Sensortech Systems ST-3300 Series User manual

© Sensortech Systems, Inc. 2016 Page 1 of 13 Rev.8-2016

ST-3300

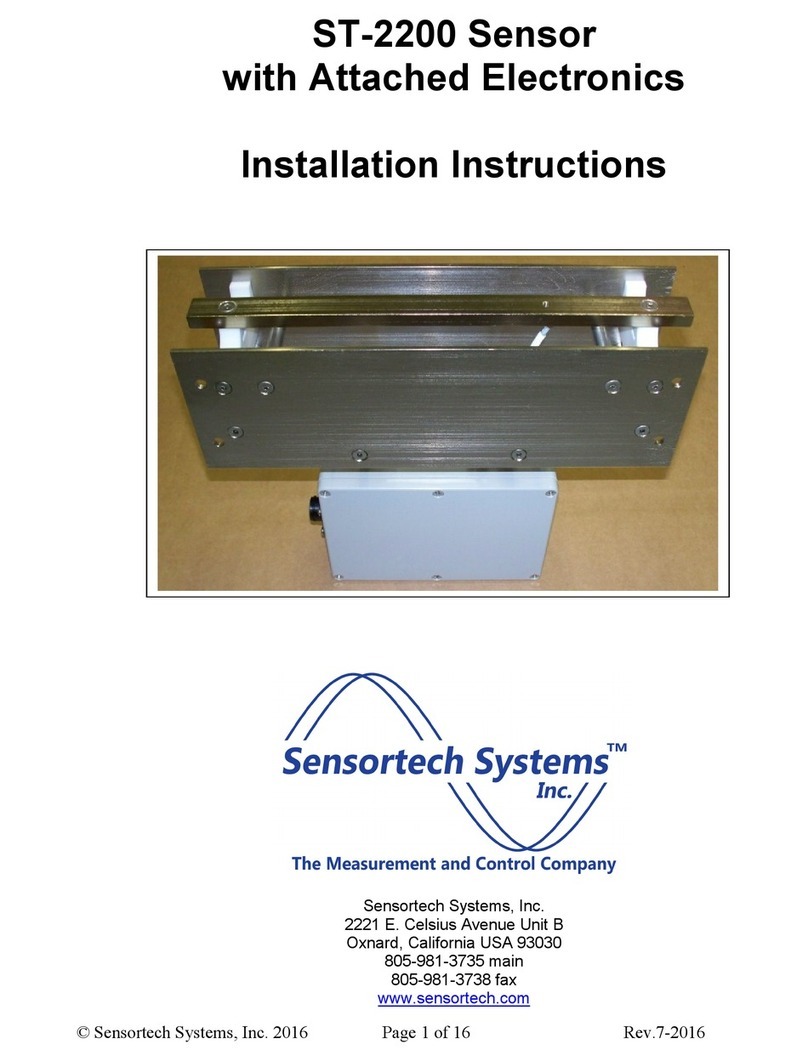

Ceramic Face Sensor

with Attached Sensor Electronics Unit

Installation Instructions

Sensortech Systems, Inc.

2221 E. Celsius Avenue Unit B

Oxnard, California USA 3030

805- 81-3735 main

805- 81-3738 fax

www.sensortech.com

© Sensortech Systems, Inc. 2016 Page 2 of 13 Rev.8-2016

ST-3300 Low Temperature Moisture Measurement System

The main components in the system are:

3.

Fi ure

1

.

