PowerCab2 Technical Manual

6

2PERFORMANCE SPECIFICATIONS

PowerCab2 factory-packaged non-stop DC power systems, specially hardened for use in harsh industrial

environments. Advanced technology switch mode power conversion is significantly smaller & lighter than

conventional line frequency (e.g. SCR) power conversion and, even without a battery connected, delivers lower

output ripple and much faster dynamic response.

Forced ConductionTM cooling keeps the high efficiency power electronics free of dust and dirt, making PowerCab2

well-suited for operation in industrial, utility, power plant, and other harsh environments. Two variable speed,

premium ball-bearing fans cool each rectifier. Rectifiers maintain nearly full output capability even if one fan fails.

A fan failure alarm system with local and remote indication enables service dispatch while the second fan

continues to run. The fan module is easily replaced in the field with common tools.

9 standard Form C contact alarms are factory set and field reconfigurable, with indication via communication port,

front panel LCD and five assignable alarm relays. Four additional high current alarm relays are optional.

Options include various cabinet size/configurations, NEMA 3R ingress protection, fans, heaters, batteries, DC

distribution breakers, supplemental surge suppression, and DNP3 data communications. Modbus data

communications comes standard with each system. Systems can be equipped with multiple communication

protocols. Specifications are detailed in the table below, see following sections for installation and operation

instructions. Multiple systems can be housed in a single cabinet, allowing for full redundancy or dual AC feed

systems.

Specifications

AC input

Voltage, frequency

Full output power: 358-528 VAC 3-phase line to line connected, 50% power

limit from 188-357 VAC. 47-63 Hz.

Input current

96A maximum at 358VAC (for maximum configured unit), see section 4.4

Overcurrent

protection

3-pole UL 489 listed circuit breaker

25 kAIC standard, 65 kAIC optional, lockable. Two breakers optional for dual

AC feed.

Optional breaker status provides indication and alarm when the AC breaker

is in open or tripped position

Optional breaker shunt trip provides input overvoltage damage protection

by turning off breaker when the input voltage exceeds an adjustable level

AC transient

protection

Layered electrical transient defenses. Optional UL1449 Type 1 Listed

supplemental surge protection, alarmed and with field replaceable

elements, surge capacity rated 75kA 8/20 µs; visual and remote indications.

Loss of phase

Continues operating with current limit reduced to 50%

Efficiency

Up to 95%, see section 7.14

Power Factory & Total

Harmonic Distortion

To 0.98 typical at maximum rated load current and boost charge voltage.

Total Harmonic Distortion <3%

DC output

Voltage

120 VDC or 240VDC nominal. 120VDC: output adjustable from 8-160V. 240

VDC: output adjustable from 16-320V. If AC voltage is not applied, charger

powers down below 60VDC.

Current

120VDC output limit: 56kW or 400A, whichever is less.

240VDC output limit: 56kW or 200A, whichever is less.

Soft Start

System gradually increases current with a maximum of 5 seconds to full-

required output

Charging modes

Multi-stage, including float, boost, HELIX and commissioning charge modes

Current limit

100% current capability subject to temperature limits and AC voltage limits;

field adjustable to max rated current.

SENS PowerCab2 Technical Manual

7

Charging

characteristic

Constant voltage, current limited; patented Dynamic Boost and HELIX

control

Line & load regulation

±0.5%

Output ripple

<30mV with battery, <100mV off-battery for 120VDC, <200mV off-battery

for 240VDC. Delivers fast-responding, stable, well-filtered DC without

battery.

Step response

8ms typical, to recover within 1% of rated output voltage from load step

change of 50% rated output current

Output protection

Electronic current limit. 2-pole UL 489 listed charger feed and battery main

circuit breakers.

Output ≤200A: 10 kAIC standard, 25 kAIC optional. Output >200A: 50 kAIC

standard, 100 kAIC optional. Lockable.

Optional breaker status provides indication and alarm when the Charger

breaker is in open or tripped position

DC distribution

Internal panel, 2-pole UL 489 circuit breakers, 22 or 34 positions

DC surge protection

Layered electrical transient defenses. Optional UL1449 Open Type 2 Listed

supplemental surge protection, alarmed and with field replaceable

elements, surge capacity rated 75kA 8/20 µs; visual and remote indications.

Includes replaceable fuses, refer to separately provided diagrams.

Batteries

Optional, type lead-acid, NiZn or NaCl (salt), 40-200Ah (varies based on

battery type). Optional battery monitoring.

DC power supply

operation

Delivers fast-responding, stable, well-filtered DC without battery

Battery temp.

compensation

Standard. On-board sensor modifies output voltage when temperature is

between 0°C and+40°C. Slope adjustable, factory set to –0.18% per degree

C. Optional remote battery monitor provides battery temperature probe.

Dead battery charge

Starts into and recharges zero-volt battery

Redundancy

Optional N+1 or N+2 redundancy provides more power modules than are

required to meet the rated output. All modules will actively share the load

up to the rated current of the system. Should a power module fail, each

remaining module will equally share the connected system load and battery

recharge demand.

Output blocking

protection

Prevents sparking during battery connection or during hot swap operation

Output Derating

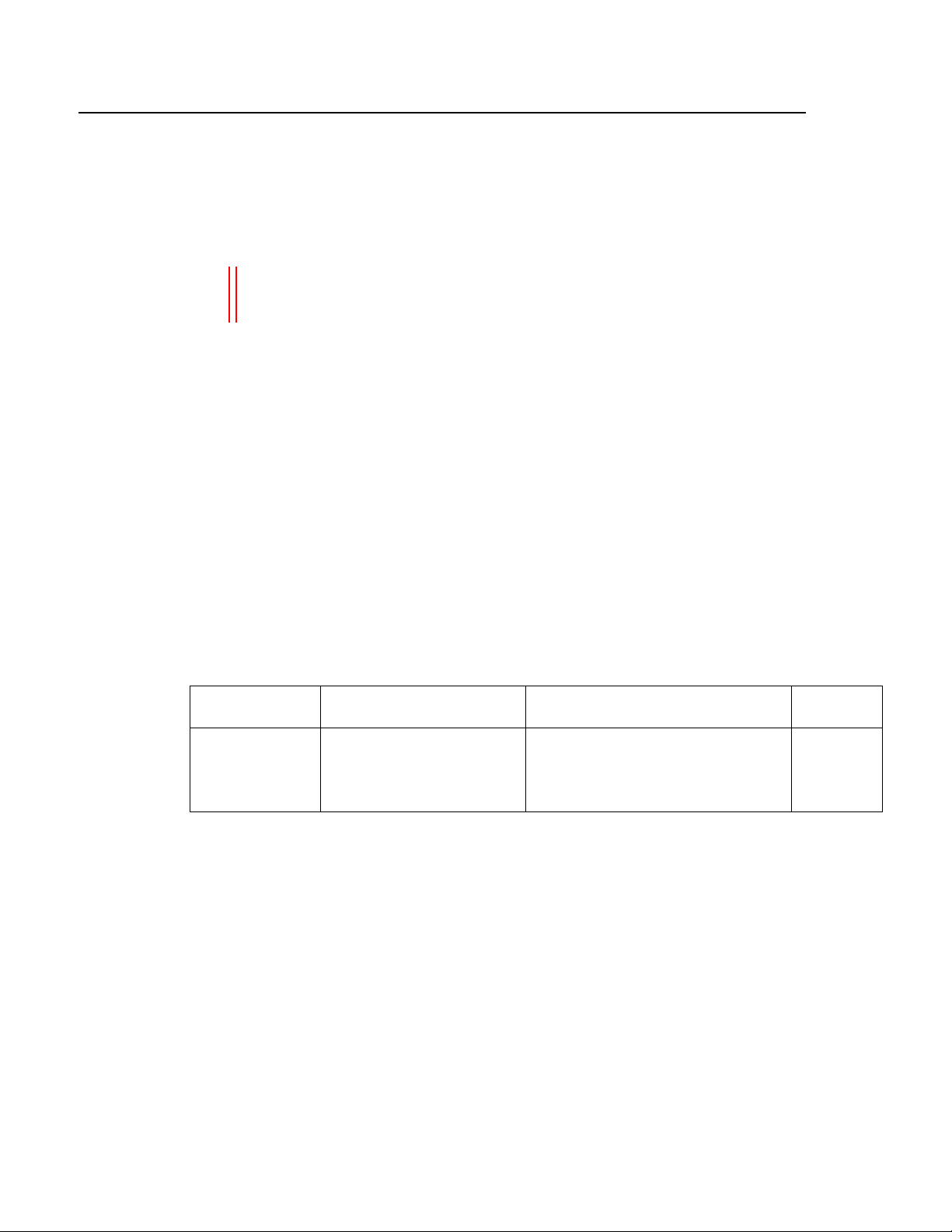

Input Voltage/#

Phases

% Output

Power

Available

Max. Available Output

Current Per Module*

140VDC

60VDC

30VDC

400-480VAC/3-ph

Full Rating

(7kW)

50A

50A

50A

400-480VAC/1-ph

50% (3.5kW)

25A

50A

50A

208-240VAC/3-ph

50% (3.5kW)

25A

50A

50A

208-277VAC/1-ph

25% (1.75kW)

12.5A

29A

50A

*120V-50A shown, divide current values in half for 240V-25A modules

Auxiliary DC power

supply

Optional, 12-48VDC, 300W, consumes one distribution breaker position

Auxiliary AC inverter

Optional, 120VAC 60Hz or 230VAC 50Hz, 600/1000/1100/2000/3000W

options, consumes one distribution breaker position

SENS PowerCab2 Technical Manual

8

Adjustment &

Controls

Charge mode control

Fully automatic patented Dynamic Boost system. Manual boost, timed

boost & & battery commissioning charging options are available from front

panel control.

