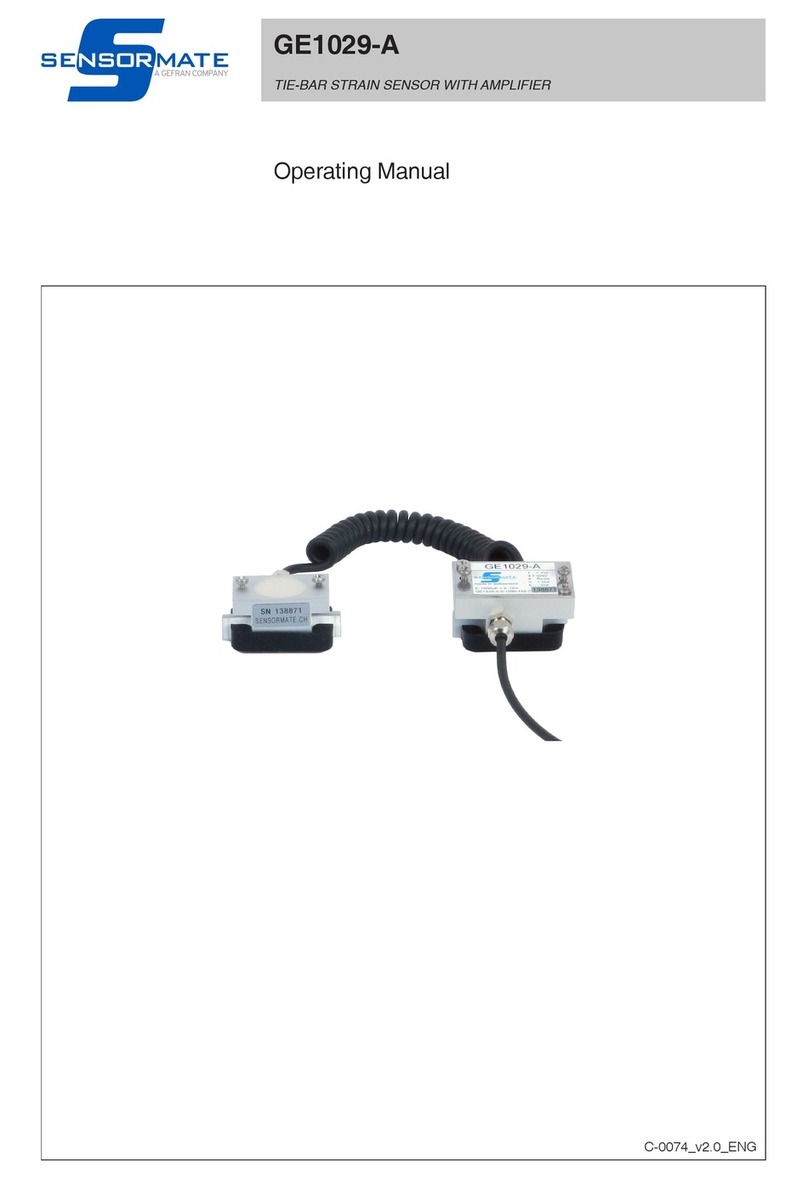

Sensormate QE1008-W User manual

Wireless magnet mount strain sensors

QE1008-W

Magnet-extensometer with press on strain gauge and wireless transmission

Operation Manual

SWISS MADE QUALITY

SENSORMATE AG

Steigweg 8

CH-8355 Aadorf TG

Switzerland

Tel. +41 (0)52 242 18 18

Fax +41 (0)52 364 32 72

Email: [email protected]

www.sensormate.ch

Preface

Dear Customer

Sensormate AG would like to thank you most sincerely for choosing a sensor system

from the QE1008-W product series.

This operation manual is intended for sales partners, customers and skilled service

personnel.

We seek to ensure that the product works to your full satisfaction. Adherence to this

operation manual ensures optimum function and service life of the QE1008-W sensor

system.

The graphics and photos in this operation manual are purely schematic examples.

Your product may look dierent to what is illustrated.

We are continually improving our products. If you should have any questions concerning

your product or this operation manual, please contact our Customer Service department

or visit our homepage.

Original language: German

WEEE Information

“Attuazione della direttiva 2012/19/UE sui

riuti di apparec¬chiature elettriche ed elett-

roniche (RAEE)”

Il simbolo del cassonetto barrato riportato sull’ap-

parecchiatura o sulla sua confezione indica che

il prodotto alla ne della propria vita utile deve

essere raccolto separatamen¬te dagli altri riuti.

La raccolta differenziata della presente ap-pa-

recchiatura giunta a ne vita è organizza¬ta e

gestita dal produttore.

L’utente che desideri disfarsi dell’apparec-chi-

atura dovrà quindi contattare il produt¬tore per

ricevere indicazioni sul sistema da quest’ultimo

adottato per consentire la rac¬colta separata

dell’apparecchiatura giunta a ne vita.

L’adeguata raccolta differenziata per l’avvio

successivo dell’apparecchiatura dismessa al

riciclaggio, al trattamento e allo smaltimento

ambientalmente compatibile contribuisce ad

evitare possibili effetti negativi sull’ambiente e

sulla salute e favorisce il reimpiego e/o riciclo dei

materiali di cui è composta l’ap¬parecchiatura.

“Implementation of Directive 2012/19/EU on

waste electrical and electronic equip¬ment

(WEEE)”

The symbol showing a crossed-out wheeled bin

on equipment or its packaging indicates that the

product must be collected separately from other

waste at the end of its useful life.

The manufacturer is responsible for organ¬ising

and managing the separate collection of this

piece of equipment at the end of its useful life.

Users wishing to dispose of the equipment must

therefore contact the manufacturer to obtain inst-

ructions from the same on how to have the equip-

ment collected separately at the end of its useful

life.