Ceramic Face Sensor Antenna with

Attached Sensor Electronics Unit

Power/Interface Option

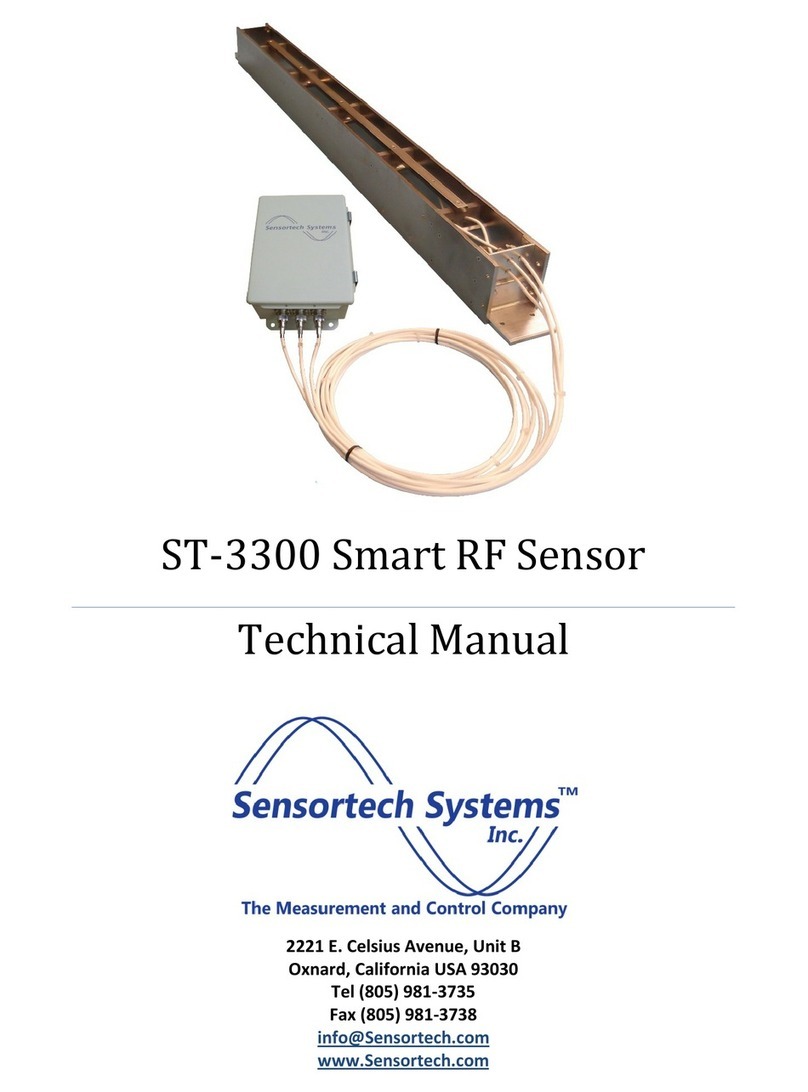

2. ST-3300 I/O Unit – a NEMA4 rated metal enclosure

containing +/-15V DC power supply and control

signals for the Ceramic Face Sensor with Attached

Sensor Electronics Unit. The I/O Unit connects to

the user’s A/C power and provides terminal blocks

for user interface to RS-485, 4-20mA output and

Digital Input signals.

1. ST-3300 Ceramic Face Sensor with Attached

Sensor Electronics Unit – a ceramic face sensor

designed to be in contact with the board product

mounted between rollers. T

he Sensor Electronics

Unit is mounted directly below the Sensor

Antenna. The Sensor is rated for +32 to +122°F

(0 to +50°C) operation. The Sensor Electronics

Unit is contained in a NEMA4 rated metal

enclosure containing the RF moisture

measurement and control electronics. Power

requirements are +15V/-15V dual 40W supply.

Communications are via RS485 and self-

powered, isolated 4-20mA output. The

Power/Interface Option shown below which

conveniently provides necessary power and I/O

connectivity.

Fi ure

2

.

I/O Unit

© Sensortech Systems, Inc. 2016 Page 3 of 13 Rev.8-2016

Fi ure

3

.

System Wirin Dia ram

© Sensortech Systems, Inc. 2016 Page 4 of 13 Rev.8-2016

Fi ure

4

.