Front panel control

Change all parameters including voltages, current limits, alarm parameters,

network configurations, time-outs, and more

Computer adjustment

Change all parameters, troubleshoot, create/save configuration files for

quick download to chargers using network connection and SENS Setup

Utility software available at www.sens-usa.com

Status

reporting

LEDs

Two multi-color front panel status LEDs

Metering

AC/DC Voltmeter accurate to ±1%; AC/DC ammeter to ±1%; AC frequency

meter to ±1.5%; DC Output Watts; DC Output as a percent of maximum

rated output

Status display

20-character display of status & alarm messages.

Alarms

Alarm Outputs

Factory set, field reconfigurable, latching and non-latching. Alarms available

via communication port, alarm relays, and on LCD.

Alarm Inputs

Two optional input contacts (via optional battery monitor) to monitor status

of, and modify charger operation based on, external devices such as battery

room fan or hydrogen monitor.

Alarm Form C

contacts

Nine Form C contacts, rated 30V, 2A resistive, assignable. Up to four

optional 120V, 5A resistive or 150VDC, 3A / 240VAC, 10A assignable.

Pilot relay functions

Form C contacts configurable as pilot relays to switch external loads based

on user-configurable conditions.

Networking

Modbus

Modbus RS-485 on terminal blocks or TCP/IP on RJ-45 port

DNP3

Optional DNP3 RS-485 on terminal blocks or TCP/IP on RJ-45 port

SENSbus

Proprietary bus for connection of paralleled chargers and SENS accessories

Environmental

Operating

temperature

-40°C to +70°C; full spec from -40°C to +50°C. Display may be unreadable

and suffer reduced life above 65°C. Cold starts down to -40°C.

Ingress protection

NEMA1/IP20 or NEMA3R/IP34

System fan

Optional cabinet door fan, thermostat controlled, turns on at +40°C,

includes replaceable fuses, refer to separately provided diagrams

Heater

Optional cabinet heaters, keeps batteries above freezing

Humidity

5% to 95%, non-condensing

Altitude

0-6,500 ft (2,000 meters). Above this altitude, output is derated 0.012% per

additional meter at rated ambient temperature.

Vibration & shock

resistance

EN60068-2-6, EN 60068-2-64 & EN 60068-2-27

Electrical transient

ANSI/IEEE C62.41, EN 61000-4-12 on power terminals, IEC 61000-6-5 and

ANSI/IEEE C37.90 (withstands 4kV line‐to‐line/line‐to‐earth without optional

AC surge protection, 6kV or greater with optional AC surge protection)

Abuse

protection

Reverse polarity

Charger self-protects without output protective device clearing. Indication

via LED & LCD.

Wrong voltage

battery

Charger-battery voltage mismatch shuts down charger after 5 minutes.

Indication via LED and LCD.

Overvoltage

shutdown

Selective; shutdown only operates if charger causes the overvoltage

condition

Overtemperature

protection

Gradual output power reduction if heatsink temperature becomes

excessive; recovery is automatic.

SENS PowerCab2 Technical Manual

9

Regulatory

Compliance

North America

C-UL Listed for US & Canada: UL 508A

NFPA-70, NEMA PE-5, PIP (optional)

FCC Part 15, Class A commercial use and ICES-003 (Canada)

Construction

Housing

Floor mount; integrated key lock

Housing material

Aluminum with powder coated finish or stainless steel

Weight

Refer to separately provided system diagrams for weight information

Cable entry

Rear, bottom or side access, refer to separately provided system diagrams

Network/Alarm

connections

Modbus: RJ-45 or terminal blocks 28 to 16 AWG. Form C alarms: 28 to 16

AWG.

Power connections

AC breaker: 14 –1/0AWG

DC Distribution breakers: ≤20A: 14 –10AWG. >20A: 10 –1/0AWG.

SENS PowerCab2 Technical Manual

10

3MOUNTING INSTRUCTIONS

INSTALLATION OF THE UNIT MUST COMPLY WITH LOCAL ELECTRICAL CODES AND OTHER APPLICABLE

INSTALLATION CODES AND BE MADE ACCORDING TO THE INSTALLATION INSTRUCTIONS AND ALL

APPLICABLE SAFETY REGULATIONS.

Printed circuit boards contain static sensitive components. Damage can occur even when static levels are too

low to produce a noticeable discharge shock. To avoid static discharge damage, handle circuit boards by the

panel they are installed on only. Remove covers only when access is essential for installation and service and

replace promptly when finished.

3.1. Mounting Location

See separately provided system diagrams for dimensions and mounting information.

3.1.1. System is rated NEMA1/IP20 or NEMA3R/IP34.

3.1.2. Charger will operate at full specification when located where temperatures are within -40°C

(-40°F) to +50°C (122°F). Output power is gradually reduced at higher temperatures.

3.1.3. Leave clear space around all system ventilation openings.

3.1.4. The cabinet is intended to be floor mounted. The mounting surface must safely support the

weight of the system and the fixed wiring.

3.1.5. Allow sufficient room for routing the fixed wiring to the system. All field connections wires enter

the system from the rear, top or bottom.

3.1.6. Do not mount the system above any heat generating equipment or where it could get wet.

3.2. Mounting Instructions

3.2.1. Drill floor mounting holes and mount system using dimensions on separately provided system

diagrams. Mounting hardware is not included with the system and must be provided by the

installer.

3.2.2. Mount the system before connecting AC, DC, communications and alarm wiring to ensure

unobstructed access to mounting holes.

3.2.3. Inspect the connections, busbars, and wiring for any loose debris or damage from installation.

3.2.4. Use all mounting points provided on the separately provided system diagrams.

3.2.5. Ensure all ventilation openings are clear and unobstructed.

SENS PowerCab2 Technical Manual

11

4SETUP AND WIRING

IMPORTANT! The system is configured at the factory and typically requires no adjustments before operating.

Refer to the label on the inside front door for factory configured output and alarm relay assignments. The system

may be reconfigured using the front panel keypad or by software programming using the SENS Setup Utility.

All wiring must comply with applicable codes and local ordinances. See separately provided system diagrams for

access covers and conduit entry holes. Disconnect wires to remove covers as needed; do not hang covers from

wires.

WARNING:

OPEN THE SYSTEM AC, CHARGER AND BATTERY BREAKERS TO ENSURE THAT AC AND

BATTERY POWER ARE DISCONNECTED BEFORE WIRING THE SYSTEM

4.1. Wire Ratings and Sizes

4.1.1. All power conductors should be rated for use at 90°C or higher and 600V or higher. Alarm relay

conductors and communications data cable should be rated for use at 75°C or higher.

4.1.2. Coordinate the AC input conductor size with the customer-provided feeder branch circuit

protection device.

4.2. Grounding Instructions and Connection

4.2.1. System must be grounded to reduce risk of electric shock. The system must be connected to a

grounded, metal, permanent wiring system, or an equipment-grounding conductor (earthing

conductor) must be run with the circuit conductors and connected to equipment-grounding

terminal on system.

4.2.2. Connect the equipment grounding conductor to the ground lug located inside the cabinet (see

separately provided system diagrams for location). This lug is marked with the ground symbol.

This should always be the first wire connected and the last wire disconnected. Tighten

connections to torque specified below.

