Sensorsoft SS6610J User manual

SensorsoftTemperature and Humidity

Meter User’s Manual

Models SS6610J and SS6610C

Manual P/N 071-0080 Rev 7 May 21, 2019

Copyright © 2003-2019 Sensorsoft Corporation, All rights reserved.

Sensorsoft is a registered trademark of Sensorsoft Corporation.

Table of Contents

About this Manual............................................................................................................................ 4

Glossary of Acronyms ..................................................................................................................... 4

Overview.......................................................................................................................................... 5

Installing the Sensorsoft Temperature and Humidity Meter............................................................ 6

Choosing an Installation Location................................................................................................ 6

Connecting the Sensorsoft Temperature and Humidity Meter to a serial port............................ 6

SS6610J (v6.5) Sensorsoft Temperature and Humidity Meter Specifications................................ 8

SS6610C (v6.5) Sensorsoft Temperature and Humidity Meter Specifications............................... 9

Resolution, Accuracy and Calibration ........................................................................................... 10

Avoiding invalid judgments or comparisons .............................................................................. 10

Appropriate measurement instruments to making comparisons............................................... 10

Correct method for making comparisons................................................................................... 11

What to do if you believe the Sensorsoft device is reading incorrectly ..................................... 11

Making extension cables for C-Suffix Sensorsoft Devices............................................................ 12

Making communication cables for J-Suffix Sensorsoft Devices.................................................... 14

Writing custom software programs for the Sensorsoft Temperature and Humidity Meter............ 17

Simple Text Commands Interface ............................................................................................. 17

Sensorsoft Device Monitoring .NET Component for Windows.................................................. 17

Sensorsoft Device Protocol (SSDP) for Advanced Programmers............................................. 17

Getting Help................................................................................................................................... 26

Limited Warranty........................................................................................................................ 26

Technical Support...................................................................................................................... 26

30 Day Money Back Guarantee................................................................................................. 26

Returns....................................................................................................................................... 26

Sensorsoft Temperature and Humidity Meter User’s Manual

4

About this Manual

This document contains information about using the Sensorsoft Temperature and Humidity

Meter.

When other sections of this manual are referenced, italics are used.

The Sensorsoft Temperature and Humidity Meter may be referred to as a device, Sensorsoft

device or SSD (SensorSoft Device) throughout the manual.