Sensor Installation Dia ram

© Sensortech Systems, Inc. 2016 Page 5 of 13 Rev.8-2016

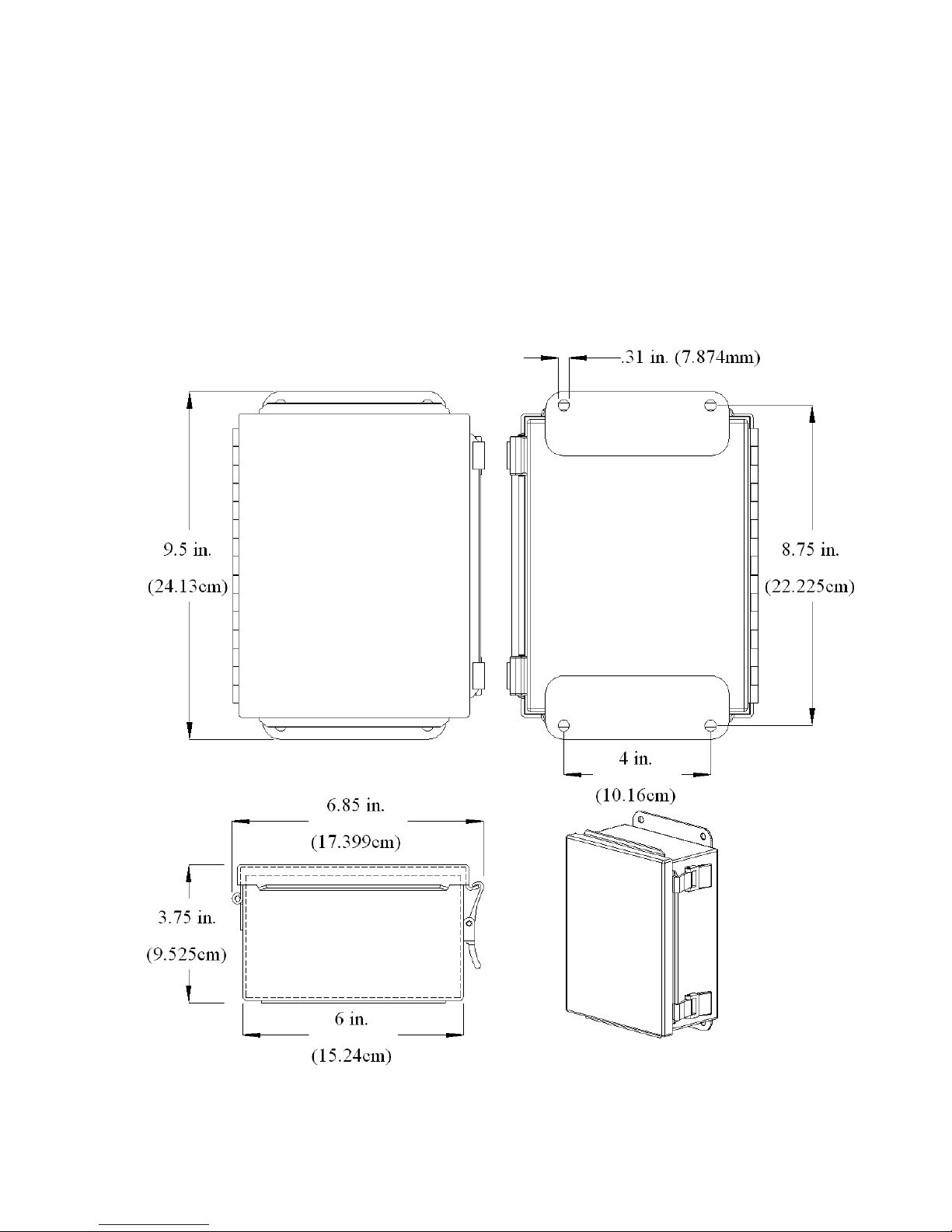

Fi ure

5

.

12 x 7 inch (30.48 x 17.78cm) Ceramic Face Sensor Dimensions

© Sensortech Systems, Inc. 2016 Page 6 of 13 Rev.8-2016

Fi ure

6

.

Example of Mountin Saddle for Ceramic Face Sensor Installation

© Sensortech Systems, Inc. 2016 Page of 13 Rev.8-2016

ST-3300 Ceramic Face Sensor Installation Guidelines

Locatin the Sensor

Select a location to install the Sensor where the board product being measured will remain flat

during travel over the Sensor location for the full length or width of board.

Avoid locations where the contact (vertical height) between the board and Sensor may change

during board travel due to changing slope or roller height change on conveyor.

Care must be taken to position the Ceramic Face Sensor level with the top of the adjacent rollers.

Maintaining contact with the ceramic face and preventing vertical board movement while arriving,

travelling over and leaving the Sensor results in the best measurement accuracy.

A typical Sensor mounting location is using the recommended saddle or a Mounting Beam

supported by height adjustable posts mounted to the cement floor centered between level rollers

approx.6 to 8 inches (15-20cm) apart.

Preparin for the installation

1. Select a suitable location for the Ceramic Face Sensor where the spacing between rollers

allows the installation of the Sensor so that the board travels smoothly and evenly

approaching and leaving the Sensor location. This requires level rollers. Do not mount any

portion of the ceramic face of the Sensor below belts or metal framework. The Sensor length

should be aligned so that the entire ceramic face is covered by the board stream. Normal

measurement area is x 5 inches (22. x 12.7cm) for the Sensor with an overall size of 12 x

7 inches (30.5 x 17.8cm). Allow for some side to side board movement.