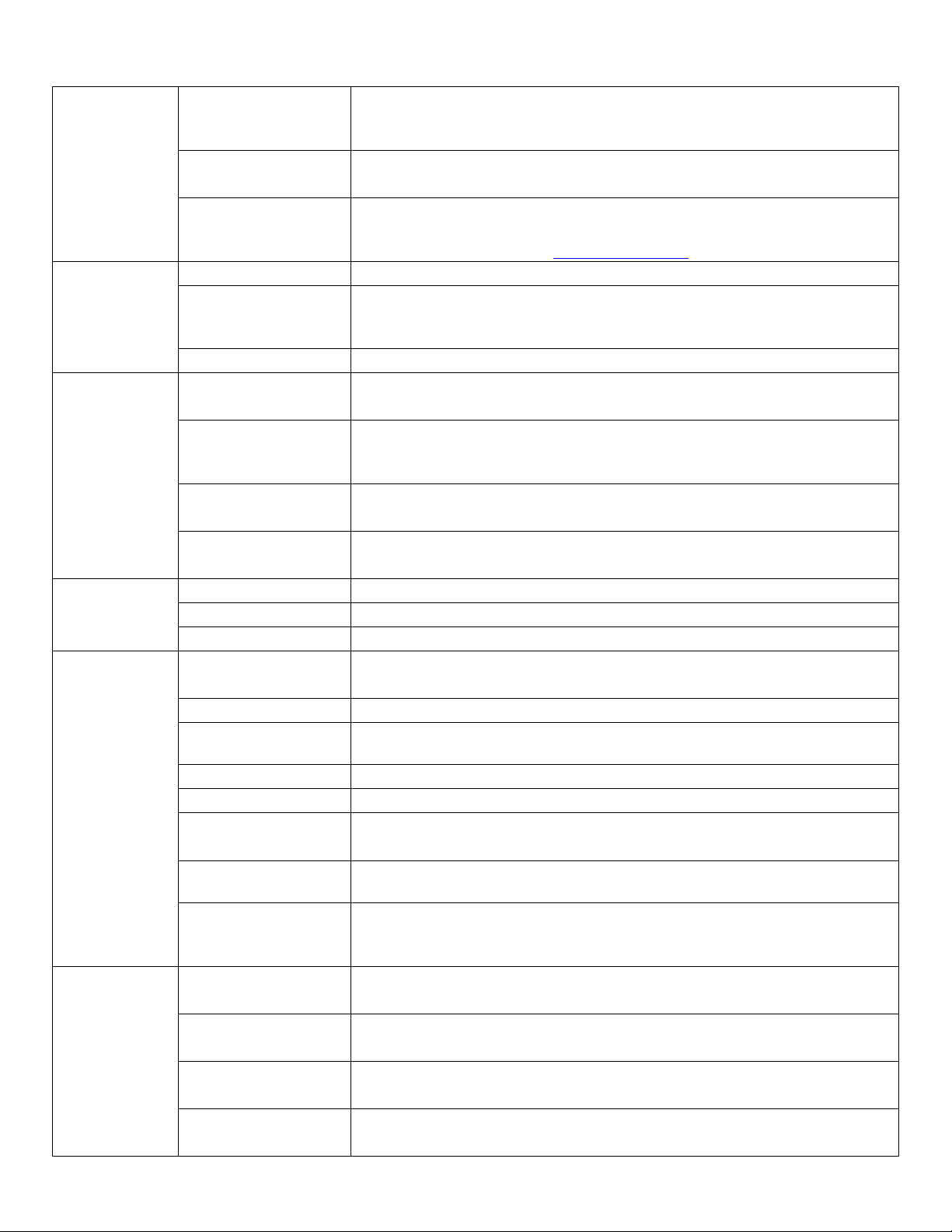

Ground Allowed Wire Gauge and Torque Requirements

Ground

Connection Type

Allowed Wire Gauge

Required Torque

Tool

Barrel lug

14-2/0 AWG (2.5-70 mm2)

14-10AWG: 35.0 In-Lb (3.95 Nm)

8 AWG: 40.0 In-Lb (4.52 Nm)

6-4 AWG: 45.0 In-Lb (5.08 Nm)

3 –2/0 AWG: 50.0 In-Lb (5.65 Nm)

3/16 inch

hex

4.2.3. Two holes for an optional chassis ground connection exist external to the cabinet on one foot.

Connect ground cables using M6 or ¼ inch fasteners as desired. This connection is optional. The

equipment ground lug provided internal to the system (described above) is still required whether

this connection is used or not.

4.2.4. Per UL 508A, the negative output is grounded. Remove or modify the ground cable if a floating or

positively grounded output is required.

4.3. DC Distribution Connection

Ensure batteries are disconnected from DC bus. Connect the DC output conductors to the DC output

distribution breakers in the system. Always observe proper polarity of the DC output leads. DC

distribution breakers accept 14AWG –10AWG wire for ≤20A and 10AWG –1/0AWG wire for >20A.

Tighten connections to torque specified on breakers. Connect DC distribution ground wires to the ground

bar provided near the breakers; ground bar accepts 14 –4AWG wire. Route DC wiring at least ¼ inch

(6 mm) away from AC wiring and alarm wiring. See separately provided system diagrams for more details

SENS PowerCab2 Technical Manual

12

and breaker handles for output breaker current ratings.

Per UL 508A, the negative output is grounded. Remove or modify the ground cable if a floating or

positively grounded output is required.

4.4. AC Connection

This unit is to be permanently connected to the AC circuit and to the battery. The unit is rated to operate

at full power on any 3-phase AC input within the range of 358-528VAC, 47-63Hz. The unit is rated to

operate at 50% power from 188-357VAC, 47-63Hz.

Ensure that the AC input supply is de-energized. Connect the AC line conductors to the AC input breaker

in the system. AC breaker accepts 14 –1/0AWG wire. Tighten connections to torque specified on the

breaker. Connect ground wire to the ground bar provided near the breaker; ground bar accepts 14 –

4AWG wire. Route AC wiring at least ¼ inch (6 mm) away from DC wiring and alarm wiring. See

separately provided system diagrams for more details and breaker handle for input breaker current

rating. See product label on inside front door for input current rating. Note that the input current

conductors and feeder protection must be sized according to the input current shown on the product

label.

4.5. Standard Alarm Connections

See label on inside of system door for original factory alarm relay assignments. Alarm relay assignments

are custom configurable using the SENS Setup Utility. Alarm circuits are rated 2A at 30V AC or DC.

Connect alarm wiring to the respective terminals on the pluggable terminal block. To make wiring easier,

the terminal block unplugs from its header. Pull terminal block straight out from header to remove.

Connect wires to terminal block by tightening screws at each position. After wires are connected, plug

terminal block securely back into header. Wire from FAIL or OK to COM depending on whether the alarm

should be present on an open or closed circuit (see table below). Connect alarm terminals only to low

voltage, limited energy (“Class 2”) circuits. The terminals accept 28-16 AWG (0.08-1.5 mm2) conductors.

Tighten connections to 2.0 Lb-In (0.22 Nm) using a small slotted driver. Route alarm wiring at least ¼ inch

(6 mm) away from DC wiring and AC wiring. P-clamps provided with system (see envelope inside cabinet)

to install and route alarm wiring as desired.