By collecting the disused equipment sepa¬rately,

it can be recycled, treated or disposed of in an

environmentally friendly manner, thus helping to

prevent the environment and public health from

being affected negatively and enabling reuse and/

or recycling of the materials forming the same

equipment.

„Umsetzung der Richtlinie 2012/19/EU über

Elektro- und Elektronik-Altgeräte (EEA)“

Das Symbol der durchgekreuzten Mülltonne auf

dem Gerät oder der Geräteverpackung weist da-

rauf hin, dass Sie das Produkt am Ende seines

Lebenszyklus separat entsor¬gen müssen.

Die Getrenntsammlung dieses Geräts an seinem

Lebenszyklusende wird vom Her¬steller organi-

siert und besorgt.

Der Nutzer, der das Gerät entsorgen möchte,

muss sich daher an den Hersteller wenden,

um Auskunft über seine Vorgehensweise zur Ge-

trenntsammlung des Geräts an dessen Lebens-

zyklusende zu erhalten.

Die entsprechende Getrenntsammlung für die

anschließende Zuführung des Altgeräts zum

Recycling, zur Wiederaufbereitung und zur

umweltverträglichen Entsorgung trägt dazu bei,

negative Auswirkungen auf die Umwelt und die

Gesundheit zu unterbinden und begünstigt die

Wiederverwendung und/oder das Recycling von

Werkstoffen, aus denen das Gerät besteht.

“Transposition de la Directive 2012/19/UE re-

lative aux déchets d’équipements électriques

et électroniques (RAEE)”

Le pictogramme de la poubelle barrée, gu¬rant

sur l’équipement ou sur son emballage, indique

que le produit en n de vie doit être traité séparé-

ment des autres déchets.

Le ramassage sélectif de cet équipement en n

de vie est organisé et géré par le constructeur.

Tout utilisateur qui souhaiterait se débarras¬ser

de l’équipement devra donc contacter le const-

ructeur pour obtenir des informations concernant

la méthode adoptée pour per¬mettre le ramassa-

ge sélectif de l’équipe¬ment en n de vie.

Un ramassage sélectif correct, en vue de l’ache-

minement de l’équipement vers des opérations

de recyclage, de traitement et de mise au rebut

respectueuses de l’environne-ment, contribue

à réduire les impacts poten-tiellement néfastes

sur l’environnement et la santé, outre à favoriser

la réutilisation des matériaux/composants dont

l’équipement est constitué.

DE EN

FR IT

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 5 / 38

Inhalt

1. Intended use 6

2. Basic safety regulations 7

2.1. Explanation of symbols 7

2.2. Basic safety regulations 7

2.3. Organisational measures 7

3. Liability and warranty 8

3.1. Area of application 8

3.2. Exclusion of liability and warranty 8

4. Product description 9

4.1. Introduction 9

4.2. Scope of delivery 10

4.3. Technology 11

5. Technical data 12

6. Terminology 15

7. Mounting and installation 16

7.1. Mounting for bending compensated tie bar strain measurement 16

8. Operation and control 20

8.1. Sensor QE1008-W 20

8.2. Wireless receiver QE1008-W-G 21

8.3. Activating the system 22

8.4. QE Booster 23

8.5. Application software 24

8.6. Measuring the tie bar strain distribution 25

8.7. Measuring the tie bar bending (tie bar crack detection) 26

8.8. Assigning a QE1008-W sensor 27

8.9. New assignment of all QE1008-W sensors 29

9. Troubleshooting 31

10. Maintenance of QE1008-W sensors 32

10.1. Inspection 32

10.2. Servicing 33

11. Accessories and spare parts 34

12. Technical support 34

13. Service and repairs (RMA) 35

14. Notes 37

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 6 / 38

1. Intended use

This product has been built according to the latest technology and certied safety

regulations.

This product is intended exclusively for the dened purpose

(→ see Chapter 4) and services (→ see Chapter 5).

Any other use or usage beyond this scope is not regarded as the intended use.

Use for the intended purpose includes reading, understanding and adhering to the

operation manual.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 7 / 38

2. Basic safety regulations

The details given here do NOT replace the regulations of the machine manufacturer.

They are a minimum requirement for the safe use of the system.

2.1. Explanation of symbols

2.1.1. Notes

Information for the optimum operation and service life of the product.

Non-observance can lead to malfunctions and damage to the

product or accessories.

2.2. Basic safety regulations

• Basically, the general accident prevention regulations and safety-related legislations

of the relevant country/region must be observed.

• Use this product only if it is in a perfect technical condition. Use it correctly while

keeping in mind the safety aspects and hazards detailed in the operation manual. In

particular, malfunctions which can aect safety, must be eliminated immediately.

The manufacturer shall not be responsible for any damages that may result thereby.

The user shall bear full responsibility.

• Work to be carried out must be completed in accordance with local legislation and

implementary provisions. If instructions in this operation manual dier from the

statutory requirements, please follow the more restrictive option. If these provisions

contradict each other, please contact your sales partner or Customer Services at

Sensormate AG before starting work.

2.3. Organisational measures

The operation manual must always be readily available with the product.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 8 / 38

3. Liability and warranty

3.1. Area of application

The area of application of the QE1008-W sensors is described in Chapter 1 (Intended

use) and Chapter 5 (Technical data).

3.2. Exclusion of liability and warranty

Exclusion of liability and warranty arises:

• If the QE1008-W is used outside of the specied area of application

(see Chapter 1).

• If the notes and instructions in this manual are not observed.

• If the QE1008-W and its associated equipment are not operated correctly.

• If the QE1008-W is not serviced or is serviced incorrectly, including the use of non-

prescribed spare parts.

• If unapproved accessories and components are used without written approval from

Sensormate AG, which could directly or indirectly aect the QE1008-W sensors and

associated accessories.

• If any kind of modication is made to the products supplied by Sensormate AG.