Glossary of Acronyms

RWME – Remote Watchman Enterprise software for Windows

RWMC – Remote Watchman Client software for Windows

SCOM – Serial Communications Tool software for Linux and UNIX

SSDP – Sensorsoft Device Protocol

SSA – SensorSoft Alert appliance

SSD – SensorSoft Device

Sensorsoft Temperature and Humidity Meter User’s Manual

Overview

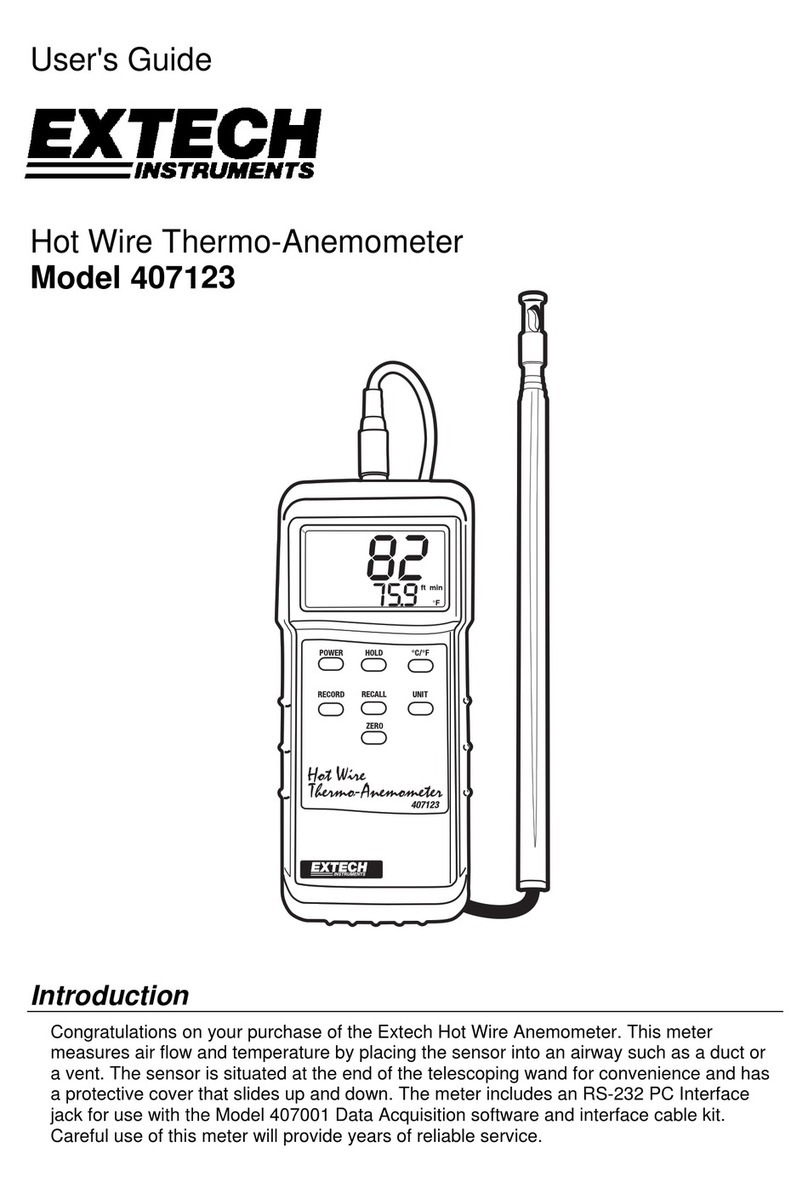

The SS6610J and SS6610C Sensorsoft Temperature and Humidity Meters are RS232 compatible

serial devices based on the Sensorsoft Device Protocol (SSDP). The SS6610J and SS6610C have

built-in temperature and humidity sensors and are intended for applications requiring

measurement of temperature and relative humidity in heated or air conditioned rooms and

warehouses. These products are not conformal coated and are therefore not intended for

environments with high moisture or condensation.

Sensorsoft devices offer the following benefits over other RS232 serial devices:

Powered from the serial port (no external power or battery required)

CRC error detection (detects transmission errors and improves reliability) (SSDP only)

Virtually unlimited cable lengths (1000 ft) (SSDP only)

Plug and go operation (little or no user configuration required)

Sensorsoft makes several SSDP-compliant software applications that permit you to read these

devices, send alerts, record and (in some cases) graph data. These include:

Sensorsoft Remote Watchman Client (RWMC) for Windows

Sensorsoft Remote Watchman Enterprise (RWME) for Windows

Sensorsoft Serial Communications Tool (SCOM) for Linux and UNIX

Sensorsoft Alert Appliance (SSA)

In addition, there are many manufacturers who provide support for Sensorsoft devices within

their products. Some of these include:

ServersCheck Sensor Gateway and software

Lantronix SecureLinx (SLC) Console Manager

As of firmware version 6.5, these Sensorsoft devices respond to Simple Text Commands when

used with a text-based terminal or scripting language. Additionally, we’ve provided several

means for customers to write software integrating Sensorsoft devices into their systems. This is

discussed further in the section, Writing custom software programs for the Sensorsoft

Temperature and Humidity Meter.

5

Sensorsoft Temperature and Humidity Meter User’s Manual

Installing the Sensorsoft Temperature and Humidity

Meter

Installation of the Sensorsoft Temperature and Humidity Meter requires the following steps:

Choosing an Installation Location

Connecting the Sensorsoft Temperature and Humidity Meter to a serial port

Starting the Sensorsoft software. (Please refer to the specific software manual that applies to

your installation.)