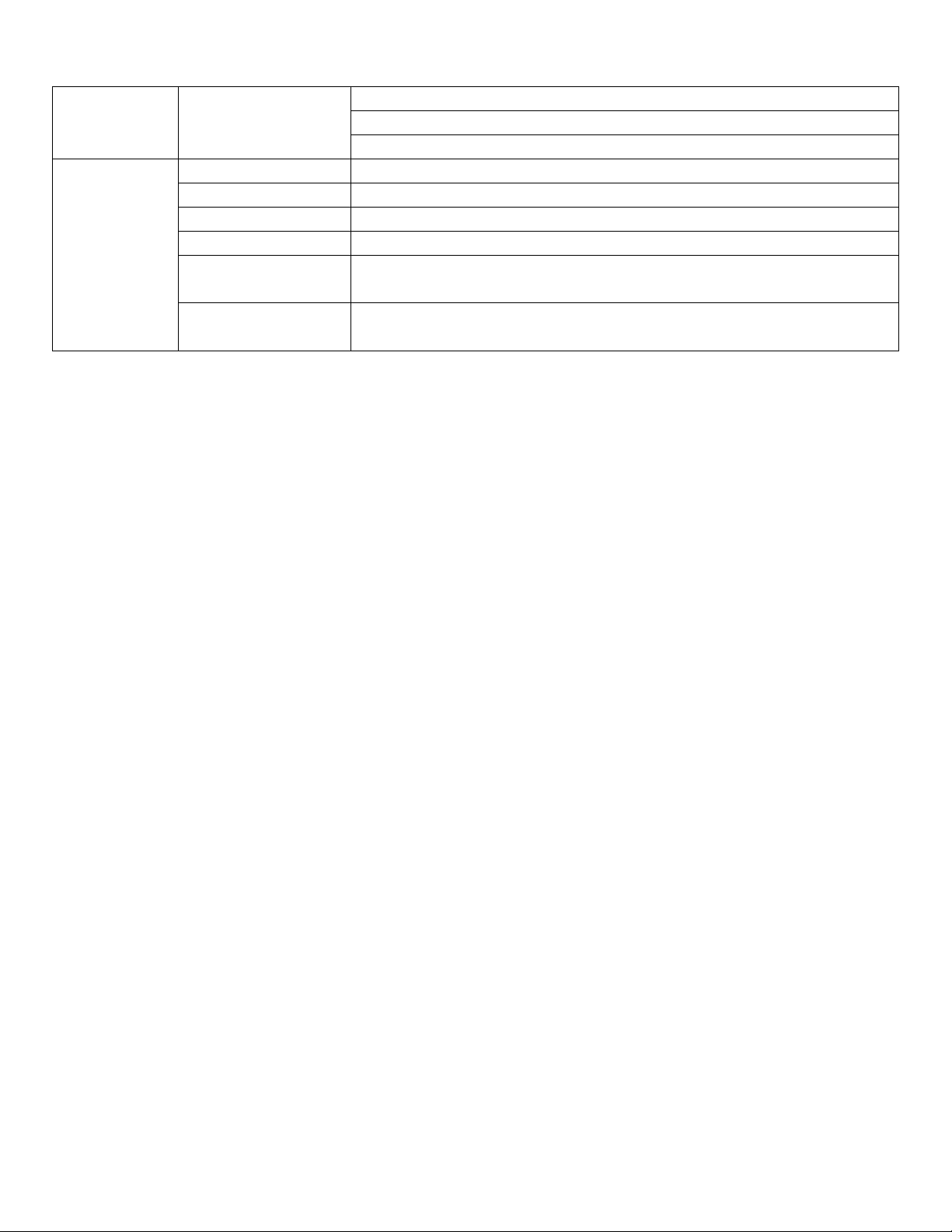

Standard Alarm Connections

9 RELAYS,

3 POSITIONS PER

RELAY:

COM, OK, FAIL

PULL TO REMOVE

FROM HEADER

SENS PowerCab2 Technical Manual

13

Typical Alarm Relay Contact Wiring for Stationary Power Configuration

Wire from COM to OK for alarm present on open circuit or from COM to FAIL for present on closed circuit.

RELAY 1

Non-latching Coil

RELAY 2

Non-latching Coil

RELAY 3

Latching Coil

RELAY 4

Latching Coil

RELAY 5

Latching Coil

Relay

Contacts

Summary

Alarm*

AC Fail and

Charger Fail

Battery

Discharging

Alarm

High DC Alarm

Low DC Alarm

Common

COM (TB1-1)

COM (TB1-4)

COM (TB1-7)

COM (TB1-10)

COM (TB1-13)

Open on

alarm

OK (TB1-2)

OK (TB1-5)

OK (TB1-8)

OK (TB1-11)

OK (TB1-14)

Close on

alarm

FAIL (TB1-3)

Defaults to FAIL

with no AC and

DC power

(normally closed)

FAIL (TB1-6)

Defaults to FAIL

with no AC and

DC power

(normally closed)

FAIL (TB1-9)

FAIL (TB1-12)

FAIL (TB1-15)

RELAY 6

Latching Coil

RELAY 7

Latching Coil

RELAY 8

Latching Coil

RELAY 9

Latching Coil

Relay

Contacts

Summary

Alarm*

Assignable

Assignable

Assignable

Common

COM (TB1-1)

COM (TB1-4)

COM (TB1-7)

COM (TB1-10)

Open on

alarm

OK (TB1-2)

OK (TB1-5)

OK (TB1-8)

OK (TB1-11)

Close on

alarm

FAIL (TB1-3)

FAIL (TB1-6)

FAIL (TB1-9)

FAIL (TB1-12)

*Summary alarm includes AC Fail, Charger Fail, Battery Discharging, High DC and Low DC alarms.

Functions and operation assigned to each relay are typical. Different functions and assignments are available

both from the factory and by reassignment using the SENS Setup Utility.

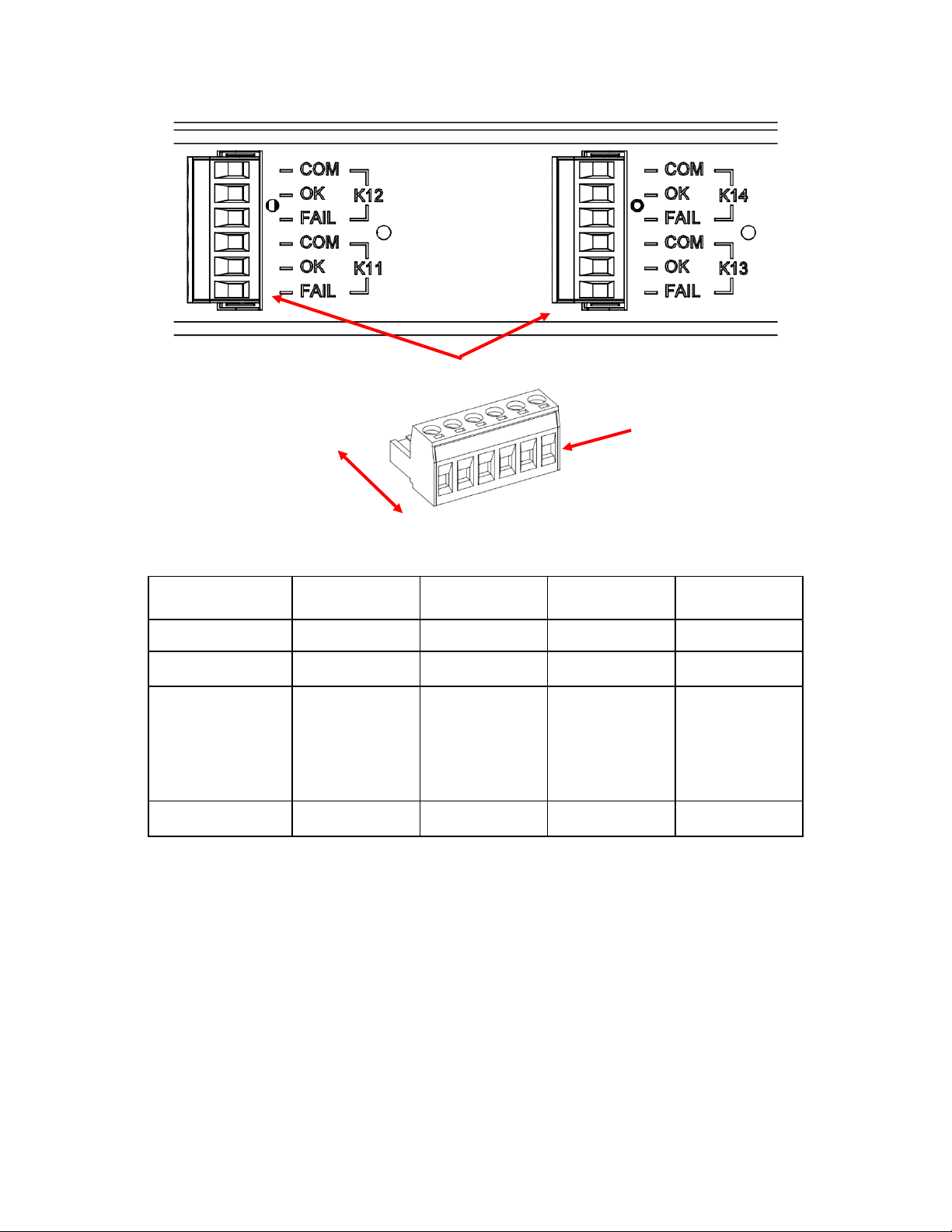

4.6. High Current Relay Connections—Optional

Optional high current relay assignments are custom configurable using the SENS Setup Utility. There are

two high current alarm relay options available from the factory. The first variant of alarm circuits (2) is

rated 5A at 120VAC. The second variant of alarm circuits (2) is rated 3A at 150VDC and 10A at 240VAC.

Connect optional alarm wiring to the respective terminals on the pluggable terminal block. To make

wiring easier, the terminal block unplugs from the header. Pull terminal block straight out from header to

remove. Connect wires to terminal block by tightening screws at each position. After wires are

connected, plug terminal block securely back into header. Wire from FAIL or OK to COM depending on

whether the alarm should be present on an open or closed circuit (see table below). The terminals accept

26-12 AWG (0.14-4.0 mm2) conductors. Tighten connections to 5.5 Lb-In (0.62 Nm) using a small slotted

driver. Route alarm wiring at least ¼ inch (6 mm) away from DC wiring and AC wiring. P-clamps provided

with system (see envelope inside cabinet) to install and route alarm wiring as desired.

