Sensor Networks JAWS 2.0 User manual

Operator Manual

Basic and Ultimate Kits

2

3

Contents

JAWS

™ Overview ................................................................... 4

Precautions ..................................................................................... 5

Setup ............................................................................................... 6

Powering the System .................................................................. 6

HD Display / Controller ................................................................... 7

Operation........................................................................................ 8

Grabber Operation...................................................................... 8

Changing Jaw Sets....................................................................... 8

Battery Status.............................................................................. 8

Power Saving Modes................................................................... 8

Battery Charging ......................................................................... 9

Operation with AC Mains Power .............................................. 10

Securing with a Lanyard............................................................ 11

Spare Parts................................................................................ 11

JAWS

™ Ultimate Kit Accessories .......................................... 12

Interchangeable Jaw Sets ......................................................... 12

Retrieval Accessories ................................................................ 12

Interconnecting Long Push Poles and Case .............................. 13

Specifications ................................................................................ 14

Care............................................................................................... 14

Warranty....................................................................................... 15

Appendix ....................................................................................... 16

Using the Accessories ............................................................... 16

Contact Us..................................................................................... 22

4

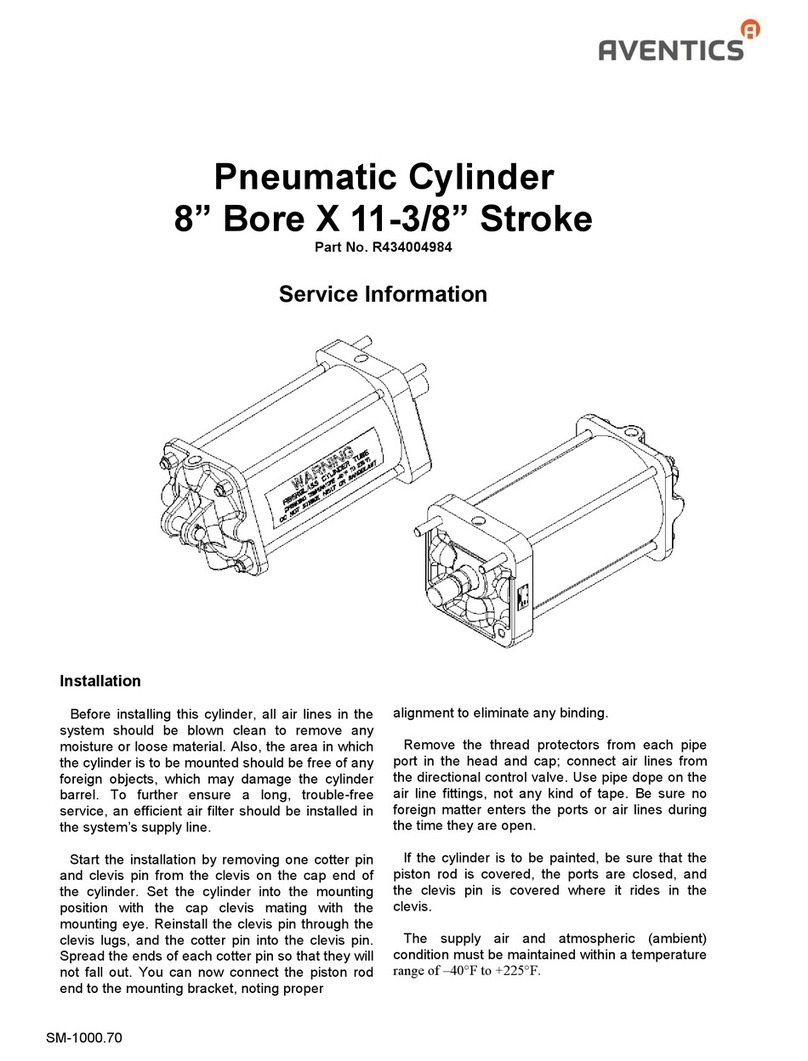

JAWS

™Overview

The

JAWS

™is a motorized retrieval device designed to be robust

and work in most environments. With a battery power pack, the tool

is portable and can be carried easily to any job site. Interchangeable

jaws sets and accessories allow equipping the tool to secure a large

variety of irregularly-shaped objects. A full line of accessories is

available in the

JAWS

™Ultimate Kit to deliver the tool to most

remote locations.

