SENSIRION SFC6 Series User manual

www.sensirion.com

Version 1 –Mar 2023

1 / 13

Copyright © Sensirion AG 2022.

Engineering guidelines for Mass Flow Controllers

(SFC6xxx) and Mass Flow Meters (SFM6xxx)

Summary

This guide provides recommendations for evaluation, testing and integration of Sensirion Mass Flow Controllers and

Meters. It is applicable to SFC6xxx as well as SFM6xxx products.

For clarity, the document was written for Mass Flow Controllers, yet most guidelines are also valid for Mass Flow Meters.

www.sensirion.com

Version 1 –Mar 2023

2 / 13

Copyright © Sensirion AG 2022.

Contents

1. How to choose your Mass Flow Controller (Mass Flow Meter)........................................................................................................... 3

1.1. Flow Selection for SFC6000(D)/SFM6000(D)............................................................................................................................. 3

2. How to operate your Mass Flow Controller................................................................................................................................................. 3

2.1. Digital interface ..................................................................................................................................................................................... 3

2.2. Analog interface: Coming Soon ..................................................................................................................................................... 4

3. Testing recommendations................................................................................................................................................................................... 5

4. Common pitfalls ...................................................................................................................................................................................................... 5

4.1. Flow appears to be off by several %............................................................................................................................................. 5

4.2. Settling time is longer than specified .......................................................................................................................................... 5

5. Design recommendations ................................................................................................................................................................................... 5

5.1. The effect of orientation and temperature on accuracy ...................................................................................................... 5

5.2. The effect of vibrations on valve function.................................................................................................................................. 6

5.3. Pressure drop and input pressure ................................................................................................................................................. 6

6. Fluidic and electrical connectors ...................................................................................................................................................................... 7

6.1. Mounting guide .................................................................................................................................................................................... 7

6.1.1. Mounting from the bottom of device ................................................................................................................... 7

6.1.2. Mounting from the bottom of device ................................................................................................................... 7

6.1.3. Downmount manifold .................................................................................................................................................. 8

7. Useful resources ...................................................................................................................................................................................................... 9

7.1. Documentation...................................................................................................................................................................................... 9

7.2. CAD models..........................................................................................................................................................................................12

7.3. Software tools......................................................................................................................................................................................12

7.3.1. Control Center software ............................................................................................................................................12

7.3.2. Software drivers ............................................................................................................................................................12

7.4. Calibration and FAQ ..........................................................................................................................................................................12

www.sensirion.com

Version 1 –Mar 2023

3 / 13

Copyright © Sensirion AG 2022.

1. How to choose your Mass Flow Controller (Mass Flow Meter)

Sensirion offers several families of Mass Flow Controllers and Meters. The following covers the 6000 series family.

•SFC6000 (SFM6000) family offers the best price to performance ratio for a mass flow controller in a compact and

lightweight package and is fully customisable to your needs. Minimum order quantities apply when purchasing

from Sensirion.

•SFC6000D (SFM6000D) are SFC6000 mass flow controllers and SFM6000 mass flow meters available in fixed

configurations with pre-configured multiple gas calibrations, different flow ranges and exchangeable fittings

available via distribution.

To help you choose the right Mass Flow Controller, a “Selection guide”is available on the Sensirion website. Please see

the useful resources section below.

1.1. Flow Selection for SFC6000(D)/SFM6000(D)

The Sensirion SFC6000 flow controllers and SFM6000 flow meteres are available for full flow rates from 0.5 slm to 50 slm.

SFC6000D and SFM6000D are available at different flow ranges, shown in Table 1, to suit your application best.

Product

Variant

Flow Range

SFC6000D-/SFM6000D-

5 slm

5 slm –0 slm

20 slm

20 slm –0 slm

50 slm

50 slm –0 slm

Table 1. Flow ranges of the respective product variants of SFC6000D and SFM6000D

2. How to operate your Mass Flow Controller

The evaluation method depends on whether your Mass Flow Controller has a digital or an analog interface.

2.1. Digital interface

There are several ways to operate Sensirion digital Mass Flow Controllers exist. They vary in complexity and implementation

flexibilities.

•The EK-F5x evaluation kit together with Sensirion Control Center is the fastest way to start working with your

device. It is a plug-and-play solution, which will enable you to control and configure your device (e.g. choose the

gas calibration). The EK-F5x evaluation kit combines a power supply (adapters for most sockets worldwide are

included) and a USB-A plug for your PC. It connects to your device with a M8 or DB9 plug (an adapter is available

for other plugs –please contact Sensirion). EK-F5x is available from distribution. Please note, Mass Flow Controller

or Flow Meter are not included and must be purchased separately.