Choosing an Installation Location

Locate the Sensorsoft Temperature and Humidity Meter close to the equipment or airflow you’re

monitoring. Since the SS6610J and SS6610C are not waterproof or weatherproof, keep the

following rules in mind:

Keep the Sensorsoft device housing out of contact with direct sunlight, UV exposure, and

dripping water.

Protect the Sensorsoft device from high traffic areas that could wear/damage the housing or

cable.

Never allow the plastic housing of the Sensorsoft device to come into contact with harsh

chemicals or cleaning agents. If the housing needs to be cleaned, use a damp cloth or vacuum

cleaner.

Use a Velcro fastener (P/N F1000 or F1001) to affix the Sensorsoft device to a stable surface.

Connecting the Sensorsoft Temperature and Humidity Meter to a

serial port

If you have a SS6610C (C-Suffix) Sensorsoft Temperature and Humidity Meter, plug its molded

DB-9F connector into an available RS232 serial port connector (DB-9M) on your computer or

device server.

If you have an SS6610J (J-Suffix) Sensorsoft Temperature and Humidity Meter, use the

appropriate C20XX cable to connect this device to your computer or device server. (Please refer

to the Sensorsoft price list for available types of cables.)

If you intend to make a custom cable for a J-Suffix Sensorsoft device, please refer to Making

communication cables for J-Suffix Sensorsoft Devices.

If you are connecting a Sensorsoft Temperature and Humidity Meter to a serial port or

device/console server, configure the port as follows:

1200 bps, 8 bits, no parity, 1 stop bit

6

Sensorsoft Temperature and Humidity Meter User’s Manual

Turn off autobaud

Flow control set to “None”

Non-telnet binary (raw) transfer mode

Assert RTS and DTR always

If using a device/console server, refer to its documentation for more details on the above.

Note the physical port number where you plugged the cable into your computer or device/console

server. If the Sensorsoft device is being plugged into a Windows based computer that has only

one COM port, the port number is usually COM1. If you are using a USB to serial adapter, you

need to refer to the operating system’s serial port (COM) listing. In Microsoft Windows, this is

usually “Device Manager->Ports (COM&LPT).” In Linux or UNIX, refer to the /dev/tty

directory.

7

Sensorsoft Temperature and Humidity Meter User’s Manual

SS6610J (v6.5) Sensorsoft Temperature and Humidity

Meter Specifications

Measurement/Operating Temperature Range: -40 º C to +60 º C (-40 º F to +140 º F)

Temperature Resolution or precision: 0.1 º C (0.18 º F) and 0.5 º C (0.9 º F)

Temperature Accuracy: +/- 0.5 º C (+/- 0.9 º F) between 0 º C to +60 º C (32 º to 140 º F)

+/- 1 º C (1.8 º F) over remainder of temperature range

Relative Humidity Measurement Range: 0 to 100 % RH

Relative Humidity Resolution or precision: 0.1 % RH and 1 % RH

Relative Humidity Accuracy: +/- 3 % RH between 10 % RH and 90 % RH

+/- 5 % RH below 10 % RH and above 90 % RH

Relative Humidity Long Term Stability: < 1 % RH/year

Calibration: Calibrated at the factory. Re-calibration in the field is not possible, but sensors can

be replaced.

Maximum measurement rate: One reading every second

Housing Dimensions: 8 cm (3.1") x 4 cm (1.6") x 2 cm (0.8")

Housing Material: Injection-molded ABS thermoplastic

Housing Colour: Light gray

Sensor type: Semiconductor

Communications connector: 8 position modular jack, (accepts 8 position plug RJ45)

Power source: Port-powered (RTS and DTR, both asserted) or via External DC power connector

Power supply current drain: < 10 mA

External DC power connector: 2.1 mm power jack, automatic polarity correction and over-

voltage protection.

External power supply voltage: 6.0 - 12.0 VDC

Communications Interface: RS232C using TX,RX,RTS,DTR and GND. One device per serial

port.

