BAL9100-0138i-EN

www.conductix.com translated document page 3 of 56

5.8.1 Design Standards for 400 V Versions..................................................................................................................21

5.8.2 Additional Design Standards for 480 V Versions..................................................................................................21

5.9 Safety Features of the Track Supply Module........................................................................................................21

5.10 Grounding ..........................................................................................................................................................21

5.11 ESD Protection...................................................................................................................................................22

5.12 Illumination and Plug Socket | Track Supply IP54 ................................................................................................22

6Options ..........................................................................................................................................................................23

6.1 Variant with Air Conditioning Unit (Side Mounting) ...............................................................................................23

6.2 Integrated Tuning Unit (only in Combination with Air Conditioning Unit) ................................................................23

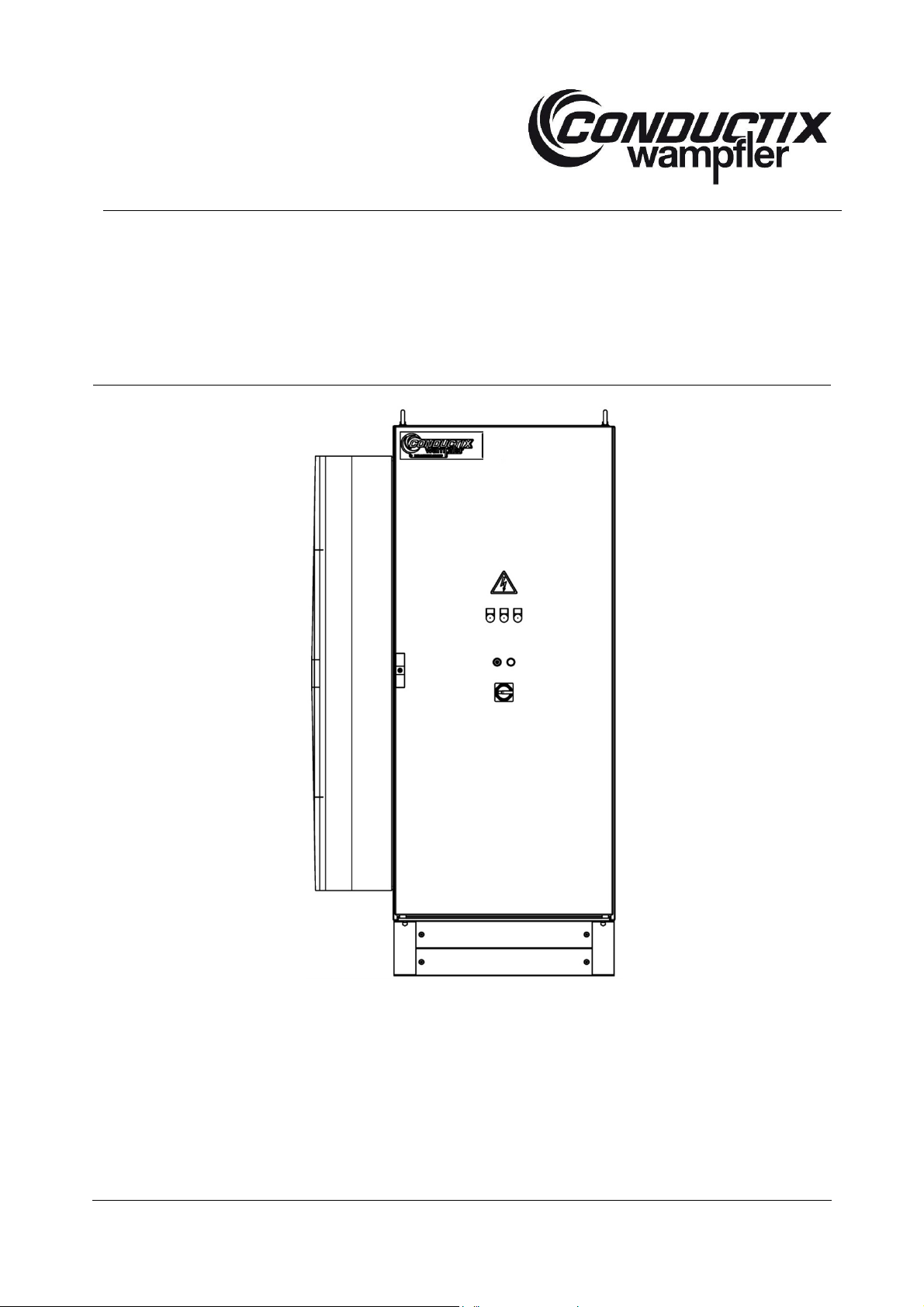

7Track Supply Module......................................................................................................................................................25

7.1 Indicator Circuit Board of the Track Supply ..........................................................................................................26

7.2 LED-Display .......................................................................................................................................................26

7.3 Version Number of the Software..........................................................................................................................28

7.4 Modes of Operation ............................................................................................................................................28

7.5 Language Setting, Time and Date .......................................................................................................................29

7.6 Warning Messages.............................................................................................................................................30

7.7 Error Codes........................................................................................................................................................30

8Fuses.............................................................................................................................................................................33

8.1 Semiconductor Main Fuses | Track Supply Module..............................................................................................33

8.2 Other Protective Devices (Fuses)........................................................................................................................33

9Transport, Packaging and Storage..................................................................................................................................34

9.1 Transport............................................................................................................................................................34

9.1.1 Safety Instructions for Transport..........................................................................................................................34

9.1.2 Transport Inspection ...........................................................................................................................................34

9.2 Packaging ..........................................................................................................................................................35

9.3 Storage of Packages...........................................................................................................................................35

10 Installation......................................................................................................................................................................36

10.1 Who is allowed to do the Installation?..................................................................................................................36

10.2 General Installation Recommendations ...............................................................................................................36

10.3 Place and Conditions of Installation.....................................................................................................................37

10.4 Electrical Regulations .........................................................................................................................................37

10.5 Electrical Connection ..........................................................................................................................................38

10.5.1 Power Connection ..............................................................................................................................................38