•Most OEM projects will require designing custom cabling (including a power supply) together with an

implementation in the desired programming language. The SFC6000 provides an I2C and a RS-485 interface (the

respective guides are found in Section 7.1 in Useful Resources). Sensirion provides ready-to-use libraries in C and

Python, as illustrated in Table 2. These libraries can be used to control multiple devices at the same time (please

make sure the devices have unique SHDLC and I2C addresses for RS-485 and I2C interfaces, respectively). However,

this also involves the highest implementation effort out of the options mentioned here.

www.sensirion.com

Version 1 –Mar 2023

4 / 13

Copyright © Sensirion AG 2022.

Quick, plug-and-play

Simple implementation and flexibility

MFC

MFC

EK-F5x

Evaluation Kit

Sensirion

Control Center

EK-F5x

Evaluation Kit

Sensirion C / Python library

RS-485: Custom design with full implementation flexibility

I2C: Custom design with full implementation flexibility: Coming Soon

MFC

MFC

Custom cabling and external power

supply

Sensirion C / Python library

Custom cabling and external power

supply

Sensirion C library

Figure 1. Overview of different options for evaluating digital Mass Flow Controllers and Mass Flow Meters

The following illustrates the available software drivers for respective PC interfaces for the SFC6000 and SFM6000 variants.

PC interface

Python driver

C driver

Sensirion Control

Center

USB (EK-F5x

Evaluation kit)

Available

Available

(For Raspberry pi)

Available

RS-485

Under Development

Available (Arduino

shield)

-

I2C

-

Under Development

(For Arduino)

-

Table 2. The available drivers for different modes of communication for the SFC6000 and SFM6000. Links to the software

can be found in the software tools section below.

2.2. Analog interface

The analog output pin gives out an analog linear voltage representing the flow value in standard liter per minute

(slm). The formula for converting the voltage value to slm is given by:

i.e. the analog voltage range from 0.5 V to 4.5 V is linearly mapped to the flow range of 0 slm to full scale flow slm. The

identical conversion formula applies for the analog input voltage.

www.sensirion.com

Version 1 –Mar 2023

5 / 13

Copyright © Sensirion AG 2022.

3. Testing recommendations

It is recommended to start by testing the communication with the device, using the EK-F5x Evaluation Kit and Control

Center.

As a second step, connect the device to a gas supply (or a source of vacuum). For better accuracy, mount the Mass Flow

Controller horizontally and use the same pressure as during factory-calibration (specified in the datasheet, by default for

most products 3 bar inlet vs outlet).

Try using different setpoint steps to test the Mass Flow Controller. If the chosen setpoint can’t be reached, try increasing

the supply pressure, removing fluidic resistances like filters, or using tubes with a larger diameter. If the supply pressure

used is significantly lower than the calibration pressure, the controller can be slower than expected. On the other hand, if

the supply pressure is significantly larger than the calibration pressure, the Mass Flow Controller may become unstable. In

these cases, lowering or increasing the controller gain to adapt the controller accordingly. This can be done conveniently

with Sensirion Control Center. For detailed instructions, see the “Control Center manual”, linked in “Useful resources”

Section 7.3.1.

4. Common pitfalls

4.1. Flow appears to be off by several %

If the flow appears to be off by several % (especially around 7%) against your reference, there are good chances the flow

units of the two devices are not the same. The conversion difference between standard litres and norm litres is around 7%,

due to the different reference temperatures used for standard and norm litres. Please make sure that the Mass Flow

Controller and your reference are using the same units when testing. Further information about the flow unit conversion

can be found in a dedicated application note, “Reference and Flow Conversions between mass and volumetric flow”, in the

“Useful resources” Section 7.1.

4.2. Settling time is longer than specified

The most common cause for observing longer than expected settling time is trying to verify it from a position of fully closed

valve. Solenoid valves are commonly affected by so-called “sticking effect”. To open the valve from closed position (setpoint

0), a certain overvoltage is required to overcome the stiction effect. This can lead to a spike in the flow (especially for low

setpoints) or a longer than expected settling time. By adjusting the “Initstep” or “Controller gain” of the Mass Flow

Controller, the behaviour can be tuned to the specific requirements.