Maximum communications cable length: 305 m (1000 ft.) using recommended cable type. Low

capacitance shielded cable or UTP is recommended.

Firmware Version: 6.5

Communications Protocol: Sensorsoft Device Protocol (SSDP) Version 2.0 and Simple Text

Commands

Error control: 16 bit CRC (cyclic redundancy checking) for detection of communication errors

between the device and host computer (SSDP only)

8

Sensorsoft Temperature and Humidity Meter User’s Manual

SS6610C (v6.5) Sensorsoft Temperature and Humidity

Meter Specifications

Measurement/Operating Temperature Range: -40 º C to +60 º C (-40 º F to +140 º F)

Temperature Resolution or precision: 0.1 º C (0.18 º F) and 0.5 º C (0.9 º F)

Temperature Accuracy: +/- 0.5 º C (+/- 0.9 º F) between 0 º C to +60 º C (32 º to 140 º F)

+/- 1 º C (1.8 º F) over remainder of temperature range

Relative Humidity Measurement Range: 0 to 100 % RH

Relative Humidity Resolution or precision: 0.1 % RH and 1 % RH

Relative Humidity Accuracy: +/- 3 % RH between 10 % RH and 90 % RH

+/- 5 % RH below 10 % RH and above 90 % RH

Relative Humidity Long Term Stability: < 1 % RH/year

Calibration: Calibrated at the factory. Re-calibration in the field is not possible, but sensors can

be replaced.

Maximum measurement rate: One reading every second

Housing Dimensions: 8 cm (3.1") x 4 cm (1.6") x 2 cm (0.8")

Housing Material: Injection-molded ABS thermoplastic

Housing Color: Light gray

Sensor type: Semiconductor

Communications cable: Integrated 6 m (20 ft.) cable with DB-9F (female) mini D-SUB

connector

Power source: Port-powered (RTS and DTR, both asserted).

Power supply current drain: < 10 mA

Communications Interface: RS232C using TX,RX,RTS,DTR and GND. One device per serial

port.

Maximum extension cable length: 305 m (1000 ft.) using recommended cable type. Low

capacitance shielded cable or UTP is recommended.

Firmware Version: 6.5

Communications Protocol: Sensorsoft Device Protocol (SSDP) Version 2.0 and Simple Text

Commands

Error control: 16 bit CRC (cyclic redundancy checking) for detection of communication errors

between the device and host computer (SSDP).

9

Sensorsoft Temperature and Humidity Meter User’s Manual

Resolution, Accuracy and Calibration

The terms resolution, accuracy and calibration frequently cause misunderstanding for many

individuals who have not been trained in metrology. We explain these terms here and how they

might apply to your application of Sensorsoft devices.

Resolution or precision is the fineness of the measurement. It is usually specified in terms of the

smallest unit that can be resolved.

Accuracy is the trueness of the measurement or how close it can be to the true value (National

Standard). Accuracy is often specified as a percentage (i.e. +/- 3 %) of the reading, or a fixed

value (i.e. +/- 0.5) that can vary from the true value of the reading.

Calibration is a process where accuracy is verified (and often corrected) with respect to a

standard. Calibrations are routinely carried out to certify that a device has not lost its accuracy,

linearity and stability. Calibrations can be carried out at a time interval that is required by your

industry. In many cases, this is at least once every year.

When a calibration or verification takes place, it must always be done with equipment that has

significantly better accuracy and resolution then the device under testing. When a calibration

check is performed on a “Unit under Test” with an instrument traceable to the National Standards

Laboratory, the “Unit under Test” is also considered to be traceable.