JAWS

™Basic Kit Contents

• JAWS 2.0 HD grabber

• JAWS 2.0 HD display/controller

• 50ft (15m) power/video cable

• AC adapter/charger

• operator manual

• hex key, spare screws

JAWS

™Ultimate Kit Contents

• JAWS 2.0 HD grabber • JAWS 2.0 HD display/controller

• AC adapter/charger • operator manual

• 50ft (15m) power/video cable + 50ft (15m) extension cable

• Jaw Sets: fork and tine | flat serrated | short serrated | sampling cups

curved serrated | needle-nose | tool adapter

• Tools: 2 snares: sm, lg | 2 magnets: sm, lg | Storage Case

4 hooks: sm, med, lg, xl

• Push Poles:

40 push poles - 60in (150cm) length

10 each: Ø 3

16in, 1

4in, 5

16in, 3

8in (Ø5,6,8,9mm)

4 push poles - 16in (40cm) length

1 each: Ø 3

16in, 1

4in, 5

16in, 3

8in (Ø5,6,8,9mm)

1 push pole - 12in (30cm) length × Ø 5

16in (Ø8mm)

1 push pole - 6in (15cm) × Ø 5

16in (Ø8mm)

• Push Pole Accessories:

quiver | tee handle | adjustable elbow

rubber flex joint | spring flex joint

•Miscellaneous: hex keys | spare screws | hoist lifting ring

5

Precautions

•EXPLOSION HAZARD: Do not use

JAWS

™ in an

explosive or hazardous environment.

•BODILY HARM HAZARD: Do not position

JAWS

™ near

moving machinery.

•Do not operate

JAWS

™ in temperatures below 0°F or above

120°F (-20°C - 50°C)

•Do not submerge

JAWS

™ in acids or caustics.

•Do not submerge

JAWS

™ deeper than 50 feet (15m) in water

or any other liquid. (Additional depth is attainable with a longer

main cable)

•Do not force

JAWS

™ into openings smaller than its diameter.

•Use only the supplied battery power pack as the

JAWS

™

power source.

•Keep the battery power pack away from high heat and equipment

that produces sparks.

•Replace any damaged or defective battery.

•Do not submerge battery power pack.

•Use only supplied charger to charge the battery. Follow battery

condition indicator on charger.

6

Setup

1. Connect main cable to grabber. Align the red dots and push

connector in until it clicks.

2. Connect extension cable as needed. Use without this cable is

recommended as the extra cable length consumes power that

would otherwise be available for the tool.

3. Connect cable to power pack.

4. Attach push rod or other rodding accessories to manipulate

the tool into position for grabbing.

Powering the System

ON: Press in the switch and release to start the system, the

status LED will blink Green while starting. The video will

display after 15 seconds. The status LED will change to Blue

indicating the system is ready.

OFF: Press in the switch for 2 seconds to power down the

system.