2. Fabricate support posts and mounting for installing the Sensor on posts attached to the

cement floor to reduce vibration. High vibration may damage the Sensor. Ensure the support

posts have height adjustment for Sensor to roller and board alignment.

3. Two M12 cables connect the smart sensor to the I/O unit. We recommend these cable be

run through conduit for their protection.

4. Run cables for Low Voltage Signals from the I/O Unit to the plant control panel in conduit or

cable tray.

5. The I/O Unit requires single phase 50-60 Hz 0-250VAC @ 0.1KW.

6. Connect cabling to I/O Unit terminal blocks for A/C Power, RS-485 serial links and/or a 4-

20mA output for moisture value. See Table 1 & 2.

7. Run 14-18AWG Earth Ground wire from local ground point to Sensor Antenna mounting

location and to I/O Unit mounting location. This ground is for RF shielding and is required for

best measurement accuracy.

Important: Do not mount the Sensor where excessive heat transfer will occur. Operating

temperature in excess of 140°F 60°C will result in permanent damage.

Provide a local Earth Ground for the Sensor. Ensure a mounting tab of the Sensor is

connected to local Earth Ground. Add a 14-18 AWG direct wire connection from the

Sensor Antenna to a local Earth Ground potential. Ensure the Sensor Antenna is also

grounded to a process frame or conveyor frame, etc. This is not a safety requirement, but

may influence instrument performance.

© Sensortech Systems, Inc. 2016 Page 8 of 13 Rev.8-2016

Mountin the Sensor

The Sensor is typically mounted after the dryer between rollers level with the top of adjacent

roller surfaces. The Ceramic Face Sensor with Attached Sensor Electronics Unit is rated from

0°C to 50°C ambient temperature and should be mounted on a low vibration adjustable posts

mounted to the cement floor. The Sensor is attached to the mounting saddle or mounting beam

using the four mounting holes on the ends of the Ceramic Face Sensor frame (see Figure 5 & 6).

The Ceramic Face Sensor construction allows board product to contact the ceramic face for

moisture measurement.

The Ceramic Face Sensor is attached to the Mounting Saddle or mounting beam using adjustable

vertical posts with the four 0.25 in (6.3mm) diameter holes on the tabs located on each end of the

Sensor.

An important alignment is for the Ceramic Face Sensor to be level with the product being

measured. If one end of the ceramic face is further away (not in contact) with the product than the

opposite end, it will be less sensitive to changes in moisture than the end of the ceramic face that

is in contact (closer) to the product.

Board product should be in contact with the Ceramic Face Sensor with no air gap between the top

of the Sensor to the bottom of the board product for the full length and wide of the ceramic face.

The antenna and sensor should be isolated as much as possible from conveyor vibration.

Vibration can loosen nuts, bolts, and electronic components.

Due to the close roller spacing for non-rigid board products, it may be necessary to shorten a roller

located where the Sensor will be installed. See Figure 4.

Levelin the Rollers

Use a level or straight edge that spans at least 6 rollers. Lay the level or straight edge across the

three rollers before the Sensor and three rollers after the Sensor. Place level on the rollers near

the bearing ends.

Shim the two outer rollers’ bearing assemblies so that they are level.

Shim the remaining four rollers’ bearing assemblies so that each roller is within 0.01 inches

(.25mm) of level.

Lay the level along the first roller. Shim its bearing assembly on the other side so that it is level

lengthwise.

Lay a level across the six rollers near their ends.

Shim the last roller’s bearing assembly so that it is level with the first roller.

Shim the remaining four rollers’ bearing assemblies so that each roller is within 0.01 inches

(.25mm) of level.

© Sensortech Systems, Inc. 2016 Page 9 of 13 Rev.8-2016

Bearing

Shim

Conveyor

Frame

Level

Rollers

Level

Roller

Fi ure

7

.

Example of Roller Ali nment

© Sensortech Systems, Inc. 2016 Page 10 of 13 Rev.8-2016

Mountin the I/O Unit

The ST-3300 I/O Unit is typically mounted near the Sensor in a conveniently accessible location

for periodic maintenance and calibration tasks. Two standard M12 cables are used to connect

the Sensor Electronics Unit to the I/O Unit. The M12 cables come in standard lengths of 33 ft.