Avoiding invalid judgments or comparisons

Using any of the following measurement devices or situations is unacceptable for comparing to,

or judging the accuracy of a Sensorsoft device:

Low cost measurement device purchased from a retail store

Digital display on HVAC or cooling/heating equipment

Location of the active sensing element is unknown or hidden

Measurement device has its active sensing element more than one inch (2.5 cm) away from

the Sensorsoft device’s sensing element

Measurement device has lower accuracy specifications as compared to the Sensorsoft device

Measurement device has unknown accuracy specifications

Measurement device has not been calibrated within one year, has no calibration certificate or

is not traceable to a reference standard

Appropriate measurement instruments to making comparisons

We recommend one of the following instruments (or equivalent with a recently dated traceable

calibration certificate) for judging the accuracy or stability of your Sensorsoft device:

Vaisala HM40 series Hand held Humidity & Temperature Meter (approx. price $500-1000

US)

10

Sensorsoft Temperature and Humidity Meter User’s Manual

Vaisala HMT330 series Humidity & Temperature Transmitter and external probe (Wall

mount, RS232 interface, order with 115/230 VAC power supply, approx. price $1900-2500

US)

More details about the above instruments are available on Vaisala's web site:

https://www.vaisala.com

Correct method for making comparisons

Keep the following points in mind when checking the Sensorsoft device for accuracy or stability:

1. Use one of the above recommended instruments (or equivalent that has a recent calibration

certificate (within one year).

2. The sensing elements of Sensorsoft device and the traceable instrument must be touching or

within one inch (2.5 cm)

3. Allow sufficient time (30-60 minutes) for the Sensorsoft device and the traceable

measurement instrument to acclimatize to the environment.

4. Make sure you know how to get a live (up to the second) temperature or humidity reading

from the Sensorsoft device through its software.

5. For reading the Sensorsoft device during the comparison use the higher resolution variable,

not the lower resolution variable.

6. Have the published accuracy specifications for the Sensorsoft device and the traceable

measurement instrument readily available for comparison.

What to do if you believe the Sensorsoft device is reading incorrectly

If, after following the above method, you find the Sensorsoft device isn’t reading within its stated

specifications, you can obtain an RMA to return it to our factory for repair. See Returns at the end

of this manual. Charges may apply if the unit is out-of-warranty or if we find no evidence that the

device is out-of-calibration.

11

Sensorsoft Temperature and Humidity Meter User’s Manual

Making extension cables for C-Suffix Sensorsoft

Devices

In some applications it’s not possible to use pre-assembled cables. When installing the Sensorsoft

device at a remote location, it may be necessary to run cables through walls, ceilings or conduits

where connectors would get jammed. In this situation it makes sense to terminate the cables on-

site using hand crimp tools. The following details will assist you in this process.

NOTE - A C-suffix Sensorsoft device has a built-in cable. This includes

model SS6610C.

Figure 1: Illustrates a C-suffix Sensorsoft device with a built-in molded cable and DB-9F connector.

IMPORTANT - A properly made extension cable will allow your

Sensorsoft device to operate reliably over long cable lengths up to

305 m (1000 ft) using SSDP-compliant software.

12

Sensorsoft Temperature and Humidity Meter User’s Manual

Figure 2: C2100 cable is used to extend the cable length for model SS6610C. The DB-9F end of the cable plugs into a

DB-9M serial port. The DB-9M end of the cable plugs into the DB-9F connector on the SSD.

PIN-OUT OF THE DB-9F CONNECTOR ON MODEL SS6610C

Note: Only positions used in Sensorsoft device application are shown

Position Function

2 TX (data to computer)

3 RX (data from computer)

4 POWER (connects to DTR on computer)

5 Ground

7 POWER (connects to RTS on computer)

The following are specialized tools and parts needed to make good quality extension cables:

Hand Tools:

Tyco Crimping Tool P/N 90312-1 or 90302-1, for subminiature D pin or socket contacts

Tyco PROCRIMPER P/N 58448-2, for subminiature D pin or socket contacts

Tyco Insertion/Extraction Tool P/N 91285-1, for subminiature D connector contacts

Materials:

CP Technologies CAT5E UTP stranded, P/N E-207-4P-C5-LGY, 1000 ft, light gray, RoHS

(4 pair, 8-#24 AWG wires, category 4 or better, 75 C)