SENS PowerCab2 Technical Manual

14

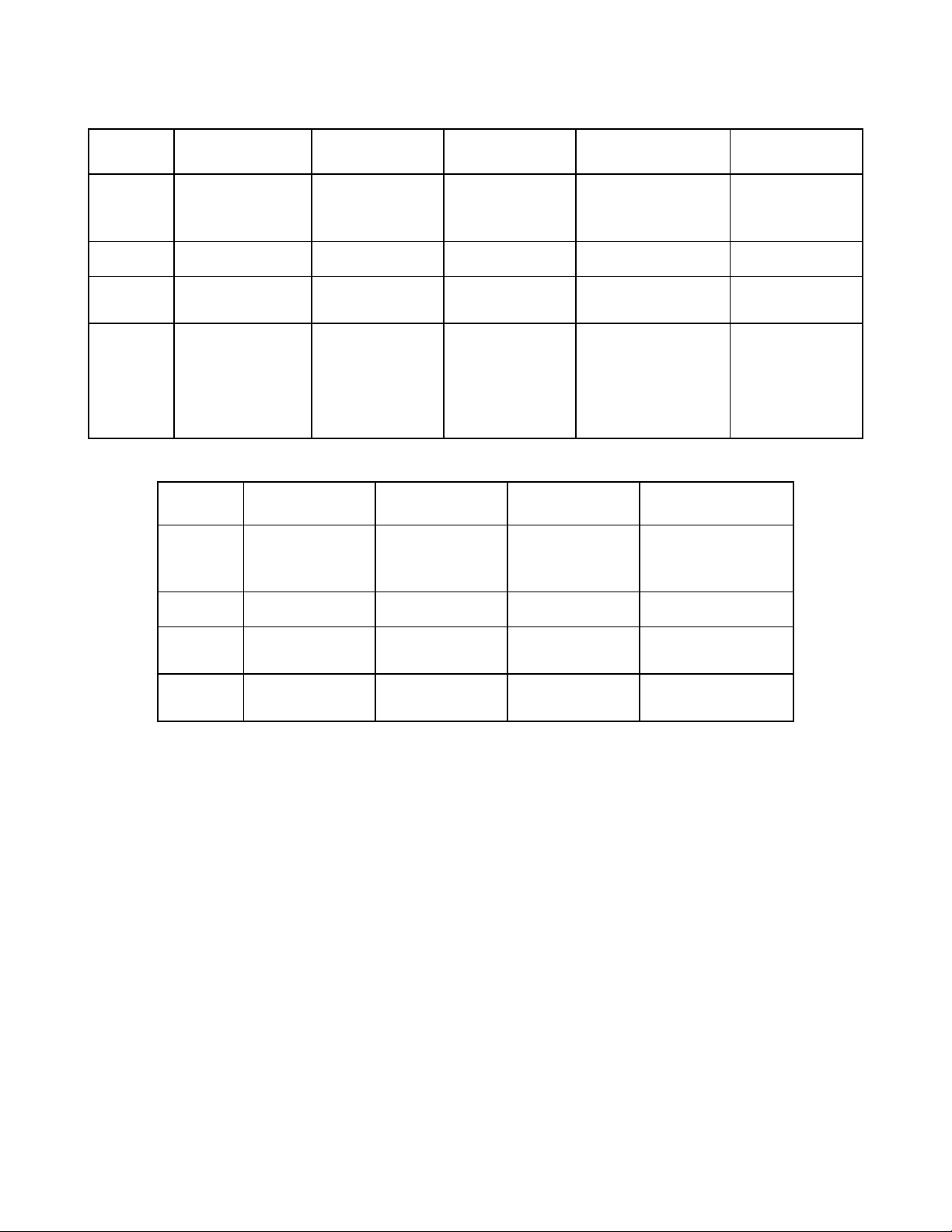

Optional High Current Relay Connections

Optional High Current Relay Connections

Wire from COM to OK for alarm present on open circuit or from COM to FAIL for present on closed circuit.

RELAY 11

Non-latching Coil

RELAY 12

Non-latching Coil

RELAY 13

Non-latching Coil

RELAY 14

Non-latching Coil

Relay Contacts

Assignable

Assignable

Assignable

Assignable

Open on alarm

OK (TB1-1)

OK (TB1-4)

OK (TB1-1)

OK (TB1-4)

Close on alarm

Defaults to FAIL

with no AC and

DC power

(normally closed)

FAIL (TB1-2)

FAIL (TB1-5)

FAIL (TB1-2)

FAIL (TB1-5)

Common

COM (TB1-3)

COM (TB1-6)

COM (TB1-3)

COM (TB1-6)

2 RELAYS,

3 POSITIONS PER

RELAY:

COM, OK, FAIL

PULL TO REMOVE

FROM HEADER

SENS PowerCab2 Technical Manual

15

Pin 1

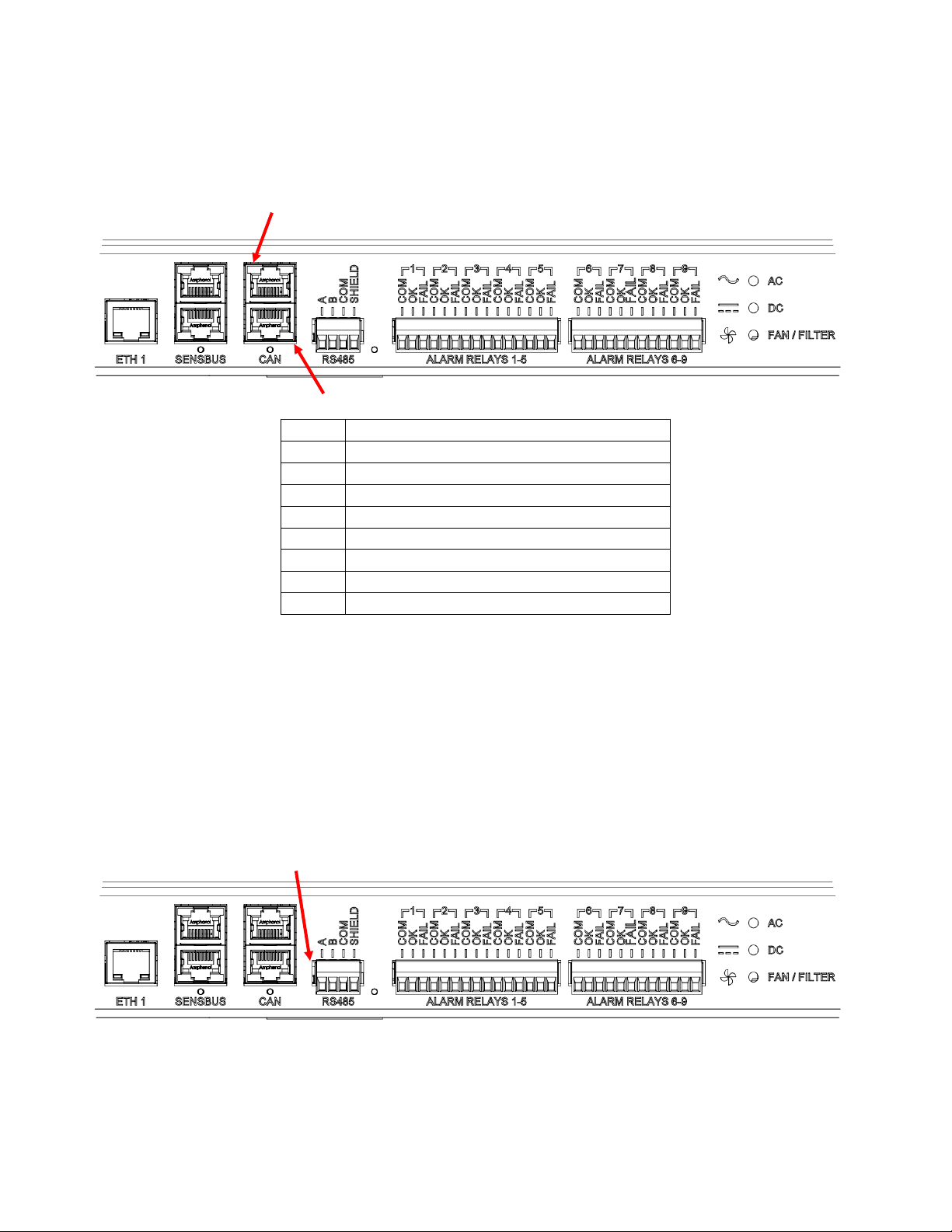

4.7. CANbus Connections

Every system includes CANbus via two RJ-45 jacks. The ports are in parallel and either port may be used.

See table below for connector pinout. Communications are isolated. This interface is intended for

communication with customer devices including battery monitoring systems, user interfaces, and

customer-specific CAN protocol communications. Consult the factory for configuration and setup.