(10m). An important consideration for the I/O Unit location is the need to maintain the ambient

temperature below 50°C.

The I/O Unit is wired via two wire 4-20mA and/or 5 wire RS-485 interface to the plant master

control for monitoring and control.

Fi ure 8.

I/O Unit Dimensions

© Sensortech Systems, Inc. 2016 Page 11 of 13 Rev.8-2016

Fi ure

9

.

I/O Unit Terminal Board Layout

© Sensortech Systems, Inc. 2016 Page 12 of 13 Rev.8-2016

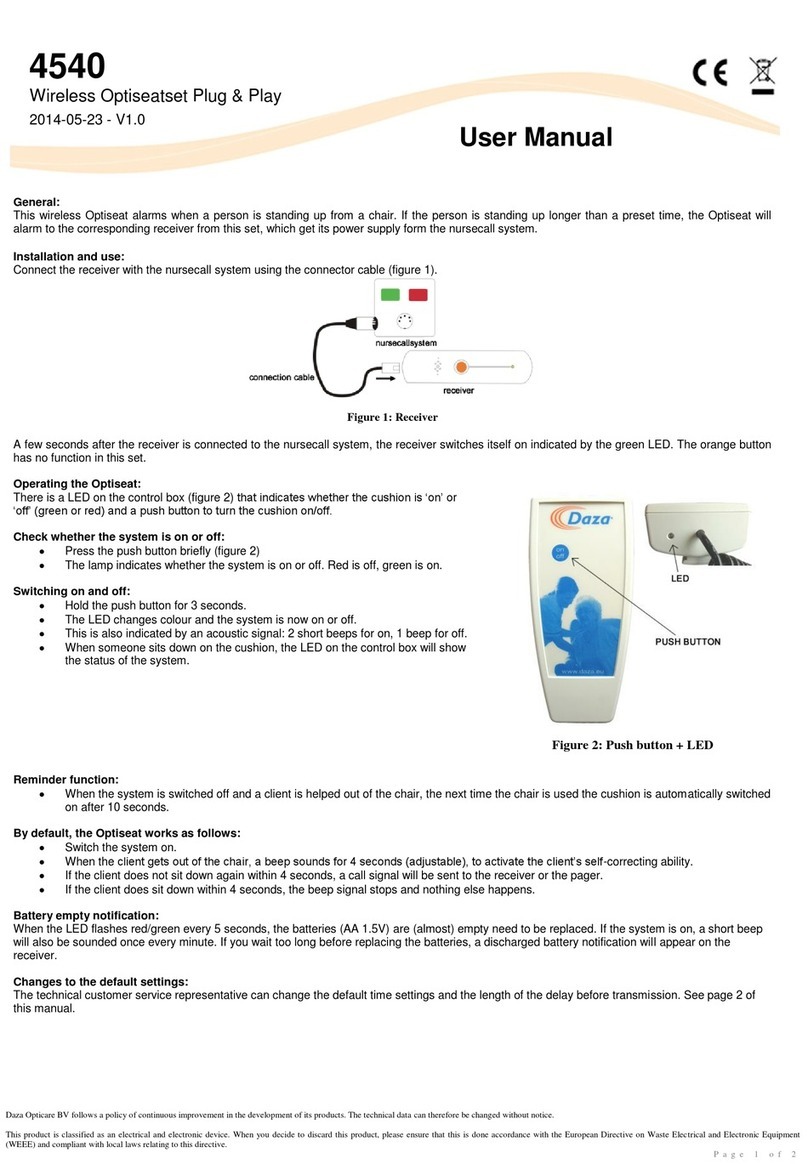

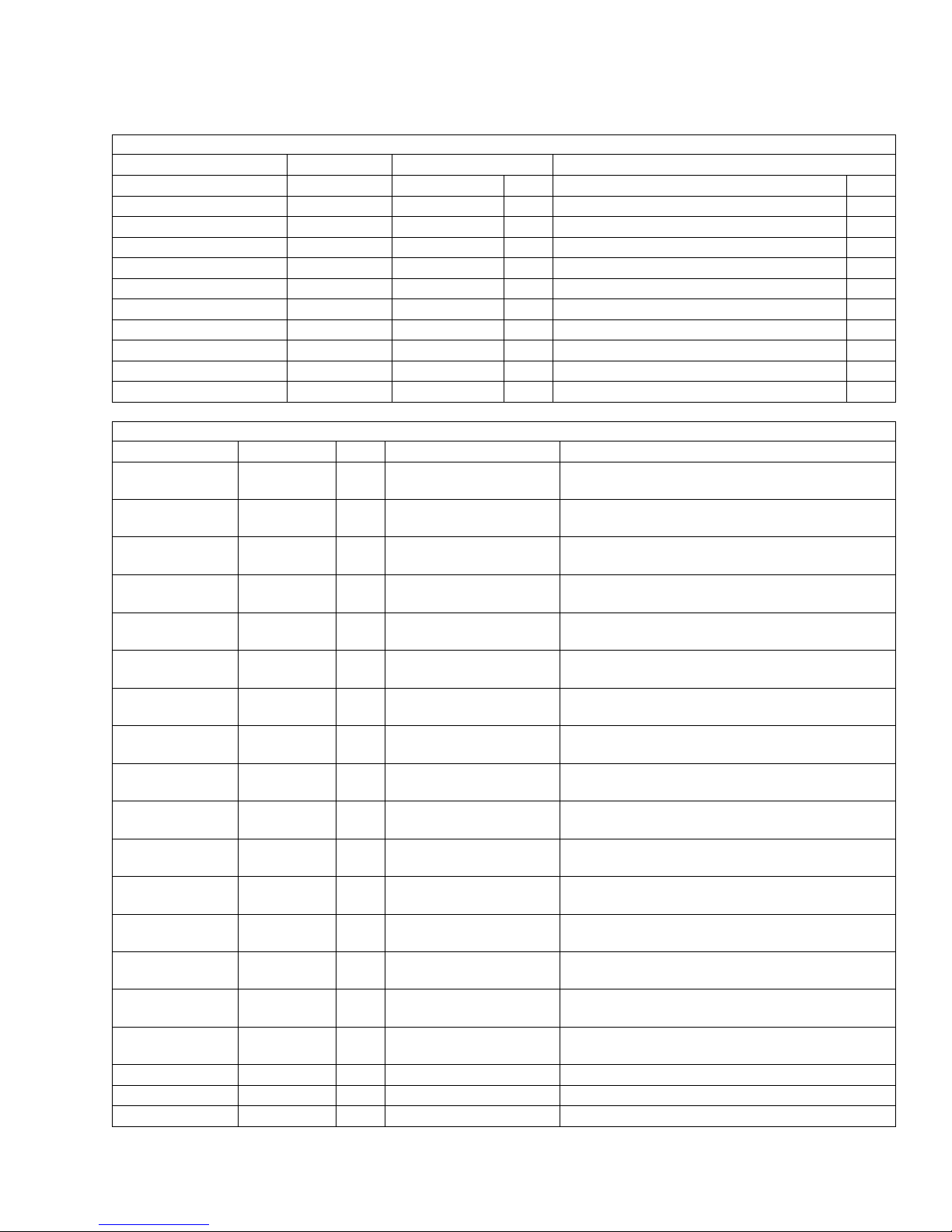

I/O Unit Connector / Terminal Block Si nals

Table 2: EXTERNAL SIGNALS

Internal Si nal Connector Pin External Si nal External Si nal Description

+15VDC J5 1 Digital Input +15VDC

I/O Unit Internal +15VDC (< 100mA) to power

Proximity Detector or Micro-Switch

Ground J5 2 Digital Input Ground

I/O Unit Internal Ground to power Proximity

Detector or Micro-Switch

Dig In + J5 3 Digital Output+

Proximity Detector or Micro-Switch Output for

gated measurement control

Dig In - J5 4 Digital Output-

Proximity Detector or Micro-Switch Output for

gated measurement control

4-20mA Out + J6 1

User PLC/Controller

Positive 4-20mA Input

Moisture or Product Temperature measurement

output value

4-20mA Out - J6 2

User PLC/Controller

Negative 4-20mA Input

Moisture or Product Temperature measurement

output value

G J7 1

Users RS-485 Bus B

Ground User PLC/Controller RS-485 Ground

OP- J7 2

Users RS-485 Bus B

RxD- Users PLC/Controller RS-485 RxD-

OP+ J7 3

Users RS-485 Bus B

RxD+ Users PLC/Controller RS-485 RxD+

IP+ J7 4

Users RS-485 Bus B

TxD+ Users PLC/Controller RS-485 TxD+

IP- J7 5

Users RS-485 Bus B

TxD- Users PLC/Controller RS-485 TxD-

G J8 1

Users RS-485 Bus A

Ground Users PLC/Controller RS-485 Ground

OP- J8 2

Users RS-485 Bus A

RxD- Users PLC/Controller RS-485 RxD-

