Metek TWRF1 SCR Series Operation and maintenance manual

SCR POWER CONTROLLER

for RF Applications

Instruction, Operation and

Maintenance Manual

Number: 9100051

Revision 2

530 Lakeview Plaza Blvd, Ste C

Worthington, Ohio, USA 43085

Toll F re e : 1 - 8 88- PWR- C NTL (7 9 7 -26 85)

Ph o n e: 61 4 -3 0 8-550 0

Fa x : 614 - 3 08 - 5506

Web: w w w .hd rpow e r. c o m

TWRF1 SCR Series

30-225 Amperes

Single-phase

Phase-fired

This manual applies to all Model TWRF1 SCR Power Controls. Former TWRF1 manual – 9100026 has been

replaced with this manual.

For the support representative nearest you, please call Ametek HDR Power Systems main office at (614)-308-

5500.

Revision 1 December 2017 Initial Release

Revision 2 Aug 2022 General Revision

2022 by Ametek HDR Power Systems. No portion of this document may be reproduced either mechanically or electronically without the

prior consent of Ametek HDR Power Systems.

TWRF1 SCR Power Controller Table of Contents

Rev 2 Ametek HDR Power Systems i

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ............................................................................................................. 1

CHAPTER 1 - DESCRIPTION .............................................................................................................................. 3

1.1 General Description 3

1.2 Application 3

1.3 Operation 3

1.4 Selecting the Proper Rated Power Controller 3

1.5 Specification 4

1.6 Option ER (Extended Ramp) 4

1.7 Additional Options 4

CHAPTER 2 - INSTALLATION ............................................................................................................................ 7

2.1 Mounting the TWRF1 7

2.2 Input/Output Wiring 7

2.3 Fan Wiring (applicable to models rated 90 A and higher) 7

2.4 Wiring Overtemperature Contacts 8

2.5 Command Signal Input 8

2.6 Determining Line Frequency 9

2.7 Voltage Changeover 9

CHAPTER 3 - OPERATION ............................................................................................................................... 11

3.1 General 11

3.2 Front Panel Indicators 11

3.3 Remote Manual Control with a Potentiometer 11

3.4 Process Command Input Control 12

3.5 Auto/Manual Control with a Controller and Remote Potentiometer 13

3.6 On/Off Control 14

3.7 Shutdown 14

3.8 Overcurrent Trip 15

CHAPTER 4 - THEORY...................................................................................................................................... 17

4.1 Functional Description 17

4.2 Overview of the TWRF1 17

4.3 Digital Firing Control Circuit 17

4.4 Pulse-Train Firing 17

4.5 Phase-Lock Loop 17

4.6 SPAN and ZERO Controls 18

4.7 Voltage-Squared Feedback 18

4.8 Shut-down 18

CHAPTER 5 – TROUBLESHOOTING ............................................................................................................... 19

5.1 Customer-Service Program 19

5.2 Troubleshooting Typical Symptoms 19

5.3 Static Precautions when Servicing 19

5.4 Environmental Problems 20

5.5 Input Power and Load Connections 20

5.6 Correcting Troubles in the TWRF1 Itself 21

CHAPTER 6 - SERVICE ..................................................................................................................................... 22

6.1 Communication Procedures 22

6.2 Spare Parts Orders – Routine or Emergency 22

6.3 Spare Parts List 23

CHAPTER 7 – WARRANTY POLICY ................................................................................................................ 24

Table of Contents TWRF1 SCR Power Controller

ii Ametek HDR Power Systems Rev 2

7.1 Warranty 24

7.2 In-house Repair Services 24

7.3 Field Service Repairs 25

APPENDIX .......................................................................................................................................................... 26

Appendix A – System Schematic 26

Appendix B – 30-60 A Outline 27

Appendix C – 90-225 A Outline 28

TWRF1 SCR Power Controller Table of Contents

Rev 2 Ametek HDR Power Systems iii

TABLE OF CONTENTS

Par. Title Page

ILLUSTRATIONS

Figure 2.1 Thermostat Connections ..................................................................................................................... 8