CANbus Connections

Connector Pinout

Pin #

Purpose

1

CANbus

2

CANbus

3

No connect pass-through

4

No connect

5

No connect

6

No connect pass-through

7

Power*

8

Common (isolated)

*Main circuit PCA only, used for interconnect between SENS devices

4.8. RS-485 Connections

Every system includes RS-485 connections via a 4-pin pluggable terminal block. This interface is intended

for monitoring and communicating with the system. Available protocols include Modbus (standard on all

systems) and DNP3 (optional). Use connector position A for Modbus +D1 and position B for Modbus –D0.

The terminals accept 26-12 AWG (0.14-4.0 mm2) conductors. Tighten connections to 5.5 Lb-In (0.62 Nm)

using a small slotted driver. Route alarm wiring at least ¼ inch (6 mm) away from DC wiring, AC wiring,

low voltage wiring, and the circuit board. P-clamps provided with system (see envelope inside cabinet) to

install and route alarm wiring as desired. See manual sections on specific protocols for more information.

RS-485 Connections

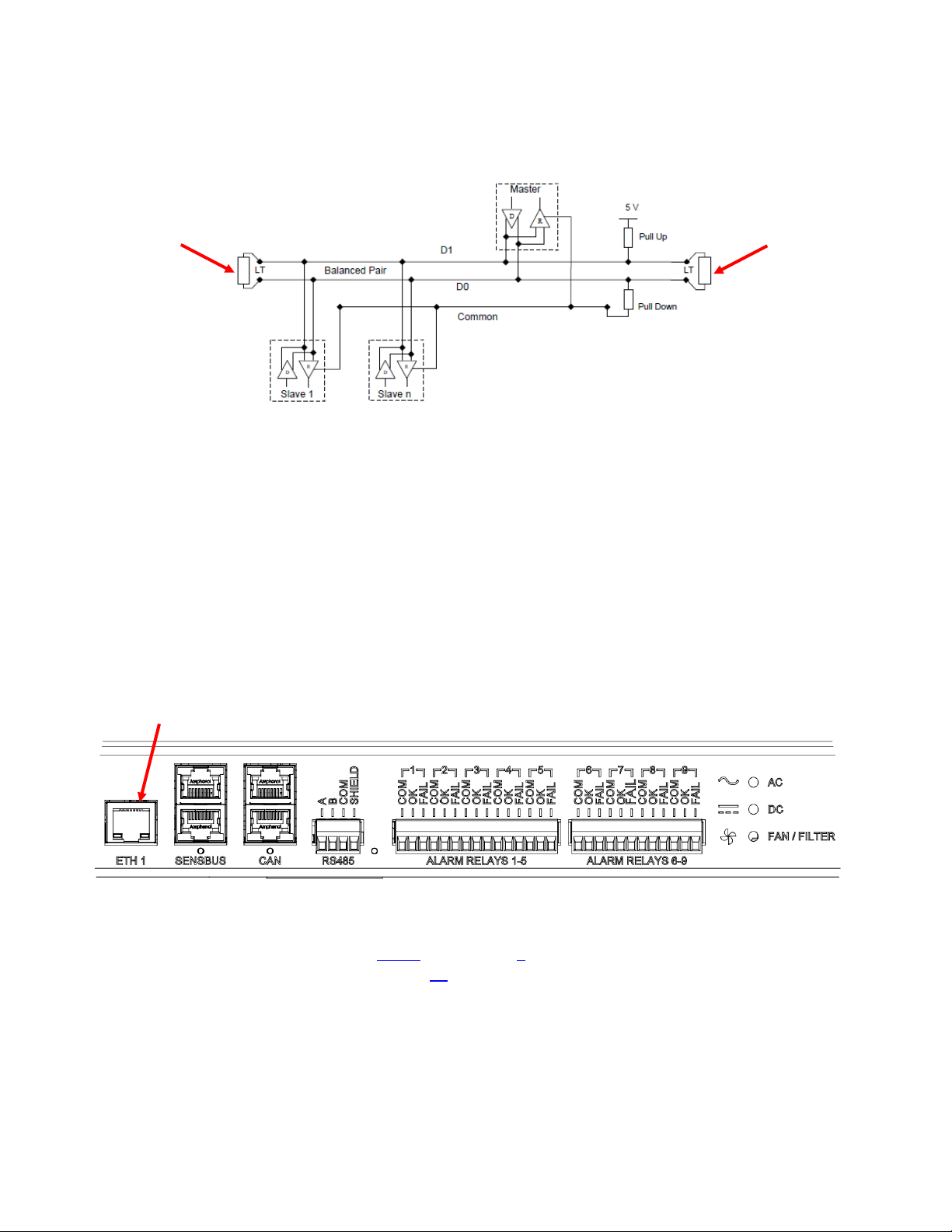

4.8.1.1. Termination

For proper Modbus RS-485 operation, a 120-ohm terminator is required at the ends of the RS-

485 bus. If multiple devices are on the bus, only the devices on the ends of the network bus

need termination resistors. The figure below shows an example of how to terminate the

network. Termination may be provided as part of the network cabling or 120-ohm

Pin 1

SENS PowerCab2 Technical Manual

16

termination plugs for the RJ-45 communications connector on the system are available to

order separately (SENS p/n 803707). SENS units are slave devices. Pull-up and pull-down

resistors are optional per Modbus specifications.

Typical Modbus Termination

LT = Line Termination 120-ohm resistor

4.9. Ethernet

The unit is equipped with an ethernet RJ45 port (labeled “ETH1”). Connect Cat5 or better ethernet cable.

This provides a 10/100 ethernet connection. P-clamps provided with system (see envelope inside

cabinet) to install and route alarm wiring as desired. Ethernet communications includes ethernet

connectivity to the system for monitoring and configuration via the SENS Setup Utility, Modbus TCP/IP

(standard on all systems) and DNP3 (optional).

Units with NaCl (salt) batteries include an alternate connection for Modbus TCP/IP (labeled “MODBUS

TCP/IP"). Connect Modbus communications to this port instead of ETH1 to receive Modbus information

from the batteries and all devices in the system. See separately provided system diagrams for location in

cabinet. The ETH1 ethernet port is still available but will not include Modbus information from the

batteries. Always use the ETH1 port for connection of the SENS Setup Utility.

ETH1 Ethernet Connection

4.9.1. Configure TCP/IP Address

Configure TCP/IP settings when connected to the ETH1 ethernet port using the SENS Setup Utility

or the keypad (see section 7.10.3). See section 9for Modbus details for all devices in the system

except NaCl batteries. See section 11 for NaCl Modbus details. Set the IP address as desired. It

may take up to 10 seconds for the network setting changes to apply. A TCP/IP address of 0.0.0.0

implies DHCP (Dynamic) addressing. Adjust the Gateway and Subnet Mask values as required. The

“Hardware Address” displayed on the front panel LCD is the MAC address corresponding to the

ETH1 interface. The MAC address for the optional NaCl batteries MODBUS TCP/IP connection is

stated on the label near the connection port. The MAC address values are not adjustable.