• Sensormate AG shall not be liable for any consequential damage caused by the

incorrect handling of its products.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 9 / 38

4. Product description

4.1. Introduction

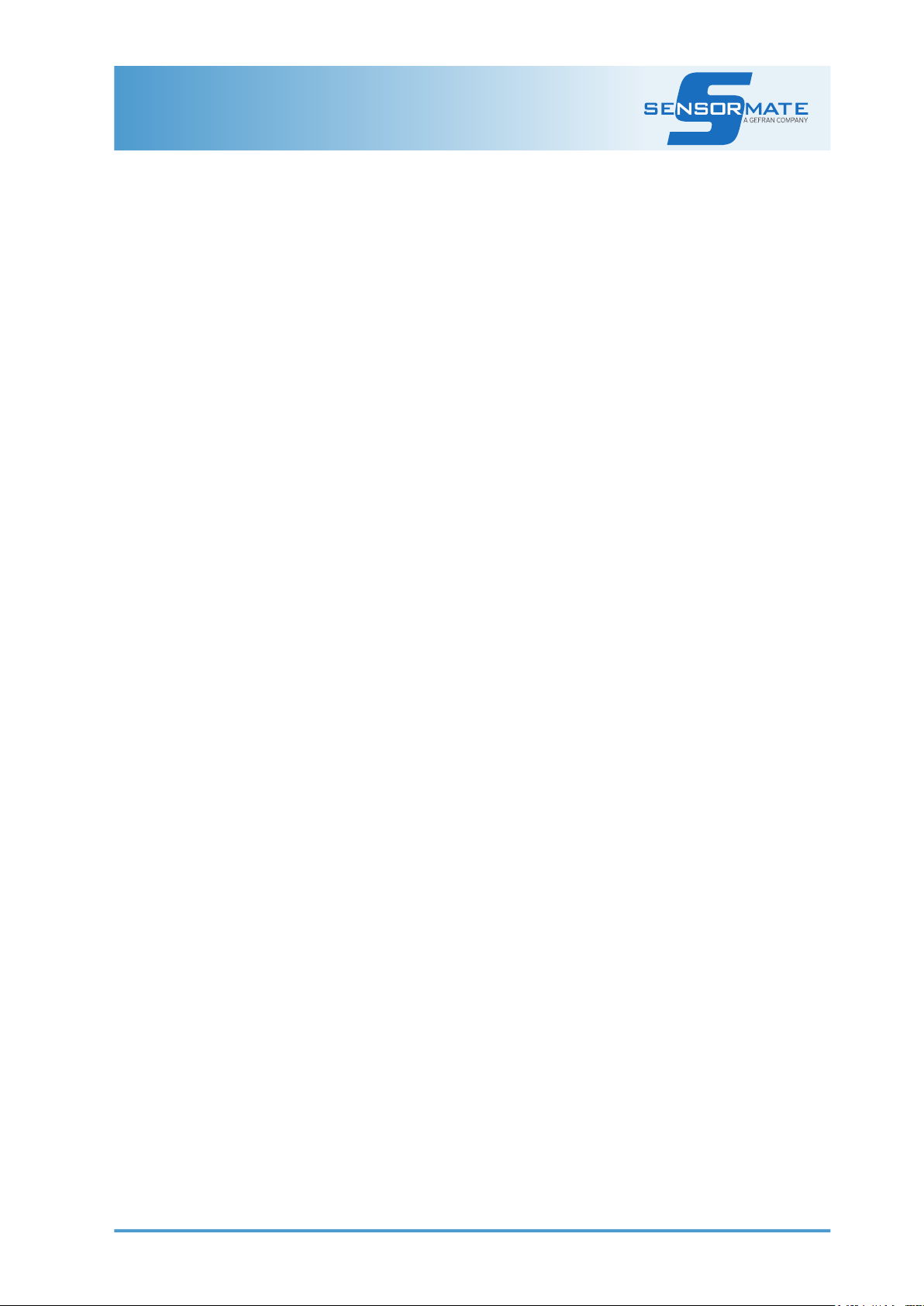

The double magnet strain measurement sensors QE1008-W are used for accurate

force and strain measurements on ferromagnetic surfaces. The use of two QE1008-W

sensors enables the system to take exact measurements of bending compensated

tie bar strains. The compact design and simple installation also oer a wide variety of

dierent applications.

Each sensor has a strain gauge signal amplier. Data is transmitted wirelessly to the

wireless receiver which is connected to the PC. The supplied software shows the

received measurement data in real-time. The data can be saved and opened using an

Excel program.

Sensor (transmitter)

Receiver with computer

Machine

Display software

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 10 / 38

4.2. Scope of delivery

Example with 8 + 1 sensors (order code: QE1008-W-09)

01 USB stick includes: – Instructions

– Software

– Brochures

02 8 sensors incl. rechargeable batteries

03 Charger with 2x connection cables for the charge bars

04 1x replacement sensor (optional)

05 Wireless receiver (Host)

06 Repair kit

07 2 x charge bars

08 Operation manual under the foam insert

01

02

03

05

07

06

08

04

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 11 / 38

4.3. Technology

Two strong magnets press the strain gauge of the patented sensor QE1008-W onto the

material to be measured.

The strain gauge is located under the foil between the two magnets. The magnets press

the strain gauge that strongly onto the surface that transmission through friction occurs.

The surface strains are hereby transmitted directly onto the strain gauge which creates

the same eect of an applied strain gauge (bonding).

The individual sensors can be used for applications such as strain measurements on tie

bars with dierent diameters to stress analyses on at surfaces.

The press-on technology of the QE1008-W enables the high-precision measurement of

strains with quick and reliable mounting, thus reducing the idle time of the machine to a

minimum.