Figure 2.2 Isolated/Non-Isolated Switches .......................................................................................................... 8

Figure 2.3 T1 Transformer Connections .............................................................................................................. 9

Figure 3.1 Control Panel .................................................................................................................................... 11

Figure 3.2 Remote Control with a Potentiometer ............................................................................................... 12

Figure 3.3 Process Controller Input Connections .............................................................................................. 13

Figure 3.4 Auto/Man Control with Controller and Remote Potentiometer ......................................................... 13

Figure 3.5 On/Off Control ................................................................................................................................... 14

Figure 3.6 Shutdown Control ............................................................................................................................. 14

Figure 3.7 Current Limit/Trip Board ................................................................................................................... 15

Figure 4.1 AC Switch and SCR On-time ............................................................................................................ 17

TABLES

Table 1.1 kVA vs. Impedance .............................................................................................................................. 4

Table 1.2 TWRF1 Model Number Breakdown ..................................................................................................... 4

Table 1.3 General Specifications of TWRF1 Models ........................................................................................... 5

Table 2.1 Wire Size Information ........................................................................................................................... 7

Table 2.2 Transformer Voltage Wiring ................................................................................................................. 9

Table 5.1 Troubleshooting Chart (Symptoms and Solutions) ............................................................................ 21

Table 6.2 Torque Specifications ........................................................................................................................ 21

Table 6.1 TWRF1 Spare Parts List .................................................................................................................... 23

Table of Contents TWRF1 SCR Power Controller

iv Ametek HDR Power Systems Rev 2

TWRF1 SCR Power Controller Safety Instructions

Rev 2 Ametek HDR Power Systems 1

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Observe all warnings and cautions in this manual. Failure to do so may result in serious injury or death.

Refer all service to properly trained and qualified service personnel. Never work alone.

Lethal voltages exist on exposed heat sinks even if the power controller is turned off. Remove power and lock

out power before attempting any service.

This manual contains important safety instructions that must be followed during the installation and

maintenance of the SCR Power controller. Read this manual thoroughly before attempting to operate this

Power controller.

An appropriate branch circuit fused disconnect or circuit breaker with this Power Controller is required to

ensure the safety of operating personnel.

CAUTION

HAZARDOUS VOLTAGES exist at the Power Controller Load, AT ALL TIMES, when input voltage is

connected. This condition exists even when the Power Controller is set to deliver zero output.

Printed circuit boards contain sensitive components that can be damaged by electrostatic discharge (ESD).

Observe precautions for handling electrostatic sensitive devices. Reference Maintenance and Troubleshooting

(Chapter 5) of this manual for details

In case of fire, use a dry chemical fire extinguisher to put out the fire. Using a liquid fire extinguisher may

cause electric shock.

The SCR Power Controller makes use of components dangerous for the environment (electronic printed circuit

boards, electronic components). The components removed must be taken to specialized collection and

disposal centers.

Safety Instructions TWRF1 SCR Power Controller

2 Ametek HDR Power Systems Rev 2

TWRF1 SCR Power Controller Description

Rev 2 Ametek HDR Power Systems 3

CHAPTER 1 - Description

1.1 General Description

The TWRF1 is a Single-phase, phase-fired power controller, and can operate with a wide variety of

input signals and line voltages up to 575 Vac and currents ranging from 30 through 225 amperes. The

TWRF1’s output voltage is proportional to its input signal, with the output voltage regulated to +1%

with a +10% line voltage change. The TWRF1 features pulse-train firing which provides high immunity

to possible SCR firing disturbances, and phase-lock loop circuitry which ensures line frequency

synchronization. Other features are input isolation from ground, soft-start, and automatic restart

circuitry. A customer provided potentiometer controls to the Command signal. A variety of other

external control methods are available, more detailed description of the features mentioned above is

provided in Chapter 3 of this manual.