Power / Video

Cable

HD Display

/ Controller

HD Grabber

7

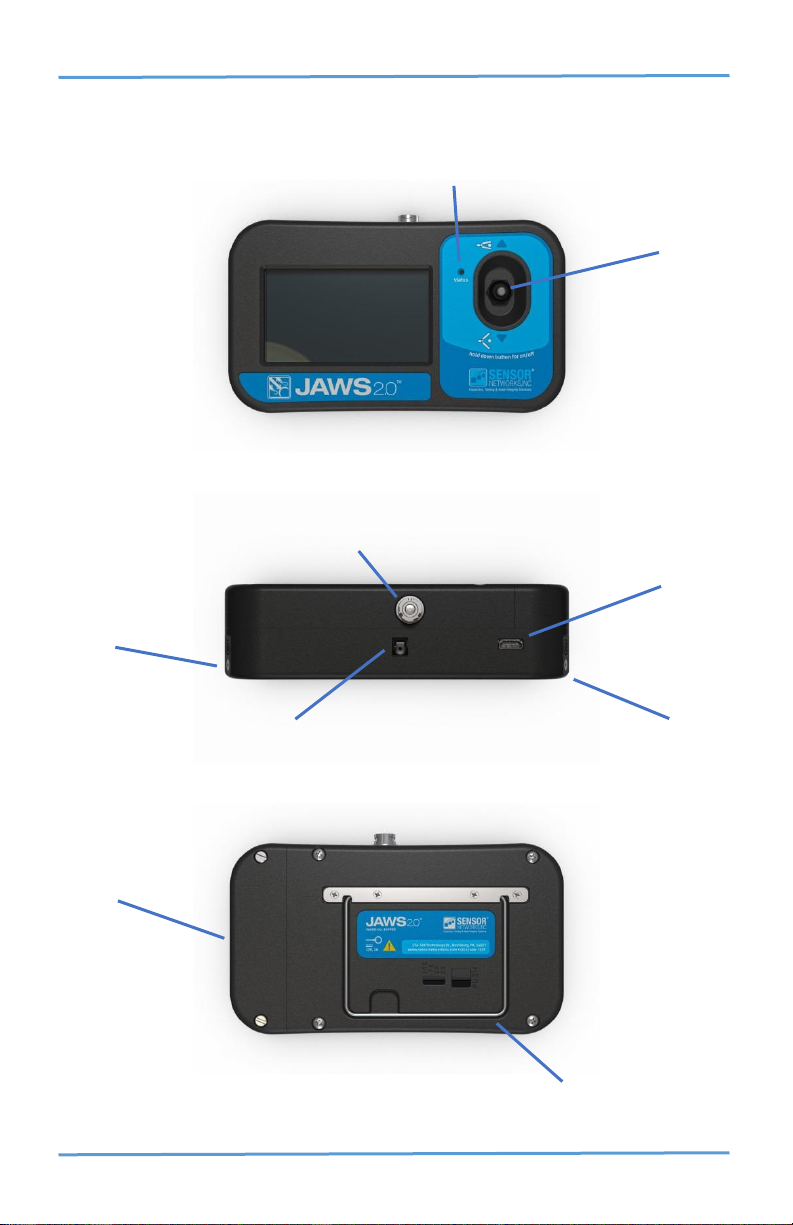

HD Display / Controller

Switch

Status LED

Cable Connector

HDMI Output

Power Connector

Battery Access

Folding Stand

¼”-20 Mount

For Lanyard

¼”-20 Mount

For Lanyard

8

Operation

Grabber Operation

Press the switch forward to close the tool jaws. When the jaws

have tightened fully, the status LED will change to Yellow.

Press the switch rearward to open tool jaws.

Changing Jaw Sets

To change the preferred jaw set on tool, use a 3/32-inch hex key

to remove the socket head screws on each jaw.

Slide each jaw off the tool and clean the interfacing surfaces.

Slide preferred jaw onto tool and install socket head screw.

Battery Status

Press the switch to the left to display the battery condition on the

status LED.

100% - 3 Green blinks

80% - 2 Green blinks

60% - 1 Yellow blink

40% - 1 Red blink

20% - 1 long Red blink

Power Saving Modes

After 10 minutes of no switch activity, the system will dim the

video display. The status LED will blink Blue. Moving the switch

will awaken the system.

After 20 minutes of no switch activity, the system will sleep using

a small amount of battery power. The status LED will blink

Blue. Moving the switch will awaken the system.

After 30 minutes of no switch activity, the system will completely

shut down and use no power. See Powering the System to

restart.

9

Battery Charging

Place the charger on a flat, level surface away from sources of

heat and moisture.

Plug the connector from the AC adapter into the back of the

charger and connect the adapter to the mains AC supply using

the cable supplied.

Place the battery into the battery bay ensuring that the 5-way

connector is fully seated. The LEDs in the status window will

provide status information and the charger will automatically

begin charging.