Examples of applications

• Bending compensated tie bar strain measurement

• Tie bar strain distribution on presses (acc. to EUROMAP #7)

• Clamping force measurement on columns

• Measurement on at surfaces

• Replacement of bonded strain gauges

The advantages of this system

• Very high accuracy: <0.5% absolute (like a bonded strain gauge)

• Used for tie bar diameters 45... >1000mm

• Bending compensated measurement

• Reliable and accurate also on at surfaces

• Supplied display software with option to save in CSV le format

• Digital and direct tie bar-related display of force in kN, tons, US-tons or µε

• No cables

• Easy to mount and remove

• Very compact design (suitable for skilled service personnel)

• Minimum space requirements and protected as all accessories are stored in a

practical carrying case.

• No more dirty cables in the machine bed

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 12 / 38

5. Technical data

QE1008-W (Sensor)

Strain gauge type Foil (GF = 2.0)

Bridge resistance 350Ω

Measuring range ± 800με

Output signal for radio transmission IEEE 802.15.4TM

Signal range 30...100m

Sensitivity tolerance ± 0.2%

Transverse sensitivity 0.9 ± 0.2 %

Accuracy < ± 0.5% FS

Linearity < ± 0.5% FS

Hysteresis < ± 0.5% FS

Repeatability < 0.2% FS

Supply voltage when charging 6.2VDC (max. 6.5VDC)

Power consumption when charging 325mA

Ambient temperature 5...65°C

Storage temperature 0...65°C

Overload capability unlimited

Type of protection IP40

Material: Housing Aluminium

Material: Cover Plastic

Weight 530g

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 13 / 38

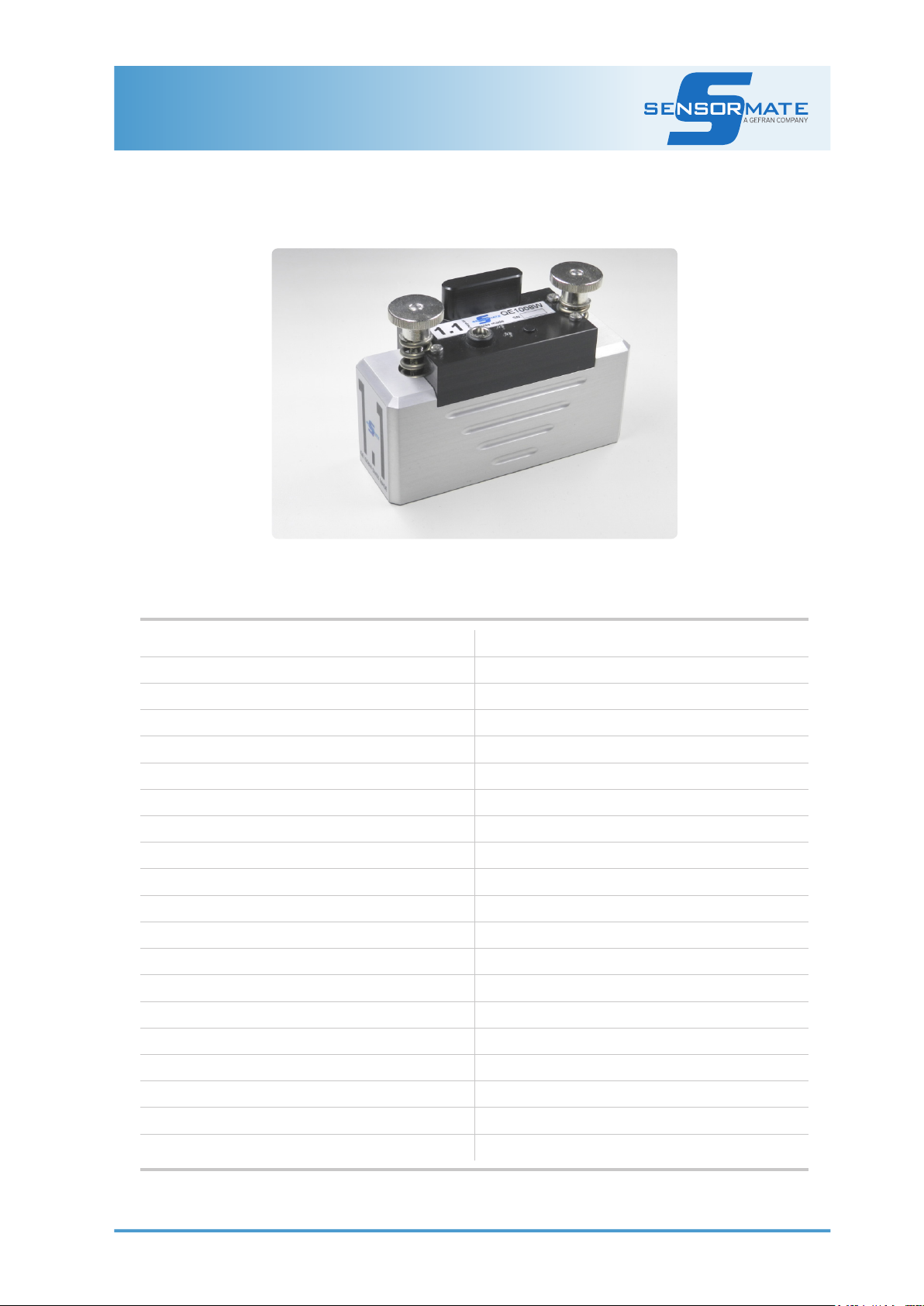

Dimensions in [mm]