1.2 Application

Phase-Fired SCR Power Controllers provide infinitely variable firing angles for precise control of

single-phase power to resistive or inductive loads. This precise control is essential for transformer

coupled loads or loads with great resistance changes due to temperature or start-up. Phase-Fired

units may also be used on straight resistive loads as well, but the lower power factor and higher

harmonics may present a problem to other equipment mounted nearby. A zero fired model would be a

better choice.

1.3 Operation

The TWRF1 accomplishes power control by the switching action of a pair of inverse-parallel power

SCRs. The switching, or gating, of the SCRs is controlled by a digital firing control circuit synchronized

“in phase” with line frequency (either 50 or 60 Hz). A soft-start (approximately a 1 cycle ramp) feature

is standard that allows the Power Controller to fire into the primary of a transformer or to control power

to heating elements which have a large resistance change during start-up. The output may be adjusted

by the on-board multi-turn potentiometers or by a voltage or current signal from a process controller.

ZERO and SPAN controls allow the user to calibrate the SCR unit's output to the process command

signal. Terminals are available for connection of a remote manual potentiometer.

An overcurrent trip is included. This circuit protects from output current overloads by serving as a fast-

gate shutdown (similar to an electronic fuse.) Trip point is adjustable from 30% to 200% of the SCR

Power Control’s current transformer rating. When the peak current level exceeds the preset trip level,

SCRs are gated off, and the load current is shut down within 1/2 cycle. A form C relay output is

provided.

The overcurrent trip includes a Form C relay output and provisions for a remote overcurrent reset push

button. The relay output terminals for the TWRF1 are 35 and 36 for the N.C. and 36 and 37 for the

N.O. The remote reset PB connects to terminals 33 and 34. Reference Figure 3.7.

1.4 Selecting the Proper Rated Power Controller

Use the Table below to select the proper sized TWRF1. You will need the incoming line voltage and

the transformer leakage impedance. For voltages other than 480V, ratio the incoming voltage using

the 480V chart provided below. For example, a 240V system the kVA would be half that on the chart

for any given kVA. The kVA is based upon the one cycle surge ratings of the SCRs installed in each

of the power controls.

Description TWRF1 SCR Power Controller

4 Ametek HDR Power Systems Rev 2

Table 1.1 kVA vs. Impedance

Impedance

Current Rating 4% 6% 8% 10% 12%

kVA

30 Amps 9 13 17 22 30

40 Amps 9 13 17 22 30

60 Amps 9 13 17 22 30

120 Amps 19 32 40 54 60

225 Amps 37 57 95 107 120

1.5 Specification

Specifications for the TWRF1 SCR power controller are given in Tables 1.1 and 1.2.

Table 1.2 TWRF1 Model Number Breakdown

TWRF1 – 480 – 120 – NO – ER – 01

NOTE: N.C. Thermostat is included in current ratings above 60 A.

1.6 Option ER (Extended Ramp)

The options limits the rate at which the output can increase to prevent high inrush currents with

transformer coupled loads or high cold-to-hot resistance ratios such as tungsten heating elements

The rate of increase is limited to approximately 100% over four seconds. The standard extended ramp

time is 12 cycles.

1.7 Additional Options

The options described above are the ones most commonly used. Additional options are available. For

more information, contact Ametek HDR Power Systems.

120 Vac - 120

240 Vac - 240

400 Vac - 400

480 Vac - 480

575 Vac -

575

30 A rms - 30

40 A rms - 40

60 A rms - 60

90 A rms - 90

120 A rms – 120

225 A rms – 225

N.O. Thermostat - NO

N.C. Thermostat - NC

Extended Ramp - ER

Can have multiple selections

4-20 mA - 01

0-10 Vdc - 02

0-5 Vdc - 03

Auto/Man - 04

Manual Pot input - 05

Others

-

xx

TWRF1 SCR Power Controller Description

Rev 2 Ametek HDR Power Systems 5

Table 1.3 General Specifications of TWRF1 Models

Input line voltage: * 120, 240, 400, 480, or 575 Vac,

+10%, -15%, Single-phase

Line frequency: * 50 or 60 Hz

Current rating:

*

As indicated by model number (refer to Table 1.2)

Thermostat contact rating: 120 Vac, 5 A; resistive

Input Signal:

Non-isolated

Isolated

0 to 1.5 V (min); 0 to 10 V (max) - Standard

0 to 6 mA (min); 0 to 20 mA (max)

Control methods: 1. Potentiometer, 5 kΩ, 1/2 watt (Customer-supplied) - Standard

2. Dry contact closure (customer-supplied).

3. Temperature or process controller

*

*

Control signal input impedance:

Non-isolated input

Isolated input

1500 Ω

500 Ω

Control signal isolation:

From SCRs 2,500 Vac

From ac power input lines 2,500 Vac

From chassis 500 Vac

Power output:

Voltage regulation Voltage Squared

Power output linearity versus

control signals input

+2% (Non-isolated)

+5% (Isolated)

Power SCRs protection:

Current surge Subcycle I² T semiconductor fuse. – OPTIONAL

Transient voltage spikes (dv/dt)

Metal Oxide Varistor (MOV) and R-C snubber across each SCR pair; all

SCRs have PIV rating of 1,400 V.

Miscellaneous:

Phase-firing timebase 0º to 180º conduction per SCR

Controls: ZERO and SPAN potentiometers; 10-turn, screwdriver-adjustable.

Ambient Temperature range:

Environment 32 ºF to 122 ºF ( 0 ºC to 50 ºC) surrounding air

Pollution degree 2

Overvoltage Category III

Storage 14 ºF to 158 ºF ( -10 ºC to 70 ºC)

Weight per unit: Current Rating

30 through 60 A

90 through 225 A

lbs

6

18

kg

2.7

8.2

Outline and mounting: See appropriate drawing in Appendix

* Specify with order

** If you will be using temperature/process controller, specify its output; e.g., 4-20 mA, 0-10 Vdc, 2-10 Vdc,

etc. with your order.

NOTE: The TWRF1 should be tested or operated with an adequate load since an open output will have line

voltage at the load connections.

Description TWRF1 SCR Power Controller

6 Ametek HDR Power Systems Rev 2

TWRF1 SCR Power Controller Installation

Rev 2 Ametek HDR Power Systems 7

CHAPTER 2 - Installation

2.1 Mounting the TWRF1

Determine the voltage and current ratings from the nameplate of the unit (refer to Table 1.2). Then

determine space and mounting hole requirements by referring to the outline drawing (at the Appendix)

that applies to your model’s current rating. Mount the unit so the line and load connections are at the

top and ensure that upward airflow over the heat sink fins is unrestricted. On high current models,

allow adequate clearance for routing the relatively large diameter input and output lines.

2.2 Input/Output Wiring

Using appropriately sized and insulated conductors for the voltage and current ratings of your model,

make connections as shown in Appendix A. (Refer to Table 2.1 for wire size information). Torque

specifications of bolted connections can be found in Table 5.2.

A ground wire is required for proper operation. Use a 14 AWG for 15-30 A and 10 AWG or larger wire

for the other sizes.

NOTICE

Use copper conductors rated 75 ºC minimum for all model current ratings.

On the “internal” side of the TWRF1, the wire from L2 should connect to the appropriate tap of

transformer T1, depending on the line voltage to be used. Check the T1 connection by opening the

TWRF1 cover; T1 terminal voltages are clearly marked. Reference Chapter 2.7.