Tyco DB-9 receptacle subminiature D connector (crimp-snap-in), P/N 205203-1 or -3

Tyco DB-25 receptacle subminiature D connector (crimp-snap-in), P/N 205207-1 or 207463-1

Tyco socket crimp contact for subminiature D connectors, P/N 1-66504-0

Tyco pin crimp contact for subminiature D connectors, P/N 1-66506-0

13

Sensorsoft Temperature and Humidity Meter User’s Manual

Making communication cables for J-Suffix Sensorsoft Devices

In some applications it’s not possible to use pre-assembled cables. When installing the Sensorsoft

device at a remote location, it may be necessary to run cables through walls, ceilings or conduits

where connectors would get jammed. In this situation it makes sense to terminate the cables on-

site using hand crimp tools. The following details will assist you in this process.

NOTE - A J-suffix Sensorsoft device has an RJ-45 jack connector. It

accepts a plug-in cable. This includes model SS6610J.

Figure 3: Illustrates a J-suffix Sensorsoft device that accepts a cable with RJ-45 plug

IMPORTANT - A properly made cable will allow your Sensorsoft device

to operate reliably over long cable lengths up to 305 m (1000 ft) using

SSDP-compliant software.

You may connect the Sensorsoft device to the port with as little as three wires (RX,TX and

GND), using inexpensive unshielded telephone wire. However, the host may need to set the

number of retries high in order to overcome the effect of occasional noise/interference and would

also require the use of an external power supply (PA6106 or PA6206) at the Sensorsoft device.

14

Sensorsoft Temperature and Humidity Meter User’s Manual

The Sensorsoft device modular-jack (RJ-45) connector uses the same UTP wire map as 10-

BASE-T. It is therefore possible to use this type of cabling system for Sensorsoft devices.

PIN-OUT OF THE MODULAR 8 POSITION JACK/PLUG ON A SENSORSOFT DEVICE

Note: Terminal No. 1 is the terminal to the extreme left as you face the cable opening, latch tab down.

Terminal Function UTP wire color

1 ST Receive Data white-green

2 Ground green

3 ST Transmit Data white-orange

4 Power +V blue

5 Ground white-blue

6 Ground orange

7 Power +V white-brown

8 Ground brown

The following are specialized tools and parts needed to make good quality cables:

Hand Tools:

Tyco Crimping Tool P/N 1-231652-0 or 2-231652-1, for modular plugs

Tyco 8 position modular die set P/N 853400-1

Tyco Crimping Tool P/N 90312-1 or 90302-1, for subminiature D pin or socket contacts

Tyco PROCRIMPER P/N 58448-2, for subminiature D pin or socket contacts

Tyco Insertion/Extraction Tool P/N 91285-1, for subminiature D connector contacts

Materials:

CP Technologies CAT5E UTP stranded, P/N E-207-4P-C5-LGY, 1000 ft, light gray, RoHS

(4 pair, 8-#24 AWG wires, category 4 or better, 75 C)

Tyco 8 position modular plug for round stranded wire cables, P/N 5-554169-3 (CAT4)

Tyco 8 position modular plug for round stranded wire cables, P/N 5-557961-3 (CAT5)

Tyco DB-9 receptacle subminiature D connector (crimp-snap-in), P/N 205203-1 or -3

Tyco DB-25 receptacle subminiature D connector (crimp-snap-in), P/N 205207-1 or 207463-1

Tyco socket crimp contact for subminiature D connectors, P/N 1-66504-0

Tyco pin crimp contact for subminiature D connectors, P/N 1-66506-0

15

Sensorsoft Temperature and Humidity Meter User’s Manual

Figure 4: The C2000 cable is used to connect a J-suffix Sensorsoft device to most computers or devices that have a

DB-9M serial port. The DB-9F end of the cable plugs into a DB-9M serial port. The RJ-45 end of cable plugs into the

SSD. M indicates male/pin type connector. F indicates female/socket type connector.