SENS PowerCab2 Technical Manual

17

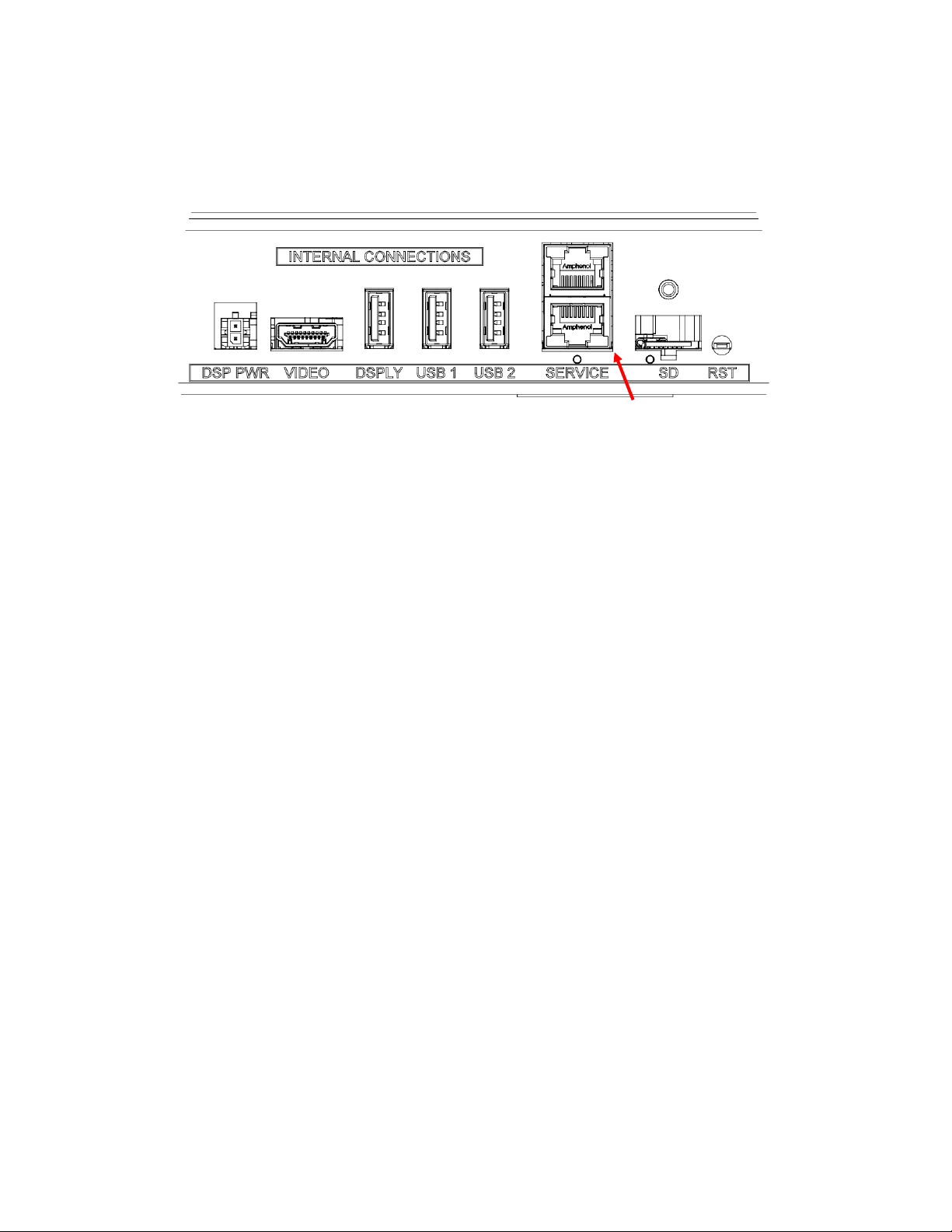

4.10. Service Connection

The unit is equipped with a Service RJ45 port. This SENSbus connection is used for internal devices and

SENS accessory connections. Do not connect multiple PowerCab2 systems together using this

connection unless directed to on the separately provided system diagrams.

Service Connection

4.11. Verify Connections

4.11.1. Verify that all connections are secure and in the proper locations. Tighten all unused screws on

terminal blocks to secure them against vibration.

4.11.2. Ensure all wires are routed in a way that access covers and doors or other objects will not pinch

or damage them.

4.12. Verify Covers

4.12.1. Verify that all covers are re-installed. These covers provide the necessary air partition for

cabinet cooling. The air partition extends the entire length from the top to the bottom of the

cabinet.

SENS PowerCab2 Technical Manual

18

5START-UP PROCEDURE

5.1. Connect Battery

Close system BATTERY and CHARGER circuit breakers to connect the battery to the charger.

5.2. Verify Configuration

Each PowerCab2 system comes configured for its application from the factory. Configuration details are

provided on the configuration label. The Config Code indicates charging algorithm and alarm setpoints

configured at the factory. Review and adjust charger configuration using the front panel keypad or the

SENS Setup Utility if factory configured settings require modification. See section 7.10 for additional

details on keypad navigation.

Example Configuration Label (inside front door)

5.3. Apply AC Input Voltage

Verify the AC input is the correct value (188-528 VAC, 47-63 Hz) and apply AC by closing the system AC

circuit breaker.

Depending on the state of charge of the batteries and the load on the DC bus, the system charger may go

into current limit at this time, in which case the output voltage will be reduced as the charger operates in

constant current mode. Eventually as the battery is charged, the charging current demand will taper to a

value below the current limit setpoint of the charger, and the charger will revert to constant voltage

output. Chargers configured to use Autoboost will operate in the boost mode for variable time ranging

from a few minutes to several hours depending on state of charge of the batteries. When in the

Autoboost mode, the charger will automatically revert from boost to float mode if the Autoboost system

has not automatically reverted to float prior to 24 hours. This is a safety feature which, if activated,

should be investigated.

5.4. Connect DC Distribution Outputs

Close each DC distribution breaker to connect external loads and devices to system DC output voltage.

5.5. Power Off

Power system off as necessary by shutting off the AC, CHARGER and BATTERY breakers in any order.

SENS PowerCab2 Technical Manual

19

6ALARMS, LEDS AND DISPLAY

6.1. LED Indicators

The system is equipped with two LEDs on the main display, one for AC status and one for DC status. See

further alarm definitions in section 6.5. See section 11 for optional NaCl (salt) battery LED indicators.

LED Definitions

AC LED

DC LED

Meaning

OFF

OFF

AC and DC not applied or charger failed or

alarm/communications circuit board cannot

communicate with main circuit board

SOLID GREEN

SOLID GREEN

AC good, DC good, in Float Mode

SOLID GREEN

FLASHING GREEN

AC good, in Dynamic Boost Mode

SOLID GREEN

FLASHING 2X GREEN

AC good, DC in current limit (max charge)

SOLID GREEN

FLASH LONG-SHORT GREEN

AC good, HELIX Eco-Float mode

SOLID GREEN

FLASH LONG-2X SHORT GREEN

AC good, HELIX Refresh Charge mode

SOLID GREEN

FLASH LONG-SHORT YELLOW

AC good, battery commissioning mode active

SOLID GREEN

FAST FLASHING GREEN

AC good, battery check in progress

SOLID GREEN

FAST FLASHING YELLOW

AC good, battery check failure

SOLID GREEN

SOLID RED

AC good, charger fail or overvoltage shutdown

(charger disabled)

SOLID GREEN

FLASHING RED/YELLOW

AC good, reverse polarity detected on output

SOLID GREEN

SOLID YELLOW

AC good, high or low DC voltage (above/below

alarm setpoint)

SOLID GREEN

FLASHING GREEN/RED

AC good, system DC output good, some individual

charger module(s) in alarm state

SOLID GREEN

FLASHING RED/YELLOW

AC good, incompatible battery (charger disabled)

SOLID GREEN

FLASHING YELLOW

AC good, positive/negative ground fault present

SOLID GREEN

FLASHING GREEN/YELLOW

AC good, output limited by high temperature

SOLID GREEN

DOUBLE FLASH YELLOW

AC good, load share fail

SOLID GREEN

DOUBLE FLASH RED

AC good, load sharing DC negative connection

open or load sharing charger address fault

SOLID YELLOW

SOLID GREEN

AC voltage/frequency out of range or AC phase

missing, DC voltage good

SOLID RED

SOLID GREEN

AC fail or over max voltage, DC voltage good

SOLID RED

SOLID YELLOW

AC fail, high or low DC voltage (above/below

alarm setpoint)

SOLID RED

SOLID RED

AC fail, charger fail or overvoltage shutdown

(charger disabled)

SOLID RED

FLASHING RED/YELLOW

AC fail, incompatible battery (charger disabled)

SOLID RED

FLASHING YELLOW

AC fail, positive/negative ground fault present

FLASH LONG-2X SHORT YELLOW

SENSbus Inactive

ALTERNATING FLASHING YELLOW

Illegal jumper configuration

ALTERNATING FLASHING RED

Missing or invalid code (boot load required)

ALTERNATING FLASHING GREEN

Charger starting up

SENS PowerCab2 Technical Manual

20

6.2. Individual Alarm Relay Contacts

The standard alarm/communications circuit board offers nine alarm discrete Form C contacts. The Form

C relay contacts change state when alarms are activated. Alarm relay assignments are custom

configurable to any of the alarm functions listed in section 6.5. See configuration label on inside front

door for original factory alarm relay assignments. See section 4.5 for typical alarm relay assignments. The

relays can be configured to be latching or non-latching with adjustable delays using the SENS Setup

Utility.

By default, the relay contacts change state 30 seconds after the onset of a fault. The relay delay is

configurable using the front panel keypad (see section 7.10) or the SENS Setup Utility. See section 6.5 for

alarm definitions.

6.3. LCD Panel

A two line by twenty-character LCD is included with every system and provides precision digital AC and

DC ammeters and voltmeters as well as information about input, output, charging status and alarms. The

voltmeters are accurate to +1% and the ammeters are accurate to +1%. The display is readable with or

without ambient lighting and operates automatically, requiring no operator intervention.

The LCD is fully operational from -20°C to +50°C. It may temporarily become unreadable below -20°C but

should recover as temperature increases. LCD life is reduced with sustained operation above 65°C.