Dimensions of QE1008-W

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 14 / 38

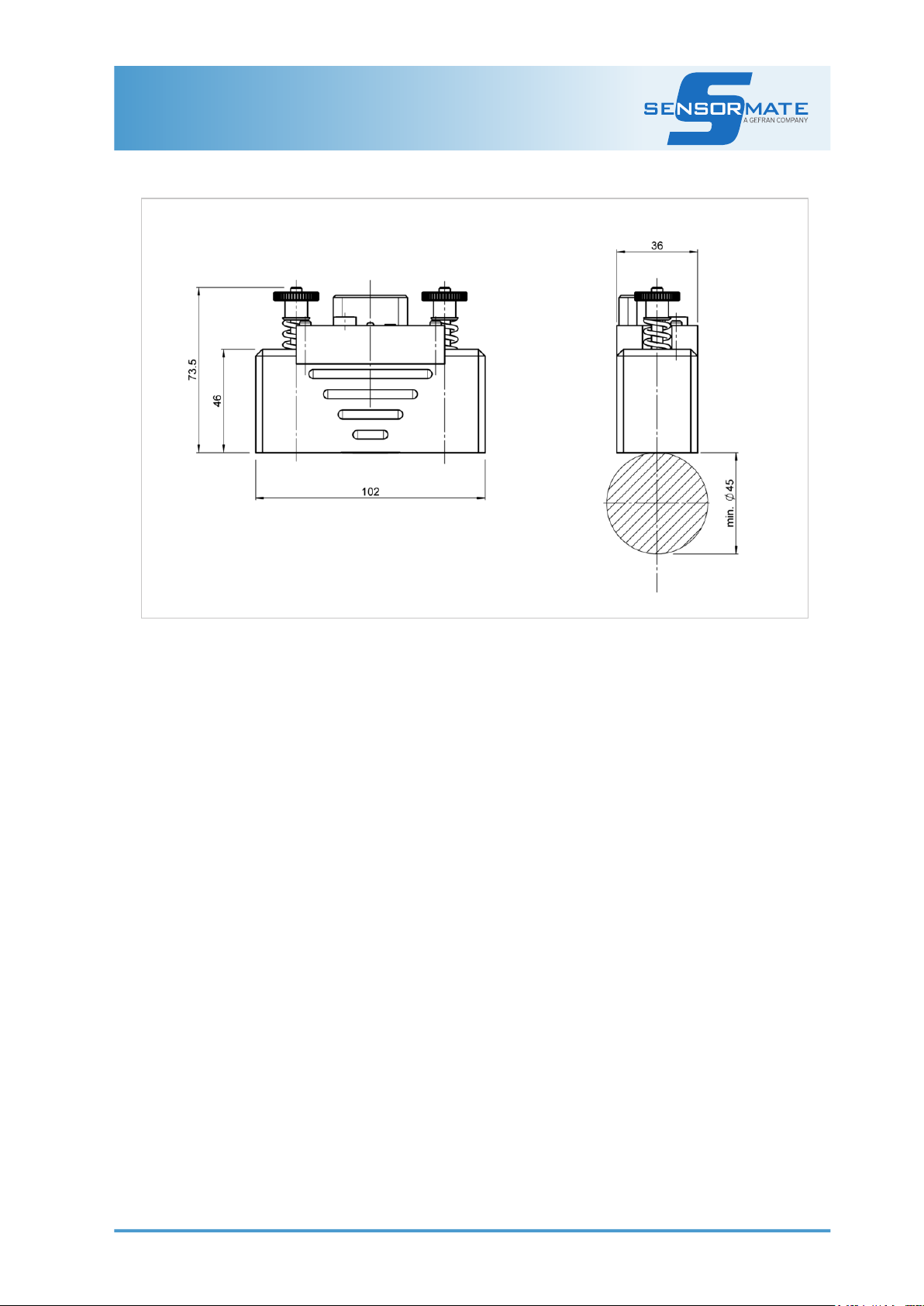

QE1008-W-USB-G (receiver)

Dimensions in [mm]

Dimensions

Transmission module

Frequency 2.405-2.480 GHz (ISM band)

Safety record standard IEEE 802.15.4TM

TX performance 0dBm / 1 mW (max.)

Range 30...100m

(dependent on operational environment)

Main functions: – Hardware CSMA-CA

– Hardware safety-related (AES-128)

The transmission module is FCC (USA), IC (Canada), ETSI (Europe) and TELEC

(Japan) certied. The MAC address is always unique and burnt into the hardware.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 15 / 38

6. Terminology

Terms Explanation

DMS Strain gauge

FS = Full Scale Calibrated measuring range

Accuracy Combined errors for linearity and hysteresis

Linearity Delta of signal curve to straight line "zero point - FS"

Hysteresis Delta of signal curve "load/relief"