Figure 5: The C2012A cable is used to connect a J-suffix Sensorsoft device to multi-port serial cards or device servers

(UDS1100, EDS1100) which have a DB-25F connector with DCE pin-out. The DB-25M end of the cable plugs into a

DB-25F serial port. The RJ-45 end of cable plugs into the SSD. M indicates male/pin type connector. F indicates

female/socket type connector.

16

Sensorsoft Temperature and Humidity Meter User’s Manual

Writing custom software programs for the Sensorsoft

Temperature and Humidity Meter

Sensorsoft provides three methods for allowing your custom software programs to communicate

with this Sensorsoft device, outlined here:

Simple Text Commands Interface

The Simple Text Commands Interface can be used interactively with a terminal program

(HyperTerminal, TeraTerm, Putty, Telnet, Screen, etc.) or by user-written programs and language

scripts. These commands make it possible to read Sensorsoft devices in many systems including

Linux, UNIX and embedded applications. The following single letter (lower case) commands

should be ended with a carriage return and or line feed character:

r read temperature and humidity

m read model number

v read firmware version

This interface outputs temperature readings in Celsius and relative humidity readings in %RH. It

only supports 0.5 C resolution for temperature readings and 1% resolution for humidity readings.

If you need temperatures in Fahrenheit (F), you will need to do a conversion in your software (i.e.

F = 9/5C + 32).

Using this method, we recommend keeping the cabling short (<100 ft) as the Simple Text

Commands Interface does not support the built-in CRC error detection.

Sensorsoft Device Monitoring .NET Component for Windows

This method involves use of the Sensorsoft Device Monitoring.NET Component for creating

software on Windows based systems. It provides a high-level Windows .NET-based API to

implement the Sensorsoft Device Protocol. You can download and learn more about this free

software at: https://www.sensorsoft.com/developers.html

Sensorsoft Device Protocol (SSDP) for Advanced Programmers

This software method is the most advanced way of supporting Sensorsoft devices. It has several

advantages over the Simple Text Commands Interface discussed above. These include:

CRC error detection for use over long serial cables (1000 ft)

higher resolution measurements (0.1)

auto-discovery by reading device ID record

The Sensorsoft Device Protocol uses a binary, packet-formatted, master-slave protocol. Your host

computer (master) must send commands to, and receive responses back from, the Sensorsoft

17

Sensorsoft Temperature and Humidity Meter User’s Manual

device (slave). All data is represented in the little endian format - least significant byte first and

the most significant byte last.

Use the following parameters when programming the serial port where the Sensorsoft device is

connected:

Bit rate:1200 bps

Bits: 8

Parity: none

Stop bits: 1

Flow control: none

Null discard: do not strip NULL bytes

In order to make use of the port-powered feature of the Sensorsoft device, you must enable serial

port lines DTR and RTS when the port is opened. A delay of 1-2 seconds is required after

opening the serial port before any commands are sent to the Sensorsoft device. This delay allows

the Sensorsoft device to power-up correctly and prevents incorrect readings.

You should also be aware that the Sensorsoft device has an inter-packet retry time-out delay. This

delay is one (1) second and is encoded into the Sensorsoft device’s firmware. If your program

sends a command to the Sensorsoft device without a response, your program must wait at least

one (1) second before re-sending that command. Possible reasons that a Sensorsoft device may

ignore your commands can be due to data transmission (CRC) errors or improper power-up delay

during hot-plugging.

Sending SSDP commands to the Sensorsoft device

Each command packet your host sends to the Sensorsoft device must be in the following format:

<CMD-byte> <PACKETlength-bytes> <ADDRESS-bytes> <ARGUMENT-byte> <CRC-bytes>

CMD-byte

A single byte command indicating the desired action you want the Sensorsoft device to perform.

PACKETlength-bytes

Two bytes indicating the total length of the packet from start to finish (includes CRC bytes).

ADDRESS-bytes

The six-byte (48-bit) address of the device you are sending the command to. This is always

“decimal 1.”