Table 2.1 Wire Size Information

Model Size Wire/Cable

30 A 8 to 0 AWG

40 A 8 to 0 AWG

60A 8 to 0 AWG

90 A 8 to 0 AWG

120 A 8 to 0 AWG

225 A 6 to 250 MCM

2.3 Fan Wiring (applicable to models rated 90 A and higher)

TWRF1 models rated 90 A and higher with cooling fans require 120 Vac power which must be

supplied by the customer. Fan power should be connected to terminals 21 and 22 as shown in Figure

2.1. Refer to Table 1.3 for fan power requirements by model.

The RF3 terminals available for the 120 Vac fan connections are shown Figure 2.1 and in the

schematic in Appendix A. Optional 220 Vac fans are available.

WARNING

Branch circuit overcurrent protection required is to be provided in

accordance with the national and local codes of the inspecting authority.

Installation TWRF1 SCR Power Controller

8 Ametek HDR Power Systems Rev 2

2.4 Wiring Overtemperature Contacts

Normally-closed (N.C.) heat sink thermostats are standard on all fan-cooled models (rated 90 A and

higher). These thermostats, which close on high heat sink temperature (200 ºF), may be used to

initiate an alarm, shunt trip, or other device for SCR protection. Thermostat connections are on

terminals 23 and 24 as shown in Figure 2.1.

If desired, normally-open (N.O.) contacts may be substituted for the normally-closed (standard). Heat

sink thermostats are optional on units with current ratings lower than 60 amperes and can be ordered

with either N.O. or N.C. contacts.

FAN POWER

120 Vac

(220 Vac

OPTIONAL)

OVER TEMP

N.O. STANDARD

(N.C. OPTIONAL)

21 22 23 24

Figure 2.1 Thermostat Connections

2.5 Command Signal Input

HDR’s TWRF Phase-Fired SCR Power Controllers are configured for a potentiometer (non-isolated)

but, has the capability of having either an isolated current or non-isolated voltage Command Signal

input. The standard input impedance is 500 ohms for isolated and 1500 ohms for non-isolated. The

potentiometer may by 500 Ω to 5 kΩ, and should be rated at 1/2 watt, minimum.

All units are equipped with DIP switches, select “isolated” position for a 4-20 mA command signal and

“non-isolated” for a voltage input such as 0-10 V dc. See Figure 2.2.

The isolated input works best with an offset Command Signal such as 4-20 mA; however, it will work

with both offset and zero based Command Signals. Zero based Command Signals may have a small

amount of non-linearity (input to output) at the low end. This should not be a problem on closed loop

systems.

Current Input Voltage / Manual Pot Input

Figure 2.2 Isolated/Non-Isolated Switches

----OPEN ----

12 3 4C1

C2

NON-ISOLATED-C2

SW2

ISOLATED-C1

SW1

TWRF1 SCR Power Controller Installation

Rev 2 Ametek HDR Power Systems 9

2.6 Determining Line Frequency

The TWRF1 is designed to operate on either 50 or 60 Hz. Usually the TWRF1 is shipped for 60 Hz

operation, unless otherwise ordered. The TWRF1 can be set for either ac line frequency by selecting

50 Hz or 60 Hz on SW3 on the control board on the inside front door.

2.7 Voltage Changeover

On occasion, customers may wish to operate a TWRF1 SCR Power Controller on line voltages other

than what was specified when originally ordered. The TWRF1 may be changed to accept a wide

range of line voltages (120, 240, 400, 480, 575 Vac), so long as the load current does not exceed the

TWRF1’s current rating. This is accomplished by performing the procedure described below.

.

Using the system schematic (located in the Appendix) as reference, perform the voltage changeover

procedure as follows.

1. Open the SCR power controller, and locate transformer T1. The primary side of T1 transformer

will contain two wires (one black, the other white and black). Refer to figure 2.3.

Figure 2.3 T1 Transformer Connections

2. Unsolder the Black/White wire on T1 from the voltage tap, and resolder it to the tap desired, as

shown in Table 2.2. Route the wires so that they are physically located under the transformer

terminals.