The settling time of Sensirion’s Mass Flow Controllers is specified for a step answer from 10% to 100% of full scale within

5% of setpoint. When starting from zero flow the settling time may be longer than specification.

5. Design recommendations

5.1. The effect of orientation and temperature on accuracy

To achieve best accuracy, it is recommended to use a design where the Mass Flow Controller is mounted horizontally.

The operation of the valve produces a significant amount of heat. The Mass Flow Controller should therefore not be placed

in a hermetically sealed space. It is recommended to design a cooling flow over the Mass Flow Controller in order to

counteract the heating from the valve. Large temperature gradient between the Mass Flow Controller and the gas it is used

to control, may adversely influence the accuracy of the device.

www.sensirion.com

Version 1 –Mar 2023

6 / 13

Copyright © Sensirion AG 2022.

5.2. The effect of vibrations on valve function

The valve used in the Mass Flow Controllers (proportional valve) is an oscillating system. Try to avoid sources of vibrations

or decouple these sources mechanically from the Mass Flow Controller. They can interfere with the proper function of the

valve.

5.3. Pressure drop, temperature and input pressure

Pressure drop is generated when gas passes through the valve of a mass flow controller. The magnitude of the pressure

drop is proportional to the flow rate and the density of the gas. Additionally, the maximum flow rate can be affected by

temperature. The magnetization of the valve decreases with a higher valve temperature caused by continuous operation

or high ambient temperature. The maximum flow decreases, as the valve is less open.

It is important to verify that at the maximum required flow rate, for a given gas, the inlet pressure is higher than the pressure

drop. If this cannot be achieved, contact Sensirion –it might be possible to order a similar mass flow controller with larger-

sized valve. Larger valves offer a lower pressure drop at the cost of a decreased accuracy/resolution at low flows.

www.sensirion.com

Version 1 –Mar 2023

7 / 13

Copyright © Sensirion AG 2022.

6. Fluidic and electrical connectors

Product reference

Fluidic connector

Electrical

connector

SFC6000D/

SFM6000D

Push-in: tube outer diameter 6 mm, Downmount

(exchangeable with Festo QSP 18 mm interface)

M8 (4 pin)

Table 3. Fluidic and electrical connectors

6.1. Mounting guide

The SFC6000 can be mounted from the bottom, the top or on a downmount manifold depending on application

requirements. A more comprehensive description of the mounting options is coming soon.

6.1.1. Mounting from the bottom of device

With the help of tapping screws (PT-screw K30, diameter = 3mm) the devices can be secured on the plate from the bottom.

One should not screw the tapping screws more than 8 mm into the body of the device. Do not use larger screws, as this

introduces stress to the device, influencing performance.

6.1.2. Mounting from the top of device

The SFC6000 and SFM6000 can also be mounted from the top when removing their cap. This is done with M2.5 X 20 screws.

www.sensirion.com

Version 1 –Mar 2023

8 / 13

Copyright © Sensirion AG 2022.

6.1.3. Downmount manifold

Downmount connectors are included with each distribution SFC6000D and SFM6000D.

Figure 2. Dowmount fittings on SFM6000(D) (left) and SFC6000(D) (right).

When using products with downmount connectors, a specific manifold must be designed and manufactured by the user.

In Table 4in the useful resources section, CAD models for a suggested manifold designs for SFC6000(D) / SFM6000(D) can

be found. They can be used as a starting point for a custom design.

4 screws can be used for mounting. The O-rings must be placed on the Mass Flow Controller side. The manifold pictured

below can be used as a starting point for the design. A mass Flow Controller is placed on top of the manifold.

Figure 3. Downmount manifold design for SFM6000(D) (left) and SFC6000(D) (right).

www.sensirion.com

Version 1 –Mar 2023

9 / 13

Copyright © Sensirion AG 2022.

7. Useful resources

7.1. Documentation

Various guides and application notes are available on Sensirion website.

Mass Flow Controllers (SFC): Product catalog (sensirion.com)

Mass Flow Meters (SFM): Product catalog (sensirion.com)

General technical download section: sensirion.com/products/downloads/

The most relevant resources are linked below.

Datasheet

Selection Guide

Quick start guide

SFC6000 gas fittings guide

www.sensirion.com

Version 1 –Mar 2023

12 / 13

Copyright © Sensirion AG 2022.