6.4. Latched Alarms

All alarm messages displayed on the front panel LCD are latching. Alarm relay configurations created

using the SENS Setup Utility may be configured as latching if desired. Once an alarm condition no longer

exists, the alarm message will no longer display in the main/home screen but will remain under the

“Latched Alarms” menu. Clear latched alarms using the keypad under the “Latched Alarms” menu (see

section 7.10.3), using the SENS Setup Utility or by cycling power.

6.5. Alarm Definitions

See section 6.1 for a description of LED indicator activity. Unless noted otherwise, the following alarms

are displayed on the LCD panel.

6.5.1. AC Line Failure

Indicates AC input voltage is not detected or is outside of the allowed 188-528VAC range.

Activates solid red AC LED. When this alarm is assigned to a relay contact AC LINE FAIL will cause

the assigned relay to change to the Failed state after the time delay.

6.5.2. High DC Voltage

Indicates DC output voltage is above the High DC Voltage factory alarm setpoint or the configured

level if setpoint is adjusted using keypad or SENS Setup Utility. Activates solid yellow DC LED.

When this alarm is assigned to a relay contact HIGH DC VOLTAGE will cause the assigned relay to

change to the Failed state after the time delay.

6.5.3. Battery on Discharge

Indicates battery is beginning to discharge and DC output voltage is below Battery Discharge

Voltage factory alarm setpoint or the configured level if setpoint is adjusted using keypad or SENS

Setup Utility. The BATTERY DISCHARGING alarm is the first to trigger of three low output voltage

alarms and is followed by LOW DC and then END OF DISCHARGE. Alarm setpoint must be set

higher than LOW DC and END OF DISCHARGE alarms. Activates solid yellow DC LED. When this

alarm is assigned to a relay contact BATTERY DISCHARGING will cause the assigned relay to

change to the Failed state after the time delay.

6.5.4. Low DC Voltage

Indicates battery has discharged and DC output voltage is below Low DC Voltage factory alarm

setpoint or the configured level if setpoint is adjusted using keypad or SENS Setup Utility. Alarm

setpoint must be set lower than BATTERY DISCHARGING and higher than END OF DISCHARGE

Table of contents

Other Sens Power Supply manuals

Popular Power Supply manuals by other brands

PS Audio

PS Audio AV-3000 Owner's reference

Conductix-Wampfler

Conductix-Wampfler 91008-111-3130923 operating instructions

Puls

Puls PIANO PIM60.241 installation manual

Campbell

Campbell PS200 user guide

Riello

Riello STEEL PRO POWER INSTALLATION, TECHNICAL ASSISTANCE SERVICE AND SYSTEM MANAGEMENT MANUAL

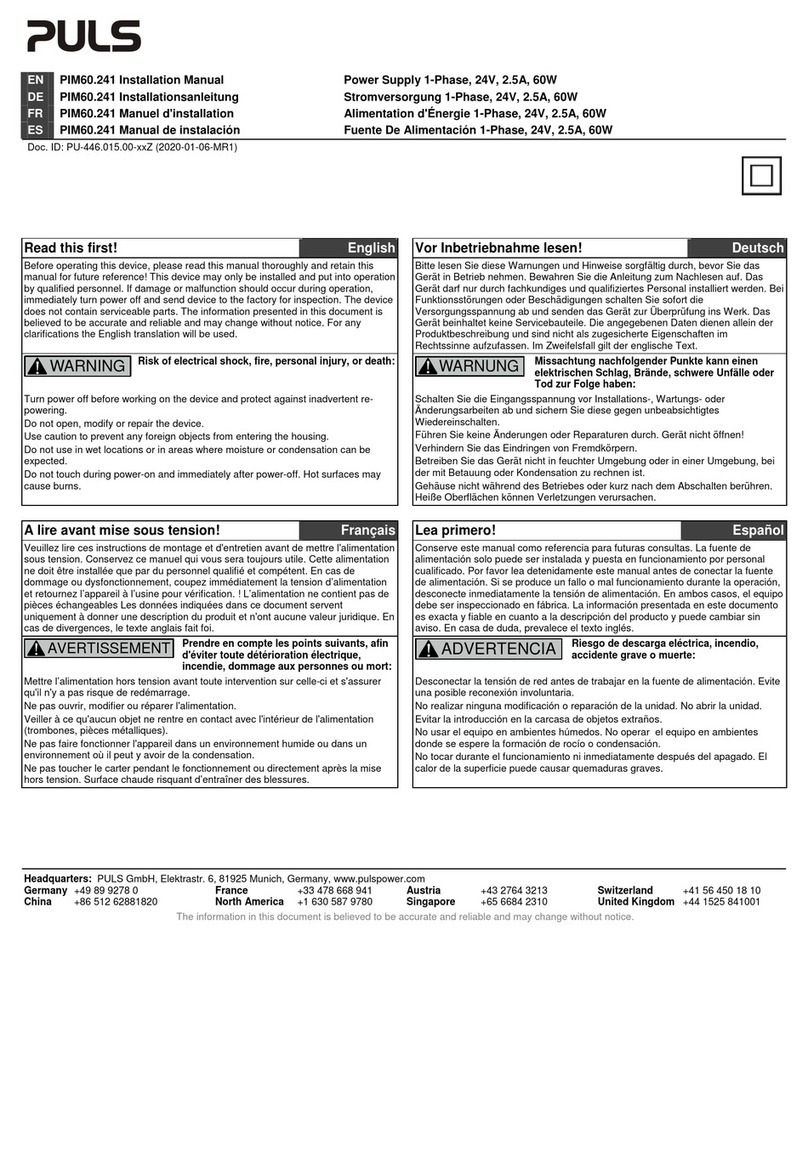

Pulsar

Pulsar PSCV5012 quick start guide

Cosel

Cosel LFA10F instruction manual

Electro-Automatik

Electro-Automatik EL 9000 T operating manual

AKO-Agrartechnik

AKO-Agrartechnik EuroGuard N 1400 operating instructions

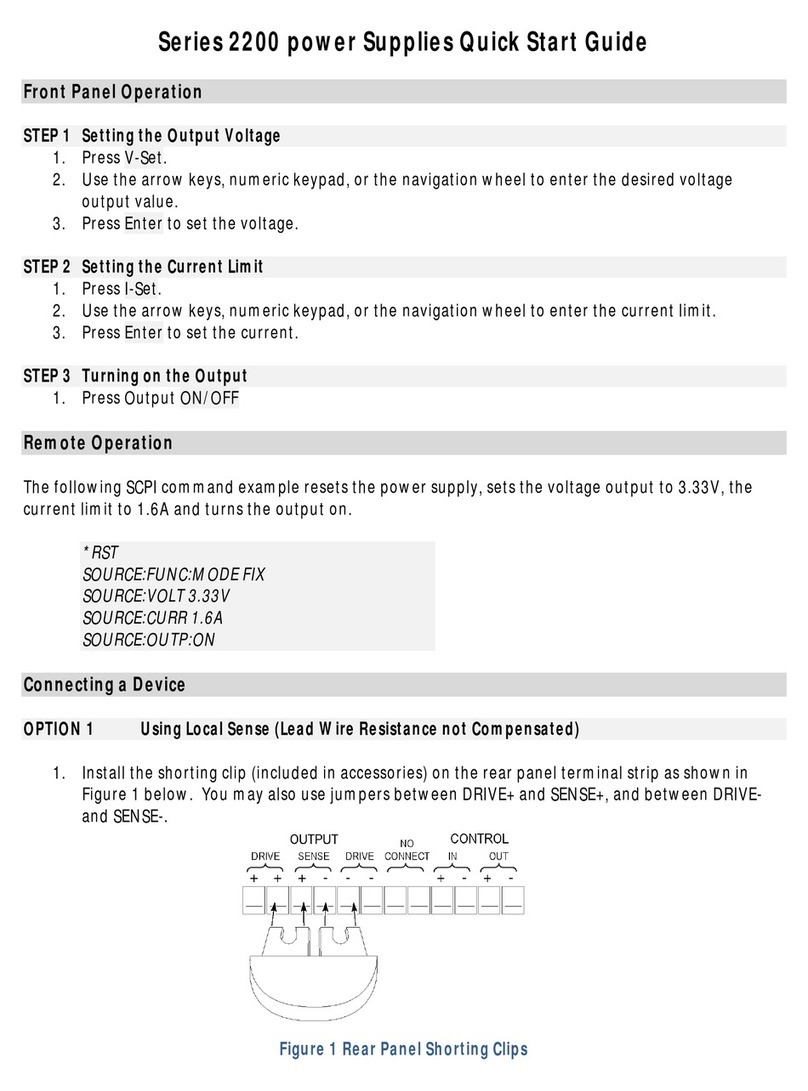

Keithley

Keithley Series 2200 quick start guide

B+K precision

B+K precision 9130 instruction manual

Fine Vu

Fine Vu FINE Safer S installation manual