Table 2.2 Transformer Voltage Wiring

Desired Voltage T1 White &

Black Wire to

120 120

208, 220, 240 240

380, 400, 415 400

480 480

575 575

3. Close the unit, and apply line power. The unit is now ready for operation on the line voltage

selected. It is a good idea to identify the unit with a label or tag, noting that TWRF1 has been

modified for line voltage other than what it was specified for. This may prevent accidental use on

an incorrect line voltage in the future.

WARNING

Voltage changeover should be performed by qualified personnel only.

Always remove power and properly lock out power to the unit before

attempting any service.

Operation TWRF1 SCR Power Controller

10 Ametek HDR Power Systems Rev 2

TWRF1 SCR Power Controller Operation

Rev 2 Ametek HDR Power Systems 11

CHAPTER 3 - Operation

3.1 General

This Chapter provides information necessary for proper setup and operation of various methods used

to control the TWRF1.

a. Front Panel indications

b. Command input control

c. Remote manual control with a potentiometer

d. Auto/manual control with a controller and potentiometer

e. On/off control

f. Shutdown

Figure 3.1 Control Panel

3.2 Front Panel Indicators

Control Power Indicator – A Red Light Emitting Diode (LED) located on the front cover of the unit

signals when the control power is present.

Command Signal Indicator - The Command Signal Indicator is a green Light Emitting Diode (LED)

located on the front cover of the unit. The brilliance of this LED will change with a current Command

Signal. The brilliance increases with an increased Command Signal and decreases with a decreased

Command Signal. The LED will not function with a voltage or manual input.

Blown Fuse Indicator - The Blown Fuse Indicator is a yellow Light Emitting Diode (LED) located on the

front cover of the unit. Switches on the fuse controls the LED. Not available on 15-40 A models

3.3 Remote Manual Control with a Potentiometer

The TWRF1 is calibrated at the Factory for the specified input type and normally does NOT need

adjustment. However, should a setup be required use the following methods. Refer to chapter 2.5 for

the Command signal input configuration.

Operation TWRF1 SCR Power Controller

12 Ametek HDR Power Systems Rev 2

a. With the power to the TWRF1 turned off, connect the potentiometer as shown in Figure 3.3. The

CW position is the full power output position. Terminal TB1-5 is internally connected to a positive

dc voltage source.

Figure 3.2 Remote Control with a Potentiometer

b. Connect a voltmeter across terminals X1 and X2 of the TWRF1. Set the voltmeter range to

measure the full output voltage.

c. Set the SPAN control and remote potentiometer fully CCW.

d. Close the fused disconnect or circuit breaker to apply power to the TWRF1. The unit should be

energized, with no output.

e. Adjust the ZERO control CW until the output just turns on, then turn the ZERO control CCW just to

the point where the output voltage reading is zero.

f. Set the SPAN control and remote potentiometer fully CW. The output should be full-on.

g. Observe the voltmeter and slowly adjust the SPAN control CCW, just to the point where the output

voltage reading is at maximum.

h. If necessary, readjust ZERO with remote potentiometer fully CCW and SPAN control and remote

potentiometer fully CW.

i. Turn off the line power to the TWRF1 and disconnect the test equipment.

3.4 Process Command Input Control

Some applications require a closed loop input from a process controller. Should an isolated setup be

required use the following methods. Refer to chapter 2.5 for the Command signal input configuration.

a. Set the ZERO and SPAN controls fully CCW (counterclockwise).

b. Connect a voltmeter across terminals X1 and X2 of the TWRF1. Set the voltmeter range to

measure full input voltage.

c. Close the fused disconnect or circuit breaker to apply power to the TWRF1. Turn the front panel

CUR/PWR potentiometer fully CW. If an isolated signal is used turn the Process controller on and

set to demand zero power output.

WARNING - ELECTRIC SHOCK CAN KILL

HAZARDOUS VOLTAGES exist at the output terminals and at the load when

the input voltage is connected. This condition exists even when the Controller is

set to deliver zero output. Always remove power and properly lock out power to

the unit before attempting any service, including the load.