OP+ J8 3

Users RS-485 Bus A

RxD+ Users PLC/Controller RS-485 RxD

IP+ J8 4

Users RS-485 Bus A

TxD+ Users PLC/Controller RS-485 TxD+

IP- J8 5

Users RS-485 Bus A

TxD- Users PLC/Controller RS-485 TxD-

G J 1 Safety Ground Safety Ground ( 0-250VAC 50-60Hz)

L J 2 Line / Hot Line / Hot ( 0-250VAC 50-60Hz)

N J 3 Neutral Neutral ( 0-250VAC 50-60Hz)

Table 1: INTERNAL SIGNALS

From

To

Si nal Color Connector Pin Connector Pin

IP+ (RS-485) BRN J3 1 J4 or to Users external TxD+ 4

IP- (RS-485) WHT J3 2 J4 or to Users external TxD- 5

OP- (RS-485) BLU J3 3 J4 or to Users external RxD- 2

OP+ (RS-485) BLK J3 4 J4 or to Users external RxD+ 3

Ground (RS-485) GRN/YEL J3 5 J4 or to Users external Ground 1

Ground (RS-485) GRN/YEL J4 1 J3 5

OP- (RS-485) BLU J4 2 J3 3

OP+ (RS-485) BLK J4 3 J3 4

IP+ (RS-485) BRN J4 4 J3 1

IP- (RS-485) WHT J4 5 J3 2

© Sensortech Systems, Inc. 2016 Page 13 of 13 Rev.8-2016

ST-3300 System Power-up

Please verify the following before applying power to the ST-3300 I/O Unit:

1. Verify Earth Ground connection to Sensor Antenna side mounting tab.

2. Securely tighten the M12 low voltage cables on top of Sensor Electronics Unit.

3. If used, verify connection on Sensor Electronics Unit to Product Temperature monitor.

4. Securely tighten the M12 low voltage cables on side of I/O Unit.

5. Verify connections on I/O Unit Terminal Block Connector J8 to Users PLC/Controller RS-485 signals.

6. Verify connections on I/O Unit Terminal Block Connector J6 to Users PLC/Controller 4-20mA signals.

7. If used, verify connections on I/O Unit Terminal Block Connector J5 to Users Digital Input signals.

8. Verify connections on I/O Unit Terminal Block Connector J to single phase 0-250V A/C with Earth

Ground.

Quick ST-3300 Calibration

Allow the ST-3300 System to warm-up >60 minutes to fully stabilize before calibration and use