ARGUMENT-byte

The number of the Sensorsoft device’s internal register or variable you want to read or write. This

byte is required for commands the request temperature or humidity readings. This byte is not

required for the status command.

CRC-bytes

18

Sensorsoft Temperature and Humidity Meter User’s Manual

A two byte (16 bit) Cyclic Redundancy Check that is calculated on the entire packet from the

CMD byte to the last ARGUMENT byte or ADDRESS byte. In the examples below, the last two

bytes in each command string are CRC bytes that were pre-calculated.

Send the following bytes to request a status reading:

<C1h><0Bh><00h><01h><00h><00h><00h><00h><00h><47h><98h>

Send the following bytes to request a relative humidity reading in % RH (1 % resolution):

<C5h><0Ch><00h><01h><00h><00h><00h><00h><00h><01h><0Eh><49h>

Send the following bytes to request a relative humidity reading in % RH (0.1 % resolution):

<C5h><0Ch><00h><01h><00h><00h><00h><00h><00h><02h><6Dh><79h>

Send the following bytes to request a temperature reading in Celsius (0.5 C resolution):

<C5h><0Ch><00h><01h><00h><00h><00h><00h><00h><03h><4Ch><69h>

Send the following bytes to request a temperature reading in Celsius (0.1 C resolution):

<C5h><0Ch><00h><01h><00h><00h><00h><00h><00h><04h><ABh><19h>

19

Sensorsoft Temperature and Humidity Meter User’s Manual

Receiving SSDP responses from the Sensorsoft device

Each response packet the Sensorsoft device returns is in the following format:

<RESPONSE-byte> <PACKETlength-bytes> <DATA-byte(s)> <CRC-bytes>

RESPONSE-byte

A single byte response code indicating the type of response. Valid codes are 90 hex or 94 hex.

PACKETlength-bytes

Two bytes indicating the total length of the packet from start to finish (includes CRC bytes).

DATA-byte(s)

Most responses return additional data in the form of byte(s). In response to a temperature

command, two bytes are returned for DATA-byte(s). In response to a status command, one byte is

returned for DATA-byte(s). See SENSORSOFT DEVICE STATUS BYTE FORMAT chart.

CRC-bytes

A two byte (16 bit) Cyclic Redundancy Check. This placeholder is filled with CRC bytes

calculated by the Sensorsoft device on the entire packet from the RESPONSE byte to the last

DATA-byte. These bytes allow the host to verify the integrity of the response packet. You may

choose to use or ignore these bytes depending on your programming skill or application.

The Sensorsoft device returns a normal RESPONSE-byte (90 hex) in acknowledgement that the

previous host command was received and executed without errors. The Sensorsoft device only

acknowledges correctly received commands that have no CRC errors. If the Sensorsoft device

detects a CRC error in a received command packet, it does not respond to the command. It is

considered the job of the host to time-out and re-transmit that command packet.

When an internal problem occurs inside the Sensorsoft device, it sends out an abnormal response

byte (94 hex) to any command from the host. If the host receives this response byte, it must

immediately read and interpret the Sensorsoft device’s status to determine the problem. See

SENSORSOFT DEVICE STATUS BYTE FORMAT chart.

The generator polynomial used for the CRC is hexadecimal 1021. The following references

provide information for readers who wish to use the CRC capability;

Calculating CRC’s by Bits and Bytes, Greg Morse, Byte Magazine, September 1986, Pg.

115-124

Implementing CRC's, Jack Crenshaw, Embedded Systems Programming Magazine, January

1992, Pg. 18-45

Technical Aspects of Data Communication, John McNamara, Digital Equipment Press 1982,

Pg. 110-122

Data and Computer Communications, 2nd edition, William Stallings, Macmillan Publishing,

Pg. 107-112

The modem reference: the complete guide to selection, installation, and applications, 2nd

edition, Michael A Banks, Brady Publishing 1991, Pg. 27-42

20

This manual suits for next models

1

Table of contents

Other Sensorsoft Measuring Instrument manuals