TWRF1 SCR Power Controller Operation

Rev 2 Ametek HDR Power Systems 13

Figure 3.3 Process Controller Input Connections

d. Adjust the ZERO control CW until the output just turns on, then turn the ZERO control CCW just to

the point where the output voltage reading is zero.

e. Set the CUR/PWR potentiometer or Process controller to demand 100% output. Observing the

voltmeter, adjust SPAN CW just to the point where the reading is below the maximum output

voltage. Then adjust SPAN CW just to the point where the meter reading is at maximum.

f. Repeat steps 3.3e and 3.3f as necessary, to ensure proper control adjustments have been made.

g. Turn off the line power to the TWRF1 and disconnect the test equipment. The TWRF1 is now

ready for automatic operation.

h. Adjust the CUR/PWR potentiometer CW until the output trips to the desired level.

3.5 Auto/Manual Control with a Controller and Remote Potentiometer

On closed loop processes it may be desirable to be able to operate the unit manually. The SCR Power

Controller has this capability designed into it. Connect the Command Signal, a Remote Manual control

and an Auto/Manual switch in the Auto position. By switching to the Manual position, the Remote

Manual control operates and the auto signal is disconnected.

With the power to the TWRF1 turned off, connect the switch, potentiometer, and controller as shown in

Figure 3.4 and remove jumper from terminal TB1-7 and TB1-8. Install the AUTO/MAN switch in the

same general location as the remote manual potentiometer. Note that the full CW position of the

potentiometer is the full-power-output position.

Figure 3.4 Auto/Man Control with Controller and Remote Potentiometer

Place the AUTO/MAN switch to AUTO and calibrate the system as described in steps 3.3b through

3.3h.

Operation TWRF1 SCR Power Controller

14 Ametek HDR Power Systems Rev 2

3.6 On/Off Control

Some applications require that a simple ON/OFF type control be used. The unit can be used in these

simple applications. It can be connected for turn on by a contact closure.

With the TWRF1 configured for non-isolated inputs and the power to the TWRF1 turned off, connect

the system as shown in figure 3.5. A closed contact will turn on (enable) the TWRF1.

Figure 3.5 On/Off Control

Calibrate the system by performing the steps in 3.3. Note that zero power demand is accomplished by

opening the contacts with the controller, and maximum power demand is present when the contacts

are closed.

3.7 Shutdown

When it is necessary to shutdown or disable the output, it is a simple matter. Connect a dry contact

closure between terminals 3 and 4 of the firing circuit as shown in Figure 3.6. A closed contact will

disable the TWRF1 output.

Figure 3.6 Shutdown Control

(Output Disabled By Contact Closure)

WARNING

This method of control is not to be used with isolated inputs!

Table of contents

Popular Controllers manuals by other brands

Clean Logix

Clean Logix ALX-ELITE user manual

XPR Access

XPR Access WS4-1D quick start guide

Global American Inc.

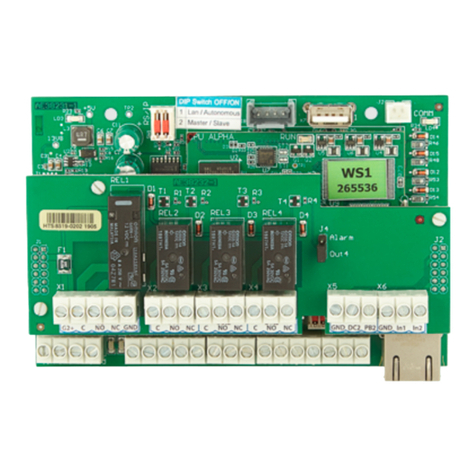

Global American Inc. 3307620 Version 1.0 user manual

Alfalaval

Alfalaval ESE02126-EN instruction manual

BZB Gear

BZB Gear BG-UHD-VWP-1X4 user manual

HANYOUNG NUX

HANYOUNG NUX HY Series instruction manual