Green flashing: Battery charging

Green solid: Battery fully charged

Red: Error

Note: The battery does not charge while installed in the

controller. Follow instructions below to charge battery.

Open the battery compartment by loosening the two screws on the

controller back cover. Pop the cover up and off.

Remove the battery and insert it into the supplied charger. Full

charge time is generally 2 hours.

10

Reverse the above operation for portable / battery operation of the

JAWS tool.

Operation with AC Mains Power

Plug the barrel connector from the AC adapter into the power

jack on the HD Display / Controller. Connect the adapter to the

mains AC power outlet.

Power on the system, see Powering the System section.

The AC adapter will power only the tool system, the battery will

not charge if installed. The system will use AC power if available

first, and only use battery when AC is not present. Restarting the

system is necessary when changing power sources.

11

Securing the controller with a Lanyard

The JAWS 2.0 power pack / controller comes with an attachment

point for (not included) hand or neck lanyards. When using with

a lanyard, be sure to use only safety “break-away” lanyards.

Spare Parts

Part Number

Description

154701

JAWS

™HD Grabber

154900

JAWS

™HD Display / Controller

154740

Power / Video Cable 50ft (15m)

154730

Extension Cable 50ft (15m)

154703

154795

154796

154705

154707

Operator Guide

Rechargeable Battery

Battery Charger

Basic Kit Carrying Case

AC Adapter

12

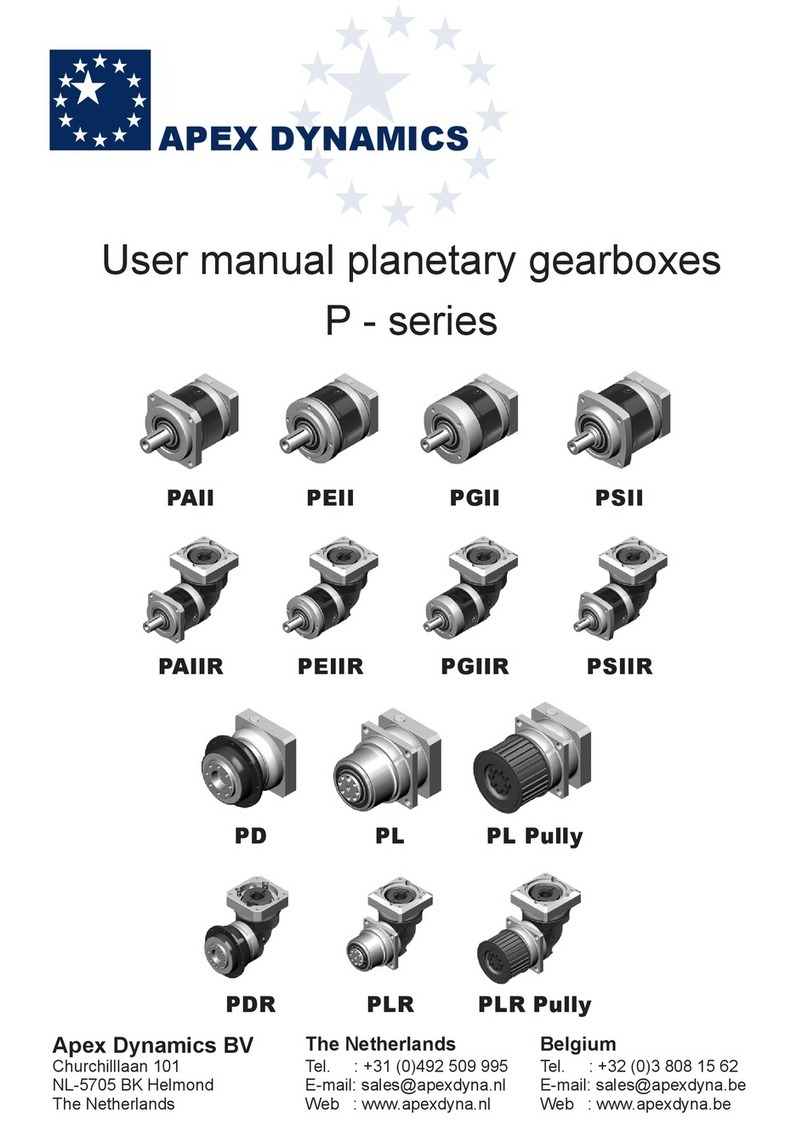

JAWS

™ Ultimate Kit Accessories

Interchangeable Jaw Sets

Part Number

Description

143360

Jaw Set, Fork & Tine

143370

Jaw Set, Flat Serrated

143380

Jaw Set, Curved Serrated

143390

Jaw Set, Needle Nose

145610

Jaw Set, Sampling Cups

153230

Tool Adapter

Retrieval Accessories

Part Number

Description

153201

Dual Magnet Kit, Small & Large

143203

Small Snare

143204

Large Snare

143220

Adjustable Elbow

143230

Tee Handle

143210

Hook, Small

143270

Hook, Medium

143280

Hook, Large

143290

Hook, Extra Large

140890

Rubber Flex Joint

143297

Spring Flex Joint

143396

Hoist Lifting Ring

143356

Plastic Vial for spare parts

143240

Ø 5/16" x 6"L (Ø 8mm x 15cm) Push Pole

143250

Ø 5/16" x 12"L (Ø 8mm x 30cm) Push Pole

153235

Ø 3/16" x 16"L (Ø 5mm x 40cm) Push Pole

153236

Ø 1/4" x 16"L (Ø 6mm x 40cm) Push Pole

153238

Ø 5/16" x 16"L (Ø 8mm x 40cm) Push Pole

153239

Ø 3/8" x 16"L (Ø 9mm x 40cm) Push Pole