Repeatability Dispersion of signal for multiple measurements

Tons Metric ton: 1t = 9.81kN

US-tons American ton: 1 US-tons = 1.1023t

µε = micro strain 1 µε = strain of 1µm/m

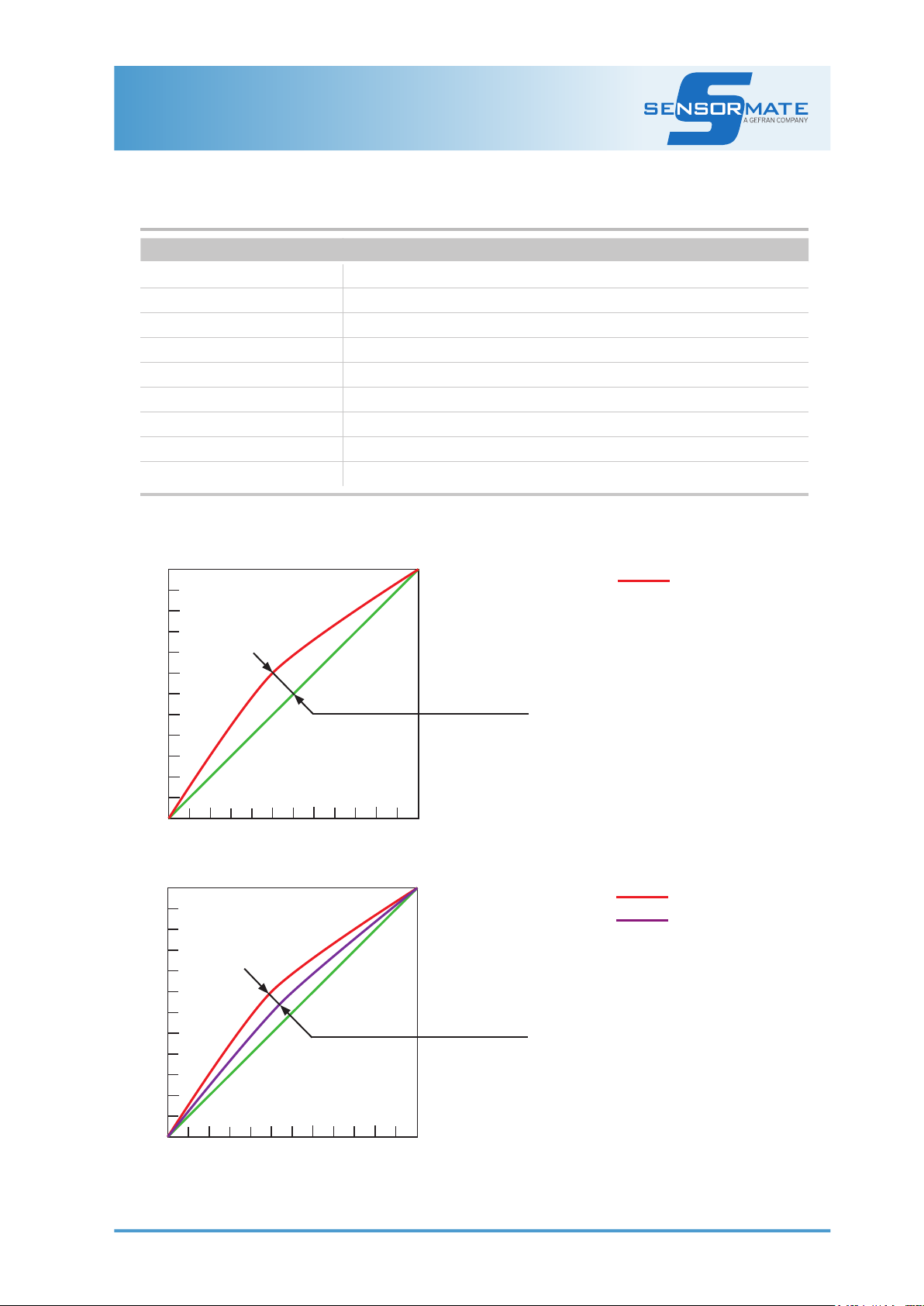

Full scale

kN

Signal load

Delta = Linearity

Linearity

0

µε

Delta = Hysteresis

Signal relief

Signal load

Full scale

Hysteresis

kN

0

µε

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 16 / 38

7. Mounting and installation

These sensors are precision instruments with a resolution of 0.001mm.

The devices must therefore be handled with great care. This instruction

manual must be read and observed by every user.