7.2. CAD models

Product

CAD model

Link

SFC6000D/

SFM6000D

Push in with green cap,

Downmount with green cap,

Downmount manifold

https://sensirion.com/resource/cad/sfc-sfm6000

Table 4. SFC6000D and SFM6000D and downmount manifold CAD models.

7.3. Software tools

7.3.1. Control Center software

Sensiron Control Center and manual

https://sensirion.com/products/sensor-evaluation/control-center/

7.3.2. Software drivers

Python driver (For use with EK-F5x evaluation kit or custom cabling)

https://github.com/Sensirion/python-uart-sfx6xxx

C driver (For use with Raspberry-Pi)

https://github.com/Sensirion/raspberry-pi-uart-sfx6xxx

Arduino Library

https://github.com/Sensirion/arduino-uart-sfx6xxx

7.4. Calibration and FAQ

Thanks to the stability of the MEMS-based sensor element and the robust mechanical design, Sensirion Mass Flow

Controllers do not drift and do not require recalibration in the field.

High manufacturing standards used during production ensure that our Mass Flow Controllers are extremely reliable and

have a very low failure rate. This is supported by field surveys and measurements.

FAQ:

sensirion.com/products/support/faq/

www.sensirion.com

Version 1 –Mar 2023

13 / 13

Copyright © Sensirion AG 2022.

Important Notices

Warning, Personal Injury

Do not use this product as safety or emergency stop devices or in any other application where failure of the product could result in

personal injury. Do not use this product for applications other than its intended and authorized use. Before installing, handling, using

or servicing this product, please consult the data sheet and application notes. Failure to comply with these instructions could result in

death or serious injury.

If the Buyer shall purchase or use SENSIRION products for any unintended or unauthorized application, Buyer shall defend, indemnify and

hold harmless SENSIRION and its officers, employees, subsidiaries, affiliates and distributors against all claims, costs, damages and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if SENSIRION shall be allegedly negligent with respect to the design or the manufacture of the

product.

ESD Precautions

The inherent design of this component causes it to be sensitive to electrostatic discharge (ESD). To prevent ESD-induced damage and/or

degradation, take customary and statutory ESD precautions when handling this product.

See application note “ESD, Latch up and EMC” for more information.

Warranty

SENSIRION warrants solely to the original purchaser of this product for a period of 12 months (one year) from the date of delivery that

this product shall be of the quality, material and workmanship defined in SENSIRION’s published specifications of the product. Within such

period, if proven to be defective, SENSIRION shall repair and/or replace this product, in SENSIRION’s discretion, free of charge to the

Buyer, provided that:

•notice in writing describing the defects shall be given to SENSIRION within fourteen (14) days after their appearance;

•such defects shall be found, to SENSIRION’s reasonable satisfaction, to have arisen from SENSIRION’s faulty design, material, or

workmanship;

•the defective product shall be returned to SENSIRION’s factory at the Buyer’s expense; and

•the warranty period for any repaired or replaced product shall be limited to the unexpired portion of the original period.

This warranty does not apply to any equipment which has not been installed and used within the specifications recommended by

SENSIRION for the intended and proper use of the equipment. EXCEPT FOR THE WARRANTIES EXPRESSLY SET FORTH HEREIN, SENSIRION

MAKES NO WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO THE PRODUCT. ANY AND ALL WARRANTIES, INCLUDING

WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY EXCLUDED AND

DECLINED.

SENSIRION is only liable for defects of this product arising under the conditions of operation provided for in the data sheet and proper

use of the goods. SENSIRION explicitly disclaims all warranties, express or implied, for any period during which the goods are operated or

stored not in accordance with the technical specifications.

SENSIRION does not assume any liability arising out of any application or use of any product or circuit and specifically disclaims any and

all liability, including without limitation consequential or incidental damages. All operating parameters, including without limitation

recommended parameters, must be validated for each customer’s applications by customer’s technical experts. Recommended parameters

can and do vary in different applications.

SENSIRION reserves the right, without further notice, (i) to change the product specifications and/or the information in this document and

(ii) to improve reliability, functions and design of this product.