153207

Ultimate Kit Carrying Case

13

Interconnecting Long Push Poles and Case

Part Number

Description

143265

Ø 3/16" x 60"L (Ø 5mm x 150cm) Push Pole

143266

Ø 1/4" x 60"L (Ø 6mm x 150cm) Push Pole

143268

Ø 5/16" x 60"L (Ø 8mm x 150cm) Push Pole

143269

Ø 3/8" x 60"L (Ø 9mm x 150cm) Push Pole

143261

Push Pole Quiver

14

Specifications

Construction

Aircraft-grade Aluminum Housing

Stainless Steel Jaw Sets

Polyurethane Cable Jacket

Polyurethane Display / Controller

Size

1.4in (37mm) Diameter

7.1in (180mm) Length

Weight

0.8lb (.36Kg) Remote Grabber Tool

3.1lb (1.4Kg) Battery Power Pack

0.7lb (0.32Kg) Cable

Jaw Opening

2.75in (70mm) maximum

Power

15 watts, 12Vdc (rechargeable NiMH battery)

Depth Rating

100ft (30m) maximum of water

Care

•Clean with mild soap and water, do not use solvents.

•Oil linkage periodically after cleaning.

•Check cable for damage, replace if jacket is breached.

•Keep battery charged, ready for use.

15

Warranty

Sensor Networks Inc. (SNI) warrants that the Products sold to Buyer

hereunder will be free from defects in material and workmanship

furnished by SNI and will conform, within normal commercial

tolerances, to applicable specifications. This warranty shall apply only

where Buyer has given SNI written notice of such defect or

nonconformity within one year (365 days) after receipt of the

Products by Buyer. This warranty does not extend to any Product

which has been subjected to abuse, misuse, neglect or accident, or to

any Product which has been repaired or altered by other than SNI.

THE FOREGOING WARRANTY IS BUYER’S SOLE AND

EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

WITHOUT LIMITATION, MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE, DESCRIPTION, QUALITY,

PRODUCTIVENESS, OR OTHERWISE.

This Warranty applies only to the original purchaser and cannot be

assigned or transferred to any third party without express written

consent of SNI. The warranty does not apply to expendable items or

normal wear and tear or failure due to overheating or radiation

exposure. Additionally, SNI assumes no responsibility, either

expressed or implied, regarding the improper usage of this equipment

or interpretation of test data derived from this product. SNI’s

responsibility and obligations, in all cases, are limited strictly to the

repair and/or replacement cost as outlined above. SNI is not

responsible for shipping costs. This warranty shall be governed by

the laws of the State of Pennsylvania.