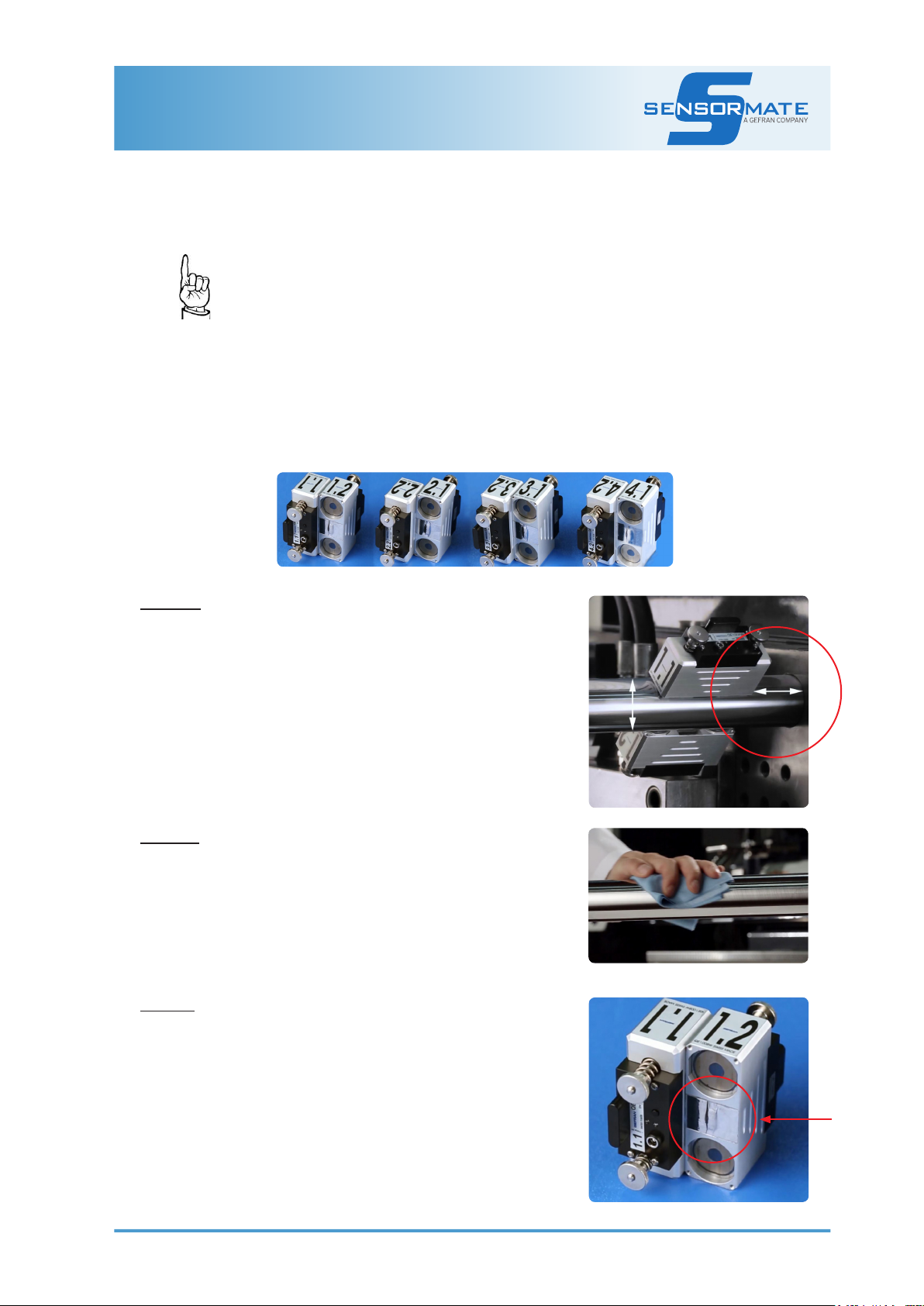

7.1. Mounting for bending compensated tie bar strain measurement

7.1.1. Preparation

The sensors must always be placed in pairs onto a tie bar (1.1&1.2), (2.1&2.2) etc.

Position

The distance between the sensor and clamping

plate must be at least once the diameter of the tie bar so

that the deformation of the tie bar can be measured

evenly and correctly.

Surface

Oil and other surface contamination, or paint which

has been applied, must be removed at the site of

installation.

Sensor

Check the charge of the current batteries

(see Chapter 8 „Operation and control“)..

Check the foil on the sensor for signs of damage.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 17 / 38

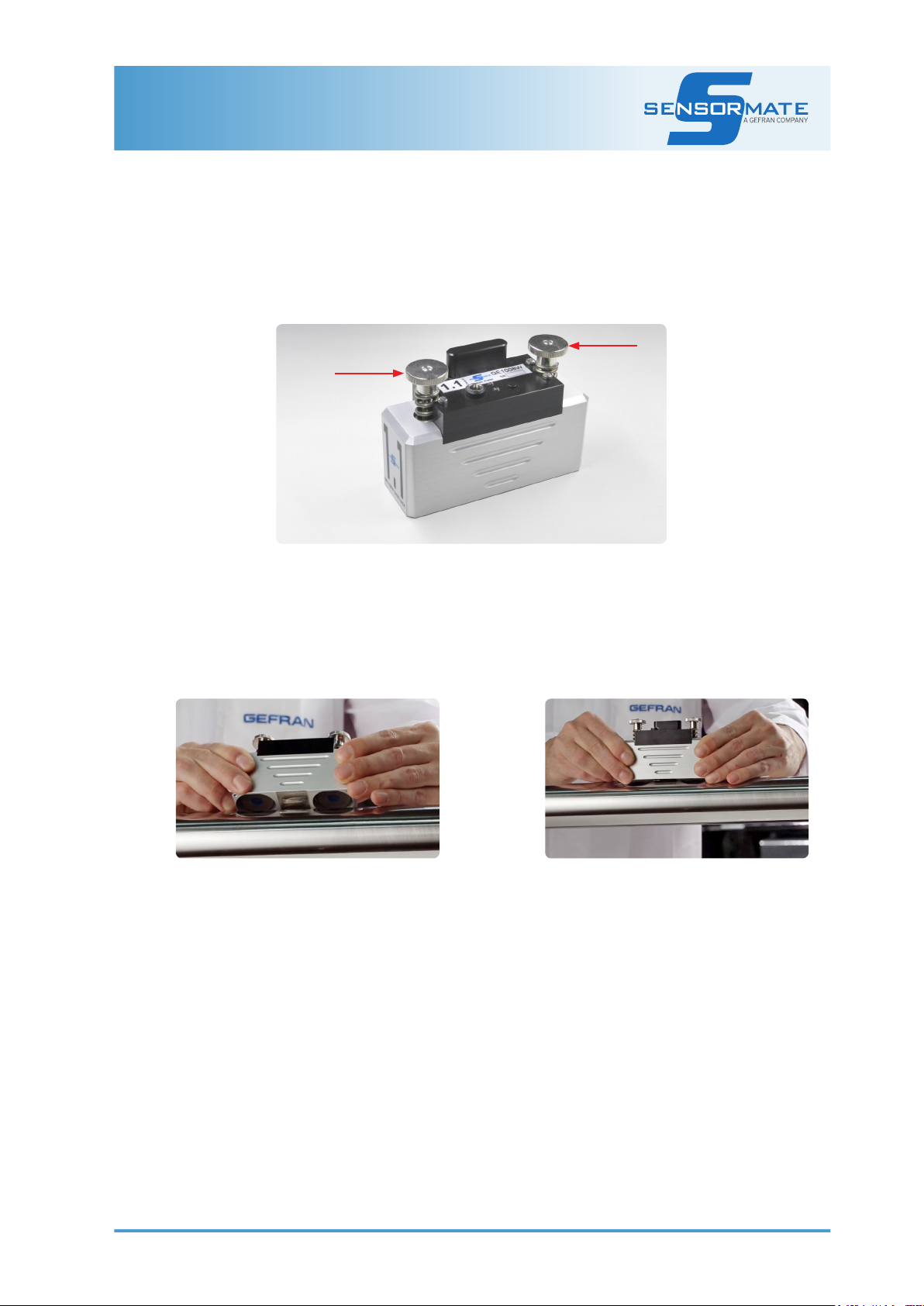

7.1.2. Positioning the sensor

1. Turn both knurled nuts so that they are ush with the end of the threaded rod.

2. The long edge of the sensor must be placed onto the surface to be measured and

then tilted. The magnets pull the sensor onto the tie bar.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 18 / 38

3. If the magnets do not automatically jump onto the measuring surface, press down

the knurled nuts one after the other. The magnets should now jump onto the tie bar.

The attraction force of the magnets is now optimal.

–The sensor on the tie bar may only be moved fractionally.