for process measurement.

Pre-Zero:

Wipe the ceramic face of the sensor clean with a broom or dry cloth. Ensure the ceramic face is

clean and dry before performing a Pre-Zero calibration. Open the lid of the IO Unit and press the

button labelled ZERO (see Figure ). The green STATUS LED with turn on for 2 seconds and

turn off after the calibration is complete. If there is an error during calibration, the STATUS LED

(D1) will blink on and off 10 times. When the Sensor is calibrated the moisture display value on

the sensor should be 0.

Standardization:

Wipe the ceramic face of the sensor and Standardization Plate clean with a broom or dry cloth.

Ensure the ceramic face of the Sensor and the and Standardization Plate are clean and dry

before performing a Standardization calibration.

Place the 12 x 7 inch (30.5 x 17.8cm) Standardization Plate, provided with the Sensor, directly on

top of the Ceramic Face Sensor. Ensure the plate is level and flat on the Sensor measurement

area. Open the lid of the IO Unit and press the button labelled STANDARDIZE (see Figure ).

The green STATUS LED (D1) will turn on for 2 seconds and turn off after the calibration is

complete If there is an error during calibration, the STATUS LED will blink on and off 10 times.

Note the reference value = 5 for the Ceramic Face Sensor Standardization Plate. When the

Sensor is calibrated the moisture display value with the Standardization Plate on top of the

sensor should be 5.

See the ST-3300 Technical Manual for more information.

For additional technical support, email us at [email protected]m or call 805- 81-3735

Monday thru Friday between 8AM-4:30PM Pacific Standard Time.

Other manuals for ST-3300 Series

1

Table of contents

Other Sensortech Systems Accessories manuals