If the equipment cannot be returned to SNI for whatever reason, the

customer agrees to pay for all travel and living expenses incurred to

have the SNI’s representative evaluate, assess or affect a field

warranty repair.

16

Appendix

Using the Accessories

Retrieval Tips and Using the JAWS 2.0 Kit

The JAWS 2.0 retrieval tool kit has been developed over decades of

successful loose-parts retrieval experience at Electric Power

Generation and Oil & Gas facilities around the world. Following are

some helpful tips and hints on how to maximize the value of your

JAWS 2.0 investment.

1. Adjustable elbow: PN 143220

Left: Connecting a push pole to the adjustable elbow. Use your

finger tip to compress the spring-loader locking pin. Slide male

fitting into the mating adaptor until seated and spring-loaded

locking pin pops into place. Right: Adjusting the elbow’s position

and tightening with hex wrench.

2. T-Handle PN 143230 handle with short pole 143250

17

The “T” Handle connects with any flex rod to provide rotational

control of the retrieval end-effectors. This function is very important

to performing successful retrievals.

3. JAWS 2.0 tool interconnects.

The adjustable elbow, the flex joints or any of the flexible rods can be

connected to the JAWS tool by squeezing the spring-loaded pushpin,

inserting and aligning the pin.

4. The small and large magnet are ideal for retrieving ferro-

magnetic objects such as most tools and metal filings.

Left: Connecting the adjustable elbow to the small rare-earth magnet.

Right: Large magnet. Both magnets are very powerful. Use care when

handling.

18

5. Snare closing in on a stainless-steel valve body. PN 143203

or 143204

The small snare (left) and the large snare (right) are used similarly

with or without the adjustable elbow. By pushing, rotating and

pulling on the flex rod, the user can lasso a large and heavy loose

part. Start by creating a large enough loop in the snare to fit over the

targeted part for retrieval. Lasso the loose part by pushing, pulling &

twisting the tool until the snare’s loop is effectively around the loose

part. By pulling the snare cable in and holding tension, large objects

can be successfully retrieved.

6. Hook closing in on a large rag. PN’s 143210,143270,143280,

or 143290

Four different hook sizes enable the retrieval of rags and other

random objects stuck in tight places. The hook is slid into and behind

the rag, then rotated for retrieval.

19

7. Flexible joints

Rubber flex joint (left) and spring flex joint right are used when the

JAWS tool or end effectors need to be pushed through an elbow or

pipe “T”.

8. Attaching the tool adaptor PN 153230 to the JAWS tool

requires removal of the one or both jaws and sliding the tool

adaptor in, securing with the 4-40 socket head screw and a

3/32-inch hex wrench. Attaching an end-effector to the tool

adaptor is the same as shown in #1 above.

The JAWS tool adaptor (left) enables the use of any end-effector

such as a magnet (center) or the snare (right). The combination of the

end effector and the JAWS tool has two benefits: Visual (CCTV)

observation of the retrieval and single-axis articulation (controlled

movement) of the tool.

20

9. Swapping the JAWS grabber options:

JAWS grabbers can be easily changed using a 3/32-inch hex wrench.

Be sure to securely tighten these before deploying the tool. Standard

/short Jaw (left) is best for navigating tight corners or elbows. The

fork & tine jaw (right) is good for softer objects.

Long flat-serrated jaw (left) provides more surface area and bite to

grab and retrieve big and heavy objects. The curved serrated jaw

(right) is well suited to grab round objects such as hammer handles.

Table of contents

Popular Industrial Equipment manuals by other brands

ABB

ABB HT598026 Operation manual

Alpha Technologies

Alpha Technologies ALPHA OUTBACK ENERGY Cordex HP LPS04 Installation & operation manual

Abe

Abe CraftCan 15 user guide

Sonny's

Sonny's APP100P2 owner's manual

Tarana

Tarana 1101-1027-KT installation guide

UniData Communication Systems

UniData Communication Systems 6526 manual