–The magnets have ground guides. Make sure that both sides of

the guide rest on the tie bar!

4. The contact force can be increased by tightening the knurled nut. (usually not

necessary.)

If a magnet jumps back, the knurled nut has been tightened too much, thereby

making the spring tension too big. Loosen the knurled nut to relieve the tension of

the spring.

–The sensor must make proper contact and be stable.

–The sensor must not move when shaken slightly.

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 19 / 38

5. Remove the 2nd sensor from the carrying case and complete steps 1 to 4.

–The sensor must be positioned parallel to the tie bar!

–The 2nd sensor pair must be placed exactly opposite (180°) and

parallel to the 1st sensor at the same position!

Correct!

Incorrect!

Not 180° opposite

Incorrect!

Not at same position

QE1008-W

Operation manual

Subject to technical modicationsQE1008-W C.0008_v4.0_01-2020_EN 20 / 38

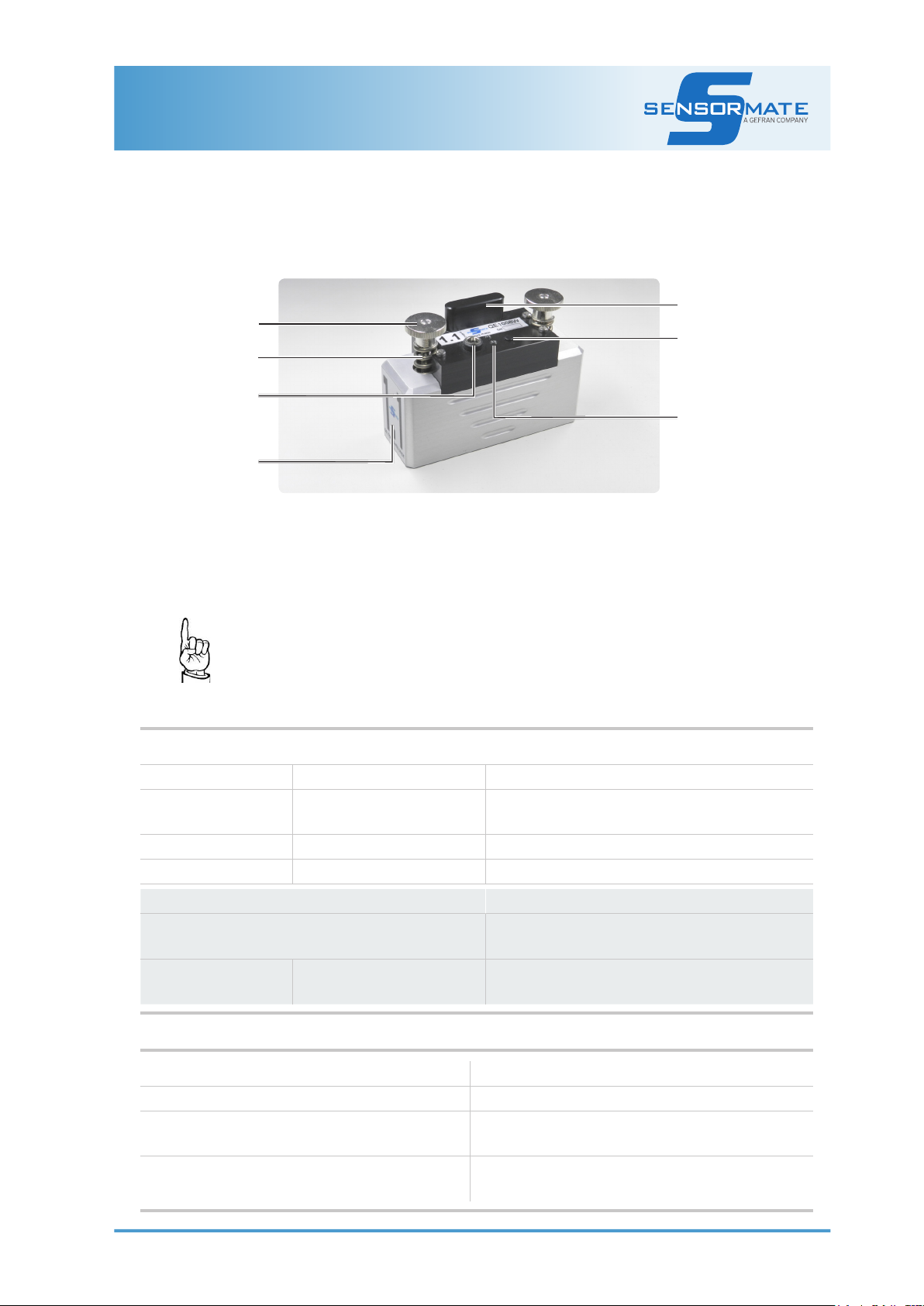

8. Operation and control

8.1. Sensor QE1008-W

LED status

Button function

Using the sensors in a new environment a new assignment as described

in chapter 8.7 should be done.

Normal operation:

LED green: on LED red: o → Receiver search

LED green: ashing LED red: o → Ready

(connected to receiver)

LED red: on LED green: on or ashing → Rechargeable battery virtually empty

LED red: ashing LED green: on or ashing → Strain gauge damaged

Special displays:

Both LEDs ash alternately → Sensor is in logon mode for

assignment

LED green: o LED red: ashing → Sensor not assigned to receiver

→ reassign

Switching on QE1008-W sensor Press button for ~1 second

Switching o QE1008-W sensor Press button for ~1 second

Logon mode for assignment Press button for ~5 seconds until the LEDs

ash alternately

Deleting assignment Press button for ~10 seconds until red LED

ashes

01 Knurled nut

02 Steel spring

03 Charging socket 6VDC

04 Slot number

05 LEDs red and green (status displays)

06 Button

07 Aerial

06

03

01

02

05

07

04

Table of contents

Other Sensormate Accessories manuals