Copyright © 2021, by SENSIRION. CMOSens® is a trademark of Sensirion. All rights reserved

Headquarters and Subsidiaries

Sensirion AG

Laubisruetistr. 50

CH-8712 Staefa ZH

Switzerland

Sensirion Inc., USA

phone: +1 312 690 5858

info-us@sensirion.com

www.sensirion.com

Sensirion Korea Co. Ltd.

phone: +82 31 337 7700~3

info-kr@sensirion.com

www.sensirion.com/kr

phone: +41 44 306 40 00

fax: +41 44 306 40 30

info@sensirion.com

www.sensirion.com

Sensirion Japan Co. Ltd.

phone: +81 3 3444 4940

info-jp@sensirion.com

www.sensirion.com/jp

Sensirion China Co. Ltd.

phone: +86 755 8252 1501

info-cn@sensirion.com

www.sensirion.com/cn

Sensirion Taiwan Co. Ltd

phone: +886 3 5506701

info@sensirion.com

www.sensirion.com

To find your local representative, please visit www.sensirion.com

This manual suits for next models

3

Table of contents

Other SENSIRION Controllers manuals

Popular Controllers manuals by other brands

Rain Bird

Rain Bird ESP-LXIVM troubleshooting guide

Rain Bird

Rain Bird ET Manager Series Installation and operation manual

Hills Reliance

Hills Reliance TouchNav User reference guide

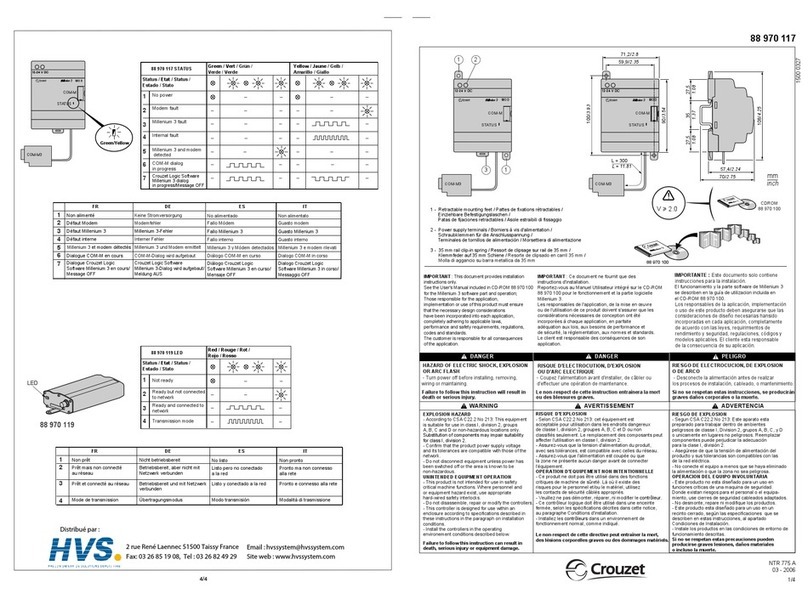

Crouzet

Crouzet 88 970 117 manual

HEIDENHAIN

HEIDENHAIN ND 280 - GUIDE Quick reference guide

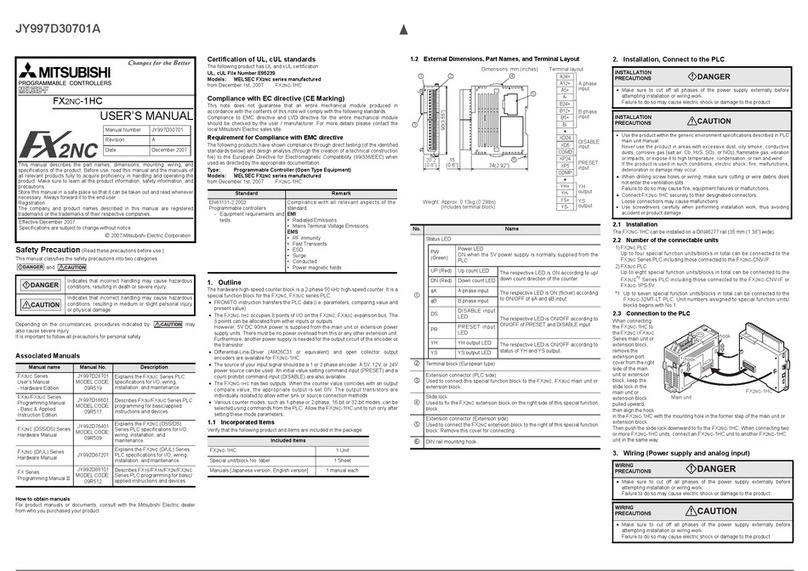

Mitsubishi

Mitsubishi FX2NC Series user manual